Dust removing and tar removing device and method for high-tar and high-dust high-temperature gas

A high-temperature gas and dust technology, which is applied in the field of gas purification, can solve the problems of short filter life and long time, and achieve the effects of improving filtration efficiency, reducing regeneration time, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

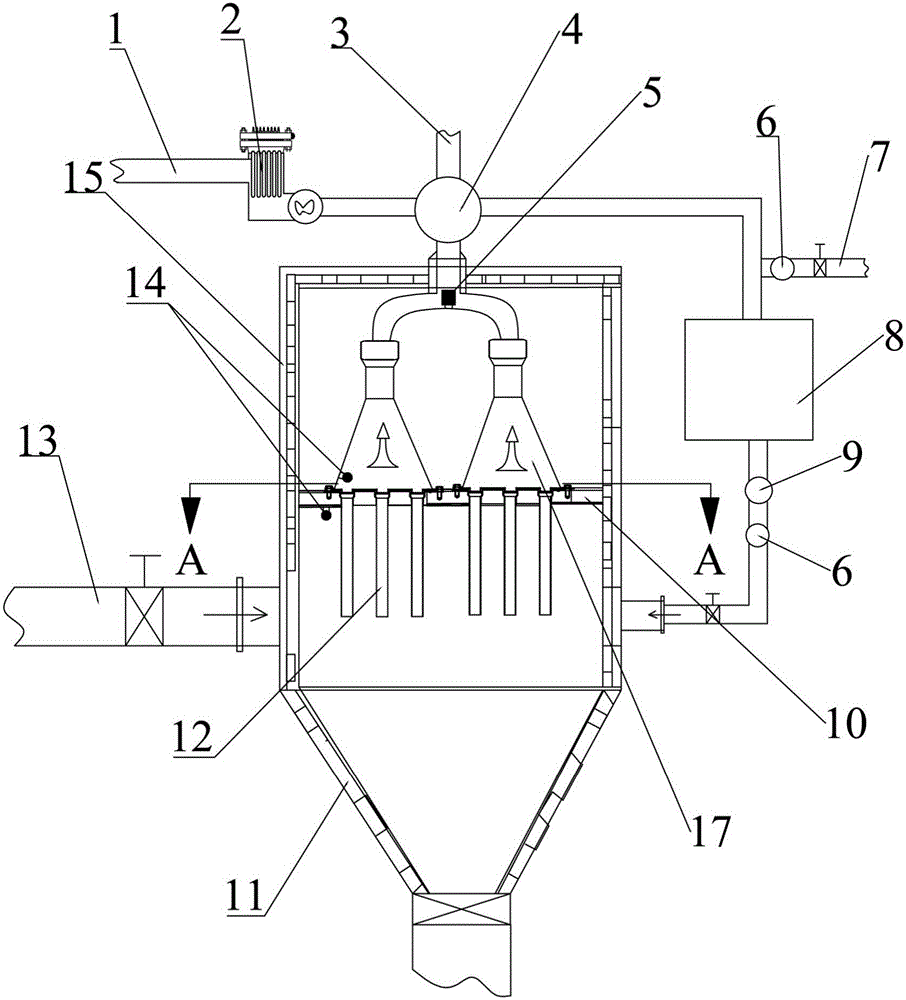

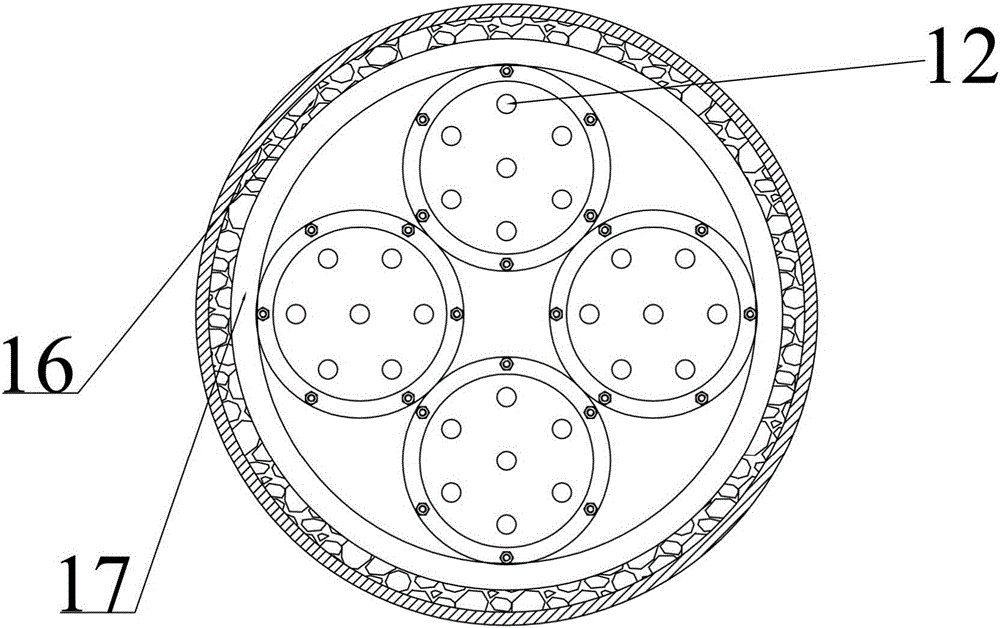

[0040] Such as figure 1 As shown, a dedusting and decoking device for high-tar and high-dust high-temperature gas includes a filter device, and the filter device includes an inlet for high-tar and high-dust high-temperature gas, and a high-temperature gas for discharging the filter export. The filter device in this embodiment is composed of several filters 12, which are fixed on the housing device through the support plate 10, and the filters 12 are divided into several filter areas. In this embodiment, there are 28 filters 12, which are evenly divided into four filter areas. Filter 12 is a ceramic dust removal pipe. The filter can also adopt other filter devices suitable for filtering gases such as dust tar. The number of filters can be set according to actual needs, and can be from several to hundreds. The root number of filters in each filter area can also be set to multiple according to actual conditions. Such as figure 2 Shown is a housing arrangement for housing a...

Embodiment 2

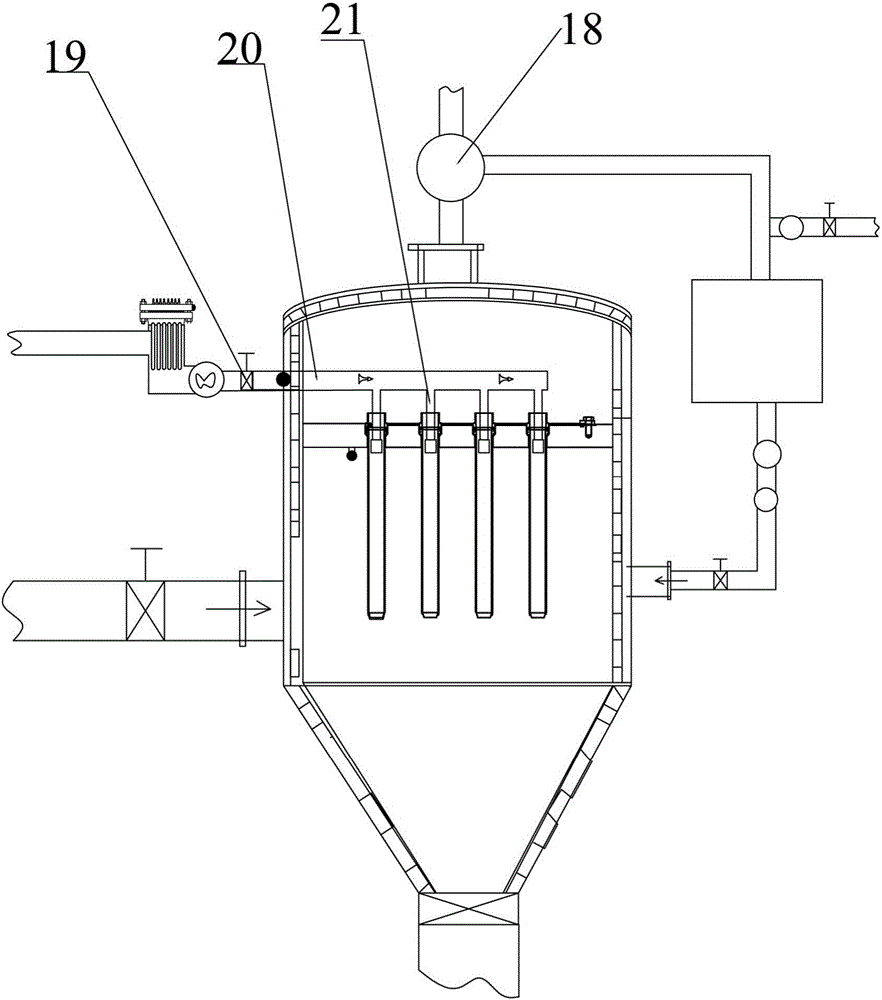

[0046] Such as image 3 As shown, it is basically the same as Embodiment 1, the difference is that the filter device is composed of several filters 12, the filter 12 is fixed on the housing device through the support plate 10, and the blowing gas delivery pipe includes Conveying the main pipe 20 and the conveying branch pipe 21 , each filter 12 corresponds to a conveying branch pipe 21 , and the conveying branch pipe 21 extends into the inside of the filter 12 , and the blowing valve 19 is set on the conveying main pipe 20 . With the above-mentioned device, the conveying branch pipe extends into the inside of the filter, and the backflushing is more thorough. In the structure of this embodiment, a storage device for storing substances that contribute to tar combustion catalysis, the storage device is connected to the delivery main pipe. The substances in the storage device can be added during backflushing, so that during the high-pressure backflushing process, the tar burning...

Embodiment 3

[0049] Such as figure 1 and 4 As shown, it is basically the same as Embodiment 1, and the difference is that in this embodiment, two filter devices and a shell device are provided, and the two sets of devices share a high-temperature gas circulation device and a high-temperature pressurized gas source 1 . With two sets of devices, one device can be filtered and purified, and the other device can be regenerated to avoid the problem of failure to filter and purify due to shutdown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com