Dephosphorization method for molten iron in converter by blowing dust removal ash

A converter and molten iron technology, applied in the direction of manufacturing converters, etc., can solve the problems of no relevant reports, secondary environmental pollution, etc., and achieve the effects of avoiding environmental pollution, improving the dephosphorization rate of molten iron, and efficient utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The present invention will be further described below in conjunction with the example of dephosphorization of 300t converter blowing dedusting ash and accompanying drawings.

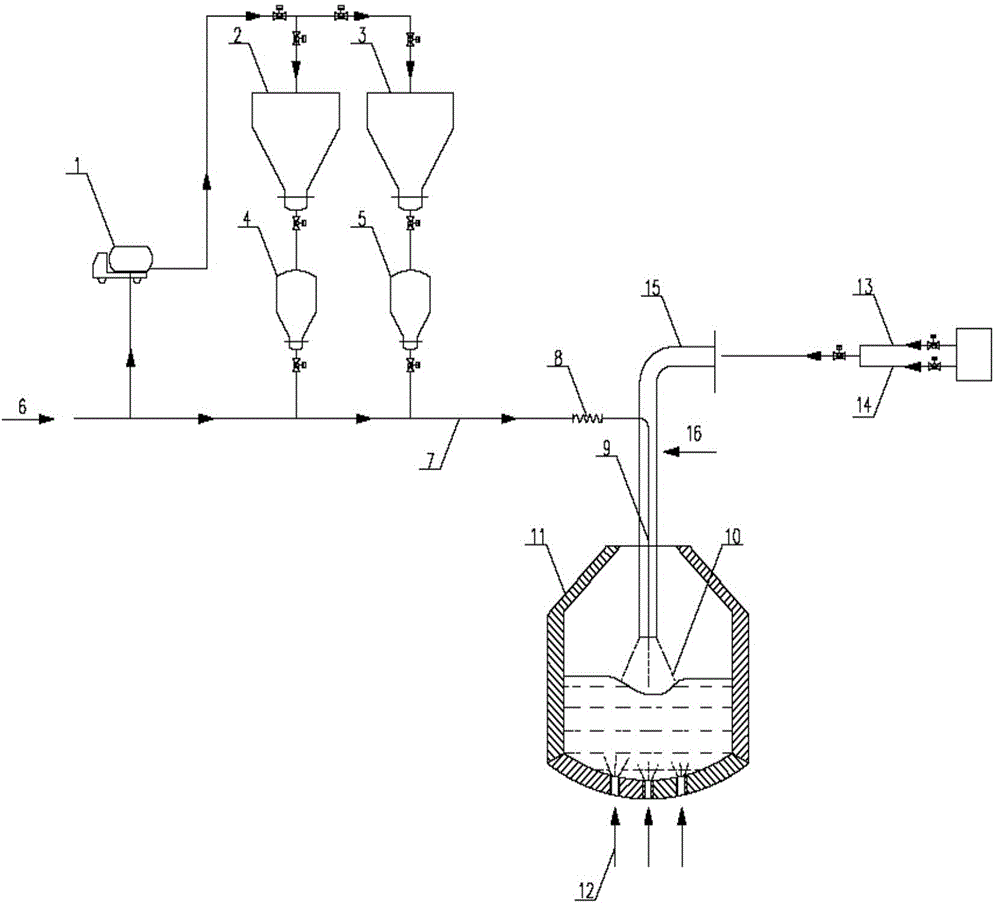

[0026] The present invention adopts following method to realize converter blowing dedusting ash dephosphorization process operation, as figure 1 As shown, the specific steps include:

[0027] (1) Hot metal preparation

[0028] In order to achieve a good dephosphorization effect, the requirements for the composition and temperature of the molten iron in the dephosphorization converter are shown in Table 1.

[0029] Table 1 Requirements for composition and temperature of molten iron fed into furnace by dephosphorization converter

[0030] C%

Si%

Mn%

P%

S%

temperature °C

3.9-5.0

≤0.35

0.08~0.50

≤0.12

≤0.07

≥1300

[0031] (2) Oxygen lance system preparation

[0032] The oxygen valve station of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com