A kind of Dendrobium officinale leaf polysaccharide and its preparation and application

A technology of Dendrobium officinale and polysaccharides, applied in the field of natural polymers, can solve the problems of inability to accurately verify the activity and function of Dendrobium polysaccharides, and achieve the effect of improving immunity, restoring normal health, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

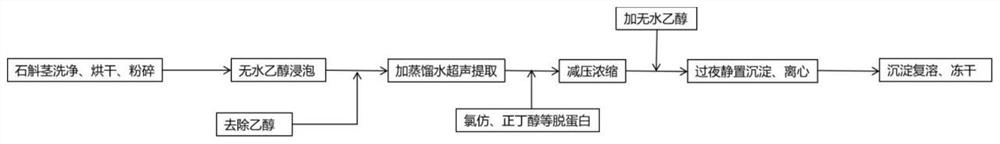

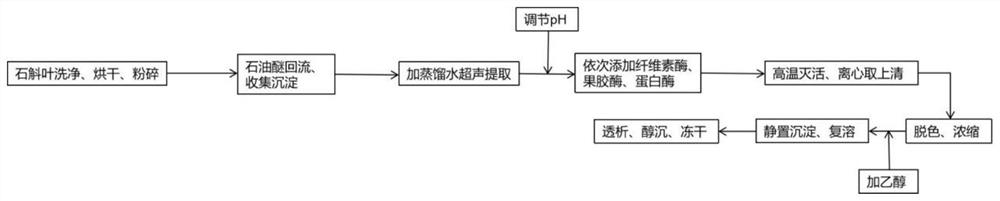

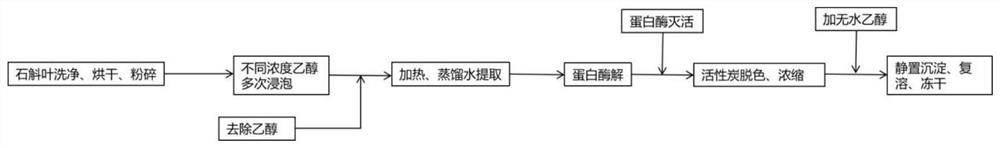

Method used

Image

Examples

Embodiment 1

[0052] (1) 100g of Dendrobium officinale leaves are washed, dried at 65°C, pulverized and crossed through a 20-mesh sieve;

[0053] (2) soaking the above materials in 70% ethanol solution for 8h, 80% ethanol for 8h, and 90% ethanol for 8h to remove impurities;

[0054] (3) The ethanol in the soaked samples was dried and removed, and 30 times the volume of water was added for extraction at 80° C. for 3 hours, and the extracts were combined after repeating 3 times;

[0055] (4) Add protease to the above extract, carry out the enzymatic hydrolysis reaction at 35°C for 3h, after completion, heat the solution to 95°C for 20min inactivation, and centrifuge to obtain the supernatant;

[0056] (5) adding 0.1% activated carbon to the above-mentioned supernatant for decolorization, and centrifuging to obtain the supernatant;

[0057] (6) the above-mentioned supernatant was concentrated, and 80% ethanol was added to stand for 12h, and the precipitate was obtained after centrifugation; ...

Embodiment 2

[0060] (1) 100g of Dendrobium officinale leaves are washed, dried at 85°C, pulverized and crossed a 30-mesh sieve;

[0061] (2) soaking the above materials in 85% ethanol solution for 12h and 95% ethanol for 12h successively to remove impurities;

[0062] (3) The ethanol in the above soaked samples was dried and removed, and 10 times the volume of water was added at 95°C for extraction for 2 hours, and the extracts were combined after repeating 5 times;

[0063] (4) Add protease to the above extract, carry out the enzymolysis reaction at 37°C for 1h, after completion, heat the solution to 100°C for 30min for inactivation, and centrifuge to obtain the supernatant;

[0064] (5) adding 0.2% activated carbon to the above-mentioned supernatant for decolorization, and centrifuging to obtain the supernatant;

[0065] (6) Concentrate the above-mentioned supernatant, add 95% ethanol and let stand for 12h, and obtain a precipitate after centrifugation;

[0066] (7) Dissolving the abov...

Embodiment 3

[0084] (1) 100g of Dendrobium officinale leaves are washed, dried at 50°C, pulverized and crossed through a 60-mesh sieve;

[0085] (2) soak the above materials in 60% ethanol solution for 6 hours, 70% ethanol for 6 hours, 80% ethanol for 6 hours, and 90% ethanol for 6 hours to remove impurities;

[0086] (3) The ethanol in the above soaked samples was dried and removed, and 25 times the volume of water was added at 75° C. for extraction for 2 hours, and the extracts were combined after repeating 3 times;

[0087] (4) Add protease to the above extract, carry out enzymolysis reaction at 40°C for 2h, after completion, heat the solution to 90°C for 15min for inactivation, and centrifuge to obtain supernatant;

[0088] (5) adding 0.15% activated carbon to the above-mentioned supernatant for decolorization, and centrifuging to obtain the supernatant;

[0089] (6) Concentrate the above-mentioned supernatant, add 85% ethanol and let stand for 12h, and obtain a precipitate after cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com