Plastic slitting and granulating machine

A granulator and slitting technology, which is applied in metal processing and other directions, can solve problems such as the axial deviation of the conveying roller, and achieve the effect of saving labor costs, eliminating the need for manual separation and crushing procedures, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

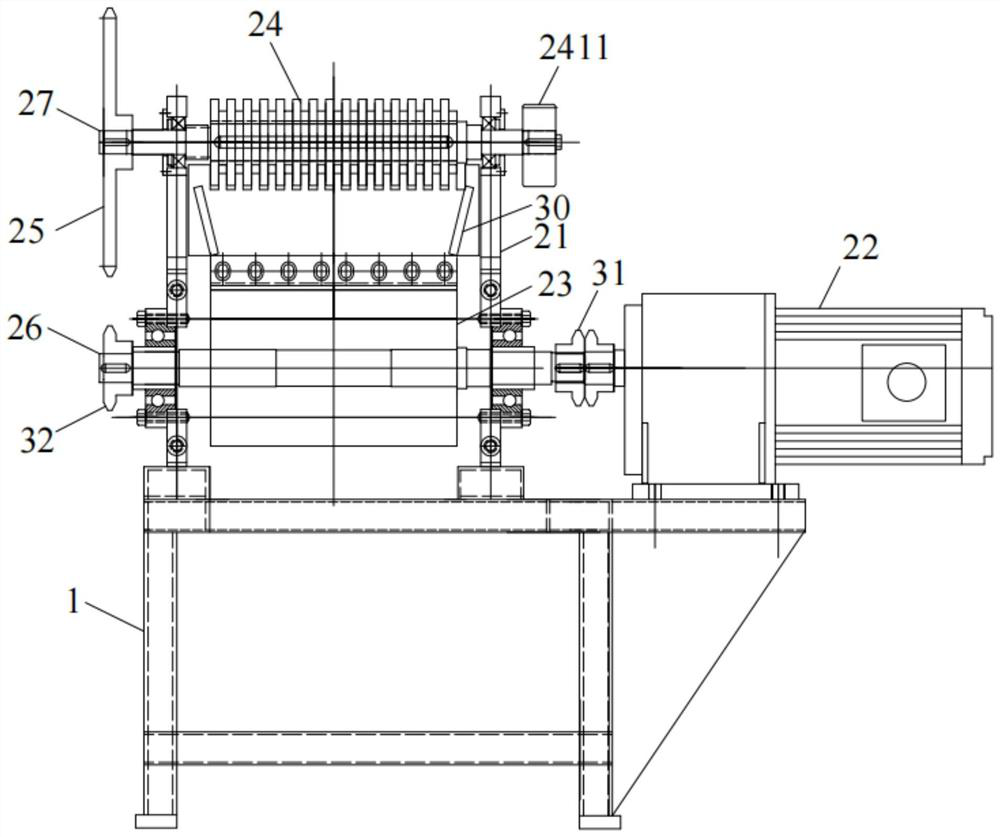

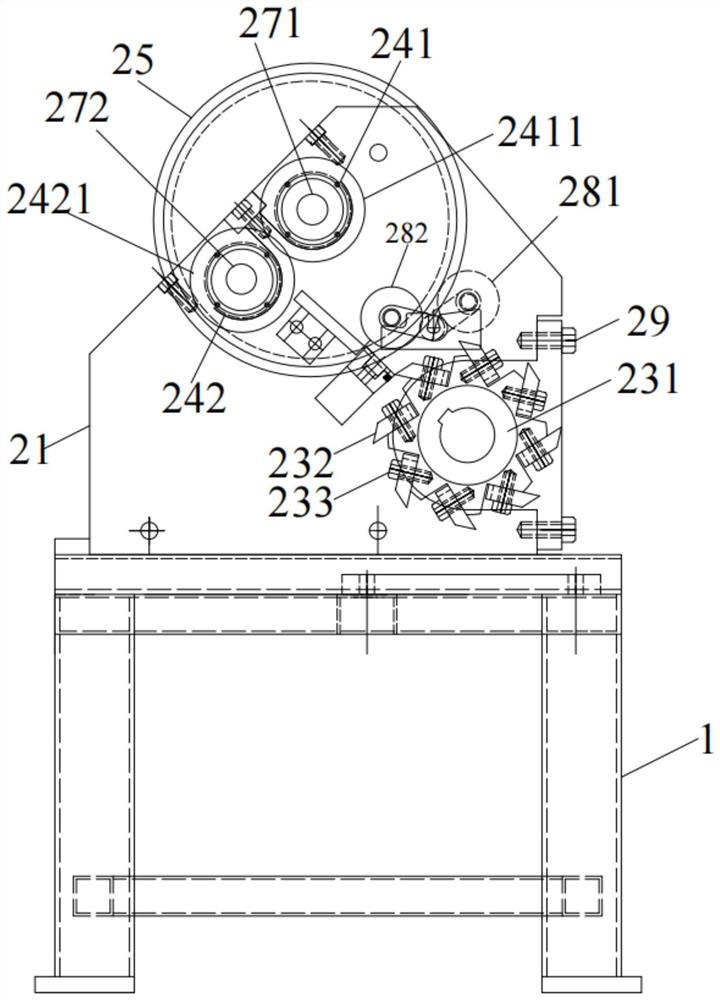

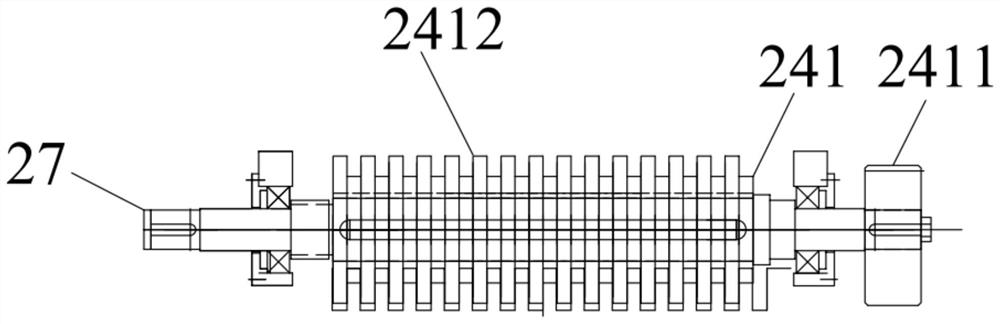

[0020] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended Figure 1-3 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

[0021] See Figure 1-3 , a plastic slitting and granulating machine, including a machine base 1 and a cutting device, the cutting device includes a fixed frame 21, a driving device 22, a rolling knife assembly 23, a cutting knife assembly 24, a large sprocket 25, a small sprocket 32. The first rotating shaft 26 and the second rotating shaft group 27, the fixed frame 21 is arranged on the upper end surface of the machine base 1, and the cutting knife assembly 24 is erected on the fixed frame 21 through the second rotating shaft group 27 At the upper end, the rolling knife assembly 23 is fixed in the fixed frame 21 through the first rotating shaft 26 and is located below the cutting knife assembly 24, and the driving device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com