Tubular pyrohydrolysis treatment method and device for sludge

A treatment method and thermal hydrolysis technology, which are applied in pyrolysis sludge treatment, dewatering/drying/concentrating sludge treatment, fertilization devices, etc., can solve the problem of low equipment utilization rate, ineffective process guarantee, and soil mechanical properties. and poor biological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

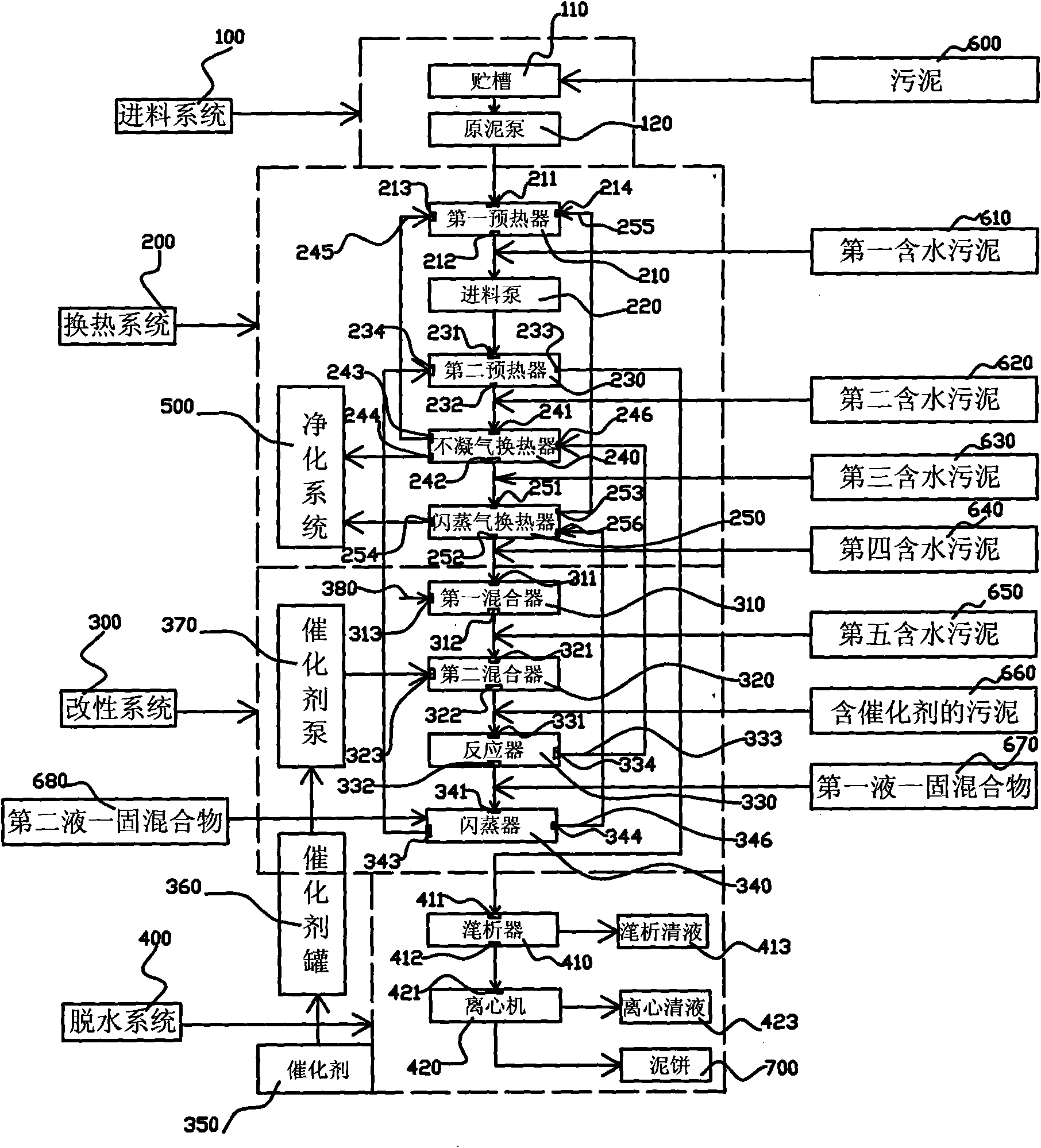

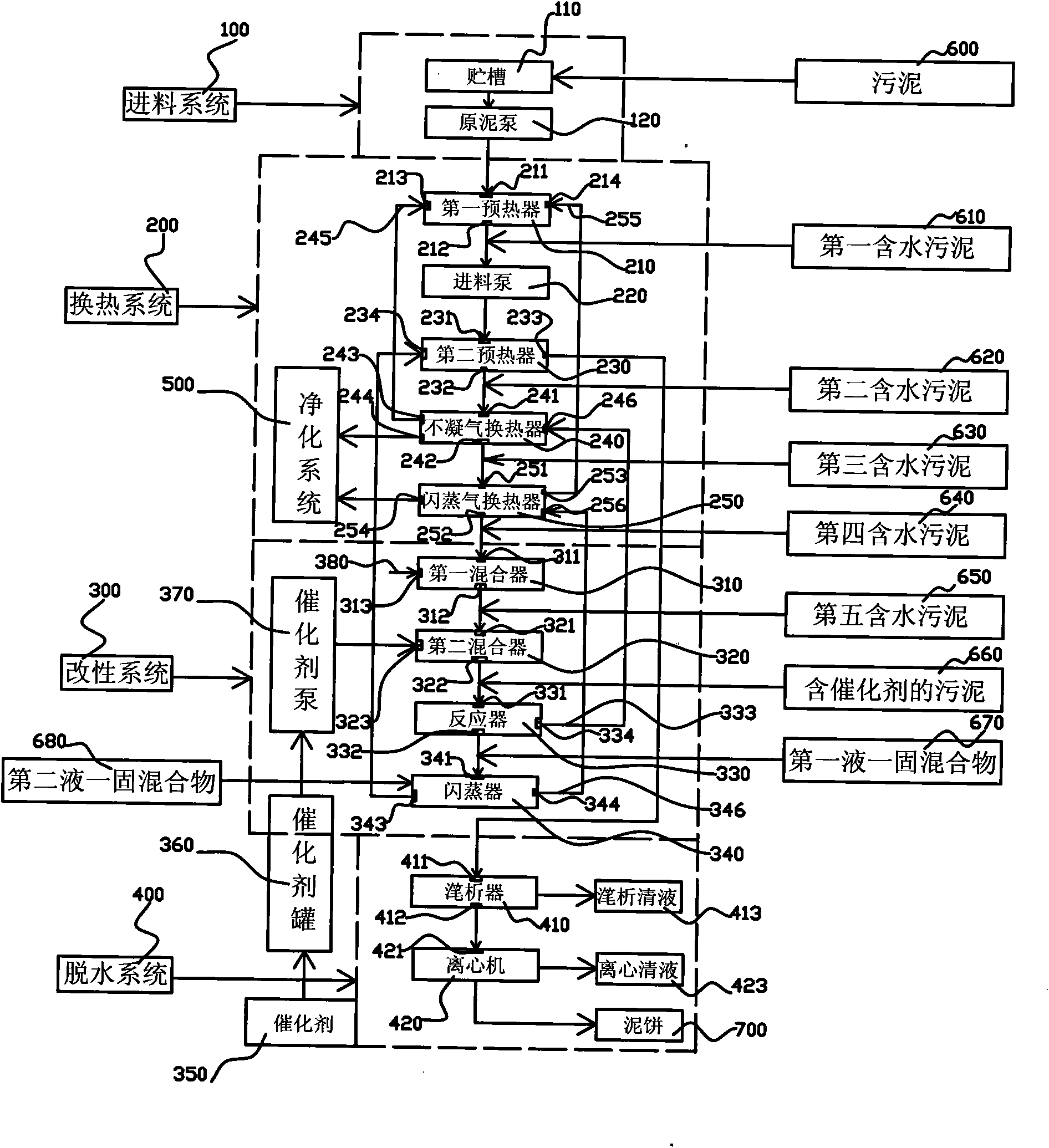

[0078] A sludge tube thermal hydrolysis treatment method, comprising the following steps, such as figure 1 Shown:

[0079] (1), preheating pressure test steps:

[0080] Use steam to preheat and pressure test the tubular sludge treatment device. The pressure test standard: the pressure of the modification system is 3.0-3.8Mpa, and the pressure of the four systems of dehydration system, heat exchange system, feed system and purification system is 0.1 -0.8Mpa, the whole preheating and pressure test process stops when the temperature of the tubular sludge treatment device reaches 150-240°C, and it also plays a role in preheating the device during the pressure test.

[0081] (2), the first preheating step:

[0082] Use the raw sludge pump 120 to continuously send the sludge 600 from the storage tank 110 to the first preheater 210 in the heat exchange system 100, and send it to the first preheater 240 in the heat exchange system 200. The liquid 245 is mixed with the second liquid...

Embodiment 2

[0107] see again figure 1 , a sludge tube thermal hydrolysis treatment method, comprising the following steps:

[0108] (1), preheating pressure test steps:

[0109] Use steam to preheat and pressure test the tubular sludge treatment device. The pressure test standard: the pressure of the modification system is 3.2-3.8Mpa, and the pressure of the four systems of dehydration system, heat exchange system, feed system and purification system is 0.3 -0.8Mpa, the whole preheating and pressure test process stops when the temperature of the tubular sludge treatment device reaches 180-240°C, and it also plays a role in preheating the device during the pressure test.

[0110] (2), the first preheating step:

[0111] Use the raw sludge pump 120 to continuously send the sludge 600 from the storage tank 110 to the first preheater 210 in the heat exchange system 100, and send it to the first preheater 240 in the heat exchange system 200. The liquid 245 is mixed with the second liquid 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com