New method for directly synthesizing branched polyethyleneimine from haloethylamine

A polyethylenimine and haloethylamine hydrohalide technology, applied in the field of polymer synthesis, can solve problems such as high corrosion, and achieve the effects of less pollution, high yield and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

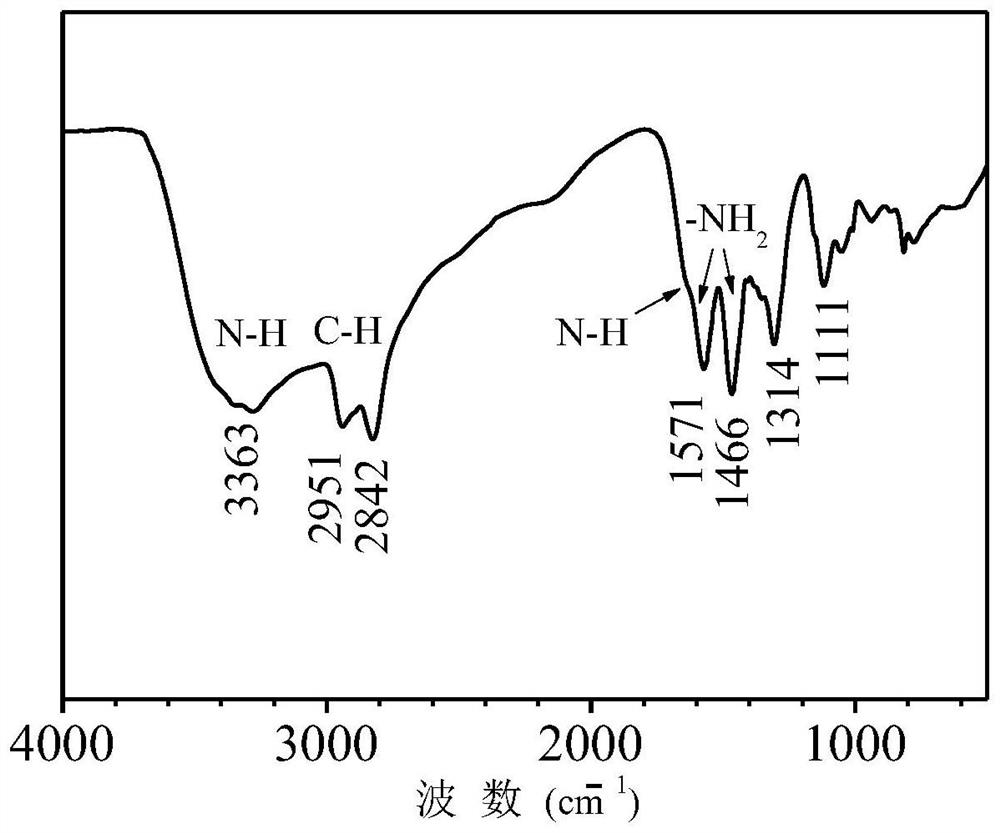

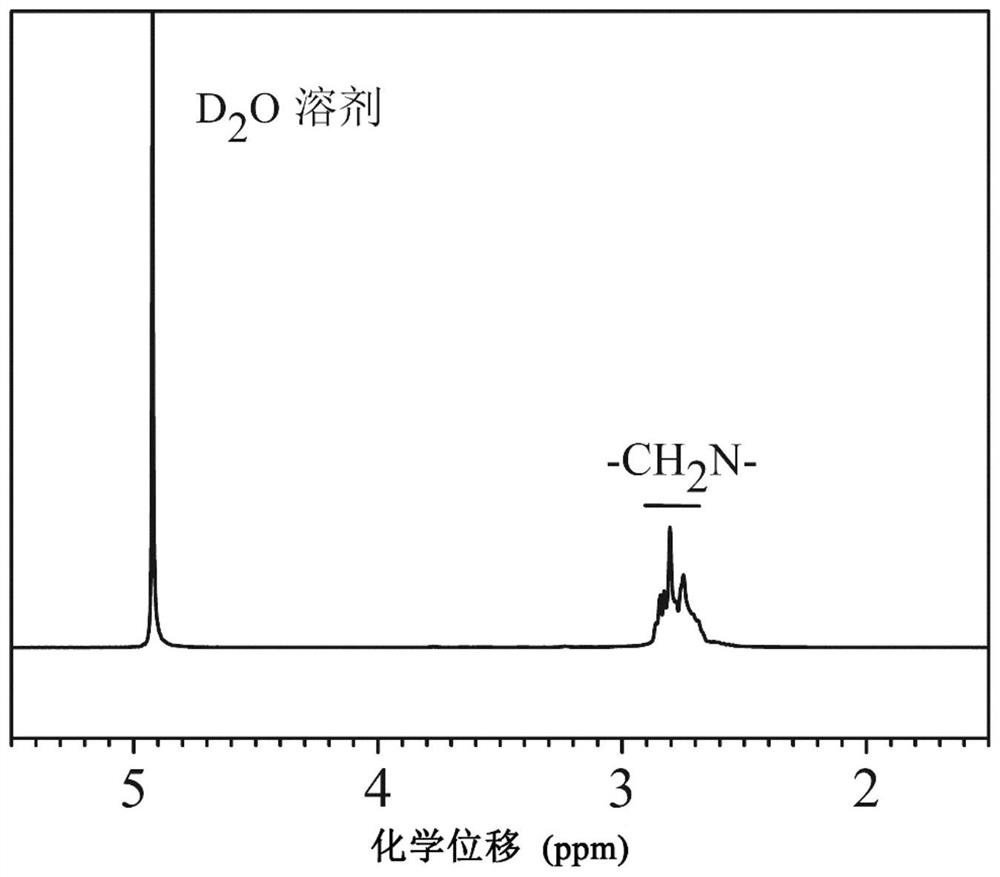

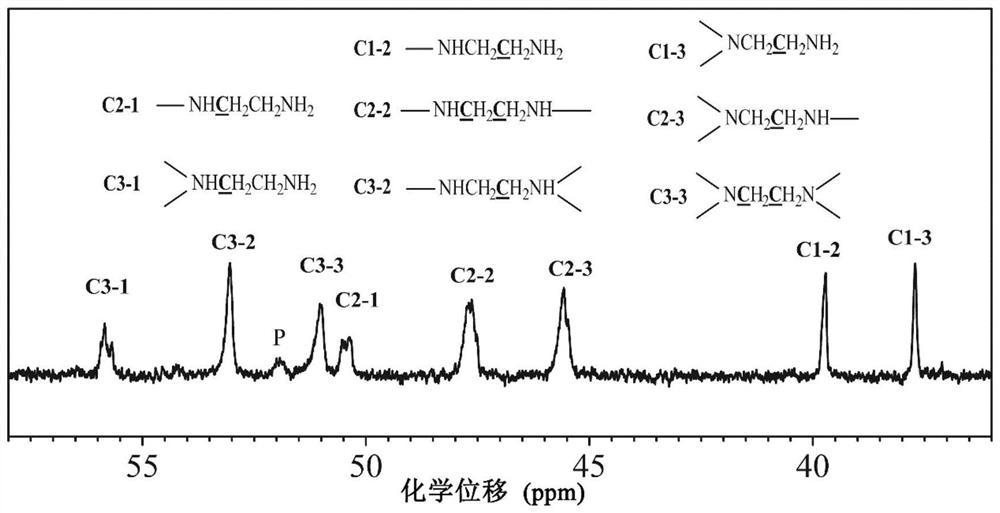

Method used

Image

Examples

Embodiment 2

[0032]Embodiment 2 and embodiment 18-22 are that other reaction parameters are constant, and the molar number of alkali used in this table, the result shows that the molar number of optimum alkali is 2, helps to obtain the product of high molecular weight. The molecular weight of the resulting product was significantly reduced when NaOH was added in amounts of 2.2 and 2.5 moles, because the excess base would cause the hydrolysis of 2-haloethylamine to ethanolamine; in stage II, ethanolamine initiates the ring-opening polymerization of ethyleneimine to give product. If there is too much ethanolamine by-product, it will lead to a decrease in the molecular weight of the resulting PEI. When NaOH is insufficient, when reducing to 1.9 as mole number, can cause part chloroethylamine and can not be converted into ethyleneimine monomer, also is unfavorable for the carrying out of reaction; Of course, also can obtain PEI product (PEI 18, table now) 1), the piperazine ring content of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com