Cryopump

A cryopump and cryopanel technology, which is applied to pumps, liquid variable displacement machines, machines/engines, etc., can solve problems such as unreasonable and increased regeneration time, and achieve the effects of suppressing increase, prolonging regeneration interval, and suppressing regeneration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the following description, the same code|symbol is attached|subjected to the same element, and repeated description is abbreviate|omitted suitably. In addition, the structures described below are examples and do not limit the scope of the present invention.

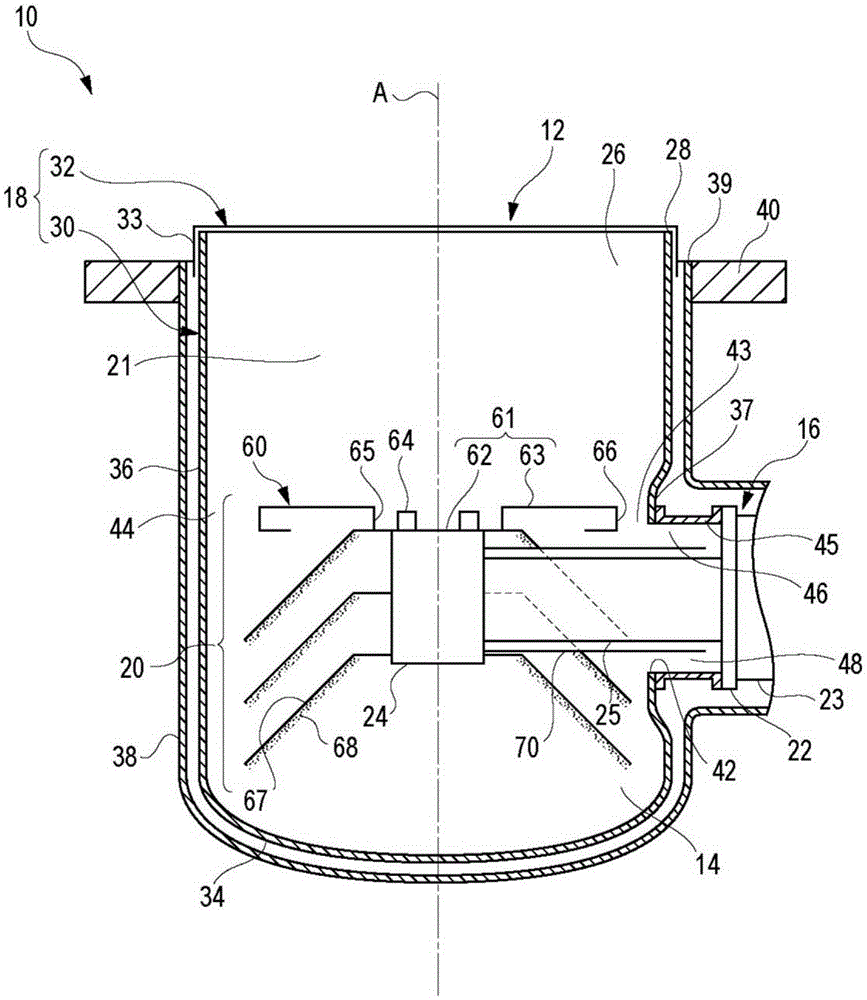

[0021] figure 1 It is a side cross-sectional view schematically showing main parts of a cryopump 10 according to an embodiment of the present invention. The cryopump 10 is installed, for example, in a vacuum chamber of a vacuum processing device, and is used to increase the degree of vacuum inside the vacuum chamber to a level required by a desired process. The vacuum processing apparatus equipped with the cryopump 10 is, for example, a sputtering apparatus. The process gas pressure in the sputtering device is, for example, in the range of 1 mTorr to 10 mTorr.

[0022] The cryopump 10 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com