Dephosphorization method for electric-arc furnace steelmaking

An electric arc furnace and charge technology, applied in the field of iron and steel metallurgy, can solve the problems of insufficient stirring strength of molten pool, difficult to meet high-efficiency dephosphorization, serious "rephosphorization" of molten steel, etc., so as to reduce the use and smelting production costs and improve the dephosphorization effect. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

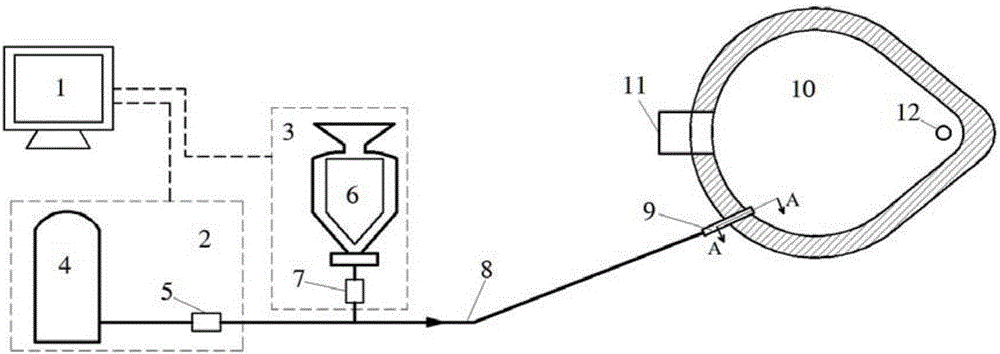

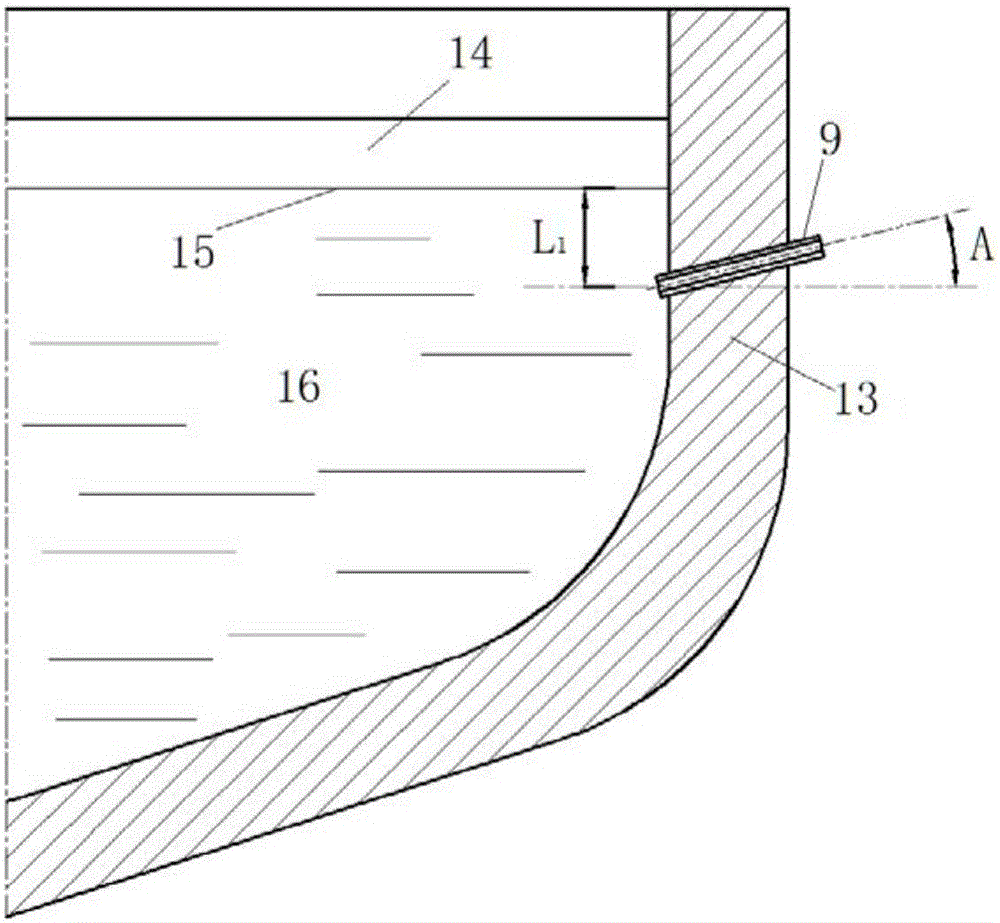

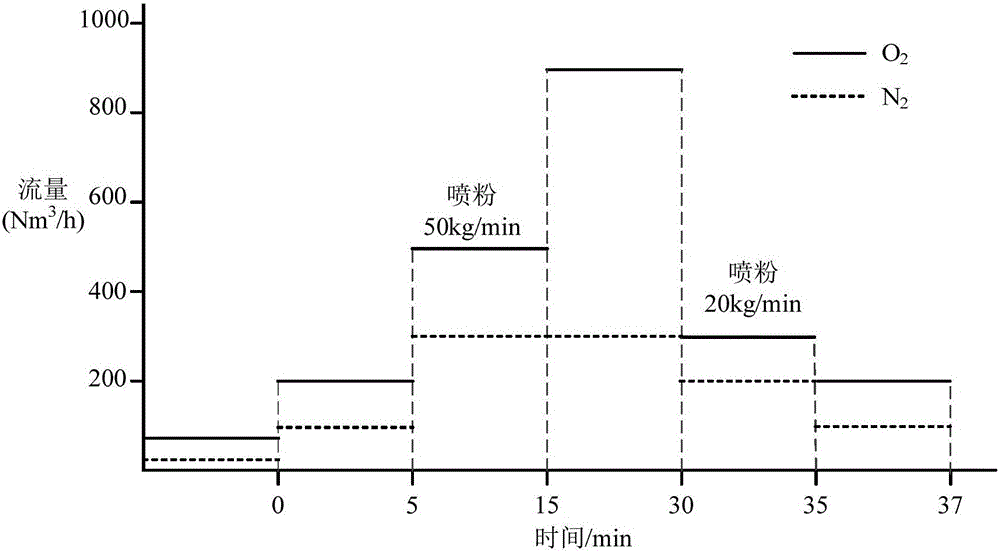

[0049] The present invention is applied in 90t electric arc furnace steelmaking, and two spray guns are installed, which are distributed on both sides of the electric arc furnace door. The outlet of the spray gun is 500mm below the liquid steel surface, and the angle with the horizontal plane is 10°. The dephosphorization powder is lime powder, the particle diameter is 50μm, and the single-gun spraying rate is 10~100kg / min. The carrier gas is oxygen, and the oxygen flow rate of a single gun is 50~1500Nm 3 / h. The annular gap gas is nitrogen, and the flow rate of a single gun is 10~500Nm 3 / h. The molten iron ratio is 40%, and the initial phosphorus content of the furnace charge is 0.1%, which is a low phosphorus content furnace charge smelting switching mode. image 3 .

[0050] 1) Before adding molten iron, the spray gun adopts the air blowing anti-blocking mode to spray: the central tube sprays oxygen with a flow rate of 60Nm 3 / h; Nitrogen gas is injected into the ann...

example 2

[0057] Example 2: The present invention is applied in 150t electric arc furnace steelmaking. Four spray guns are installed, which are evenly distributed on both sides of the electric arc furnace door. The outlet of the spray gun is 750mm below the liquid steel surface, and the angle with the horizontal plane is 15°. The dephosphorization powder is limestone powder, the particle diameter is 30μm, and the single-gun spraying rate is 10~200kg / min. The carrier gas is O 2 and CO 2 Mixed injection, single gun oxygen flow 50~2000Nm 3 / h. The gas in the annular seam is natural gas, and the flow rate of a single gun is 10~300Nm 3 / h. The molten iron ratio is 70%, and the initial phosphorus content of the charge is 0.17%, which is a high-phosphorus charge charge smelting mode. See Figure 4 .

[0058] 1) Before adding molten iron, the spray gun adopts the air blowing anti-blocking mode to spray: the central tube sprays oxygen, and the flow rate is 100Nm 3 / h; natural gas is inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com