Patents

Literature

41results about How to "Efficient dephosphorization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient smelting technology for producing low-phosphorous clean steel through converter

ActiveCN109897933AEfficient separationReduce lossManufacturing convertersProcess efficiency improvementSlagDolomite

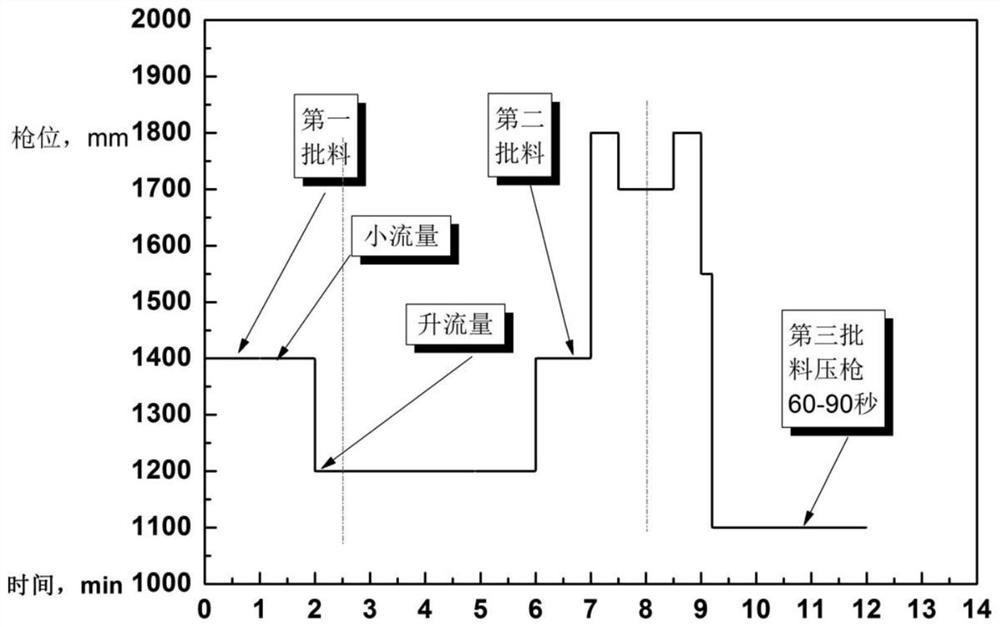

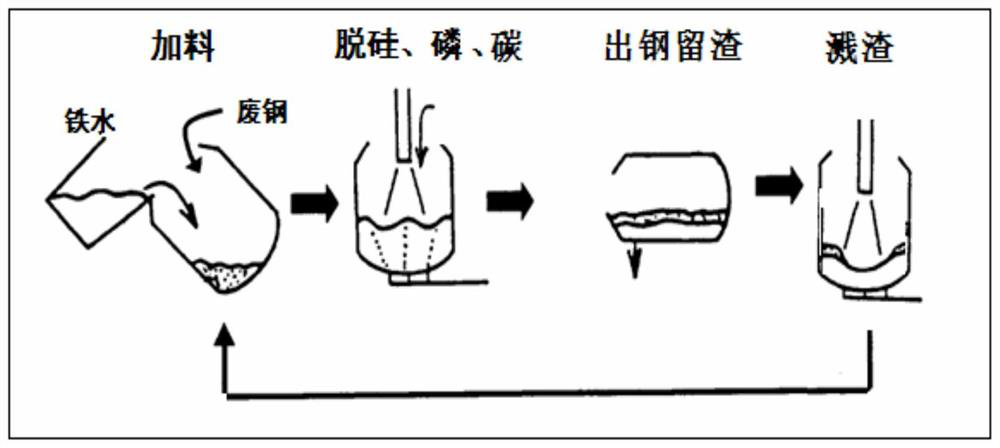

The invention discloses an efficient smelting technology for producing low-phosphorous clean steel through a converter. According to the technology, furnace slag of last furnace is subjected to slag splashing treatment, final slag is totally or partially left in the furnace, raw materials are added for smelting, during the one-time gun going and blow beginning stage, the gun position and flow of an oxygen gun are controlled, after the gun goes down and is ignited, an iron oxide ball adding and mine returning begin, then lime and light calcined dolomite are added, after all is added, the gun position is gradually hoisted up, and slag is poured; and the gun position and flow of the oxygen gun are controlled secondly, after fire is on, the lime begins to be added, the slag is adjusted in time, the position and the oxygen supply amount of the oxygen gun are controlled, finally, furnace pouring is carried out, the gun is lifted, and finally, the furnace slag is totally left in the converterfor slag and phosphorous curing, and used for smelting in next furnace. According to the technology, the slag added when the converted smelts the low-phosphorous clean steel is adjusted in time, thegun position and the oxygen supply amount of the oxygen gun are controlled, the final point steel tapping condition can meet the high-cleanness low-phosphorous steel converter final point control condition with C larger or equal to 0.12% and P smaller than or equal to 0.006%.

Owner:ZENITH STEEL GROUP CORP

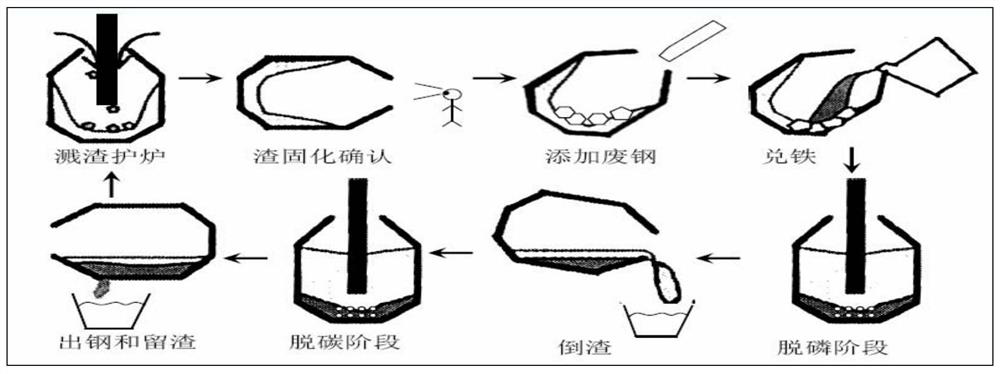

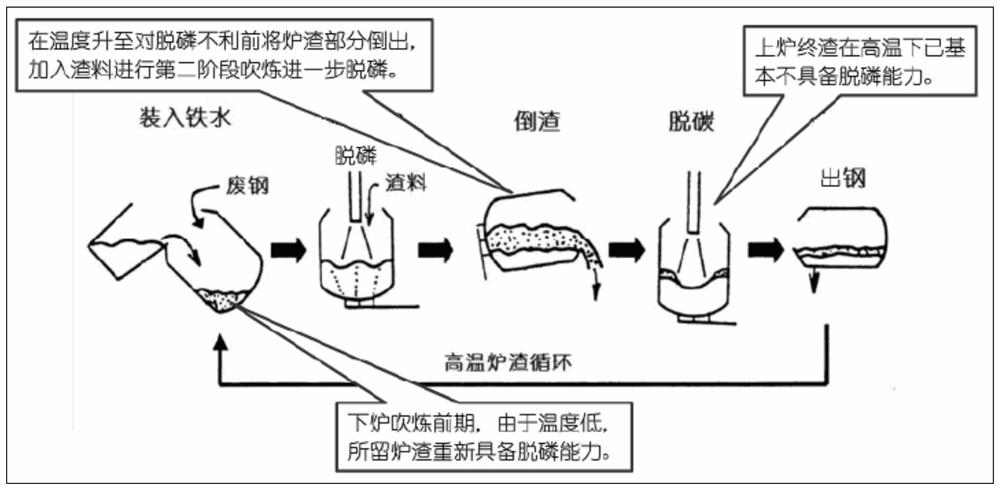

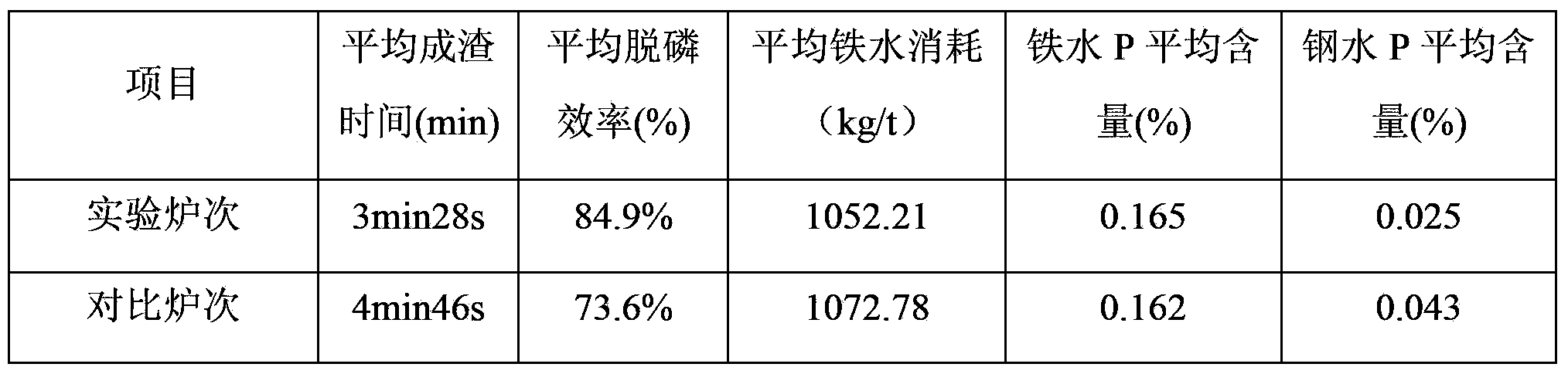

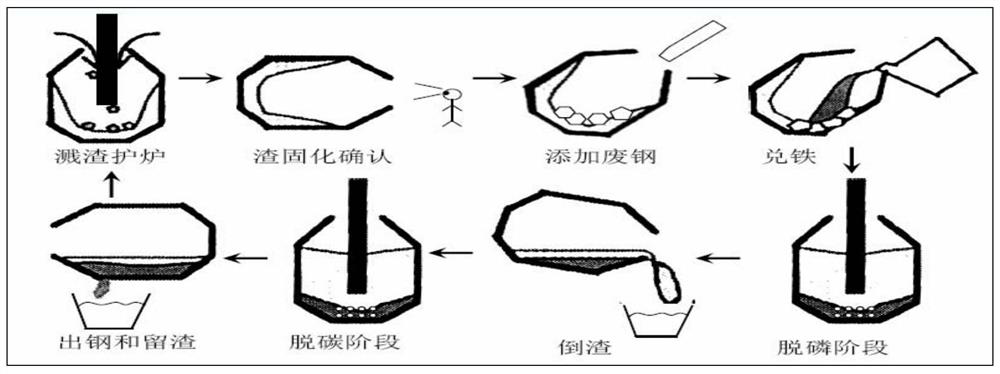

Converter less-slag smelting method

ActiveCN111719032ASuitable for industrial productionGood effectManufacturing convertersProcess efficiency improvementSlagDecarburization

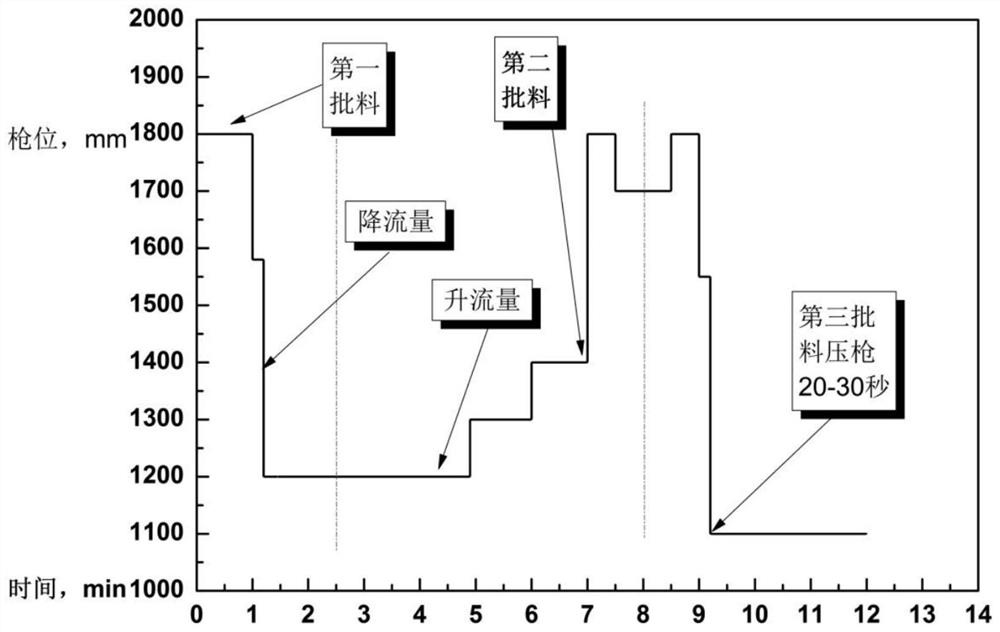

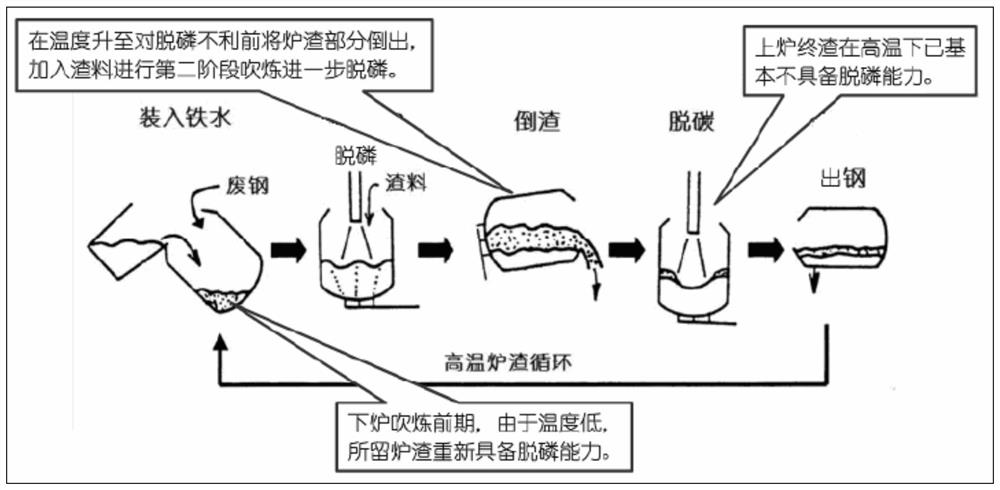

The invention relates to the field of smelting, in particular to a converter less-slag smelting method. During smelting, double slag and remaining slag operation are combined, the technological process comprises the steps of slag splashing for protection of a converter, converter slag solidification, converter slag solidification confirmation, scrap steel adding, iron adding, converter smelting slagging, dephosphorization slag putting in the early stage, gun lowering for blowing and decarburization again, steel tapping and slag remaining; the thermodynamic condition that the early-stage temperature is low and is beneficial to the dephosphorization reaction is utilized, the upper converter final slag is used in the initial stage of lower converter blowing, dephosphorization is carried out,before the temperature rises to be adverse to dephosphorization, part of the converter slag is poured out, then slag charge is added for slagging, second-stage blowing is carried out, dephosphorization is further carried out; and a low-lance-position and large-oxygen-supply converter efficient dephosphorization technology is adopted, and sufficient deslagging is carried out after dephosphorizationis finished. According to the converter less-slag smelting method, through the application of the double slag-remaining slag and remaining slag processes, an obvious effect is obtained, the ash consumption of the converter is greatly reduced, and the slag amount is reduced.

Owner:BENGANG STEEL PLATES

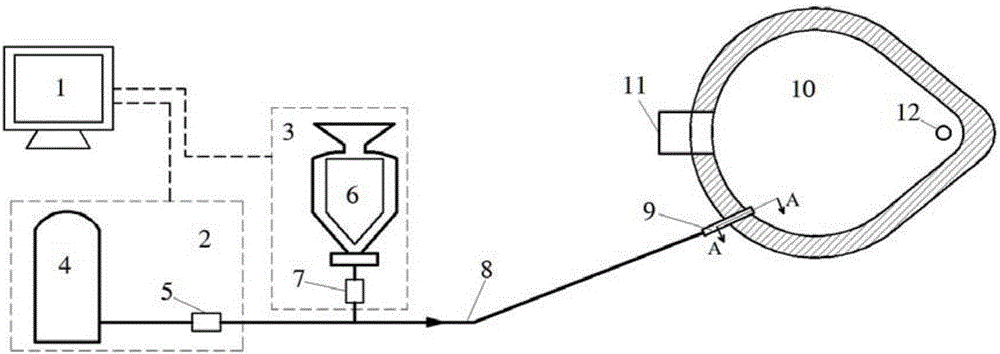

Dephosphorization method for electric-arc furnace steelmaking

ActiveCN105803155AImprove product qualityFully functional abilityProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

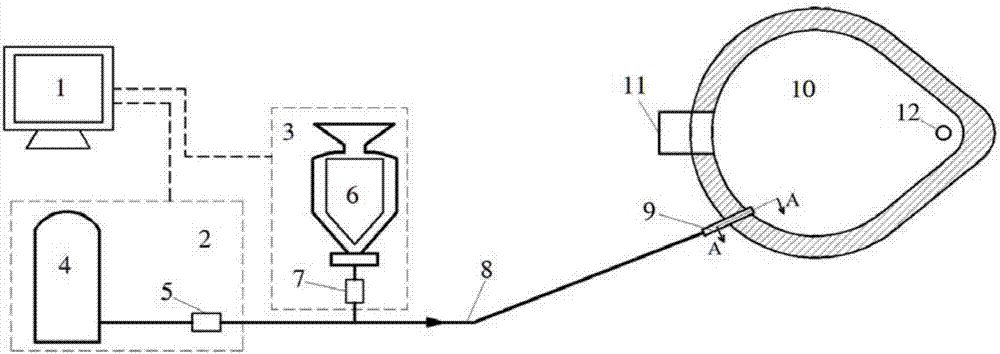

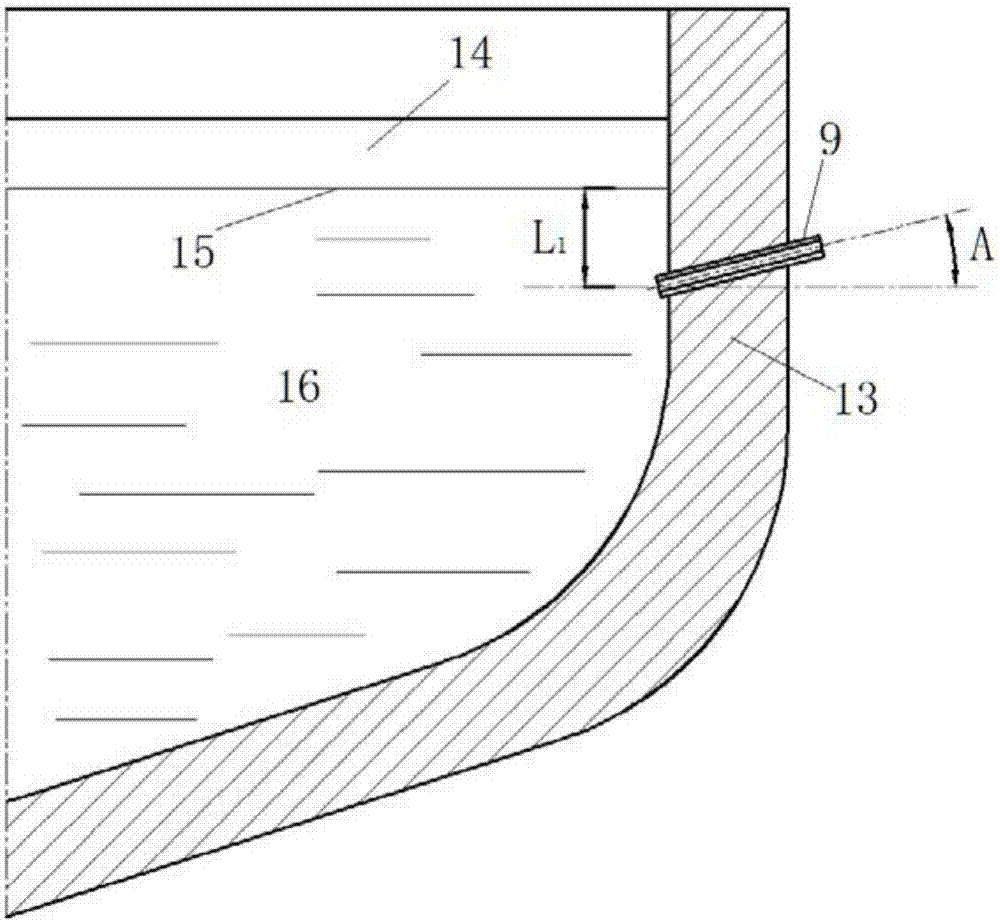

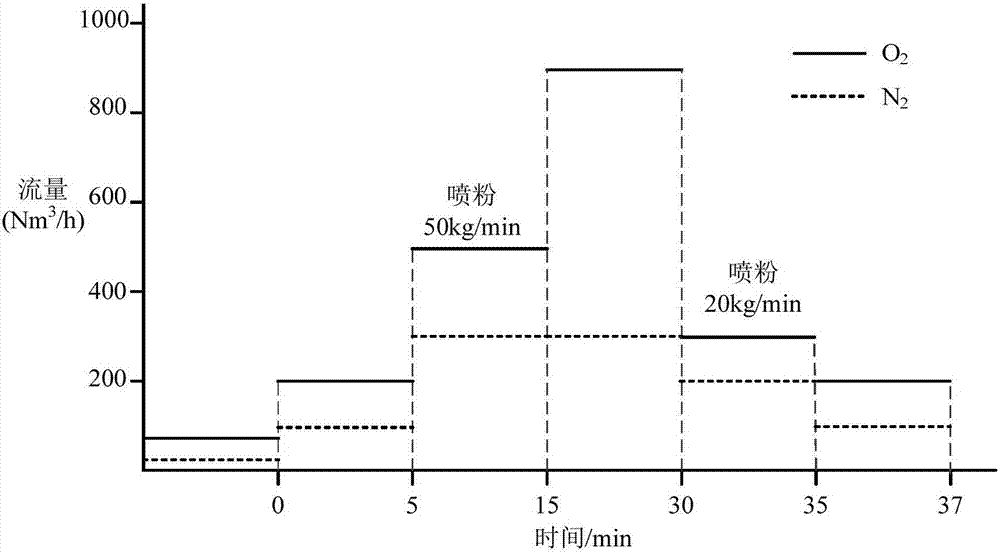

The invention provides a dephosphorization method for electric-arc furnace steelmaking, and belongs to the field of electric-arc furnace steelmaking. The dephosphorization method is characterized in that the same spray gun is utilized for delivering oxygen gas, protective gas and carrier gas-dephosphorization powder into an electric-arc furnace molten pool directly, wherein the carrier gas-dephosphorization powder is dephosphorization powder carried in the carrier gas; gas flow violently impacts and stirs a steelmaking molten pool, so that the dephosphorization powder is in sufficient contact with molten steel directly, and good thermodynamic and dynamic conditions are provided for molten pool dephosphorization reaction, and dephosphorization efficiency of an electric-arc furnace steelmaking process is improved, consumption of slag charge such as a dephosphorization agent is reduced, a dephosphorization rate of a smelting process is increased, the quality of end-point molten steel is improved, and the production cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

Dephosphorizing and steelmaking method of medium-high-phosphorous semisteel by top-blown converter

ActiveCN103060512AEfficient dephosphorizationPrevent rephosphorizationManufacturing convertersAlkalinitySteelmaking

The invention provides a dephosphorizing and steelmaking method of medium-high-phosphorous semisteel by a top-blown converter. The method comprises the following steps of: adding remained slag, splashed slag and a slag forming agent in semisteel containing 0.25-0.80% of phosphorous to prepare 2.8-4.0 high-alkalinity furnace slag in the top-blown converter; carrying out appropriate lance height control and temperature control by adopting the top-blown oxygen supply intensity of 2.90-3.30m<3> per ton of the steel per minute, wherein the content of the phosphorous in the steel when replacing the steel is less than or equal to 0.12%, controlling the C / P is more than or equal to 10, the early dephosphorization rate is more than or equal to 80% and optimally 95%; and adding a semisteel slag forming agent and active lime after replacing the slag, slagging and melting again so as to reduce the content of the phosphorous from <=0.12% to a range required by conventional steel grade and guarantee the product quality. The method provided by the invention has the advantages that an original device does not need reformation, the dephosphorization rate is high, the influence on the melting period and the productivity of the converter is little, the application of large reserves of low-cost high-phosphorous ores can be expanded by iron making, and the production cost is reduced.

Owner:WUKUN STEEL +1

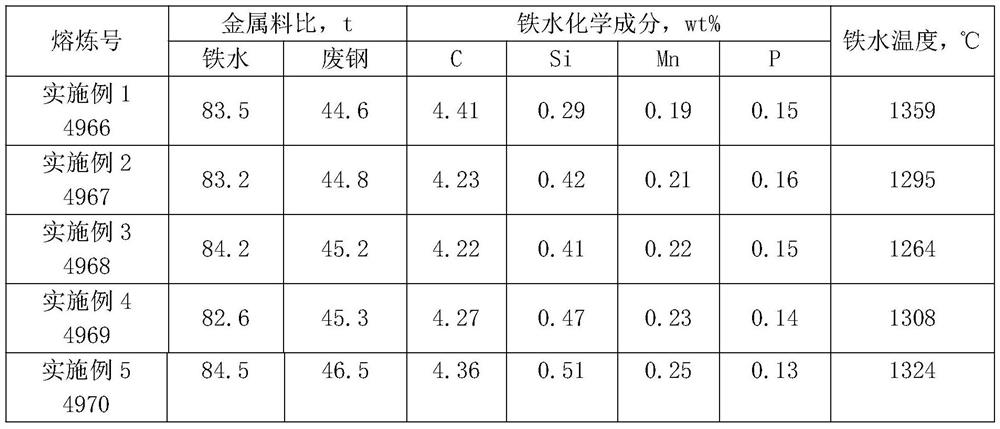

Method for smelting medium-high alloy low-phosphorous steel through electric furnace with high molten iron proportion

ActiveCN106544467AReduce steelmaking costsEfficient dephosphorizationProcess efficiency improvementElectric furnaceScrapElectric furnaces

The invention discloses a method for smelting medium-high alloy low-phosphorous steel through an electric furnace with a high molten iron proportion. Through strictly control over oxygen blowing, power transmission and feeding processes during smelting of the electric furnace, the purposes of efficient smelting, energy saving and consumption reducing are achieved. The method includes the detailed steps that the proportion of molten iron entering the furnace is controlled to be 60-80%, steel scraps are added into the furnace at a time through a basket, the molten iron enters from a door of the furnace through a molten iron adding trolley during power transmission, the flow of a multifunctional bundling oxygen lance is reasonably adjusted, power supply time is dynamically controlled, lime is supplemented into the furnace in batches in combination with an automatic feeding system, and therefore molten steel rapidly meets the requirements for components and temperature needed by a steel grade. Compared with a common electric furnace technology, the time consumed for adding the molten iron is shortened, and the smelting efficiency of the electric furnace is improved; the power supply time of the electric furnace is quite short, and therefore the energy consumption of steel smelting is lowered; during smelting of the electric furnace, efficient dephosphorizing and decarbonizing are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Dephosphorization method for molten iron in converter by blowing dust removal ash

The invention relates to a dephosphorization method for molten iron in a converter by blowing dust removal ash and belongs to the technical field of steelmaking. According to the dephosphorization process for dephosphorizing molten iron in the converter by blowing lime powder and dust removal ash through a dephosphorization oxygen lance, the device used in the dephosphorization process comprises an oxygen supply system and a powder blowing system; during the method, the oxygen supply system and the powder blowing system are adopted, the lime powder and dust removal ash are blown into a molten tank through the top-blowing dephosphorization oxygen lance, since the dust removal ash contains relatively high content of iron oxides, the content of ferric oxide in slag can be rapidly increased so as to promote the dissolution of lime and rapidly form slag having relatively high dephosphorization capability, the dephosphorization reaction is accelerated and meanwhile, the efficient utilization of the dust removal ash is achieved, the environmental secondary pollution due to the wastes is avoided and the dephosphorization method has relatively high economic and social benefits.

Owner:BEIJING SHOUGANG INT ENG TECH

Method for producing low phosphorus steel or extra-low phosphorus steel by using limestone slagging-single slagging method

ActiveCN107574281AEasy to masterImprove smelting performanceManufacturing convertersProcess efficiency improvementSteelmakingAlkalinity

The invention provides a method for producing low phosphorus steel or extra-low phosphorus steel by using a limestone slagging-single slagging method, and belongs to the technical field of steelmaking. The method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging comprises the steps that when slagging is conducted by using limestone, the oxygen consumption range of ton steel is controlled in 40-65 cubic meters, and the total adding amount of ton steel, the limestone and dolomite is 40-100 kg; the dolomite is about 1 / 4-1 / 5, accordingto converter capacity, the oxygen supplying intensity is controlled at 2-5 cubic meter / cent.ton steel, the alkalinity of final slag is controlled at 3. 0-6. 0, and the oxygen lance position is controlled within about 50% range of the decarbonization gun position; the furnace atmosphere is adjusted, the molten slag temperature is controlled between 1450-1630 DEG C, the adding batch of the limestone is controlled at 2-20 times, the eight of each batch of limestone is 30-0.5 kg / ton steel, and molten iron can be efficiently dephosphorized; and the single slagging method can produce low phosphorussteel or extra-low phosphorus steel. According to the method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging, the goal of dephosphorization can be achieved by easy operating, resources and energy can also be reduced, and workers easily master the method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method and application of eutrophic lake sediment phosphorous adsorbent

PendingCN108393063ALow costEfficient dephosphorizationOther chemical processesWater contaminantsWater bathsClay minerals

The invention discloses a preparation method and application of a eutrophic lake sediment phosphorous adsorbent. The preparation method comprises the following steps: 1) immersing clay minerals into ahydrochloric acid solution and heating and stirring in a water bath; controlling the temperature in a certain range and washing until the solution is neutral; 2) immersing into a sodium carbonate solution; heating and stirring in the water bath; controlling the temperature in a certain range and washing with distilled water until the solution is neutral; drying for a certain time in a certain drying range; 3) roasting in a muffle furnace for a certain time under the condition that the temperature is 350 to 450 DEG C; cooling to room temperature to obtain the eutrophic lake sediment phosphorous adsorbent. The invention also provides application of the adsorbent in lake endogenous phosphorous controlled ecological rehabilitation engineering. The adsorbent disclosed by the invention is low in cost, environmentally friendly and good in adsorbent effect, and contains various macro-elements and microelements which are beneficial to the growth and development of organisms; the adsorbent is good for field planting and propagation of water plants and stabilization of a water environment; efficient phosphorous removal of eutrophic lake sediment can be realized, and the endogenous phosphorous pollution problem of a eutrophic lake is effectively controlled.

Owner:INST OF AQUATIC LIFE ACAD SINICA

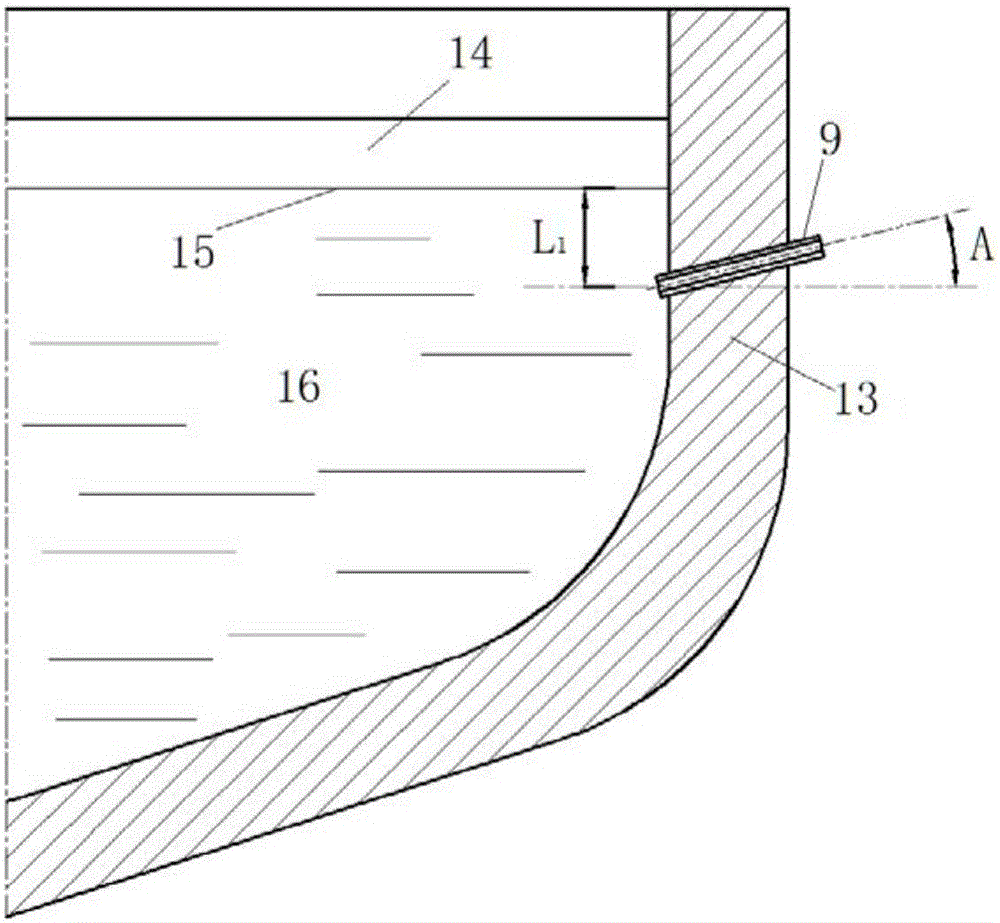

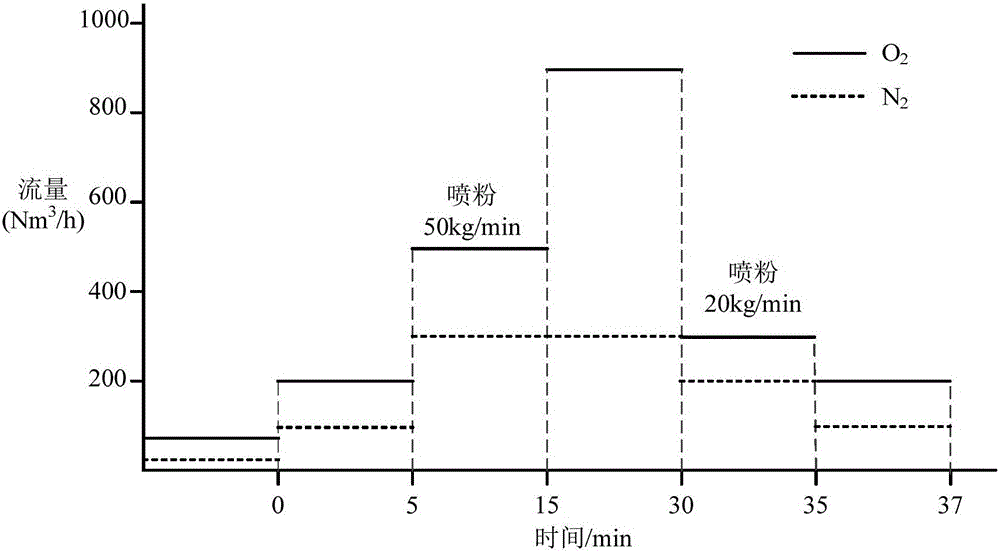

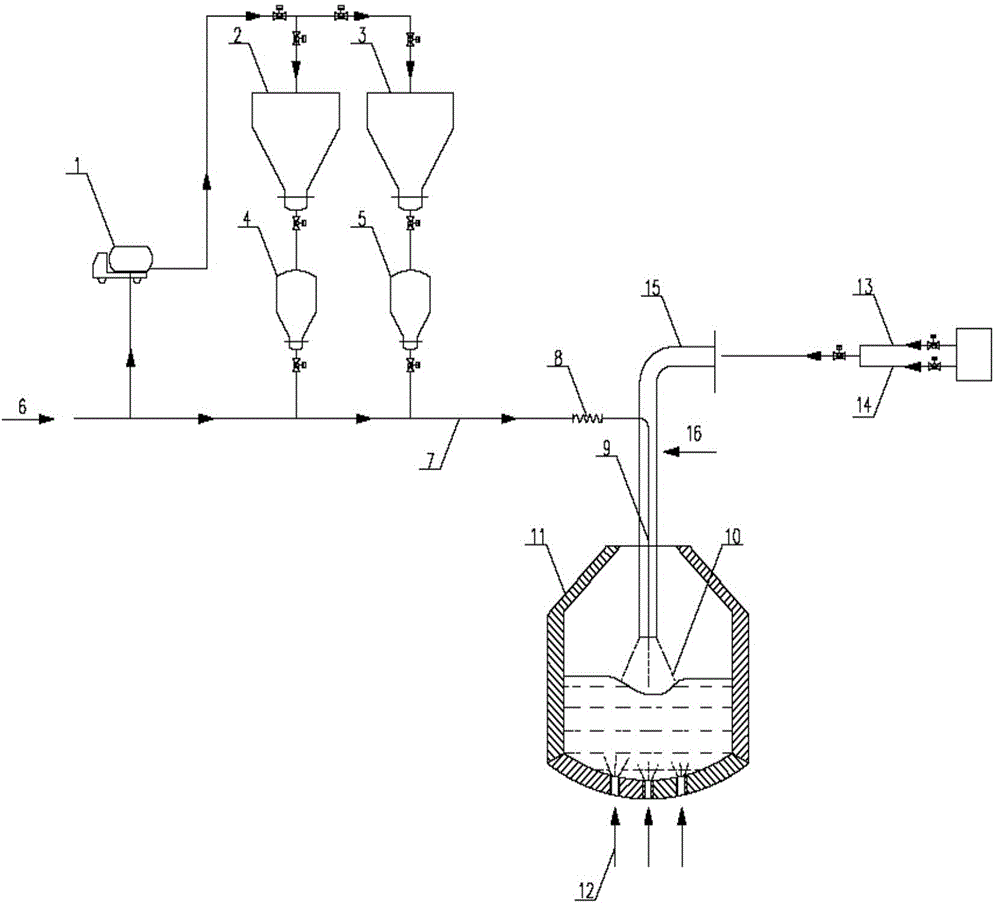

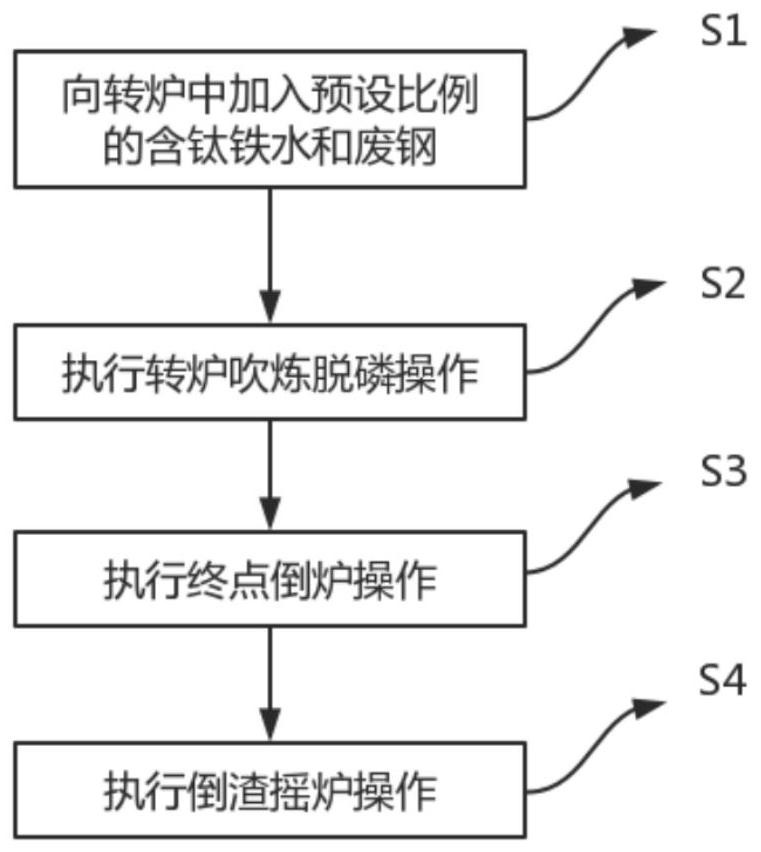

Titanium-containing molten iron converter high-scrap-ratio rapid heating production method

ActiveCN112708716AEfficient dephosphorizationMeet Phosphorus and Temperature RequirementsManufacturing convertersProcess efficiency improvementSlagTitanium

The invention discloses a titanium-containing molten iron converter high-scrap-ratio rapid heating production method. The method comprises the following steps that titanium-containing molten iron and scrap steel in a preset proportion are added into a converter; converter blowing dephosphorization operation is executed; an end-point furnace turning-down operation is executed; and slag pouring and furnace shaking operation is executed. According to the titanium-containing molten iron converter high-scrap-ratio rapid heating production method, efficient dephosphorization of the converter under the same molten iron condition at the scrap steel ratio of 20% or above is achieved, the one-time converter turning-down temperature of the converter is increased by 30-50 DEG C compared with conventional smelting operation, the requirements of the steel grade end point for phosphorus and temperature are met, and the smelting period is shortened by 1-2 minutes.

Owner:SHOUGANG CORPORATION

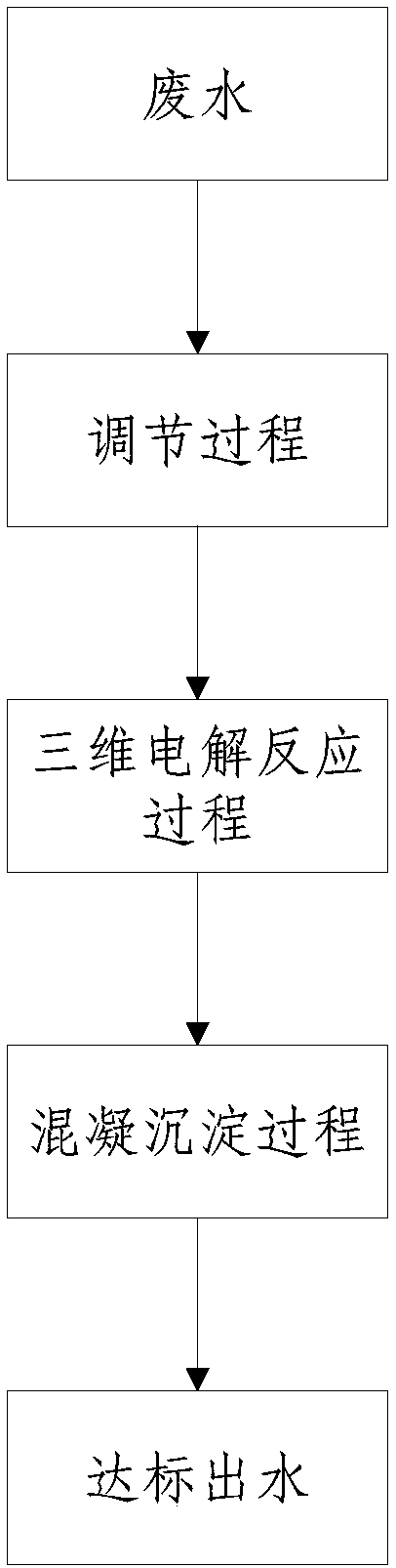

Device and method for removing phosphite in waste water

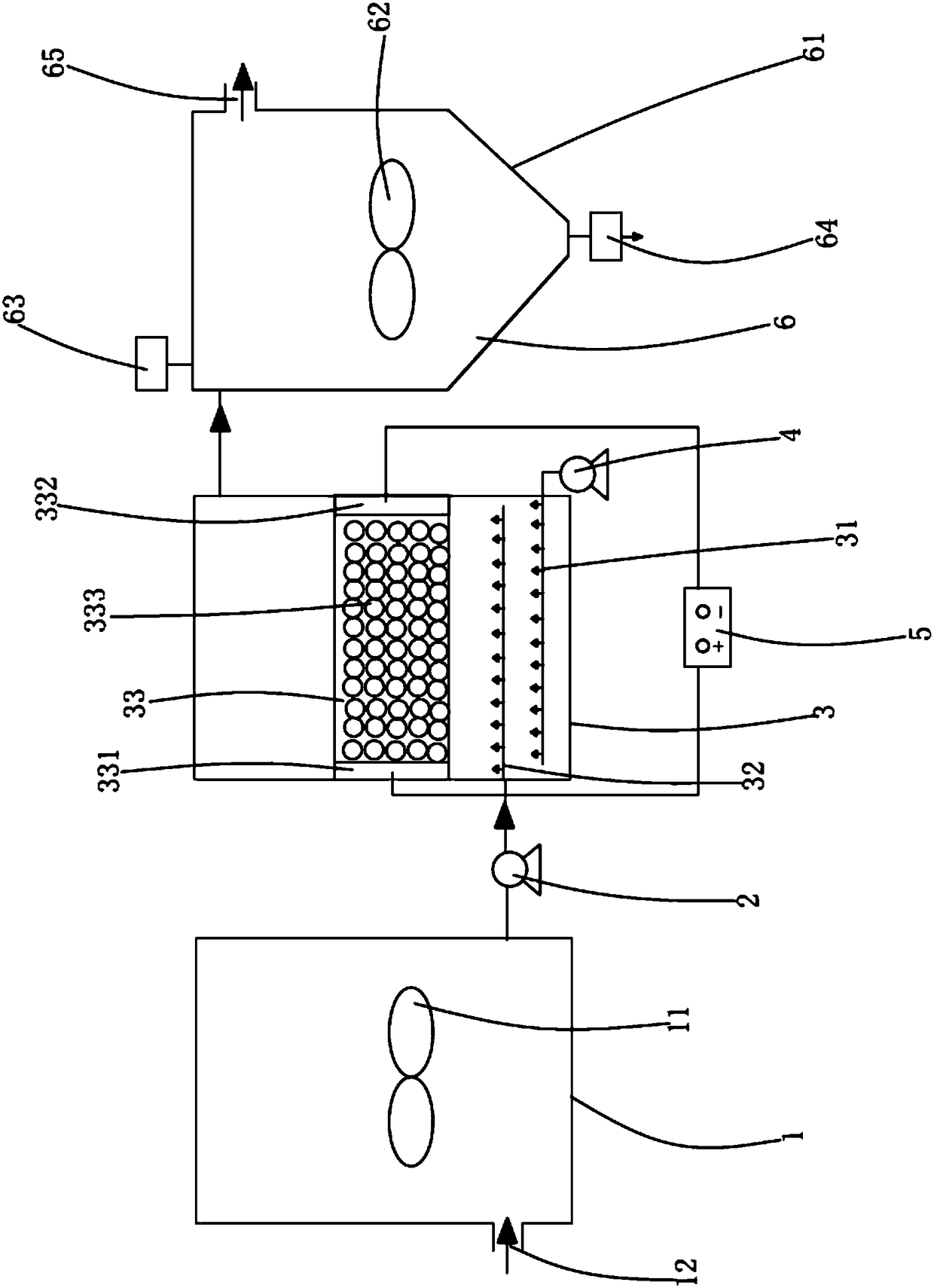

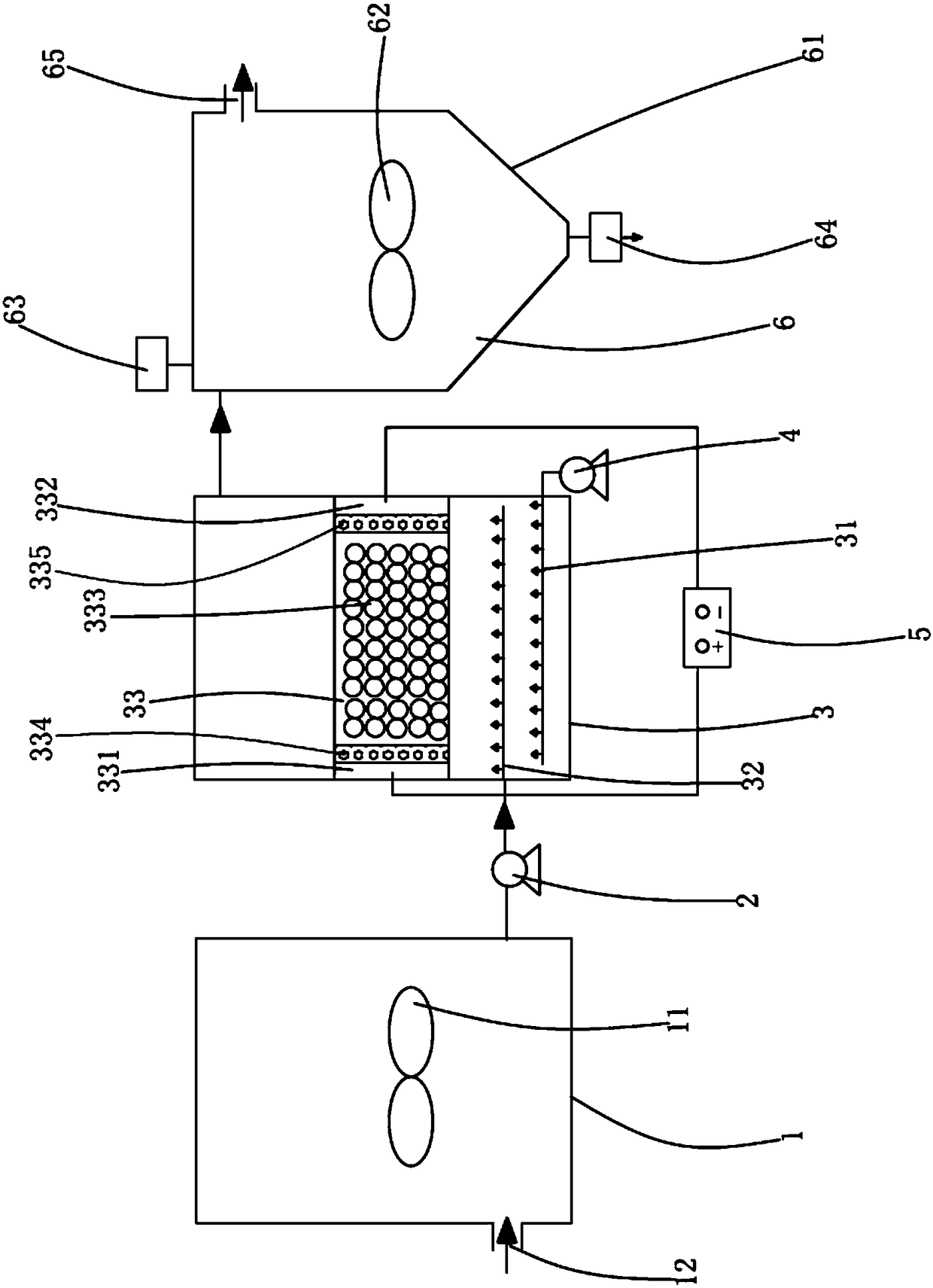

PendingCN108249644AEasy to operateReduce stepsWater contaminantsMultistage water/sewage treatmentSuspended particlesElectrolysis

The invention belongs to the field of waste water treatment, and relates to a device and method for removing phosphite in waste water. The removal device comprises a regulating pool, a three-dimensional electrolytic reaction pool and a coagulative precipitation pool which are sequentially connected through a pipeline. The removal device removes the phosphite in the waste water mainly through the effect of the three-dimensional electrolytic reaction pool. The waste water enters the three-dimensional electrolytic reaction pool after being regulated through the regulating pool, and is subjected to a three-dimensional electrolytic reaction in the three-dimensional electrolytic reaction pool, and sediment is generated finally in the three-dimensional electrolytic reaction process; and purifiedwater is obtained by removing colloidal impurities and suspended particles in the waste water through the coagulative precipitation pool, and thus the phosphorus content in the waste water can reach the drainage standard regulated by the nation. Furthermore, the removal device is simple, easy to accurately operate, small in floor space and low in maintenance cost, and the removal rate of the phosphite in the waste water is high. The device for removing the phosphite in the waste water is high in operation stability, and can effectively dispose the phosphite in the waste water with different water quality.

Owner:深圳瑞赛环保科技有限公司

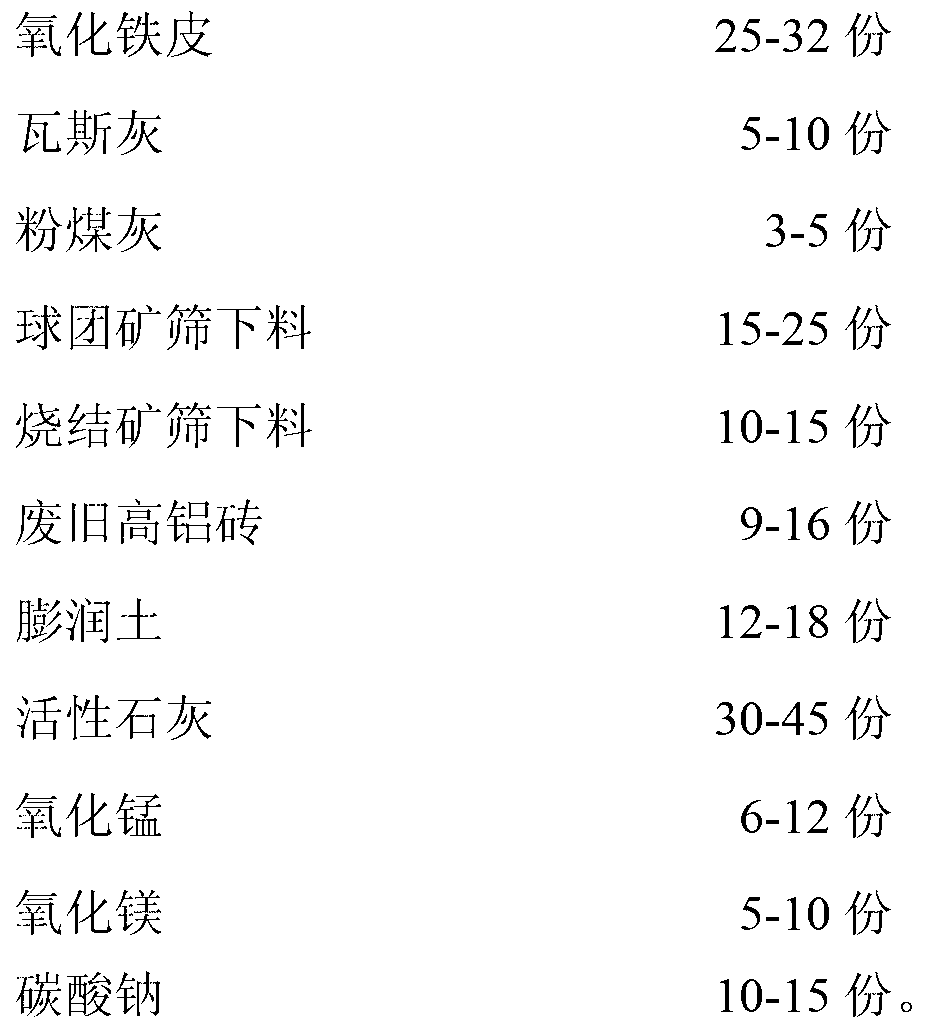

Freon-free slagging agent for rotating furnace

The invention discloses a freon-free slagging agent for a rotating furnace, mainly comprising the following materials in parts by weight: 5-30 parts of manganese (Mn), 0-20 parts of silicon dioxide (SiO2) and 10-50 parts of total iron (TFe). The freon-free slagging agent is prepared into 5-50mm particles and the adding amount thereof is determined according to the silicon content in molten iron and is controlled to be within 5-7kg / t steel. The freon-free slagging agent has the advantages of prolonging the service life of a rotating furnace body, reducing the wastage rate of fettling material, accelerating the joint concentration of steelmaking of the rotating furnace, and reducing the time of daily maintenance and overhauling. Under the condition that the materials and the status of equipment are not changed, after the rotating furnace is added with the freon-free slagging agent, the technical indexes are all improved with different degrees, also the blowing is stable, the slagging is good, the phenomenon that the slag is re-dried is avoided, the operating conditions of steelmaking of the rotating furnace are improved, certain main consumption indexes of the rotating furnace take on downward trend, and the effects of dephosphorization and desulfurization are superior to that of other slagging agents.

Owner:郑州市鑫磊冶金材料有限公司

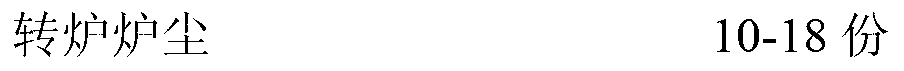

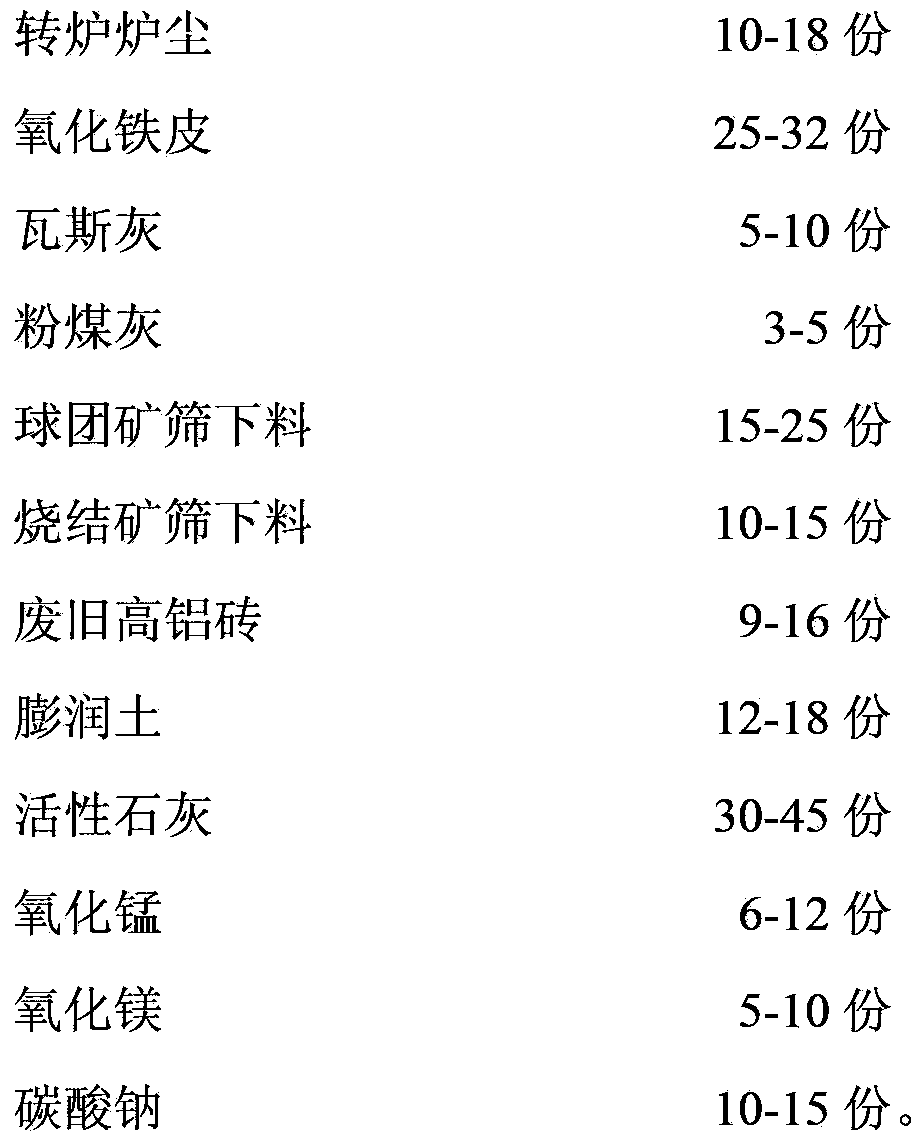

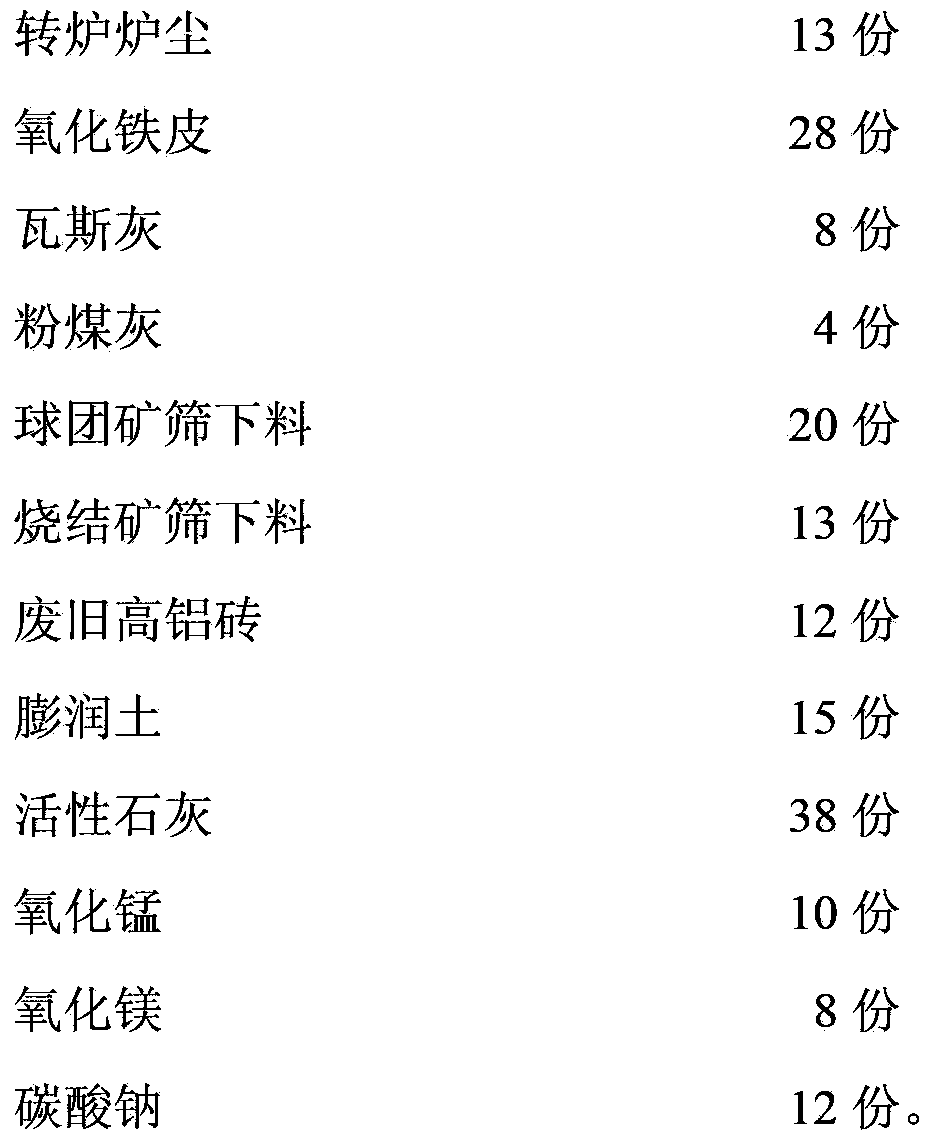

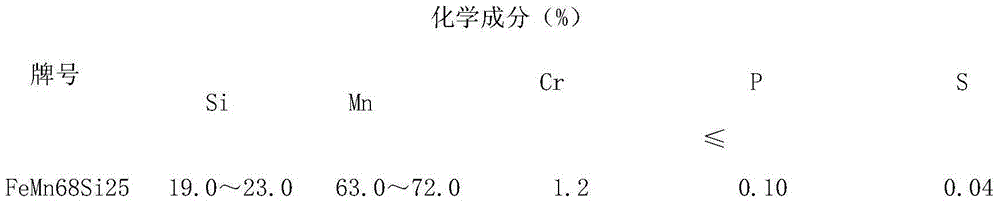

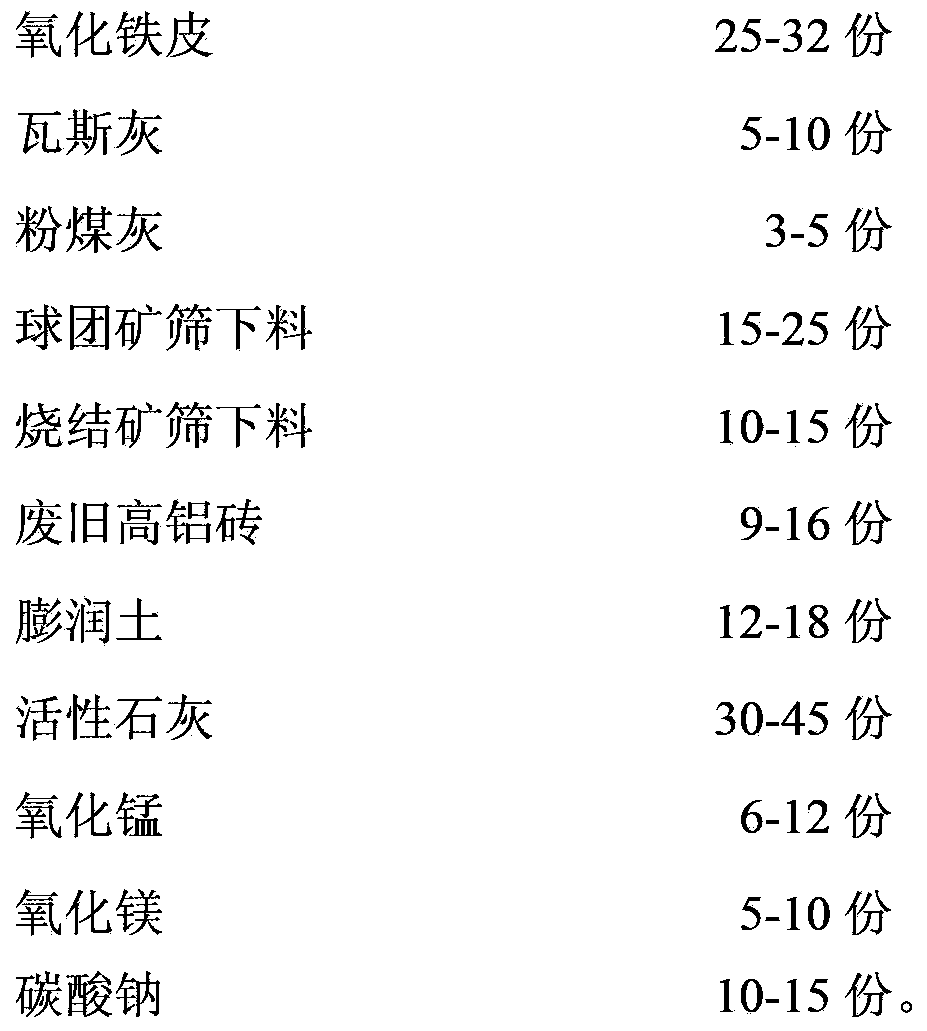

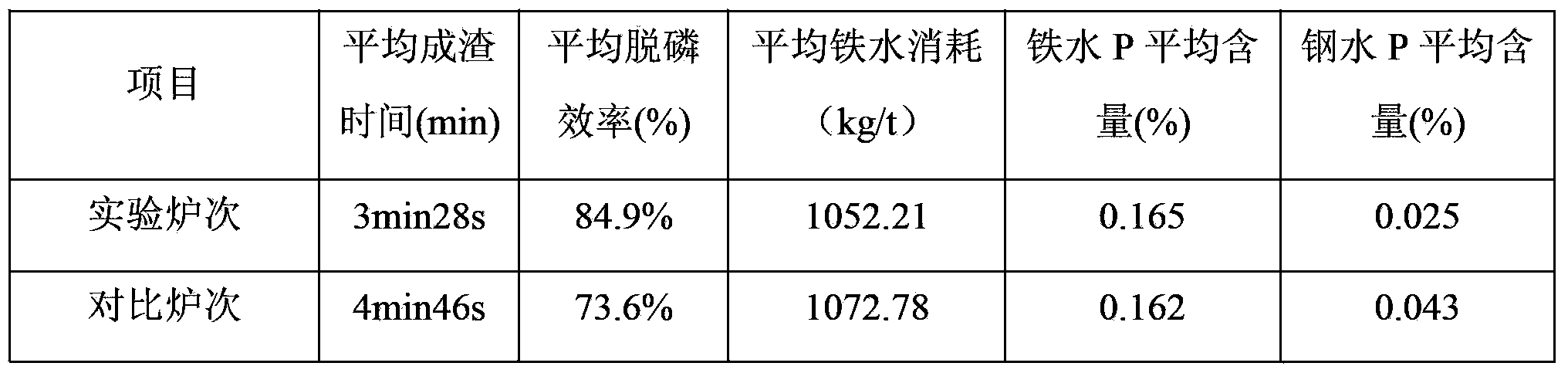

Preparation method of converter steelmaking synthetic slag former

ActiveCN103343180AReduce manufacturing costAvoid secondary processingManufacturing convertersSteelmakingBrick

The invention discloses a preparation method of a converter steelmaking synthetic slag former, belonging to the technical field of converter steelmaking of ferrous metallurgy. The method comprises the following steps of: uniformly mixing 10-18 parts of converter dust, 25-32 parts of scale, 5-10 parts of gas ash, 9-16 parts of waste high-alumina brick and bentonite to obtain a mixture B; adding 30-45 parts of active lime, 6-12 parts of active lime, 5-10 parts of magnesium oxide and bentonite into the mixture B to obtain a mixture C; mixing 10-15 parts of sodium carbonate with the mixture A and the mixture C, and pre-melting at 1,300-1,450 DEG C to obtain a mixture D; and cooling and crushing to obtain the synthetic slag former. According to the synthetic slag former, the metallurgic waste difficult to use is used as a component of the slag former, the prepared slag former has high dephosphorization efficiency, and the slag forming time is short.

Owner:MAANSHAN RUNTONG HEAVY IND TECH CO LTD

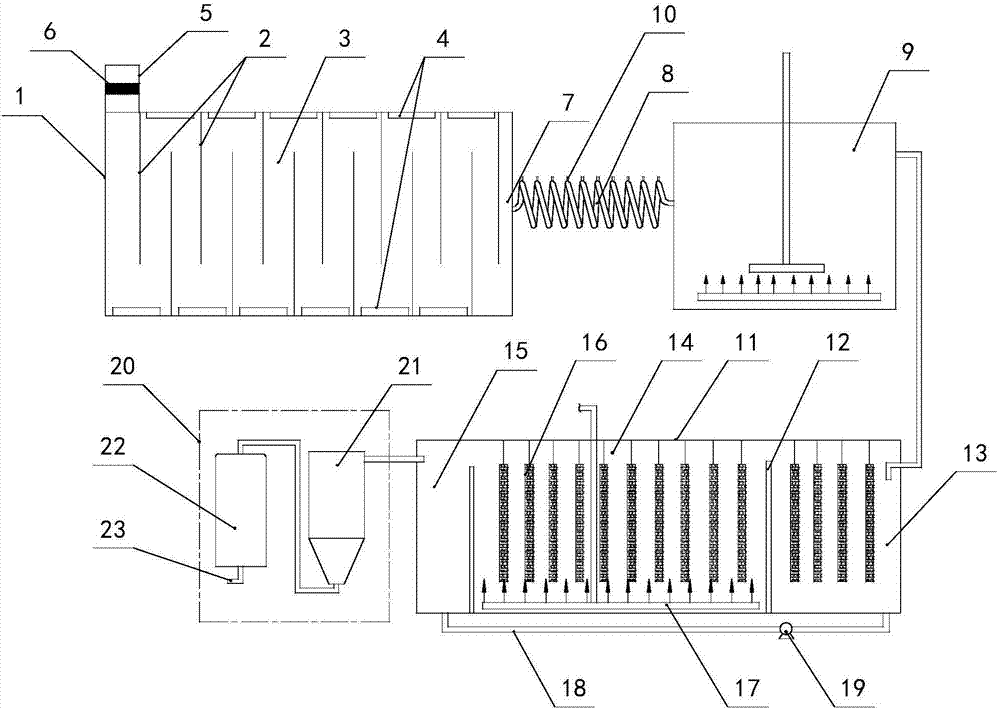

Device used for processing biological pharmacy waste water via ultrasonic inactivation

InactiveCN107043198ASimple structureEasy to useWater/sewage treatment with mechanical oscillationsWater contaminantsCavitationThermal effect

The invention discloses a biopharmaceutical wastewater treatment device adopting ultrasonic inactivation, which includes a sump pool, a regulating pool, a biological contact oxidation pool and a filter. In the sump pool, an S-shaped waste water channel is arranged through a partition, and in the pool The upstream of the waste water channel in the pool is provided with an inlet for collecting waste water and a grille is installed, an overflow outlet is set in the downstream of the waste water channel in the sump and is connected to a regulating pool through a pipeline, and the layout of intervals in the waste water channel is arranged in the sump There are plate ultrasonic generators. The biopharmaceutical wastewater treatment device using ultrasonic inactivation of the present invention can effectively kill microorganisms in the wastewater by utilizing the mechanical effect, thermal effect and cavitation effect generated by ultrasonic waves in the water body, and degrade organic substances such as halogenated hydrocarbons and aromatic hydrocarbons in the water. And effectively inactivate the virus in the wastewater.

Owner:CHENGDU YANXINGGUO TECH CO LTD

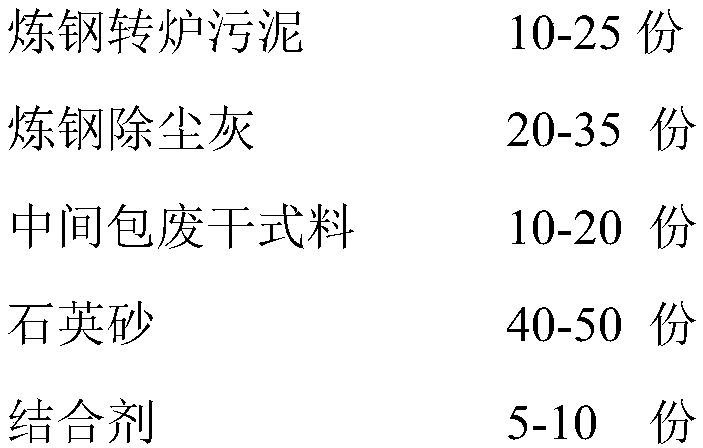

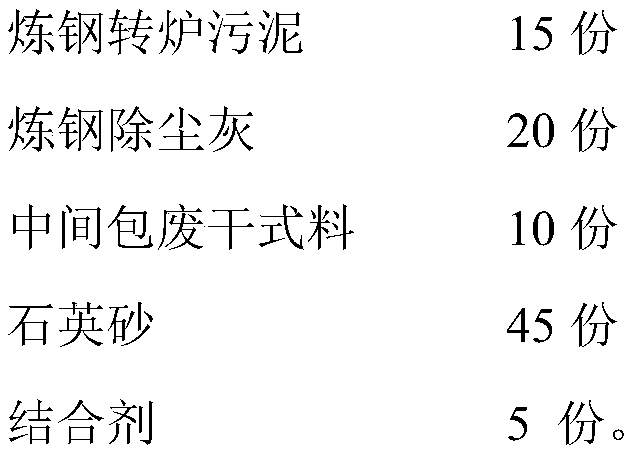

Environment-friendly converter steel-making slagging agent and preparation method thereof

InactiveCN109321705ASolve the pollution problemAchieve recyclingManufacturing convertersProcess efficiency improvementEnvironmental resistanceSocial benefits

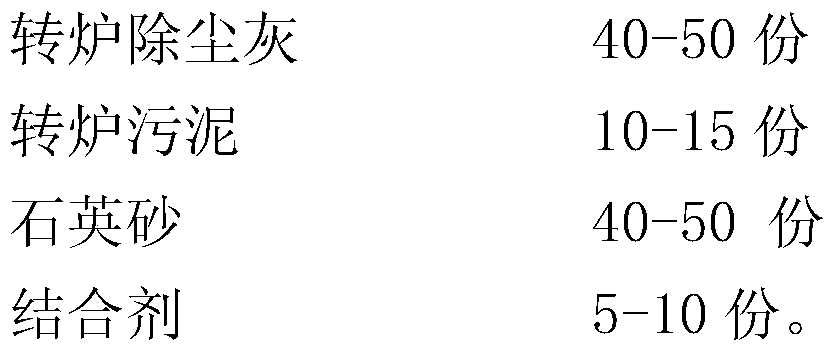

The invention relates to an environment-friendly converter steel-making slagging agent and a preparation method thereof, and belongs to the technical field of steel metallurgy converter steel-making.The technical problem that waste comprehensive utilization is difficult in the metallurgical process is solved. The environment-friendly converter steel-making slagging agent is mainly composed of 10-25 parts of steel-making converter sludge, 20-35 parts of steel-making dedust ash, 10-20 parts of tundish waste dry-type material, 40-50 parts of quartz sands and 5-10 parts of binding agents; and themethod comprises the following steps that, firstly, the dedust ash is subjected to the homogenizing treatment, then is uniformly mixed with other raw materials according to the formula, and the pellet slagging agent is prepared by adopting a ball-pressing pelletizing, drying and cooling technology. According to the preparation method, waste resource internal cyclic utilization is realized, and the method has obvious environmental protection and social benefits, the production cost of the steel-making slagging agent product is reduced, and great economic benefits are achieved.

Owner:PANZHIHUA GANGCHENG GROUP

Method for producing calcium ferrite from iron oxide

The invention discloses a method for producing calcium ferrite from iron oxide. The method utilizes an iron electrode to realize electric smelting, utilizes the iron electrode to produce calcium ferrite, prevents an additional component from entering into calcium ferrite, improves calcium ferrite purity and realizes better calcium ferrite actual use effects. In steel-making, through use of the calcium ferrite obtained by the method, a slagging rate is fast, dephosphorization efficiency is high, a lime use amount is reduced, fluorine-free steel-making is realized and environmental pollution is reduced.

Owner:ZHENGZHOU WHALE SPECIAL MATERIALS

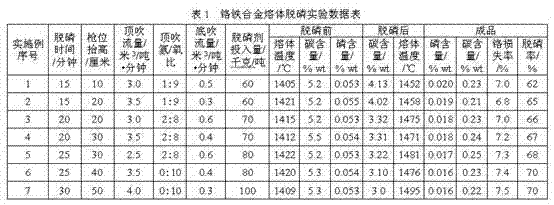

Method for argon-oxygen refining low-phosphorus ferrochrome

The invention relates to a method for argon-oxygen refining low-phosphorus ferrochrome. The method is characterized by comprising specific steps of: first high-temperature carbon decrease, to be specific, decreasing the carbon rapidly at a relatively high temperature until carbon content needed for dephosphorization is obtained, enabling the chromium loss to be minimum, cooling a melt and replacing the slag for the dephosphorization; and second high-temperature carbon decrease, to be specific, enabling the high-carbon ferrochrome melt to suffer from stepped refining at different temperatures in an argon-oxygen refining furnace based on experimental results beneficial for carbon decrease, chromium keeping and further dephosphorization, that is to say, firstly heating the high-carbon ferrochrome with a carbon content of 7.0-8.0%wt to 1750-1850 DEG C for high-temperature oxidation carbon decrease, cooling the melt to the temperature of 1400-1550 DEG C which is good for the dephosphorization when the carbon in the melt is decreased to a content upper limit of 5.0-5.5%wt which is good for the dephosphorization, then performing dephosphorization within a dephosphorization content range of 3.0-5.5%wt which is good for the dephosphorization, and then heating the melt after the dephosphorization to 1750-1850 DEG C to continue the high-temperature oxidation carbon decrease until the low-carbon ferrochrome is obtained.

Owner:CHANGCHUN UNIV OF TECH

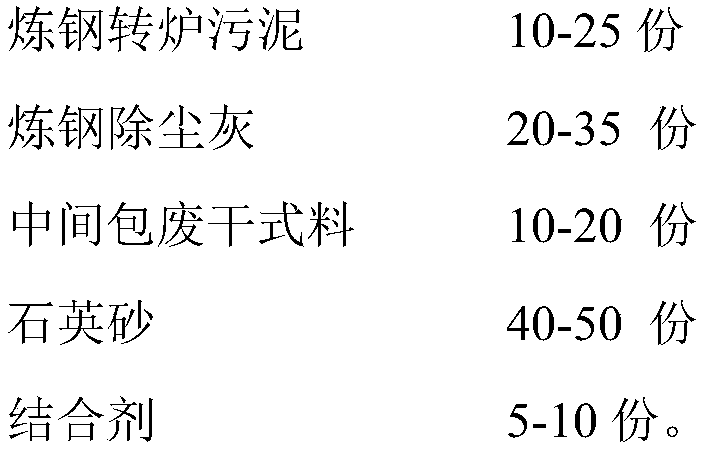

Comprehensive utilization method of converter dust removal ash

InactiveCN110951934ASolve the pollution problemAchieve recyclingManufacturing convertersProcess efficiency improvementSteelmakingDigestion Treatment

The invention discloses a comprehensive utilization method of converter dust removal ash, relates to the technical field of environmental protection, and provides the comprehensive utilization methodof the converter dust removal ash. The comprehensive utilization method of the converter dust removal ash comprises the following steps that A, digestion treatment is carried out on the converter dustremoval ash in a spray water mode; and B, the digested converter dust removal ash is uniformly mixed with other ingredients according to a formula, and a balling environment-friendly converter steelmaking slagging agent is prepared by using a compression ball granulation, drying and cooling process, wherein the converter steelmaking slagging agent raw material comprises the following components of, in part by mass, 40-50 parts of converter dust removal ash, 10-15 parts of furnace sludge, 40-50 parts of quartz sand, and 5-10 parts of binder. According to the comprehensive utilization method, waste which is difficult to comprehensively utilized in the converter dust removal ash, converter sludge and the like of an iron and steel plant is taken as an important components for preparing a slagremover, so that the waste can be recycled, the problem of environmental pollution caused by stacking or burying of the materials is solved, and internal recycling of the waste resources is realized.

Owner:PANZHIHUA GANGCHENG GROUP

Method for producing calcium ferrite by iron-electrode electric smelting of iron ore

InactiveCN103964510AFast slag formationIncrease contact surfaceIron compoundsFluorine freeActual use

The invention discloses a method for producing calcium ferrite from iron ore. The method utilizes an iron electrode to realize electric smelting, utilizes the iron electrode to produce calcium ferrite, prevents an additional component from entering into calcium ferrite, improves calcium ferrite purity and realizes better calcium ferrite actual use effects. In steel-making, through use of the calcium ferrite obtained by the method, a slagging rate is fast, dephosphorization efficiency is high, a lime use amount is reduced, fluorine-free steel-making is realized and environmental pollution is reduced.

Owner:ZHENGZHOU WHALE SPECIAL MATERIALS

Method for dephosphorization and desulphurization in process of steel production in induction furnace

The invention provides a method for dephosphorization and desulphurization in the process of steel production in an induction furnace, which is characterized by comprising the following steps of: during the smelting period and the initial period of total meltdown of charging materials, controlling the temperature of molten steel to below 1,450 EDG C, performing dephosphorization treatment on a liquid steel by using a dephosphorizing agent consisting of lime-ferric oxide-boron anhydrous, and controlling the phosphorous content in the liquid steel to below 0.01 percent; after finishing the dephosphorization, absolutely deslagging, then rapidly raising the temperature of the liquid steel to 1, 500 to 1, 600 DEG C; and performing pre-deoxidation and alloying on the liquid steel, and then adding the desulphurizing agent consisting of lime-calcium carbide-aluminum ash, performing the desulphuration on the liquid steel, and reducing the phosphorous content in the liquid steel to below 0.08 percent. The method has the advantages of combining the smelting characteristics of the induction furnace, fully utilizing favorable thermodynamic conditions of dephosphorization and desulphurization, realizing high-efficiency dephosphorization and desulphurization by slagging and greatly improving the quality of the liquid steel; and meanwhile, the method also has the advantages of low cost, less equipment investment, simple operation, easy implementation, and obvious economic benefits and social benefits.

Owner:JIANGSU UNIV

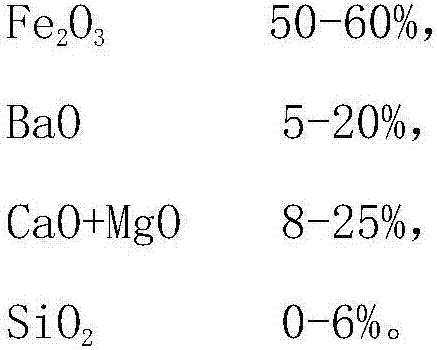

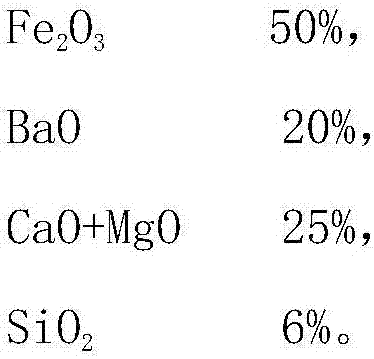

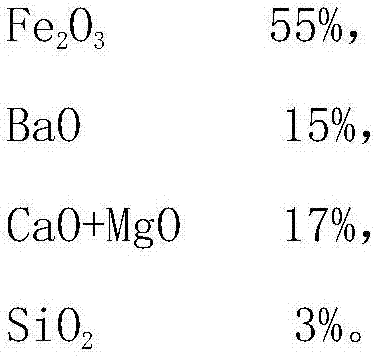

Efficient dephosphorization accelerant for converter steelmaking and preparing method thereof

InactiveCN107130085ADephosphorization effect is stableStrong thermodynamic stabilitySteelmakingResource utilization

The invention relates to a high-efficiency dephosphorization accelerator suitable for converter steelmaking and its preparation method. The innovation point is that the converter steelmaking dedusting ash is used as the base material, and its high iron oxide components and active calcium oxide components are effectively used. Recycling and recycling of waste resources in steel mills, while introducing active BaO materials, the barium phosphate formed by BaO has stronger thermodynamic stability than calcium phosphate, forming a high oxidizing, high An alkaline dephosphorization accelerator with a low melting point can realize the purpose of supplementing FeO in the converter steelmaking process and forming a stable dephosphorization product, so as to enhance the dephosphorization efficiency and finally achieve high-efficiency dephosphorization. This method can save more than 30% of the cost and dephosphorization The efficiency is about 5‑10% higher than that of traditional dephosphorization agents. At the same time, the product of the present invention effectively protects the environment, saves energy, realizes the high-efficiency utilization of resources in "turning waste into treasure" of solid waste in steelworks, obtains better economic and social benefits, and is suitable for popularization and use.

Owner:天津瑞利鑫环保科技有限公司

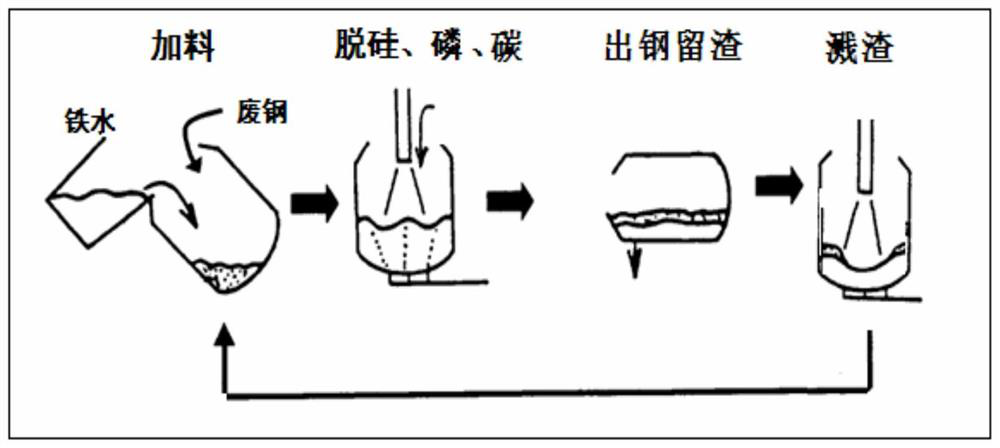

Single-converter low-iron-consumption duplex less-slag smelting method

PendingCN112779378AReduce the amount addedReduce consumptionManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses a single-converter low-iron-consumption duplex less-slag smelting method, and belongs to the technical field of smelting and continuous casting. The method comprises the following steps that S1, a metal main material is put into a converter, and converter smelting is adopted; S2, the slag obtained after the decarbonization period serves as a slagging material, blowing desiliconization and dephosphorization are carried out in the converter, and slag charge is obtained; S3, deslagging is conducted, the deslagging amount is controlled to be 50%-70%, and semi-steel molten steel is obtained; S4, metallurgical limes and light-burned dolomite are added into the semi-steel molten steel for decarburization, the blowing end point of the converter is detected, when w[C] in the molten steel at the blowing end point is 0.06-0.10%, the temperature of the molten steel is 1620-1640 DEG C, the binary alkalinity is 2.5-3.0, and tapping is conducted immediately after the blowing is finished; S5, slag splashing converter protection is carried out after tapping, and the left slag is used as the slagging material for the blowing desiliconization and dephosphorization of the next converter. According to the method, the dephosphorization rate in the converter desilicication and dephosphorization periods is greatly increased, w[P] in chemical components of the converter end point molten steel is smaller than or equal to 0.030%, the dephosphorization pressure in the converter decarbonization period is greatly reduced, less-slag smelting of the molten steel is achieved, and the molten steel quality is good.

Owner:YANGCHUN NEW STEEL CO LTD +1

A kind of electric arc furnace steelmaking dephosphorization method

ActiveCN105803155BImprove product qualityFully functional abilityProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention provides a dephosphorization method for electric-arc furnace steelmaking, and belongs to the field of electric-arc furnace steelmaking. The dephosphorization method is characterized in that the same spray gun is utilized for delivering oxygen gas, protective gas and carrier gas-dephosphorization powder into an electric-arc furnace molten pool directly, wherein the carrier gas-dephosphorization powder is dephosphorization powder carried in the carrier gas; gas flow violently impacts and stirs a steelmaking molten pool, so that the dephosphorization powder is in sufficient contact with molten steel directly, and good thermodynamic and dynamic conditions are provided for molten pool dephosphorization reaction, and dephosphorization efficiency of an electric-arc furnace steelmaking process is improved, consumption of slag charge such as a dephosphorization agent is reduced, a dephosphorization rate of a smelting process is increased, the quality of end-point molten steel is improved, and the production cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

Method for reducing smelting cost of Q460C-2 low alloy steel

The embodiment of the invention provides a method for reducing the smelting cost of Q460C-2 low-alloy steel. The method comprises the steps that final slag obtained after slag splashing treatment in a furnace is completely left in the furnace for smelting of the furnace, and 30-35 tons of waste steel and 170-180 tons of molten iron are added into the furnace for smelting, wherein the target of the final slag is that the alkalinity is 3.0-3.5, the TFe content is 18-25%, and the MgO content is 7-9%. Through the two aspects of early-stage dephosphorization and later-stage dephosphorization, the purpose of efficient dephosphorization is achieved through early-stage low temperature and large slag amount and later-stage high oxidability, high alkalinity and large slag amount, and a guarantee is provided for further replacing metal manganese with silicon-manganese alloy and further reducing the smelting cost.

Owner:TANGSHAN YANSHAN IRON & STEEL CO LTD

Converter steelmaking synthetic slag former

ActiveCN103343179BReduce manufacturing costAvoid secondary processingManufacturing convertersProcess efficiency improvementSteelmakingSodium Bentonite

Owner:湛江申翰科技实业有限公司

Dephosphorizing and steelmaking method of medium-high-phosphorous semisteel by top-blown converter

ActiveCN103060512BEfficient dephosphorizationPrevent rephosphorizationManufacturing convertersAlkalinitySteelmaking

The invention provides a dephosphorizing and steelmaking method of medium-high-phosphorous semisteel by a top-blown converter. The method comprises the following steps of: adding remained slag, splashed slag and a slag forming agent in semisteel containing 0.25-0.80% of phosphorous to prepare 2.8-4.0 high-alkalinity furnace slag in the top-blown converter; carrying out appropriate lance height control and temperature control by adopting the top-blown oxygen supply intensity of 2.90-3.30m<3> per ton of the steel per minute, wherein the content of the phosphorous in the steel when replacing the steel is less than or equal to 0.12%, controlling the C / P is more than or equal to 10, the early dephosphorization rate is more than or equal to 80% and optimally 95%; and adding a semisteel slag forming agent and active lime after replacing the slag, slagging and melting again so as to reduce the content of the phosphorous from <=0.12% to a range required by conventional steel grade and guarantee the product quality. The method provided by the invention has the advantages that an original device does not need reformation, the dephosphorization rate is high, the influence on the melting period and the productivity of the converter is little, the application of large reserves of low-cost high-phosphorous ores can be expanded by iron making, and the production cost is reduced.

Owner:WUKUN STEEL +1

A high-efficiency smelting process for producing low-phosphorus clean steel by converter

ActiveCN109897933BEfficient separationReduce lossManufacturing convertersProcess efficiency improvementSmelting processProcess engineering

The invention discloses a high-efficiency smelting process for producing low-phosphorus clean steel by a converter. After the slag of the previous furnace is splashed, all or part of the final slag is left in the furnace, and raw materials are added for smelting. Blowing stage: control the position and flow rate of the oxygen lance, start to add iron oxide balls and return ore after the lance is fired, then add lime and lightly burned dolomite, and gradually hoist the lance position after adding all of them, and dump the slag; the second time Control the position and flow rate of the oxygen lance, start to add lime after ignition, adjust the slag material in time, control the position of the oxygen lance and the amount of oxygen supply, finally turn down the furnace, lift the lance, and finally leave all the slag in the converter for slag solidification Phosphorus fixation is used for the smelting of the next heat. The invention adjusts the slag in time when smelting low-phosphorus clean steel by adding the converter, controls the position of the oxygen lance and the amount of oxygen supply, and the tapping condition at the end can meet C≥0.12 at the same time. %, P≤0.006% high cleanliness low phosphorus steel converter terminal control conditions.

Owner:ZENITH STEEL GROUP CORP CO LTD

A converter slag-less smelting method

ActiveCN111719032BSuitable for industrial productionGood effectManufacturing convertersProcess efficiency improvementSlagMaterials science

The invention relates to the field of smelting, in particular to a converter slag-less smelting method. During smelting, the double slag operation is combined with slag retention. The process flow is: slag splashing to protect the furnace → slag solidification → confirmation of slag solidification → adding scrap steel → adding iron → slag making in converter smelting → releasing dephosphorization slag in the early stage → blowing the gun again Smelting decarburization → tapping and slag retention; taking advantage of the low temperature in the early stage, which is beneficial to the thermodynamic conditions of dephosphorization reaction, the final slag from the upper furnace is used in the initial stage of blowing in the lower furnace for dephosphorization, and when the temperature rises to a temperature that is unfavorable for dephosphorization Before, part of the slag was poured out, and then slag was added to make slag, and the second stage of blowing was carried out to further dephosphorize; the high-efficiency dephosphorization technology of the converter with low gun position and large oxygen supply was adopted, and the slag was poured out in sufficient amount after dephosphorization. The invention achieves obvious effects through the application of "double slag-retaining slag" and "retaining slag" technology, the ash consumption of the converter is greatly reduced, and the amount of slag is reduced to some extent.

Owner:BENGANG STEEL PLATES

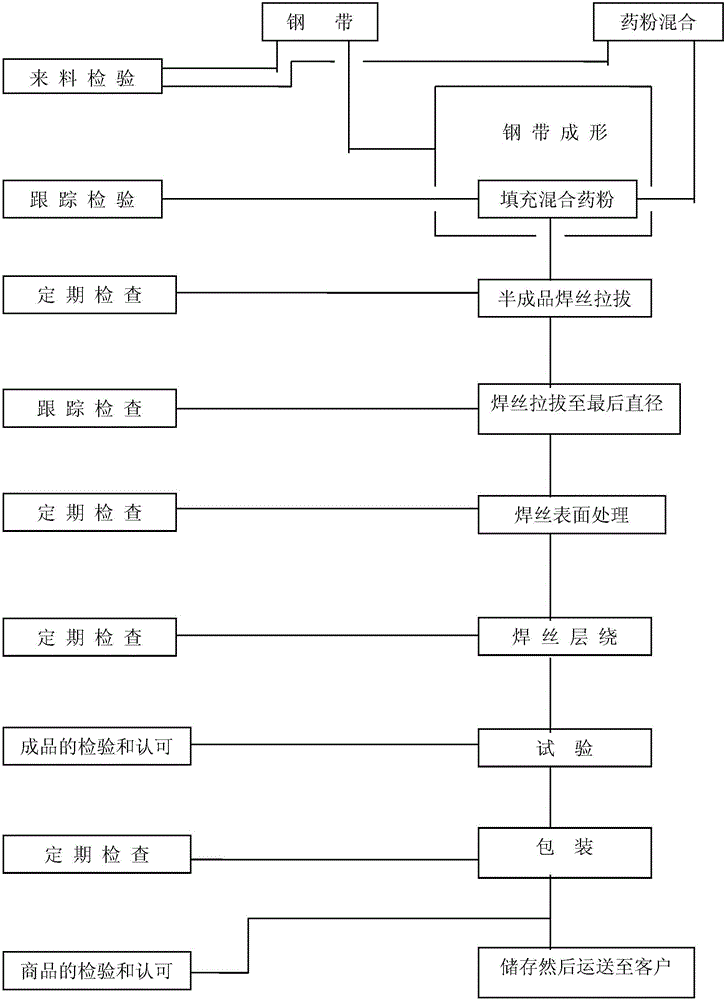

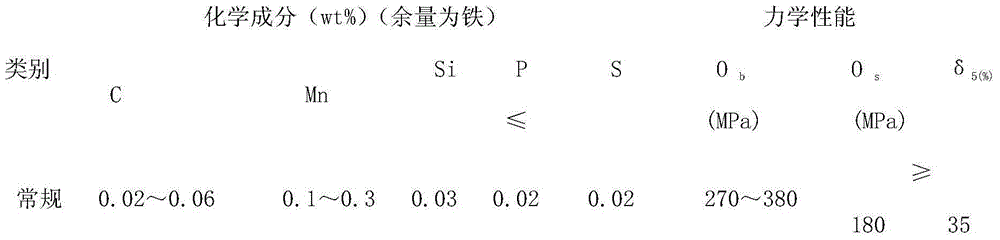

c02 or 80ar+c02 gas shielded basic flux cored wire

InactiveCN103495817BImprove toughnessHigh and low temperature impact toughness valueWelding/cutting media/materialsSoldering mediaManganeseImpact toughness

The invention provides an alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas. The alkaline welding flux cored wire comprises flux cored powder and a steel belt wrapping the flux cored powder. The alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas is characterized in that the flux cored powder of the flux cored wire is composed of, by weight, 10-25% of rutile, 15-35% of silicon manganese alloy, 25-40% of iron powder, 4-15% of nickel powder, 1-10% of aluminium magnesium alloy, 1-6% of marble, 1-6% of fluorite and 3-15% of ferrovanadium. The alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas has the advantages that the flux cored wire can be applied to welding of high-strength and high-ductility steel which is of the level larger than or equal to 700Mpa and guaranteeing overall performance, welding joints are purified and clean in the welding process, nonmetallic inclusion is little, the content of diffusible hydrogen is low, and the low temperature impact toughness value of welding metal is high.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Method for producing low-phosphorus steel or extremely low-phosphorus steel by using limestone slag-single slag method

ActiveCN107574281BEasy to masterImprove smelting performanceManufacturing convertersProcess efficiency improvementSteelmakingDolomite

The invention provides a method for producing low phosphorus steel or extra-low phosphorus steel by using a limestone slagging-single slagging method, and belongs to the technical field of steelmaking. The method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging comprises the steps that when slagging is conducted by using limestone, the oxygen consumption range of ton steel is controlled in 40-65 cubic meters, and the total adding amount of ton steel, the limestone and dolomite is 40-100 kg; the dolomite is about 1 / 4-1 / 5, accordingto converter capacity, the oxygen supplying intensity is controlled at 2-5 cubic meter / cent.ton steel, the alkalinity of final slag is controlled at 3. 0-6. 0, and the oxygen lance position is controlled within about 50% range of the decarbonization gun position; the furnace atmosphere is adjusted, the molten slag temperature is controlled between 1450-1630 DEG C, the adding batch of the limestone is controlled at 2-20 times, the eight of each batch of limestone is 30-0.5 kg / ton steel, and molten iron can be efficiently dephosphorized; and the single slagging method can produce low phosphorussteel or extra-low phosphorus steel. According to the method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging, the goal of dephosphorization can be achieved by easy operating, resources and energy can also be reduced, and workers easily master the method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of converter steelmaking synthetic slag former

ActiveCN103343180BReduce manufacturing costAvoid secondary processingManufacturing convertersSteelmakingBrick

The invention discloses a preparation method of a converter steelmaking synthetic slag former, belonging to the technical field of converter steelmaking of ferrous metallurgy. The method comprises the following steps of: uniformly mixing 10-18 parts of converter dust, 25-32 parts of scale, 5-10 parts of gas ash, 9-16 parts of waste high-alumina brick and bentonite to obtain a mixture B; adding 30-45 parts of active lime, 6-12 parts of active lime, 5-10 parts of magnesium oxide and bentonite into the mixture B to obtain a mixture C; mixing 10-15 parts of sodium carbonate with the mixture A and the mixture C, and pre-melting at 1,300-1,450 DEG C to obtain a mixture D; and cooling and crushing to obtain the synthetic slag former. According to the synthetic slag former, the metallurgic waste difficult to use is used as a component of the slag former, the prepared slag former has high dephosphorization efficiency, and the slag forming time is short.

Owner:MAANSHAN RUNTONG HEAVY IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com