Novel fluidized bed semicoke production system and process thereof

A production system and fluidized bed technology, applied in coking ovens, petroleum industry, direct heating and dry distillation, etc., can solve the problems of backward research and development of semi-coke production, immature large-scale technical equipment, single process technology, etc., and achieve comprehensive utilization of resources The effect of high level, small footprint and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

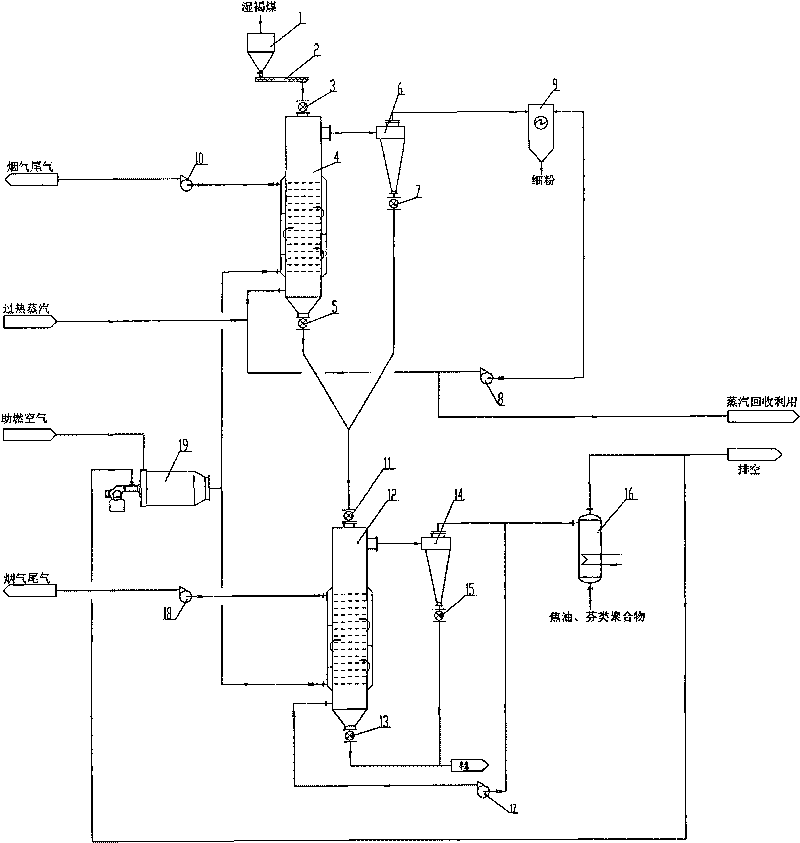

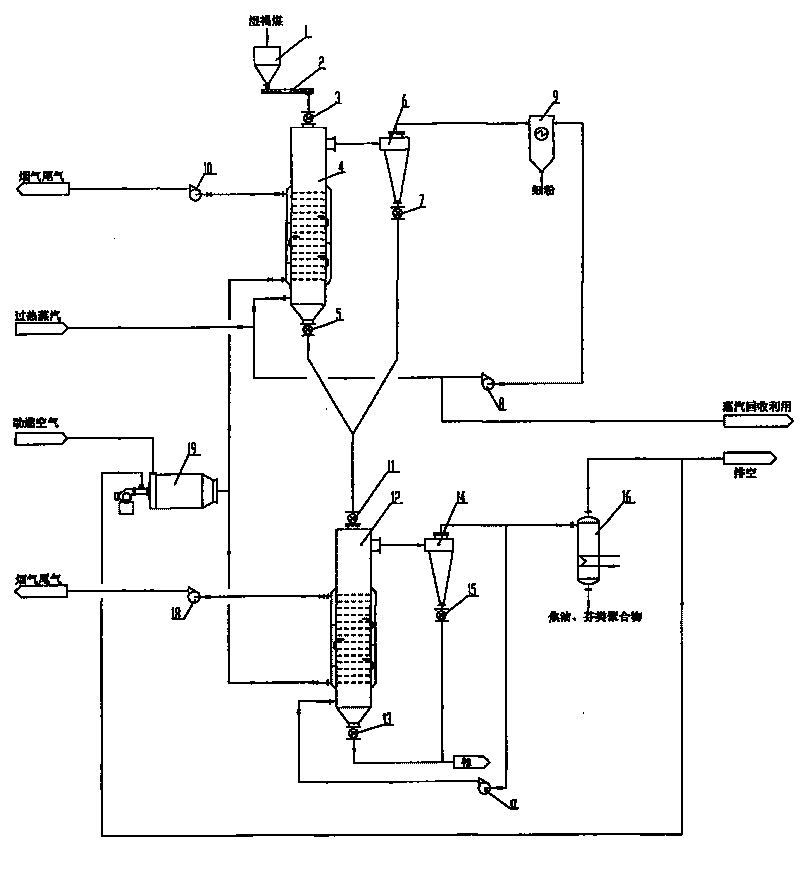

[0030] figure 1Among them, it includes a drying system and a dry distillation system, wherein the drying system is an internal heating fluidized bed dryer 4, and the feeding end of the internal heating fluidized bed drying machine 4 is connected with a feeding device, and the feeding device includes a silo 1, which It is connected with the screw conveyor 2, and the screw conveyor 2 is connected with the feed end of the inner heating fluidized bed dryer 4 through the discharge valve I3. The tail gas of the internal heating fluidized bed dryer 4 is recovered after two-stage dust removal by the cyclone dust collector I6 and the electrostatic precipitator 9 . The discharge port of the cyclone dust collector I6 is sent to the feed end of the internal heating fluidized bed dry distillation furnace 12 through the discharge valve III7; the tail gas after the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com