Combustion device of gasified carbocoal type nonflammable fine-grained fuel and combustion method with same

A combustion device and fine particle technology, applied in the direction of combustion method, fuel burned in molten state, fluidized bed combustion equipment, etc., can solve the problem of low combustion efficiency of gasified semi-coke-like refractory fine particle fuel, and avoid staying If the time is too short, the effect of prolonging the residence time and reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

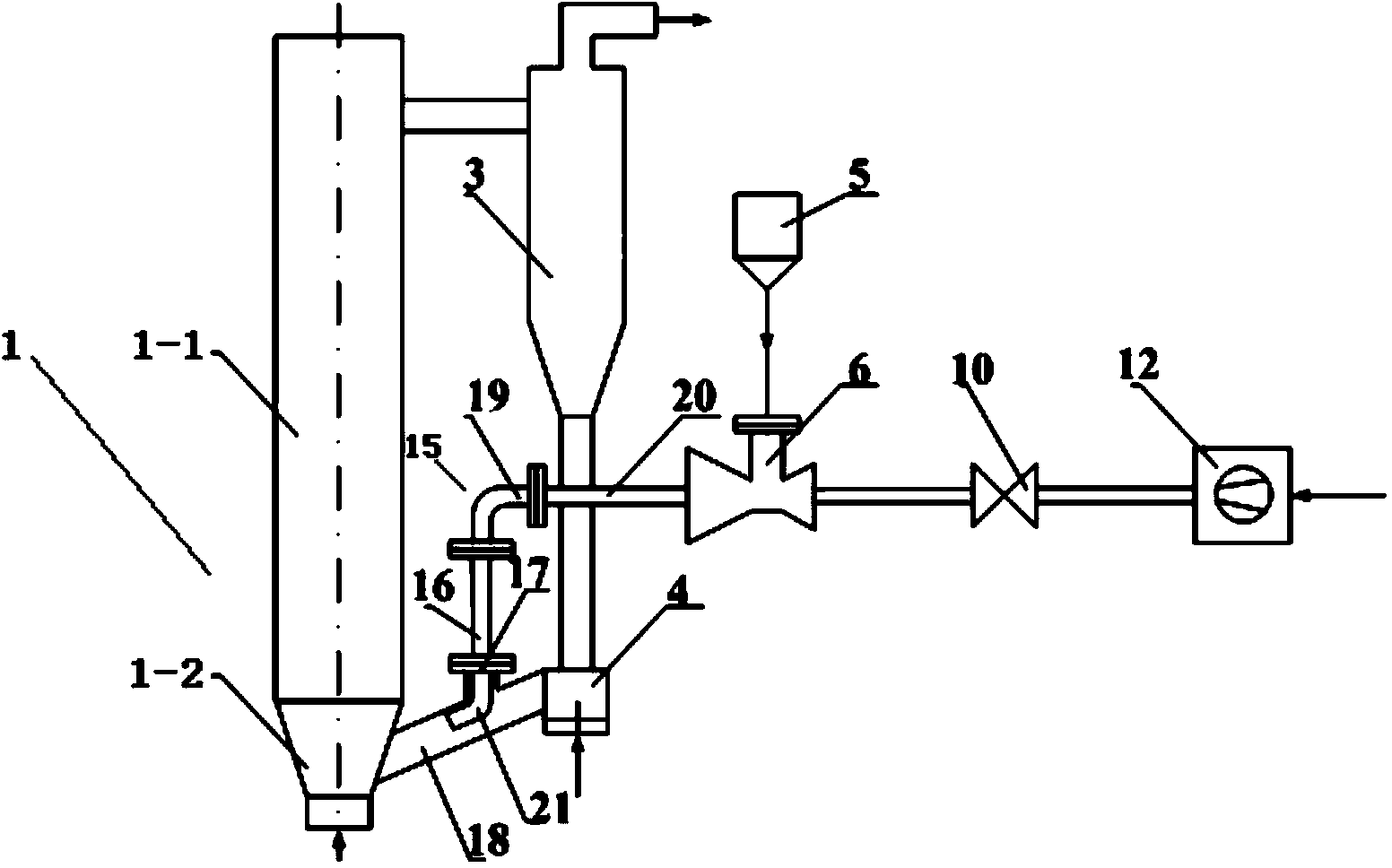

[0019] Specific implementation mode one: combine figure 1 Describe this embodiment, the combustion device of the gasified semi-coke class flame retardant fine particle fuel in this embodiment includes a raw material bin 5, a pneumatic injector 6, a Roots blower 12, a regulating valve 10, an injection pipe 15, and an inclined return pipe 18 , cyclone separator 3, return valve 4 and furnace 1, furnace 1 includes furnace dense-phase zone 1-2 and furnace dilute-phase zone 1-1, furnace dilute-phase zone 1-1 and furnace dense-phase zone 1-2 from above Arranged in order from bottom to bottom and made into one, the raw material bin 5 is located above the pneumatic injector 6 and communicates with the pneumatic injector 6, and the ejector pipe 15 includes the ejector pipe horizontal section 20, the ejector pipe elbow 19, and the ejector pipe standpipe section 16 And the ejector guide nozzle 21, the ejector horizontal section 20, the ejector elbow 19, the ejector standpipe section 16 an...

specific Embodiment approach 2

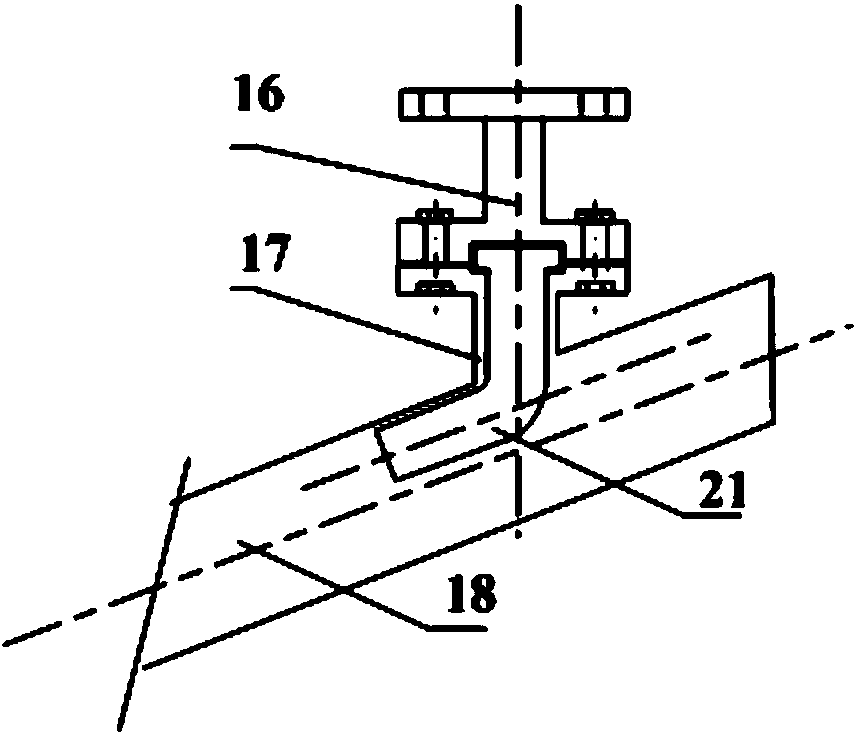

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the ejector pipe guide nozzle 21 of the ejector pipe 15 is inserted into the flange seat 17 on the return inclined pipe 18, and the ejector pipe guide nozzle 21 is above the Connect the riser section 16 of the injection pipe by flanges, and fasten the flanges with bolts. Others are the same as in the first embodiment.

[0022] The schematic diagram of the assembly of the ejector pipe guide nozzle 21 is as follows: figure 2 shown.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: each section of the injection pipe 15 is connected by a flange. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com