A converter slag-less smelting method

A technology of slag-less smelting and converter slag, which is applied in the field of smelting, can solve the problems of low economic value and achieve the effects of cost reduction, good fluidity, and resource and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

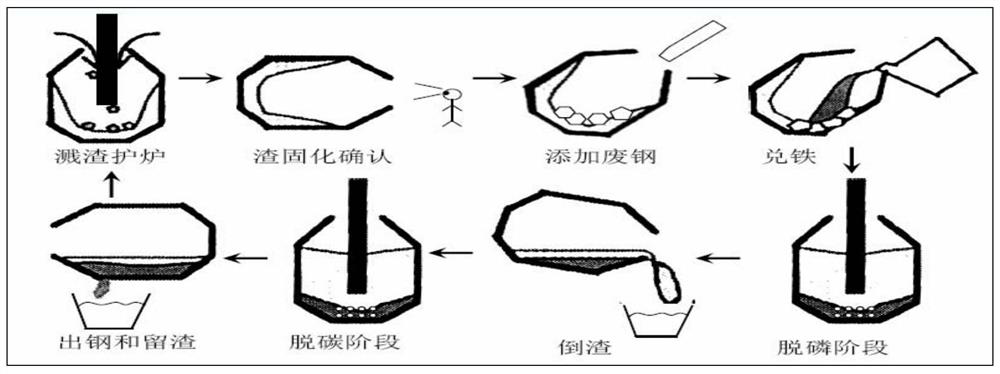

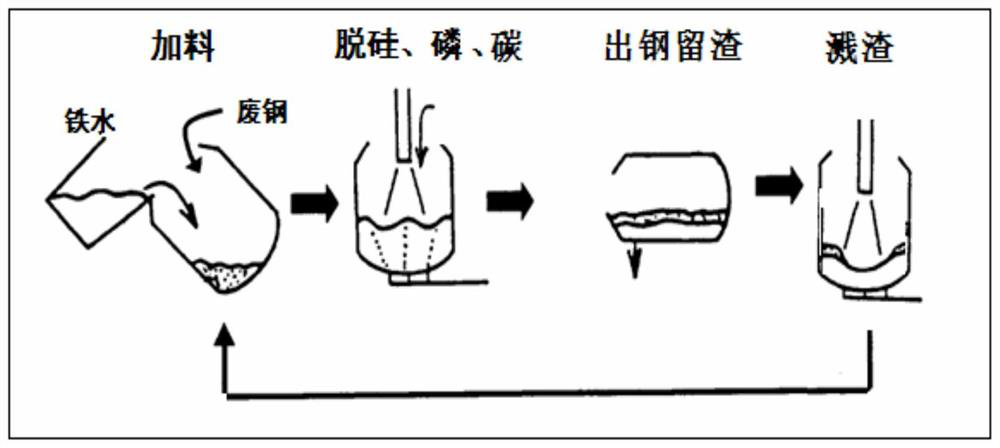

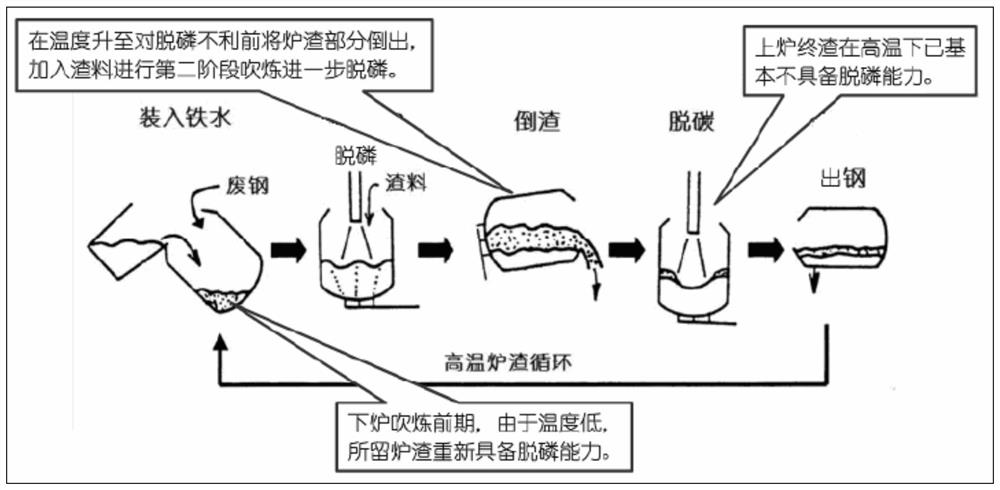

[0037] In the specific implementation process, the low-slag smelting work of the present invention mainly focuses on the high-efficiency dephosphorization technology in the dephosphorization period, the timing of slag dumping and the control of slag amount in the early stage of converter smelting, and the three technologies of rapid solidification of slag. Taking advantage of the low temperature in the early stage, which is favorable for the thermodynamic conditions of dephosphorization reaction, the final slag of the upper furnace is used in the initial stage of lower furnace blowing for dephosphorization. The slag is slag-forming, and the second-stage blowing can be used to further dephosphorize; the high-efficiency dephosphorization technology of the converter with low lance position and large oxygen supply is adopted; the rapid and sufficient slag dumping after dephosphorization is whether the converter steelmaking process with less slag can be smooth The key to the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com