Ground cement laying device and method for construction site

A technology for construction sites and laying devices, used in construction, mixing methods, building structures, etc., can solve problems such as slow cutting speed, cement adheres to blanking plates, and cannot be cleaned with baffles, so as to reduce waste and reduce waste. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

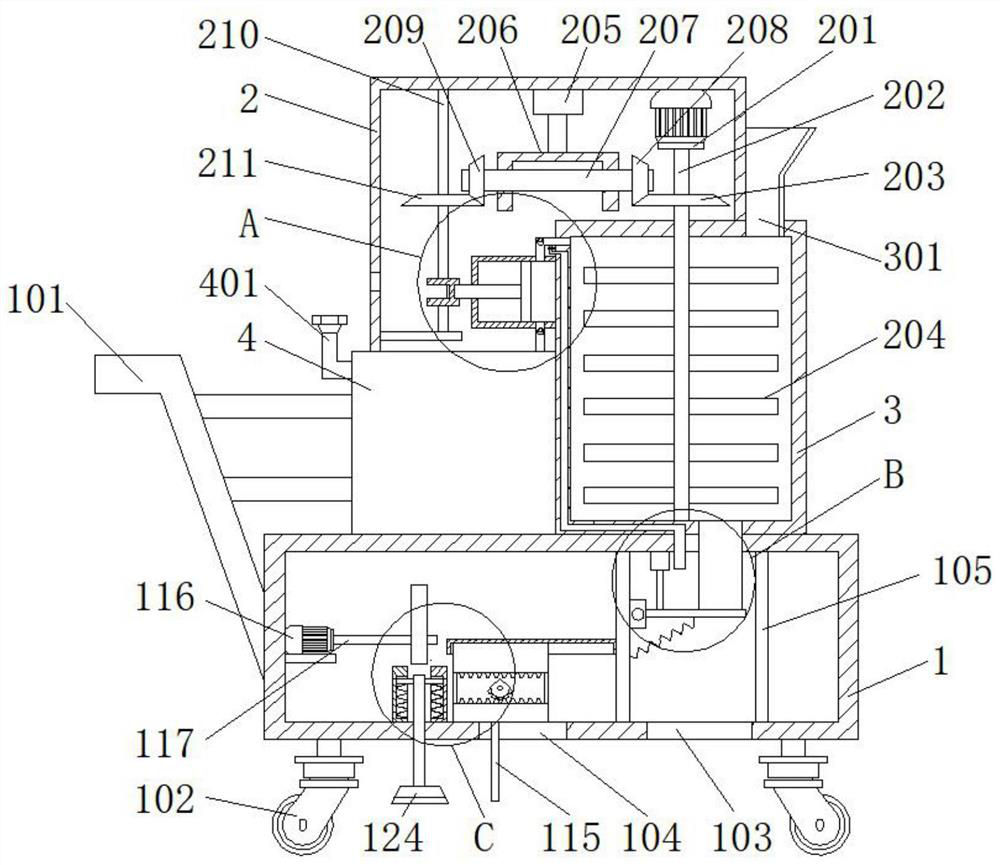

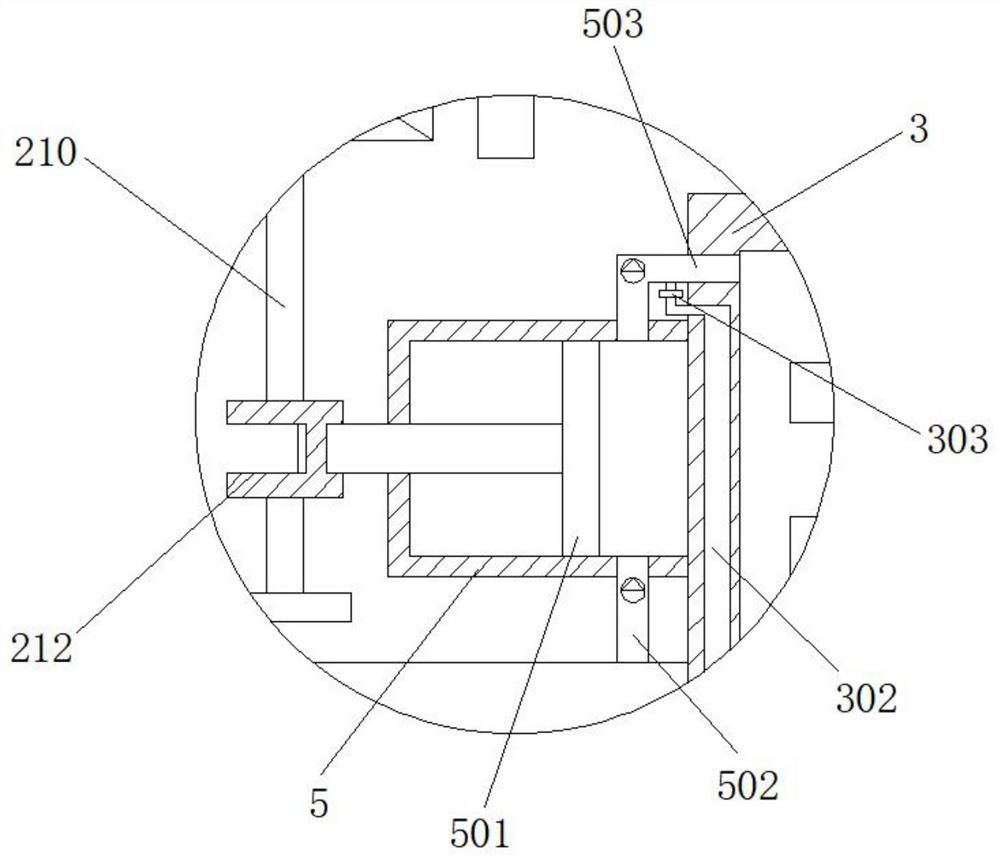

[0035] refer to figure 1 and image 3 , a ground cement laying device for a construction site, comprising a box body 1, the top of the box body 1 is fixedly connected with a storage tank 3 and a water tank 4, and the tops of the storage box 3 and the water tank 4 are fixedly connected with a connecting shell 2, and the connecting shell 2 is fixedly connected with a third motor 201, the output end of the third motor 201 is connected with a stirring mechanism, the connecting shell 2 is provided with a water replenishing and cleaning mechanism, and the connecting shell 2 is provided with a fourth rotating shaft 207, and the fourth rotating shaft 207 is respectively fixed The second bevel gear 208 and the third bevel gear 209 are connected with the stirring mechanism and the water replenishing and cleaning mechanism, and the box body 1 is provided with a flattening mechanism and a pressing mechanism.

[0036] The stirring mechanism includes a third rotating shaft 202 and stirring...

Embodiment 2

[0042] refer to Figure 1-3 , a ground cement laying device for a construction site, comprising a box body 1, the top of the box body 1 is fixedly connected with a storage tank 3 and a water tank 4, and the tops of the storage box 3 and the water tank 4 are fixedly connected with a connecting shell 2, and the connecting shell 2 is fixedly connected with a third motor 201, the output end of the third motor 201 is connected with a stirring mechanism, the connecting shell 2 is provided with a water replenishing and cleaning mechanism, and the connecting shell 2 is provided with a fourth rotating shaft 207, and the fourth rotating shaft 207 is respectively fixed The second bevel gear 208 and the third bevel gear 209 are connected with the stirring mechanism and the water replenishing and cleaning mechanism, and the box body 1 is provided with a flattening mechanism and a pressing mechanism.

[0043] The stirring mechanism includes a third rotating shaft 202 and stirring teeth 204,...

Embodiment 3

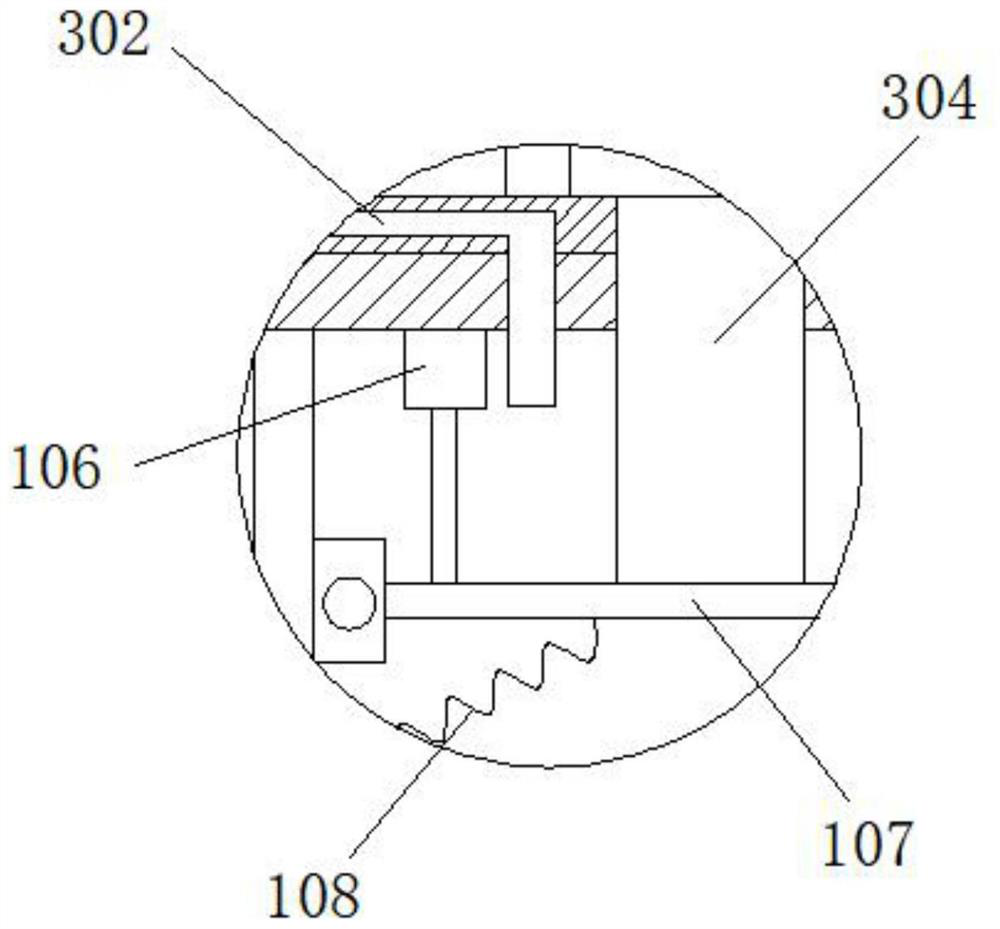

[0049] refer to figure 1 , Figure 4 and Figure 5 , a ground cement laying device for a construction site, comprising a box body 1, the top of the box body 1 is fixedly connected with a storage tank 3 and a water tank 4, and the tops of the storage box 3 and the water tank 4 are fixedly connected with a connecting shell 2, and the connecting shell 2 is fixedly connected with a third motor 201, the output end of the third motor 201 is connected with a stirring mechanism, the connecting shell 2 is provided with a water replenishing and cleaning mechanism, and the connecting shell 2 is provided with a fourth rotating shaft 207, and the fourth rotating shaft 207 is respectively fixed The second bevel gear 208 and the third bevel gear 209 are connected with the stirring mechanism and the water replenishing and cleaning mechanism, and the box body 1 is provided with a flattening mechanism and a pressing mechanism.

[0050] The flattening mechanism includes a first motor 109, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com