Method for producing ammonium sulphate grain products by using inorganic caking agent

An inorganic binder and ammonium sulfate technology, applied in the fields of application, ammonium salt fertilizer, nitrogen fertilizer, etc., can solve the problems of unable to produce granular ammonium sulfate, and achieve the effects of improving product market competitiveness, easy operation, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

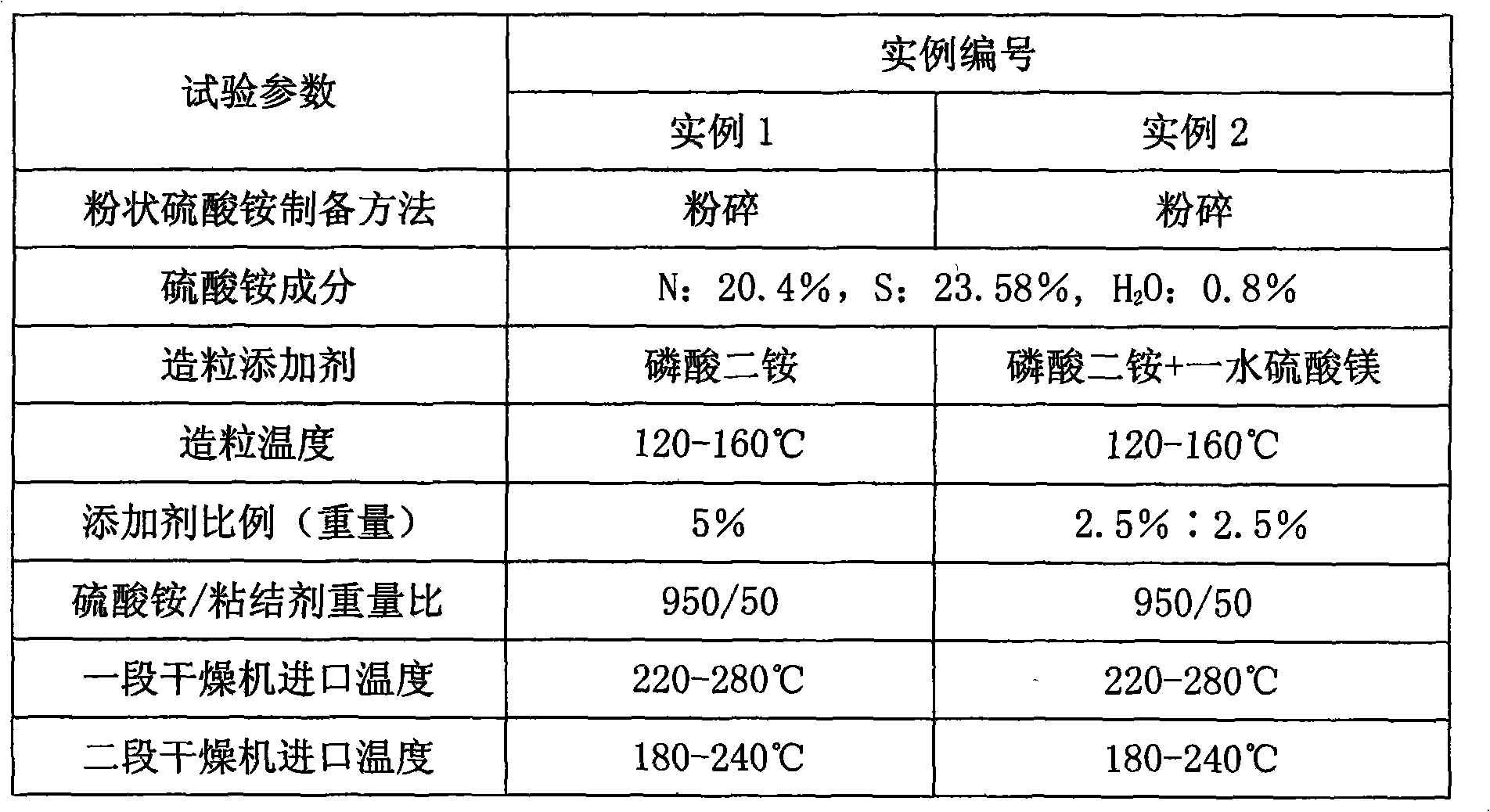

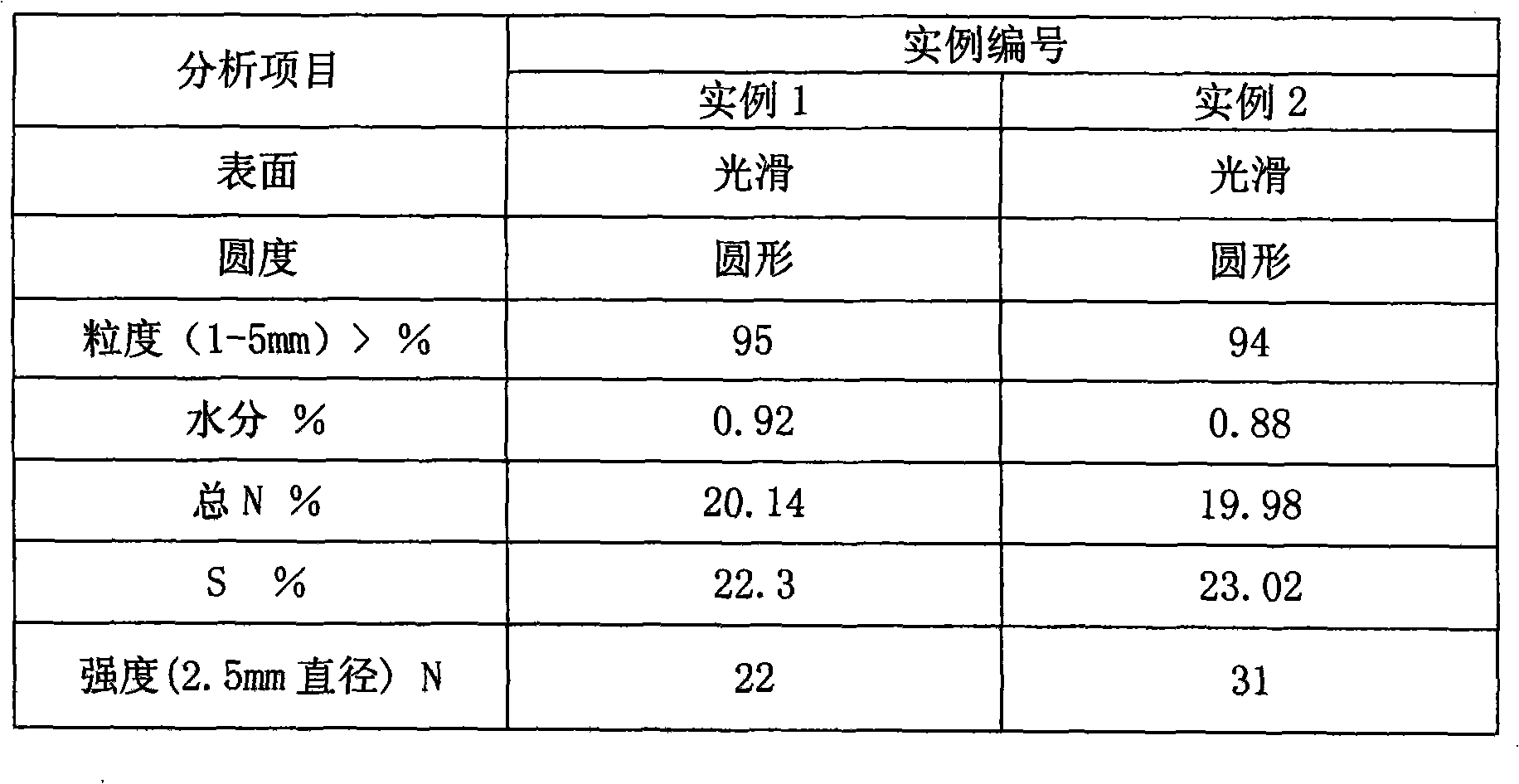

[0019] Example 1 single inorganic binder produces granular ammonium sulfate

[0020] Use diammonium phosphate as the inorganic binder, crush it to 20-200 meshes for later use; use ≤2mm ammonium sulfate crystals (the active ingredients are N: 20.4%, S: 23.58%, H 2 O: 0.8%) is crushed to 20-200 mesh by a pulverizer; mixed according to the ratio of diammonium phosphate and ammonium sulfate is 5:95, enters the granulator, and granulates through medium-pressure steam spraying, and the granulation temperature is 120 ℃~160℃; drying by two-stage dryer, the first stage drying temperature is 220℃~280℃, the second stage drying temperature is 180℃~240℃; after cooling, sieve with a sieving machine, and the selected particle size is 1~5mm The granules are ammonium sulfate products, which pass the inspection and are packaged for delivery.

example 2

[0021] The mixed inorganic binder of example 2 produces granular ammonium sulfate

[0022] The steps are the same as in Example 1, select monoammonium phosphate and magnesium sulfate monohydrate to be mixed according to 1:1 as the inorganic binder and pulverize to 20-200 mesh for later use; mix according to the ratio of the inorganic binder and ammonium sulfate as 3:97, After mixing, put it into the granulator together, control the ratio and process operation parameters, and make qualified granular ammonium sulfate products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com