Environment-friendly converter steel-making slagging agent and preparation method thereof

An environment-friendly, converter technology, applied in the field of iron and steel metallurgy converter steelmaking, can solve the problems of difficult comprehensive utilization of waste, poor dephosphorization effect, slow slagging speed, etc., achieve internal recycling, increase furnace life, reduce The effect of the amount added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

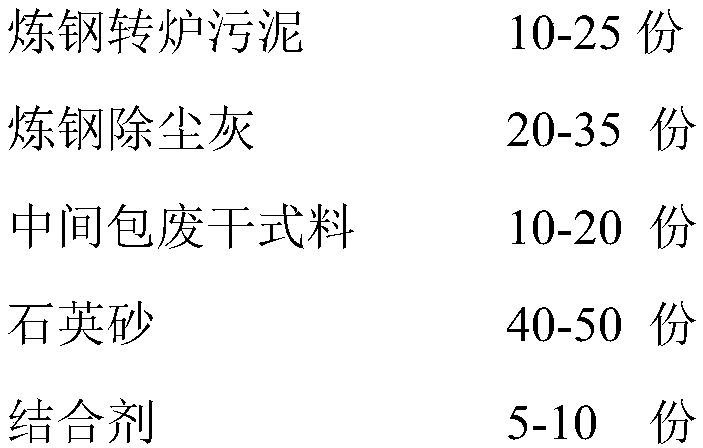

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, 25 parts by mass of converter dust are homogenized, and then mixed evenly with 10 parts by mass of steelmaking converter sludge, 15 parts by mass of tundish waste dry material, 45 parts by mass of quartz sand, and 5 parts by mass of binder, After pelletizing, drying, and cooling, an environmentally friendly converter steelmaking slag agent was obtained. The components and their mass fractions are shown in Table 1.

[0035] Table 1

[0036] components

[0037] The slagging agent provided by this embodiment has high initial slag formation speed and dephosphorization efficiency; the slagging agent provided by the present invention can recycle iron and magnesium oxide in the sludge, so that the consumption of iron and steel materials is reduced. Slag agent can save 1.26 kg / ton of steel raw materials at the same time.

Embodiment 2

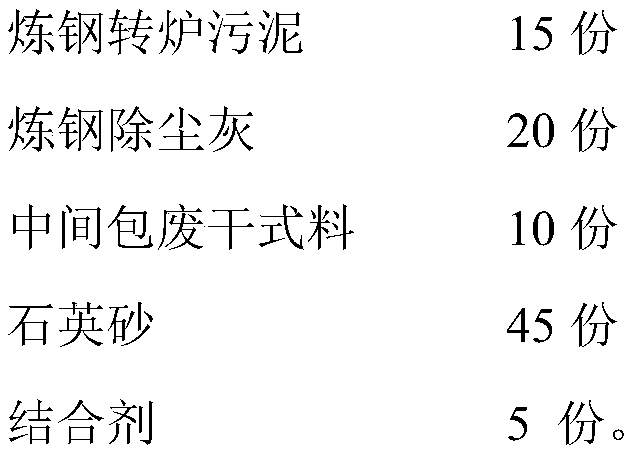

[0039] In this embodiment, 20 parts by mass of dedusting ash from the converter is homogenized, and then mixed evenly with 15 parts by mass of steelmaking converter sludge, 10 parts by mass of tundish waste dry material, 45 parts by mass of quartz sand, and 5 parts by mass of binder, After pelletizing, drying, and cooling, an environmentally friendly converter steelmaking slag agent was obtained. The components and their mass fractions are shown in Table 2.

[0040] Table 2

[0041] components

[0042] The slagging agent provided by this embodiment has high initial slag formation speed and dephosphorization efficiency; the slagging agent provided by the present invention can recycle iron and magnesium oxide in the sludge, so that the consumption of iron and steel materials is reduced. Slag agent can save 1.52 kg / ton of steel raw materials at the same time.

Embodiment 3

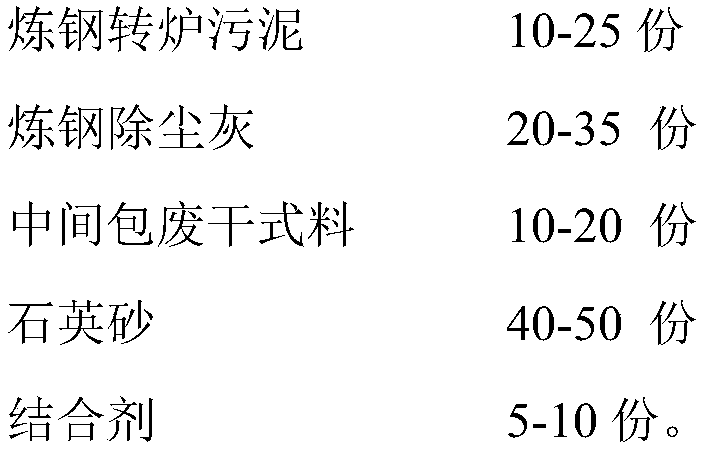

[0044] In this embodiment, 30 parts by mass of converter dust are homogenized, and then mixed evenly with 25 parts by mass of steelmaking converter sludge, 15 parts by mass of tundish waste dry material, 45 parts by mass of quartz sand, and 10 parts by mass of binder. After pelletizing, drying, and cooling, an environmentally friendly converter steelmaking slag agent was obtained. The components and their mass fractions are shown in Table 3.

[0045] table 3

[0046] components

[0047] The slagging agent provided by this embodiment has high initial slag formation speed and dephosphorization efficiency; the slagging agent provided by the present invention can recycle iron and magnesium oxide in the sludge, so that the consumption of iron and steel materials is reduced. Slag agent can save 1.47 kg / ton of steel raw materials at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com