Process for preparing fast-soluble boron by using boric acid mother liquor

A technology of boric acid mother and instant boron, which is applied in the direction of borate, boron compound, boron oxide compound, etc., can solve the problems of unsuitable industrial mass production, low production efficiency, high equipment requirements, etc., and achieve good economic and social benefits, The effect of solving environmental pollution and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

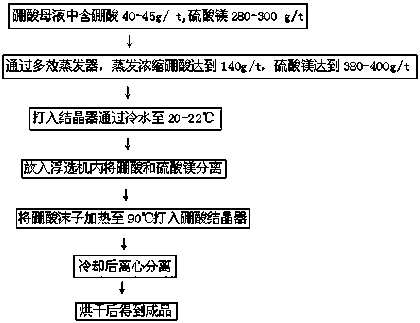

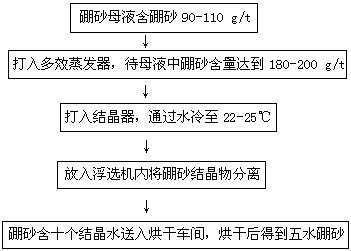

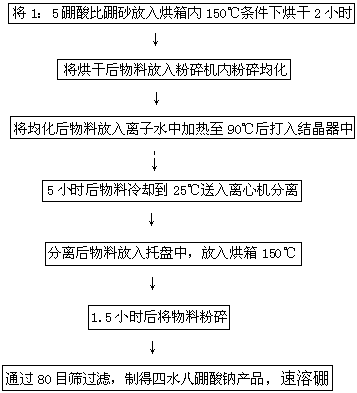

Method used

Image

Examples

Embodiment 1

[0036] Experiment: Put 10 g of instant boron into 100mex 8°C cold water, and dissolve it completely by stirring slightly for 3 minutes.

[0037] Small test starts at 10:00

[0038] Weigh 500 grams of boric acid and 250 grams of borax pentahydrate

[0039] 10:10 Put it in the oven at 150°C for 2 hours

[0040] 12:15 min crushing and homogenization

[0041] time

[0042] The pilot test starts at 9:00

[0043] Weigh 250kg boric acid and 1250kg pentahydrate borax. Send it to a tray dryer at a circulating drying temperature of 120°C for 3.5 hours.

[0044] At 12:40, pulverization and homogenization were started, 5 tons of ionized water was added to the stirring tank, and the temperature rose to 90°C after feeding for 3 hours. Pour into the crystallizer for crystallization and wait for 5 hours to cool to 25°C.

[0045] 20:50 Centrifugal drying and crushing to obtain a product of 1380kg

[0046] a jar of crystallization

[0047] time

[0048] Industrial prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com