Pressure control system and pressure control method

A pressure control and pressure technology, applied in the pressure control system and control field, can solve the problems of small increase in pressure control range, unsatisfactory, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

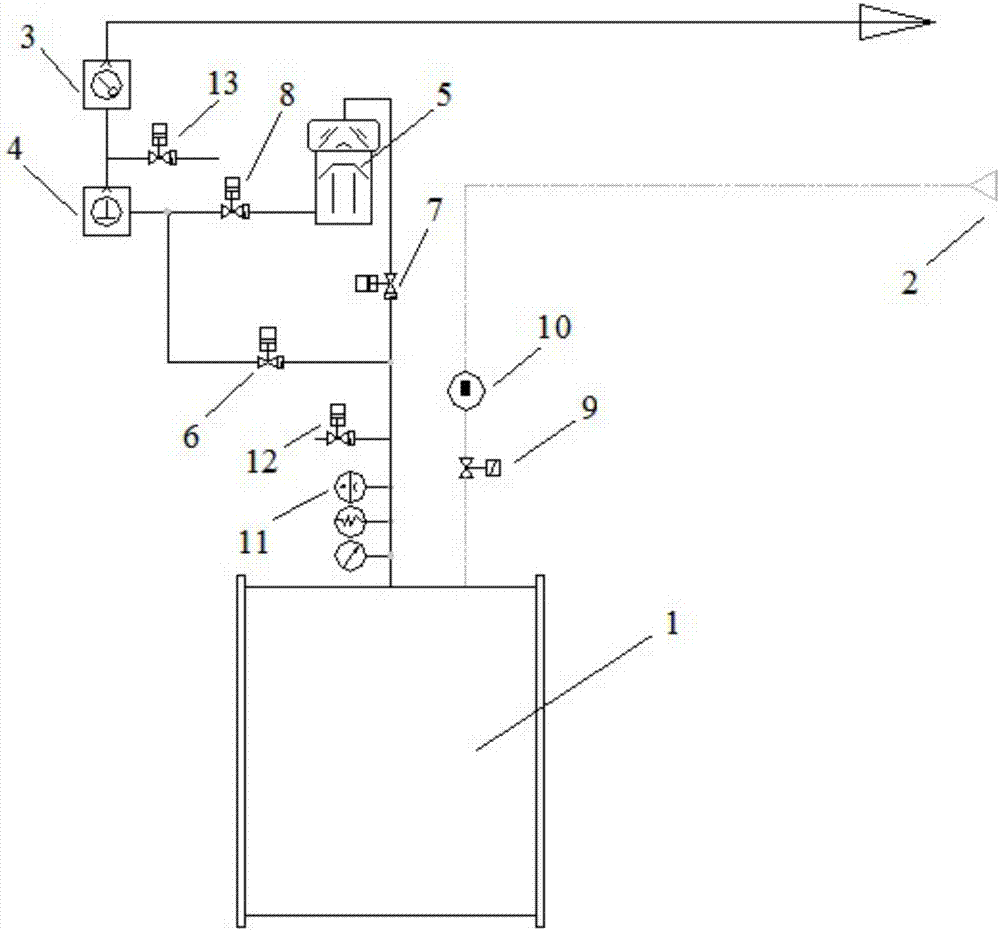

[0032] like figure 1 As shown, it is a pressure control system provided in this embodiment, including a vacuum chamber 1, a gas source 2, a vacuum pump group and a control unit; wherein, the vacuum chamber 1 communicates with the gas source 2 through an air intake pipeline, and the air intake pipeline is equipped with There is an air intake valve 9; the vacuum chamber 1 is connected to the vacuum pump group through the exhaust pipeline, and a high vacuum valve 7 is arranged on the exhaust pipeline; the air intake valve 9, the high vacuum valve 7 and the multi-stage vacuum pump group are respectively connected to the control unit; the control The unit controls the size of the pressure according to the target, and controls the pumping speed of the multi-stage vacuum pump group to realize the pressure regulation in the vacuum furnace.

[0033] In this embodiment, the gas source fills the vacuum chamber 1 with an inert gas; further, the inert gas is argon; the gas outlet of the mu...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0047] A flow meter 10 and a pressure meter 11 are also included. The flow meter 10 is arranged on the intake pipeline for controlling the intake air volume. The pressure gauge 11 is used to detect the pressure of the vacuum chamber 1 . The flow meter 10 and the pressure meter 11 are respectively connected to the control unit. In this embodiment, the opening degree of the flowmeter 10 is controlled by PID; the pressure gauge 11 is arranged on the connecting pipeline between the high vacuum valve 7 and the vacuum chamber 1 .

[0048] The following is a further detailed description through specific work projects.

[0049] After the adjustment of the vacuum pump unit is completed, the pumping c...

Embodiment 3

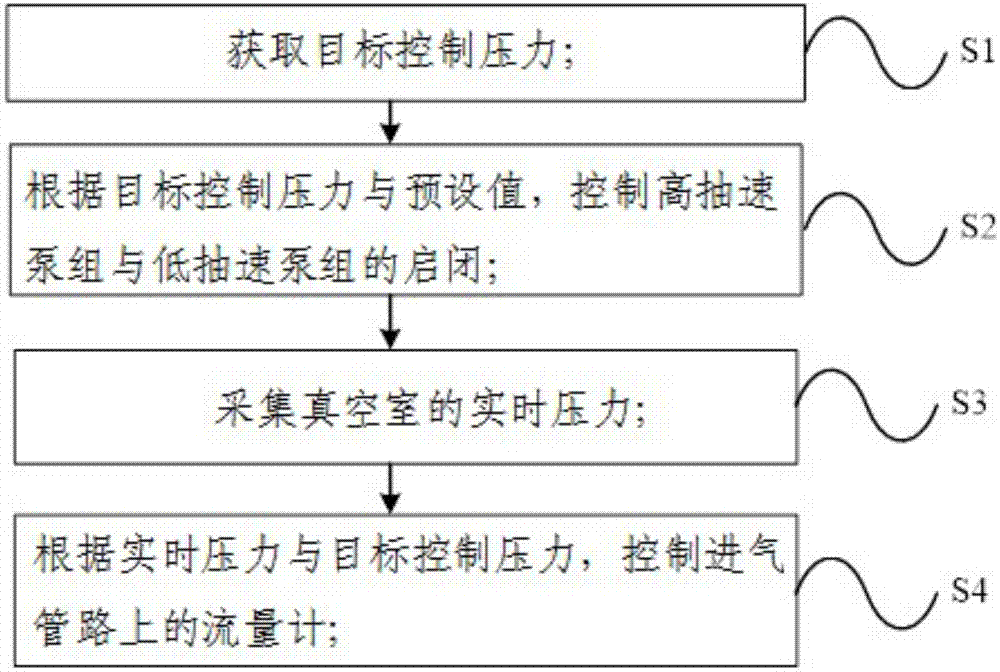

[0053] This embodiment provides a pressure control method, including the following steps:

[0054] S1. Obtain the target control pressure;

[0055] S2. According to the target control pressure and the preset value, control the opening and closing of the high pumping speed pump group and the low pumping speed pump group, as follows:

[0056] The intake valve 9 is opened, and the gas source 2 fills the vacuum chamber 1 with argon, and keeps the amount of intake constant.

[0057] If the target control pressure is lower than the preset value, the pre-pumping valve 6 is closed, and the high vacuum valve 7 and the backing valve 8 are opened. The first vacuum pump 3, the second vacuum pump 4 and the third vacuum pump 5 are running;

[0058] If the target control pressure is higher than the preset value, the high vacuum valve 7 and the front valve 8 are closed, the pre-pumping valve 6 is opened, the first vacuum pump 3 and the second vacuum pump 4 are opened, and the third vacuum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com