Beta-carotene fermentation liquor filtration and extraction process and equipment

A technology of carotene and fermented liquid, which is applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of poor filtration effect and low extraction efficiency, reduce moisture content, increase extraction yield, Effect of reducing fugitive emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

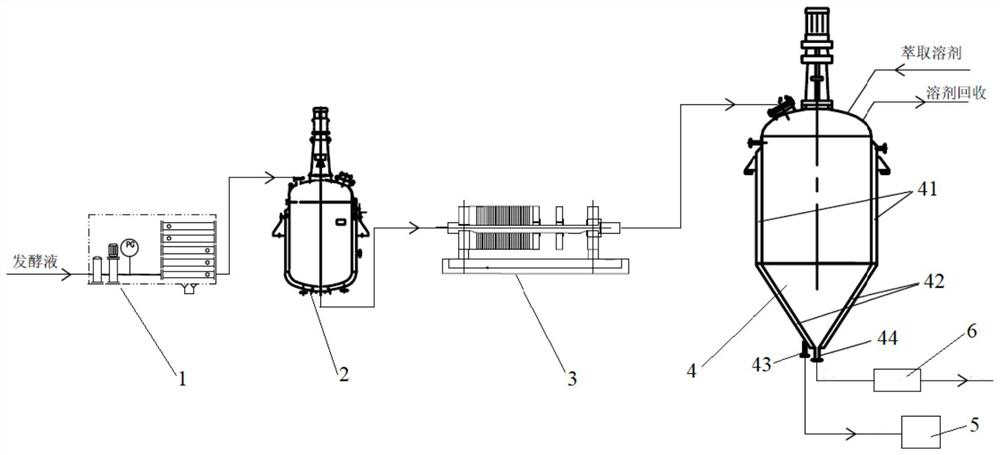

[0041] Such as figure 1 As shown, a filtering and extracting equipment for β-carotene fermentation liquid, comprising sequentially connected tubular membrane filter 1, acidification tank 2, high-pressure plate and frame filter 3, multifunctional extraction tank 4; the inner wall of multifunctional extraction tank 4 A steam jacket 41 is arranged on the top, a filter jacket 42 is arranged at the lower part of the multifunctional extraction tank 4, and an extraction liquid outlet 43 is arranged outside the filter jacket 42, and the extraction liquid outlet 43 is connected to the extraction liquid tank 5, and the lower end of the multifunctional extraction tank 4 is provided with There is a discharge port 44, and the discharge port 44 is connected to the screw slag discharger 6.

Embodiment 2

[0043] A process for filtering and extracting beta-carotene fermented liquid, comprising the steps of:

[0044] filter:

[0045] (1) Get 5000L of fermented liquid, first filter the fermented liquid with a 50nm tubular membrane filter, discard the permeate, and obtain 1000L of concentrated liquid;

[0046] (2) washing the concentrated solution from the tubular membrane filter with water into the acidification tank;

[0047] (3) adding hydrochloric acid in the acidification tank to adjust the pH value of the concentrated solution to 1.13, and then adjusting the pH value to 4.01 with sodium hydroxide solution to obtain an acidification neutralization solution;

[0048] (4) Filter the acidified neutralization solution with a high-pressure plate frame, top wash with water, extrude, and unload to obtain 460 Kg of β-carotene fermentation mycelia (water content 38.9%).

[0049] extraction:

[0050] (1) Put the β-carotene fermented mycelia into a multi-functional extraction tank, ad...

Embodiment 3

[0053] A process for filtering and extracting beta-carotene fermented liquid, comprising the steps of:

[0054] filter:

[0055] (1) Get 5000L of fermented liquid, first filter the fermented liquid with a 50nm tubular membrane filter, discard the permeate, and obtain 2500L of concentrated liquid;

[0056] (2) washing the concentrated solution from the tubular membrane filter with water into the acidification tank;

[0057] (3) adding hydrochloric acid in the acidification tank to adjust the pH value of the concentrated solution to 1.93, and then adjusting the pH value to 6.95 with sodium hydroxide solution to obtain an acidification neutralization solution;

[0058] (4) Filter the acidified neutralization liquid with a high-pressure plate frame, top wash with water, extrude, and unload to obtain 435Kg of β-carotene fermented mycelium (water content 35.4%).

[0059] extraction:

[0060] (1) Put the β-carotene fermented mycelium into a multifunctional extraction tank, add 2175L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com