Method for producing large particles of heptahydrate magnesium sulfate and monohydrate magnesium sulfate from magnesium sulfate solution

A technology of magnesium sulfate heptahydrate and magnesium sulfate, applied in the direction of magnesium sulfate, etc., can solve the problems of inability to produce large particle products and low product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

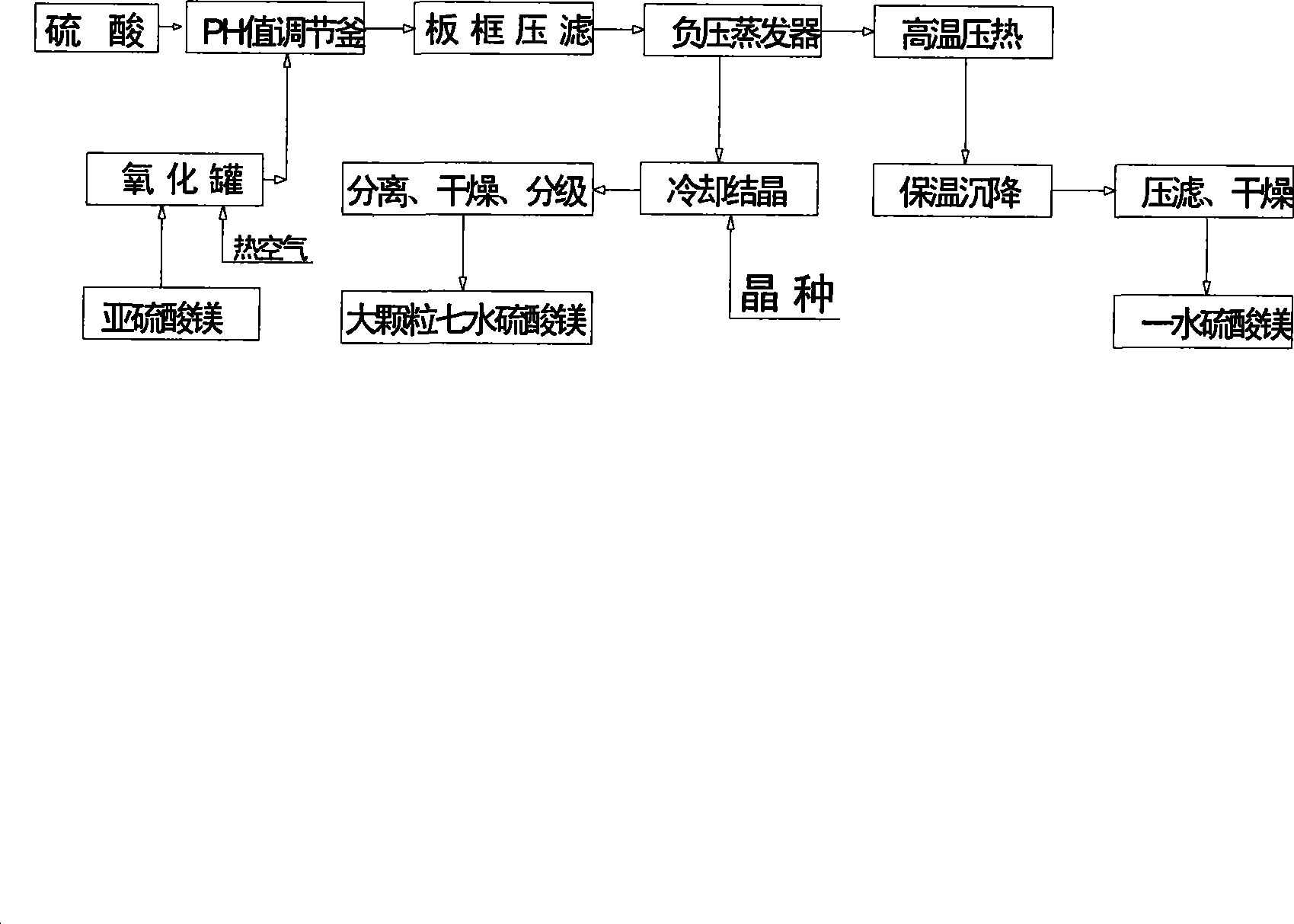

Image

Examples

Embodiment Construction

[0019] The production method of magnesium sulfate monohydrate

[0020] Get 1000Kg of magnesium sulfate circulation mother liquor, 200Kg of magnesium sulfite solid raw material. Put the above two materials into the mixing reaction tank for dispersion and oxidation treatment. Dispersion and oxidation are carried out using compressed hot air. The air temperature is 140°C, and the feed liquid temperature in the aeration tank is 110°C. Then pump the feed liquid into the adjusting kettle to adjust the pH value. The adjustment method adopts the method of adding sulfuric acid. When the pH value of the feed liquid reaches 6, stop adding acid. Then the solution with a neutral pH value is pumped into a plate and frame filter press for pressure filtration treatment, thereby obtaining a high-temperature saturated magnesium sulfate solution. Then pump this high temperature saturated magnesium sulfate solution into the negative pressure evaporator. Evaporate under negative pressure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com