Spiral pipe bending machine and pipe bending method

A pipe bender and spiral pipe technology, applied in the field of spiral pipe benders, can solve problems such as pipe jamming, insufficient position, complex structure, etc., and achieve the effects of reducing work intensity, ensuring complete removal, and adapting to a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

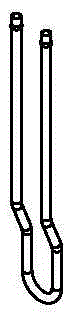

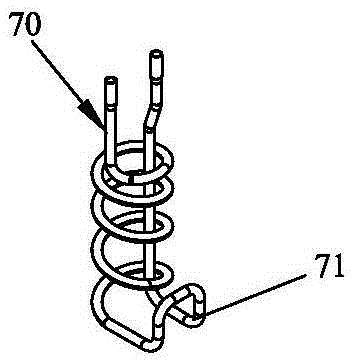

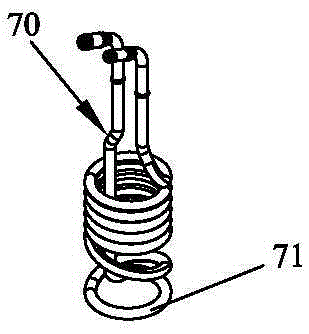

[0057] Please refer to Figure 4 and Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a spiral pipe bender, which can bend spiral pipes with different pitches without replacing any parts (see figure 2 and image 3 ). The structure of the spiral pipe bender includes a frame 10 , a control system 20 installed in the frame 10 , a spindle rotation mechanism 30 , an auxiliary spindle concentric mechanism 40 , a screw feed mechanism 50 and a spiral tube pitch adjustment mechanism 60 .

[0058] Among them, such as Figure 5 As shown, the control system 20 includes a control host 21, a touch screen 22 installed on the table of the frame 10, the touch screen 22 is connected to the control host 21, and the control host 21 is electrically connected to the main shaft rotation mechanism 30, the auxiliary main shaft concentric mechanism 40, The driving part of the spiral tube pitch adjusting mechanism 60 and the screw fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com