Activated sludge method processing technique at sewage continuous drainage interval

A technology of activated sludge method and treatment process, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

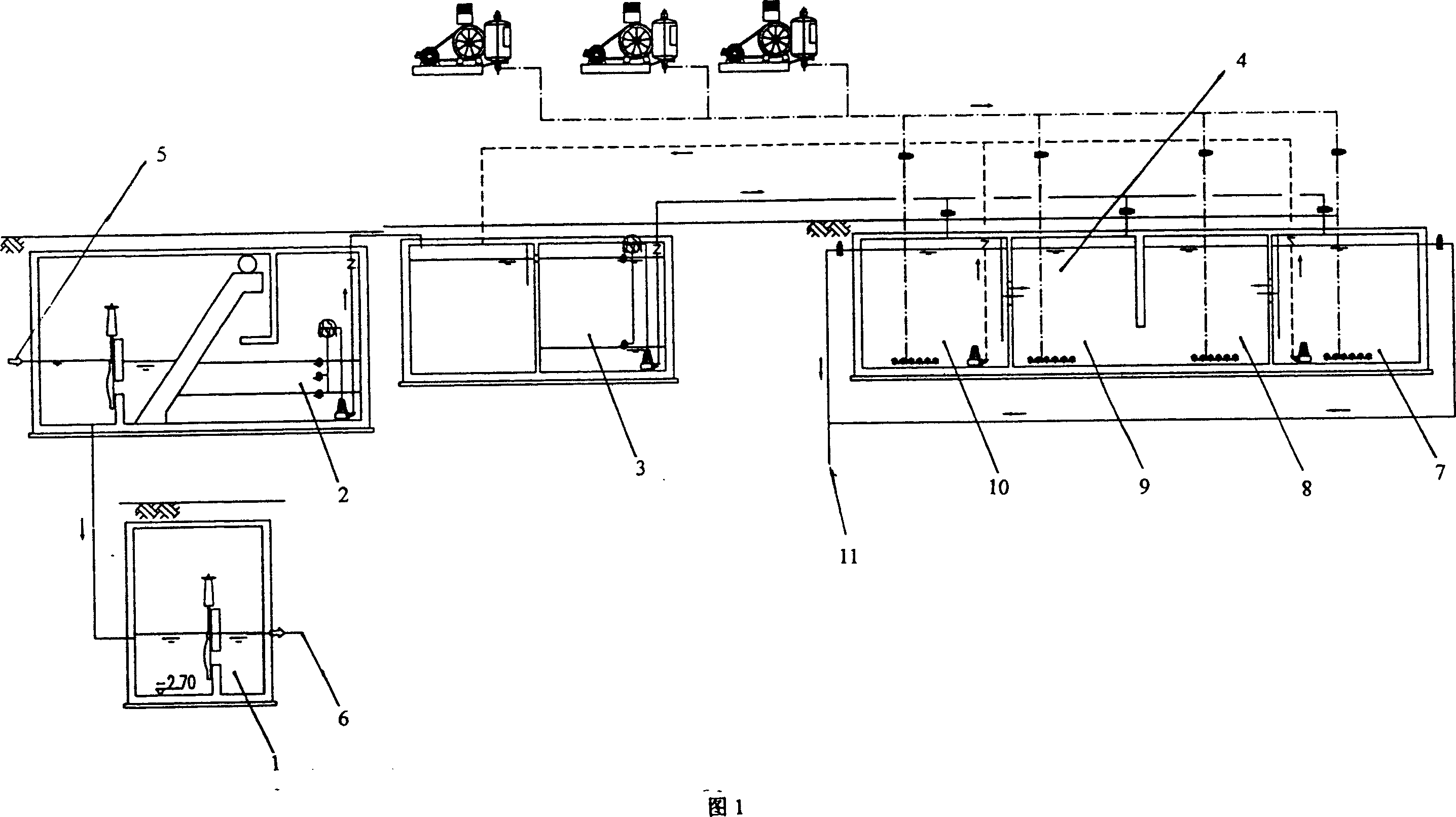

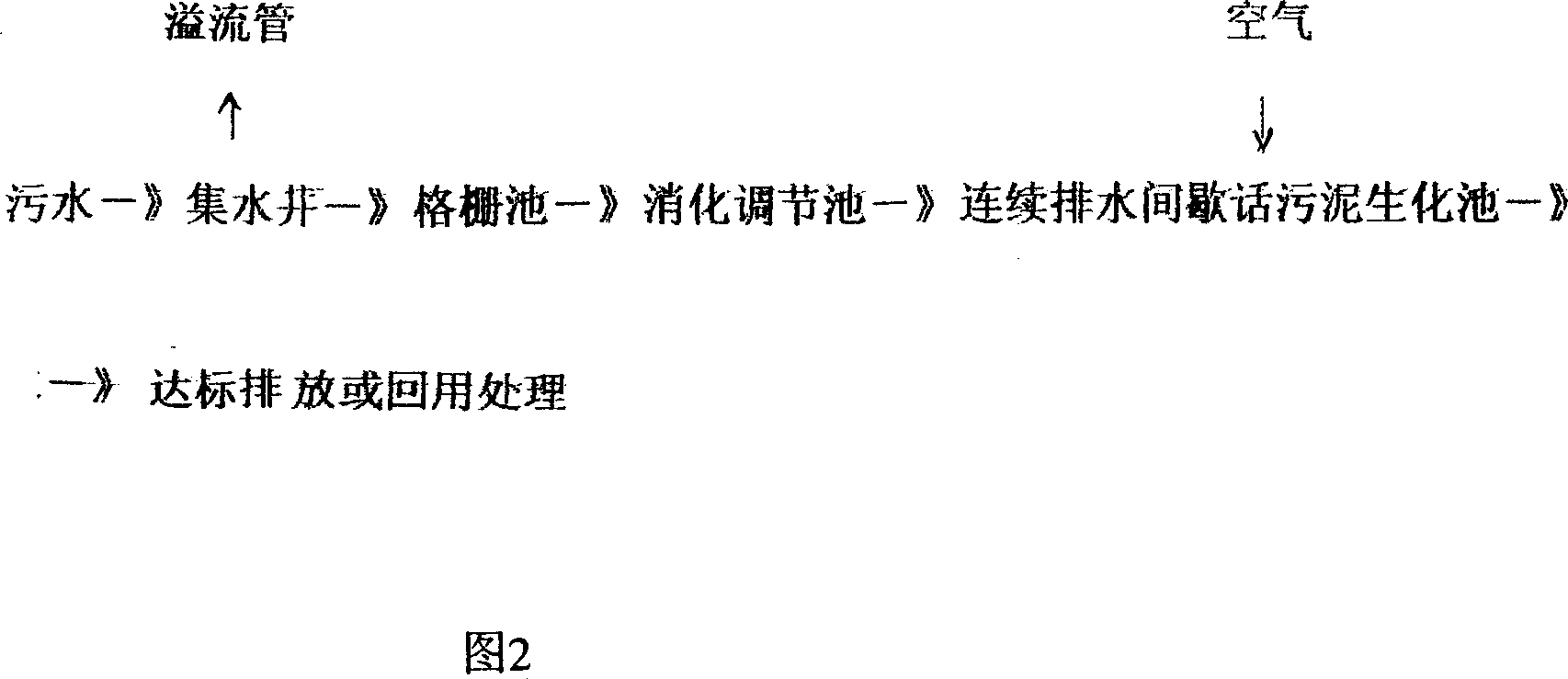

[0009] It can be seen from the figure that the system for realizing this intermittent activated sludge treatment process for continuous drainage of sewage is composed of water collection well (1), grid pool (2), digestion regulating tank (3), continuous drainage intermittent activated sludge method (XUCE) ) The biochemical tank (4) is composed of, according to the reclaimed water treatment design specification, the reclaimed water treatment project needs to build a septic tank, so the B-type septic tank is used. After the sewage is collected from the pipe network, it enters the sewage treatment system, first from the sewage pipe (5 ) Go to the collection well (1), and take into account the occurrence of special circumstances such as power outages, set up an overflow pipe (6) next to the collection well (1) to ensure that sewage can be discharged normally in the event of a power outage, and prevent sewage from overflowing the ground and polluting Surroundings. Before the sewage ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com