Efficient dephosphorization accelerant for converter steelmaking and preparing method thereof

A technology of converter steelmaking and accelerator, applied in the field of metallurgy, can solve the problems of large increase in dephosphorization cost of converter steelmaking, failure to be effectively used, increased consumption of steel materials, etc., to achieve stable dephosphorization effect and cost savings , The effect of saving production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

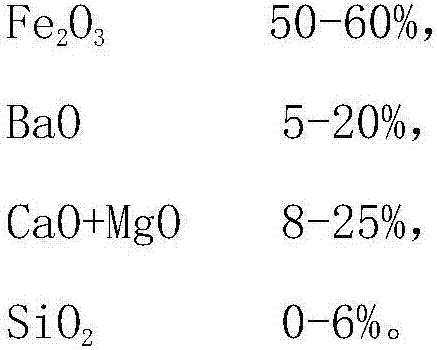

[0029] A high-efficiency dephosphorization accelerator suitable for converter steelmaking, the high-efficiency dephosphorization accelerator is composed of the following raw materials by weight percentage:

[0030]

[0031] Moreover, the melting point of the accelerator is 1200°C, the particle size is 10mm, and the strength is greater than 1KN / piece.

[0032] A preparation method suitable for the above-mentioned converter steelmaking high-efficiency dephosphorization accelerator, the method comprising the following steps:

[0033] Step 1, using the converter electrostatic precipitator in the steelmaking plant to collect converter dust;

[0034] Step 2, adding iron oxide scale and barium oxide to the converter dedusting dust collected in step 1, weighing and mixing in proportion;

[0035] Step 3, the materials mixed in step 2 are mixed evenly through a mixer;

[0036] Step 4, the material mixed and milled in step 3 is pressed into an ellipsoidal semi-finished product throu...

Embodiment 2

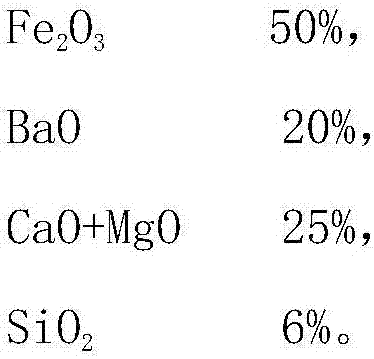

[0040] A high-efficiency dephosphorization accelerator suitable for converter steelmaking, the high-efficiency dephosphorization accelerator is composed of the following raw materials by weight percentage:

[0041]

[0042] Moreover, the melting point of the accelerator is 1300°C, the particle size is 35mm, and the strength is greater than 1KN / piece.

[0043] A preparation method suitable for the above-mentioned converter steelmaking high-efficiency dephosphorization accelerator, the method comprising the following steps:

[0044] Step 1, using the converter electrostatic precipitator in the steelmaking plant to collect converter dust;

[0045] Step 2, adding iron oxide scale and barium oxide to the converter dedusting dust collected in step 1, weighing and mixing in proportion;

[0046] Step 3, the materials mixed in step 2 are mixed evenly through a mixer;

[0047] Step 4, the material mixed and milled in step 3 is pressed into an ellipsoidal semi-finished product throu...

Embodiment 3

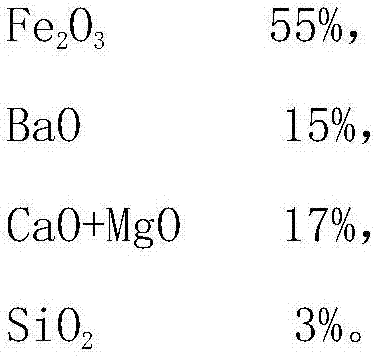

[0051] A high-efficiency dephosphorization accelerator suitable for converter steelmaking, the high-efficiency dephosphorization accelerator is composed of the following raw materials by weight percentage:

[0052]

[0053] Moreover, the melting point of the accelerator is 1400°C, the particle size is 60mm, and the strength is greater than 1KN / piece.

[0054] A preparation method suitable for the above-mentioned converter steelmaking high-efficiency dephosphorization accelerator, the method comprising the following steps:

[0055] Step 1, using the converter electrostatic precipitator in the steelmaking plant to collect converter dust;

[0056] Step 2, adding iron oxide scale and barium oxide to the converter dedusting dust collected in step 1, weighing and mixing in proportion;

[0057] Step 3, the materials mixed in step 2 are mixed evenly through a mixer;

[0058] Step 4, the material mixed and milled in step 3 is pressed into an ellipsoidal semi-finished product throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com