Sludge grading drying gasification coupled coal-fired power generation system and process method thereof

A sludge gasification and power generation system technology, applied in gasification process, pyrolysis sludge, granular/powdered fuel gasification, etc., can solve feeding equipment failure, reduce boiler efficiency, and reduce coal burnout performance and other issues, to achieve the effect of reasonable structure, convenient use and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

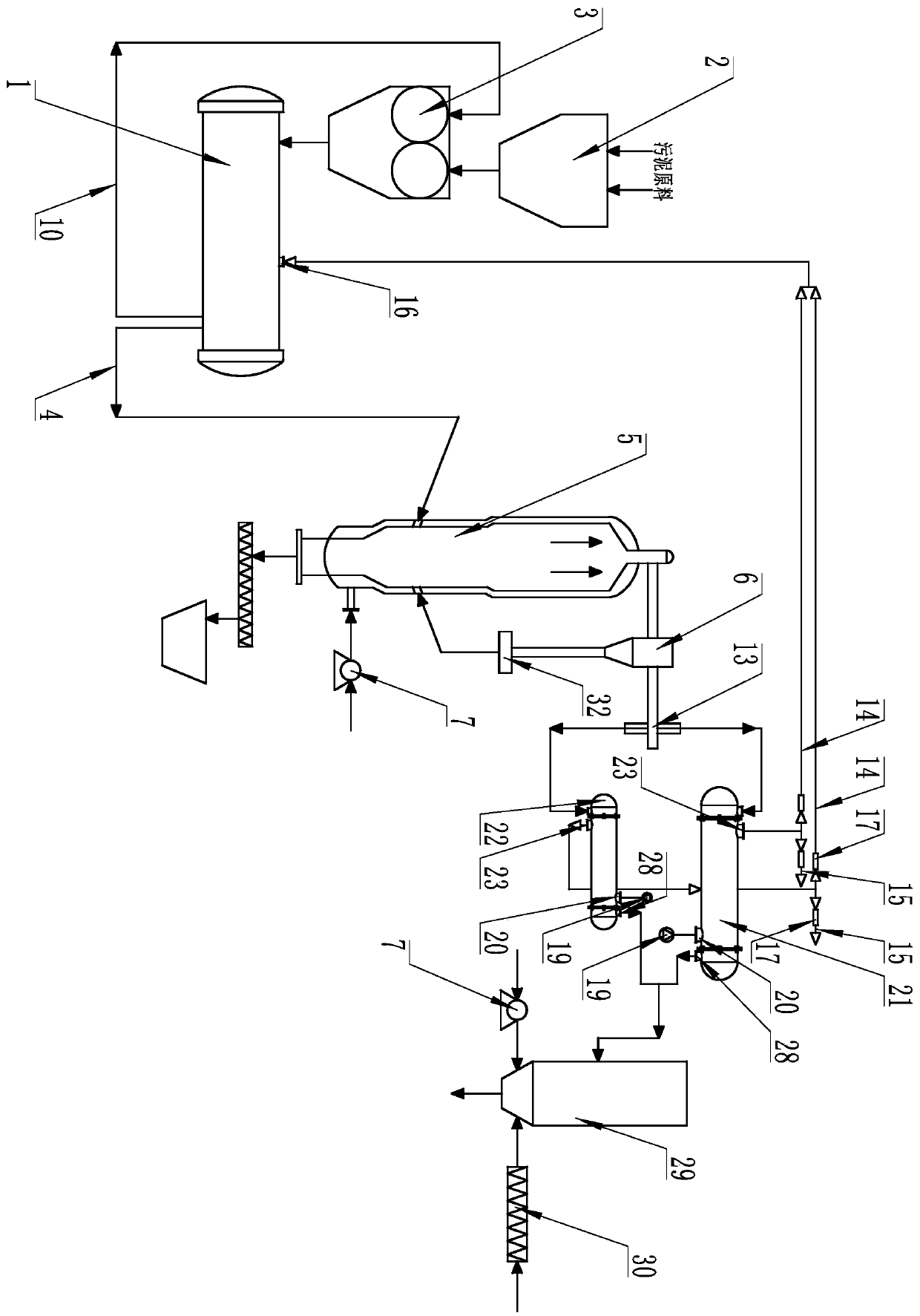

[0032] according to figure 1 , image 3 , Figure 4 The shown sludge classification drying gasification coupled coal-fired power generation system includes a sludge drying unit that uses steam to dry the sludge raw material stored in the sludge storage bin 2, and is used to dry and dehydrate the sludge The sludge gasification and combustion unit is used to transport and gasify the sludge to produce combustible gas, which is used to send the combustible gas and exhaust gas produced by the sludge gasification and combustion unit to the gas incineration unit for combustion in the coal-fired boiler 29. The sludge drying unit, the sludge gasification combustion unit and the gas incineration unit are connected in sequence, the sludge drying unit includes a drum type sludge drying box 1, and the sludge storage bin 2 It is connected to the sludge inlet of the drum type sludge drying box 1 via a sludge conveyor 3, and the sludge gasification combustion unit includes a dry sludge conv...

Embodiment 2

[0036] according to figure 1 , image 3 The difference between the present embodiment shown and Embodiment 1 is that: the gas separation outlet 13 of the cyclone separator 6 is connected to the two heat exchangers, and the two heat exchangers are respectively the first dry The drying heat exchanger 21 and the circulating drying heat exchanger 22, the steam temperature limit value of the fluid outlet 23 of the first drying heat exchanger 21 in the control unit 9 is 180°C-220°C , the steam pressure limit value is 1.5MPa-2MPa; the steam temperature limit value of the fluid outlet 23 of the circulating drying heat exchanger 22 in the control unit 9 is 120°C-160°C, and the steam pressure limit The value is 1.2MPa-1.7MPa.

[0037] Compared with Embodiment 1, this embodiment further restricts the heat exchanger, and measures the temperature of the fluid outlet through the temperature detection device 18 provided for the fluid outlet 23 of the first drying heat exchanger 21 and the ...

Embodiment 3

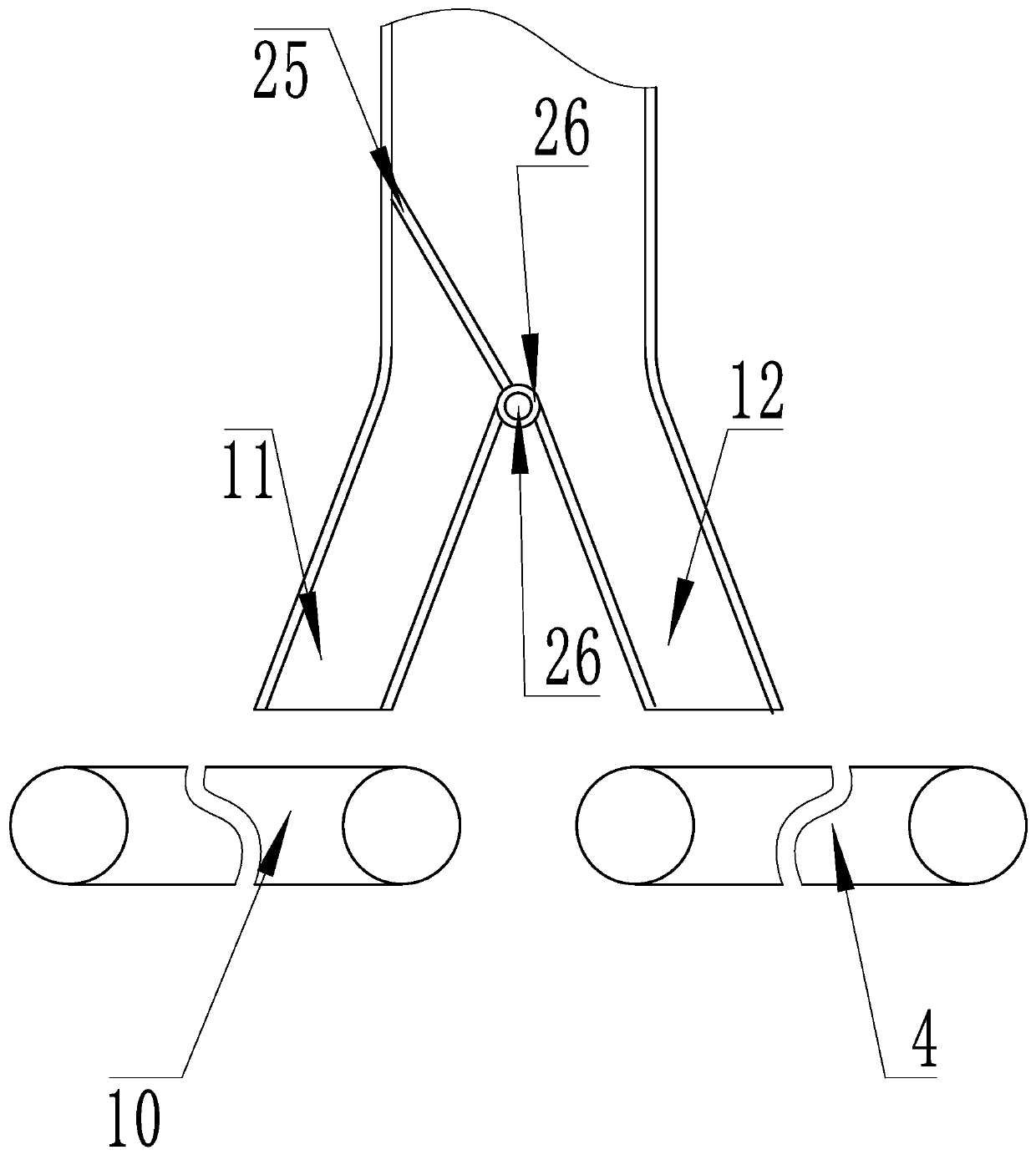

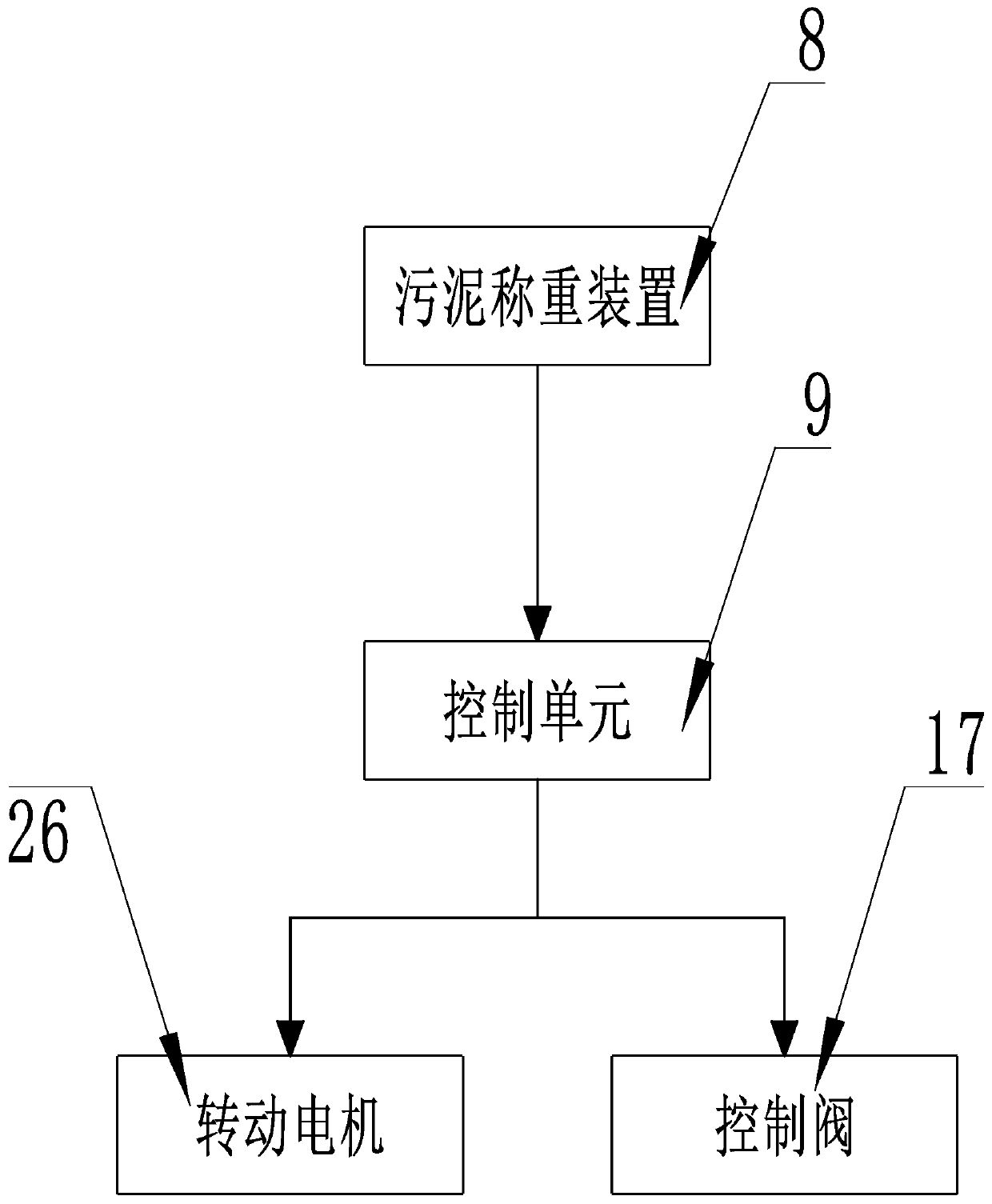

[0039] according to figure 1 , figure 2 The difference between the present embodiment shown and Embodiment 1 is that: the left and right branches of the discharge port are divided into the gasification discharge port 11 and the sludge circulation discharge port 12, and the gasification The discharge port 11 and the sludge circulation discharge port 12 are connected to form a herringbone structure, and the gasification discharge port 11 and the sludge circulation discharge port 12 are connected by a flap 25, The turning plate 25 is connected to the discharge box provided with the gasification discharge port 11 and the sludge circulation discharge port 12 through the rotating shaft 26, and the turning plate 25 is connected to the The gasification discharge port 11 and the sludge circulation discharge port 12 are adapted to rotate left and right, the rotating shaft 26 is connected to the rotating motor 27, and the rotating motor 27 is connected to the control unit 9, the gasif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com