Process for hydrogen production by adsorption catalysis of crude synthetic gas and device thereof

A crude synthesis gas, adsorption catalysis technology, applied in hydrogen/synthesis gas production, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the limitation of crude synthesis gas application, process simplification, There are many problems such as many reaction steps and purification steps, so as to broaden the selection range of raw material gas, simplify the hydrogen production process, and realize the effect of resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

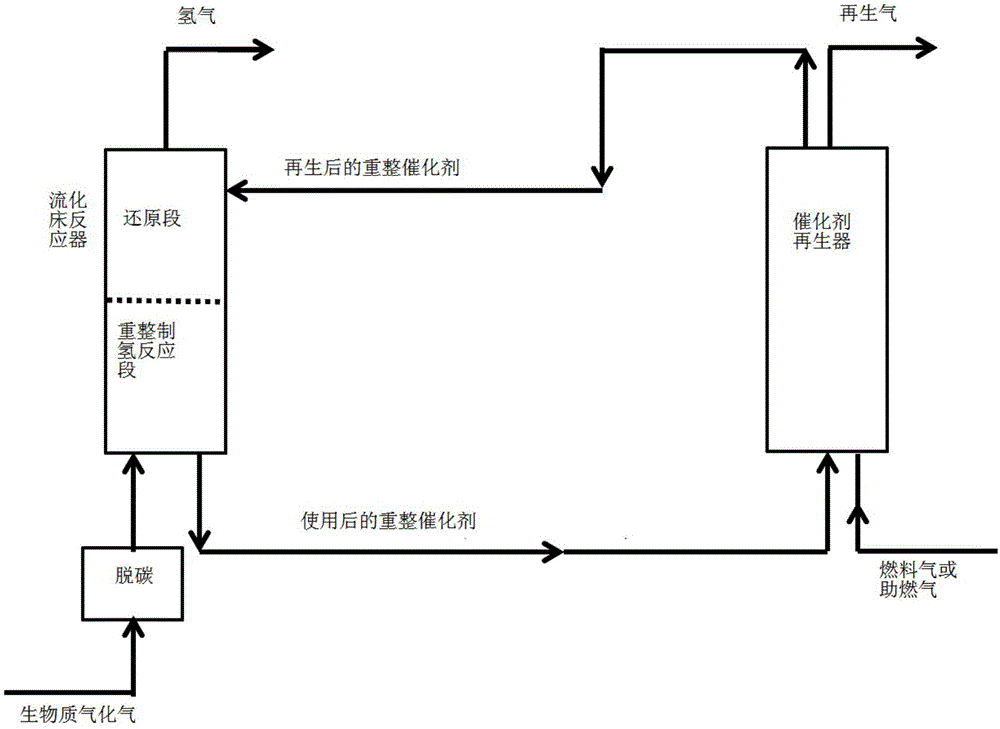

[0035] Such as figure 2 As shown, the biomass gasification gas is used as the raw material gas, and the gas composition of the raw material gas is shown in Table 1 below. The biomass gasification gas enters the reaction section at the bottom of the fluidized bed reactor after the decarburization process. The flow rate of biomass gasification gas is 2240Nm 3 / h, then feed water vapor into the reaction section of the fluidized bed reactor according to the molar ratio of 4:1 according to the water-carbon ratio (the water-carbon ratio is the molar weight of water vapor and the total carbon in the biomass gas after decarburization except carbon dioxide molar ratio), then add fresh reduced reforming catalyst with adsorption function to carry out reforming hydrogen production reaction, and the reaction space velocity is 2000hr -1 (the standard volume of the reaction raw material gas passing through the catalyst per unit volume per unit time), the hydrocarbons in the biomass gasific...

Embodiment 2

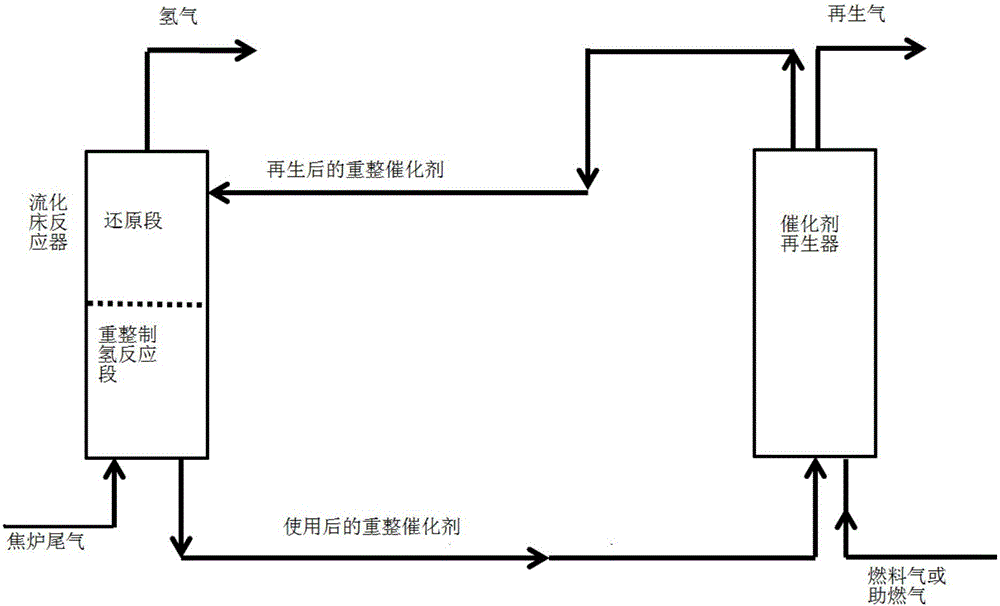

[0037] Such as image 3 As shown, the coke oven tail gas is used as the raw material gas, the gas composition of the raw material gas is shown in Table 1 below, and the gas flow rate is 2240Nm 3 The coke oven tail gas of / h is charged into the reaction section at the bottom of the fluidized bed reactor, and then feeds water vapor into the reaction section of the fluidized bed reactor at a molar ratio of 4: 1 according to the water-to-carbon ratio (the water-to-carbon ratio is the ratio of water vapor The ratio of the molar weight to the molar weight of the total carbon except carbon dioxide in the coke oven tail gas), and then add a fresh reduced reforming catalyst with adsorption function to carry out the reforming hydrogen production reaction, and the reaction space velocity is 5000hr -1 , so that the hydrocarbons in the coke oven tail gas, tar (C 10 h 8 ) and carbon monoxide into hydrogen and carbon dioxide, and the carbon dioxide produced by the reaction and the coke in ...

Embodiment 3

[0039] Such as Figure 4 As shown, the tail gas of the carbon black plant is used as the raw material gas, the gas composition of the raw material gas is shown in Table 1 below, and the gas flow rate is 2240Nm 3 The carbon black plant tail gas of / h is charged into the reaction section at the bottom of the fluidized bed reactor, and then feeds water vapor into the reaction section of the fluidized bed reactor at a molar ratio of 5: 1 according to the water-to-carbon ratio (the water-to-carbon ratio is steam The ratio of the molar weight to the total carbon molar weight except carbon dioxide in the tail gas of the carbon black plant), and then add a fresh reduced reforming catalyst with adsorption function to carry out the reforming hydrogen production reaction, and the reaction space velocity is 10000hr -1 , so that the hydrocarbons in the tail gas of the carbon black plant, tar (C 10 h 8 ) and carbon monoxide into hydrogen and carbon dioxide, and the carbon dioxide generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com