Single-converter low-iron-consumption duplex less-slag smelting method

A technology of slag-less smelting and converter blowing, which is applied in the field of single-converter low-iron-consumption double-connected slag-less smelting to reduce the consumption of iron and steel materials. Requirements for dephosphorization and smelting molten steel, problems such as desiliconization and dephosphorization of molten iron, to achieve the effect of improving converter operation efficiency, shortening smelting cycle, and reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0026] Embodiments 1 to 5 of the present invention use a 120-ton top-blown converter to smelt HRB400 steel.

[0027] A single-converter low-iron-consumption double-linked slag-less smelting method according to Embodiment 1-5 of the present invention comprises the following steps:

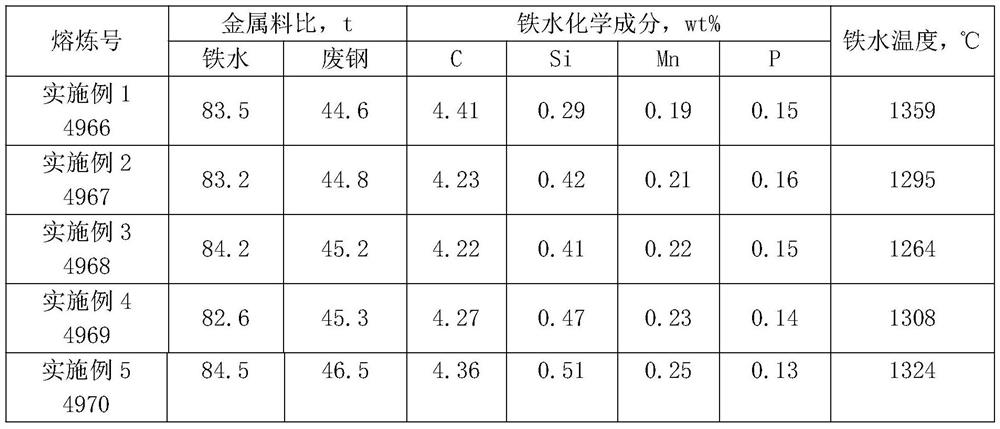

[0028] S1: Put the main metal material into the converter and use the converter for smelting. Among the raw materials of the main metal material, the contents of molten iron and steel scrap are shown in Table 1; shown;

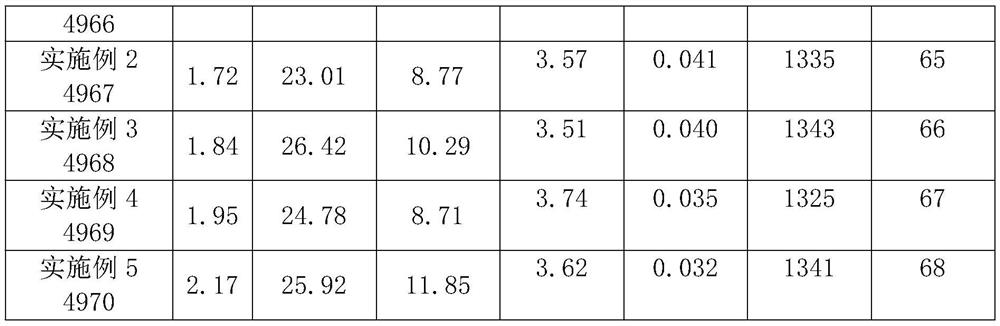

[0029] The parameters of the converter smelting metal material in Examples 1-5 of the present invention are shown in Table 1 below.

[0030] Table 1 Parameters of converter smelting metal materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com