Process for recycling boric acid and magnesium sulfate from boric acid mother solution

A technology of magnesium sulfate and boric acid mother, applied in the direction of magnesium sulfate, boron oxide, energy input, etc., can solve problems such as low production efficiency, unsuitability for large-scale production, and impact on the quality of boric acid products, so as to improve production efficiency and reduce energy consumption. Consumption, reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

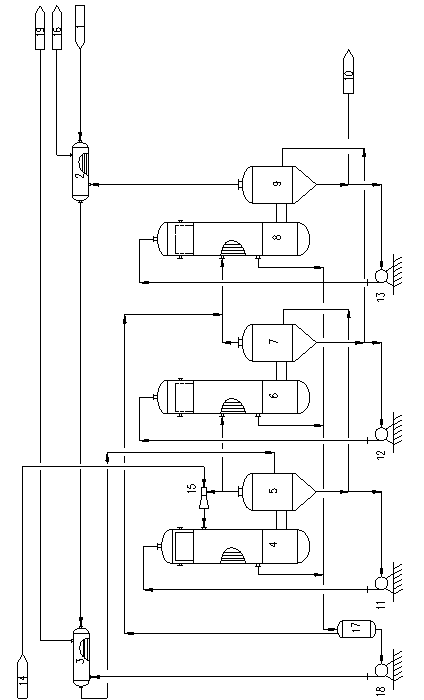

[0026] The mother liquor pool (1) contains mother liquor containing 4% boric acid and 13% magnesium sulfate (mass), with a treatment capacity of 6000kg / h, which is preheated to 75°C, and then enter the first-effect separation chamber (5), through the first-effect circulation pump (11), the mother liquor is sent to the first-effect heating chamber (4) for heating and evaporation, the boiling point temperature of the solution is controlled at 100°C, and the concentration of magnesium sulfate reaches 20%. , the gas-liquid separation is carried out in the first-effect separation chamber (5); the separated liquid enters the second-effect separation chamber (7) by the pressure difference between the two effects, and the mother liquor is pumped into the second-effect heating chamber by the second-effect circulating pump (12) (6) Heating and evaporating, the boiling point temperature of the solution is controlled at 80°C, the concentration of magnesium sulfate reaches 26%, and the ...

Embodiment 2

[0028] The mother liquor pool (1) contains mother liquor containing 3% boric acid and 15% magnesium sulfate, with a treatment capacity of 10,000kg / h, preheated to 70°C by the exhaust steam preheater (2) and condensed water preheater (3), Then it enters the first-effect separation chamber (5), and the mother liquor is sent to the first-effect heating chamber (4) for heating and evaporation through the first-effect circulating pump (11). The separated liquid enters the second-effect separation chamber (7) by the pressure difference between the two effects, and the mother liquor is sent to the second-effect heating chamber (6) by the second-effect circulating pump (12). Heating and evaporation, the boiling point temperature of the solution is controlled at 85°C, the concentration of magnesium sulfate reaches 26%, and the gas-liquid separation is carried out in the second-effect separation chamber (7); the separated liquid enters the third-effect separation chamber (9) by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com