Converter steelmaking synthetic slag former

A technology of converter steelmaking and slagging agent, which is applied in the field of iron and steel metallurgy converter steelmaking, can solve the problems of poor dephosphorization effect, difficult comprehensive utilization of metallurgical waste, and slagging speed of polluted environment, so as to increase furnace life and improve dephosphorization Phosphorus effect, effect of shortening slagging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

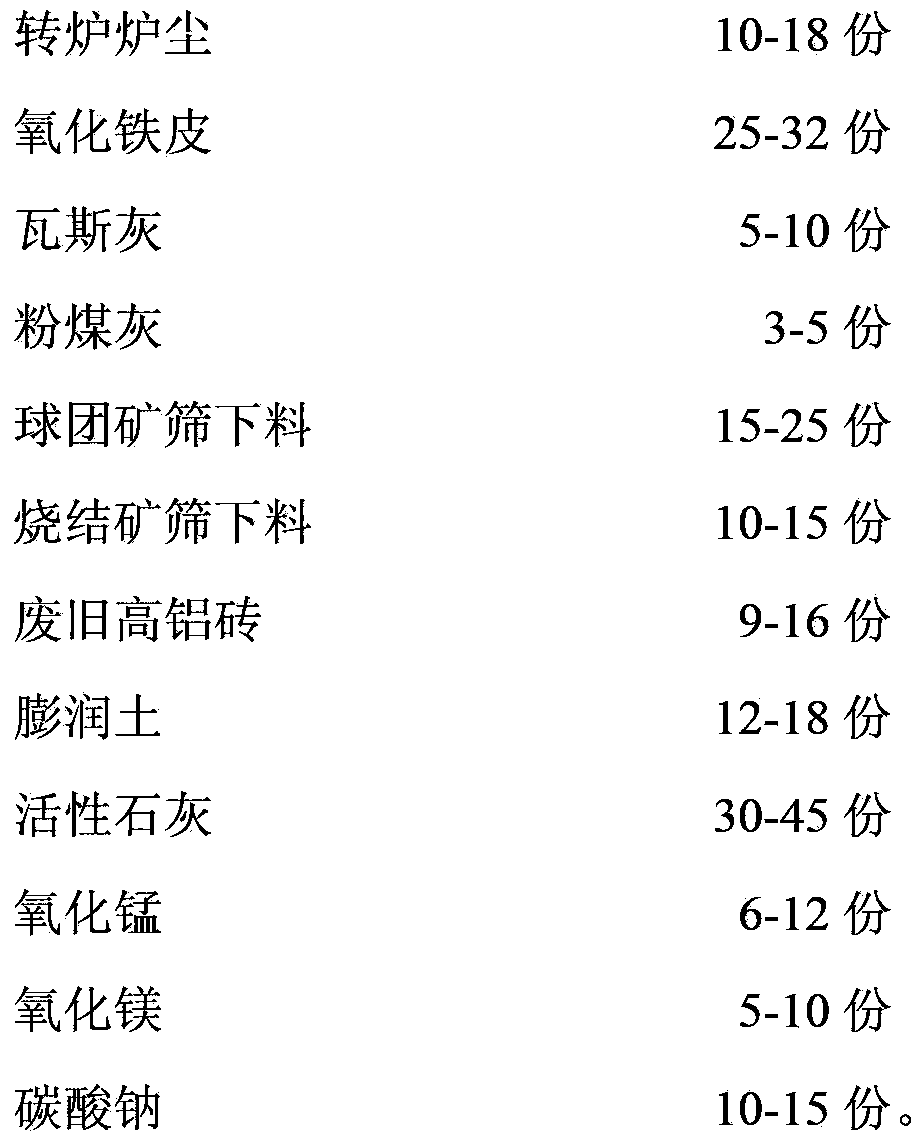

Method used

Image

Examples

Embodiment 1

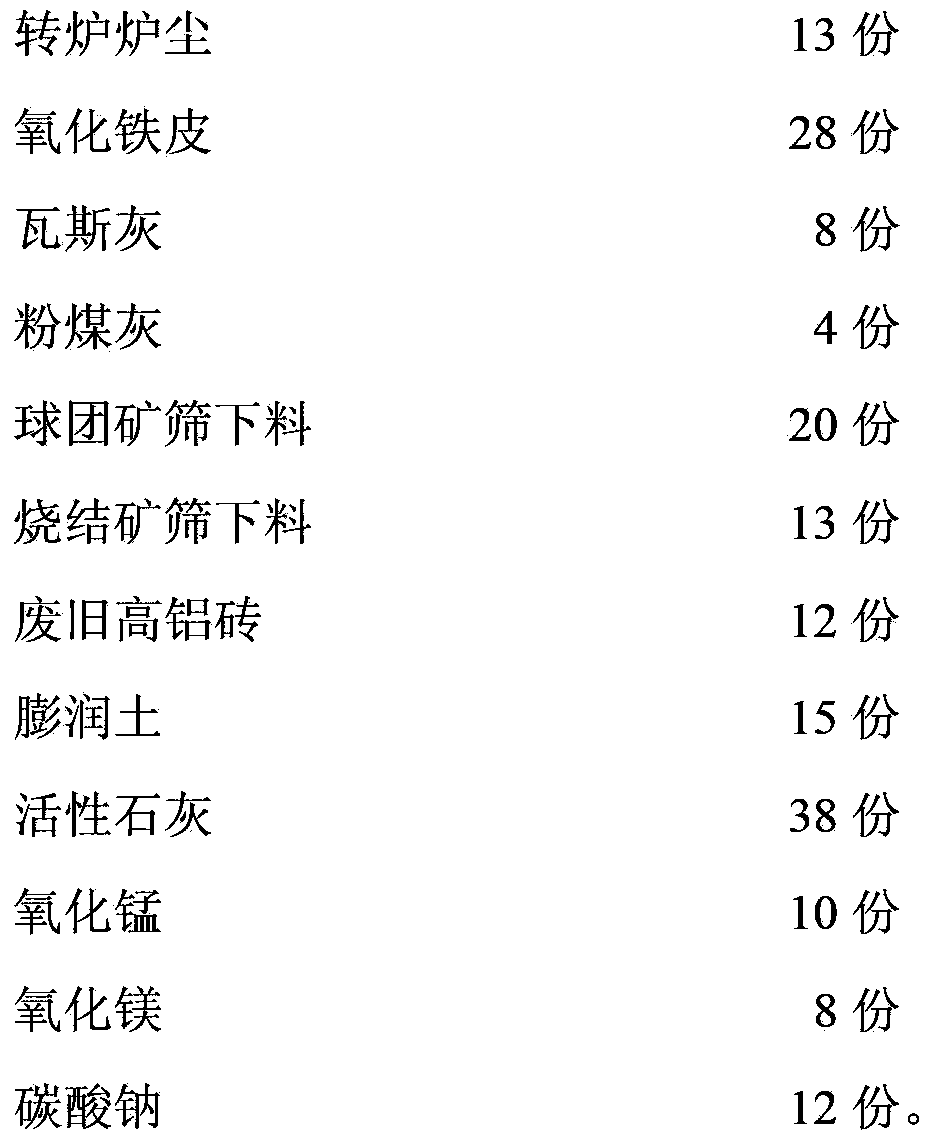

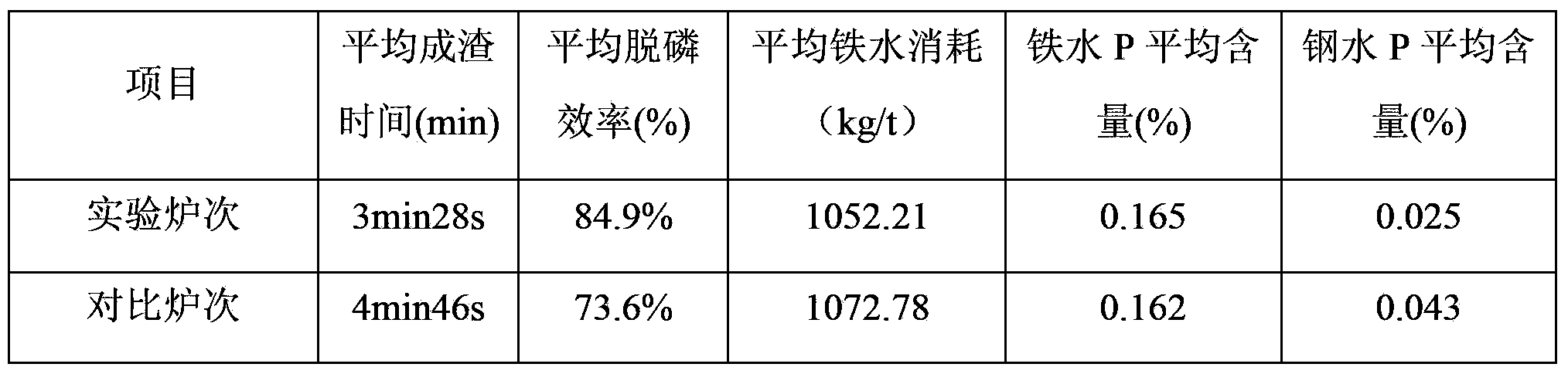

[0025] A synthetic slagging agent for converter steelmaking in this embodiment has the following components and contents: converter dust 13kg, iron oxide scale 28kg, gas ash 8kg, fly ash 4kg, pellet sieve blanking 20kg, sinter sieve Blanking 13kg, waste high alumina brick 12kg, bentonite 15kg, active lime 38kg, manganese oxide 10kg, magnesium oxide 8kg, sodium carbonate 12kg. It is worth noting that the converter dust in the present invention is the iron-containing material recovered from the furnace gas of the oxygen converter through a dust collector. In addition, the gas dust removal system of the ironmaking blast furnace is composed of gravity dust removal and fine dust removal. The gas ash used in the present invention is the dry fine dust obtained by dry dust removal in the second stage fine dust remover. The gas ash composition The mass percentage content is: TFe: 32%, C: 28%, CaO: 8.6%, SiO 2 : 5.4%, MgO: 1.5%, Al 2 O 3 : 3.2%, the rest are unavoidable impurities. ...

Embodiment 2

[0040] A synthetic slagging agent for converter steelmaking in this embodiment has the following components and contents: converter dust 10kg, iron oxide scale 25kg, gas ash 5kg, fly ash 3kg, pellet sieve blanking 15kg, sinter sieve Blanking 10kg, waste high alumina brick 9kg, bentonite 12kg, active lime 30kg, manganese oxide 6kg, magnesium oxide 5kg, sodium carbonate 10kg. It is worth noting that the converter dust in the present invention is the iron-containing material recovered from the furnace gas of the oxygen converter through a dust collector. In addition, the gas dust removal system of the ironmaking blast furnace is composed of gravity dust removal and fine dust removal. The gas ash used in the present invention is the dry fine dust obtained by dry dust removal in the second stage fine dust remover. The gas ash composition The mass percentage content is: TFe: 35%, C: 25%, CaO: 9.7%, SiO 2 : 6%, MgO: 1.2%, Al 2 O 3 : 2.4%, the rest are unavoidable impurities. The ...

Embodiment 3

[0052] A synthetic slagging agent for converter steelmaking in this embodiment has the following components and contents: 18 kg of converter dust, 32 kg of iron scale, 10 kg of gas ash, 5 kg of fly ash, 25 kg of pellet sieve, sinter sieve Blanking 15kg, waste high alumina brick 16kg, bentonite 18kg, active lime 45kg, manganese oxide 12kg, magnesium oxide 10kg, sodium carbonate 15kg. It is worth noting that the converter dust in the present invention is the iron-containing material recovered from the furnace gas of the oxygen converter through a dust collector. In addition, the gas dust removal system of the ironmaking blast furnace is composed of gravity dust removal and fine dust removal. The gas ash used in the present invention is the dry fine dust obtained by dry dust removal in the second stage fine dust remover. The gas ash composition The mass percentage content is: TFe: 28%, C: 33%, CaO: 7.5%, SiO 2 : 4.5%, MgO: 1.8%, Al 2 O 3 : 3.8%, the rest are unavoidable impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com