Processing method by shale oil through catalytic cracking

A catalytic cracking and processing method technology, applied in the field of efficient utilization of shale oil resources, can solve the problems of high content and low conversion efficiency, and achieve the effects of short process, no hydrogen consumption, and low strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

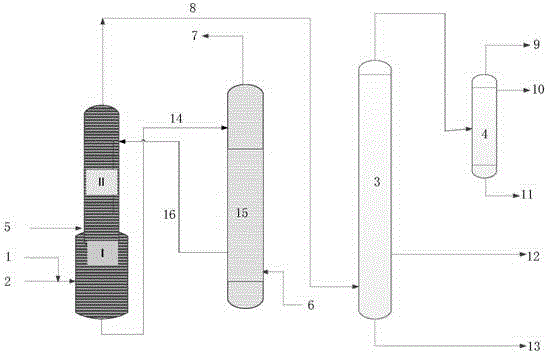

[0072] This example follows figure 1 The process was tested, using shale oil A with the composition shown in Table 1 as the raw material for catalytic cracking, the moving bed reactor and the regenerator were arranged side by side, and the CAT-2 catalyst was used, and water was used as the cooling medium in the adsorption zone. The heat exchange coil cools the sorbent. After being preheated at 220°C, the shale oil enters the bottom of the adsorption zone where the diameter of the moving bed reactor expands (the inner diameter of the reactor in the adsorption zone is twice the inner diameter of the reactor in the cracking zone, and the length of the reactor in the adsorption zone is 2 times that of the reactor in the cracking zone. 30% of the length of the reactor in the above-mentioned cracking zone), along with the water vapor fluidized medium flowing from bottom to top, at an adsorption temperature of 300°C, a weight ratio of cold catalyst to shale oil of 12, a pressure of 0...

Embodiment 2

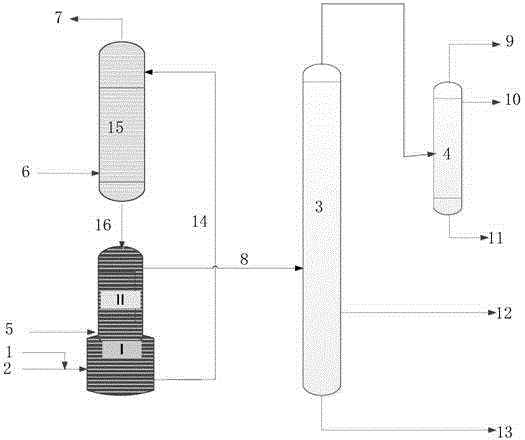

[0086] according to figure 2 The process is tested, shale oil B is used as the raw material for catalytic cracking, the regenerator and the moving bed reactor are arranged vertically up and down, the CAT-2 catalyst is used, and a small amount of water is injected between the adsorption zone and the cracking zone as a cooling medium. After being preheated at 300°C, shale oil B enters the bottom of the adsorption zone where the diameter of the moving bed reactor expands (the inner diameter of the reactor in the adsorption zone is 5 times the inner diameter of the reactor in the cracking zone, and the length of the reactor in the adsorption zone is 10% of the length of the reactor in the cracking zone), along with the water vapor fluidized medium flowing from bottom to top, at 400°C of adsorption temperature, 6.0 of the weight ratio of cold catalyst and shale oil B, and a pressure of 0.35Mpa, the adsorption time Adsorption reaction is carried out under the condition of 120s to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com