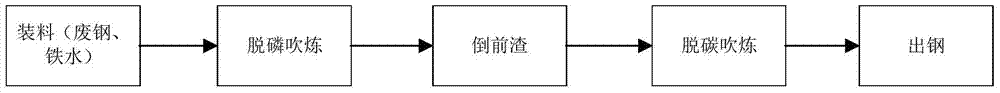

A method for producing low-phosphorus steel with a single-converter double-oxygen lance

A technology of double oxygen lance and low-phosphorus steel, which is applied in the manufacture of converters, etc., can solve the problems of unstable dephosphorization effect, achieve stable dephosphorization effect, prevent excessive foaming, and reduce splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

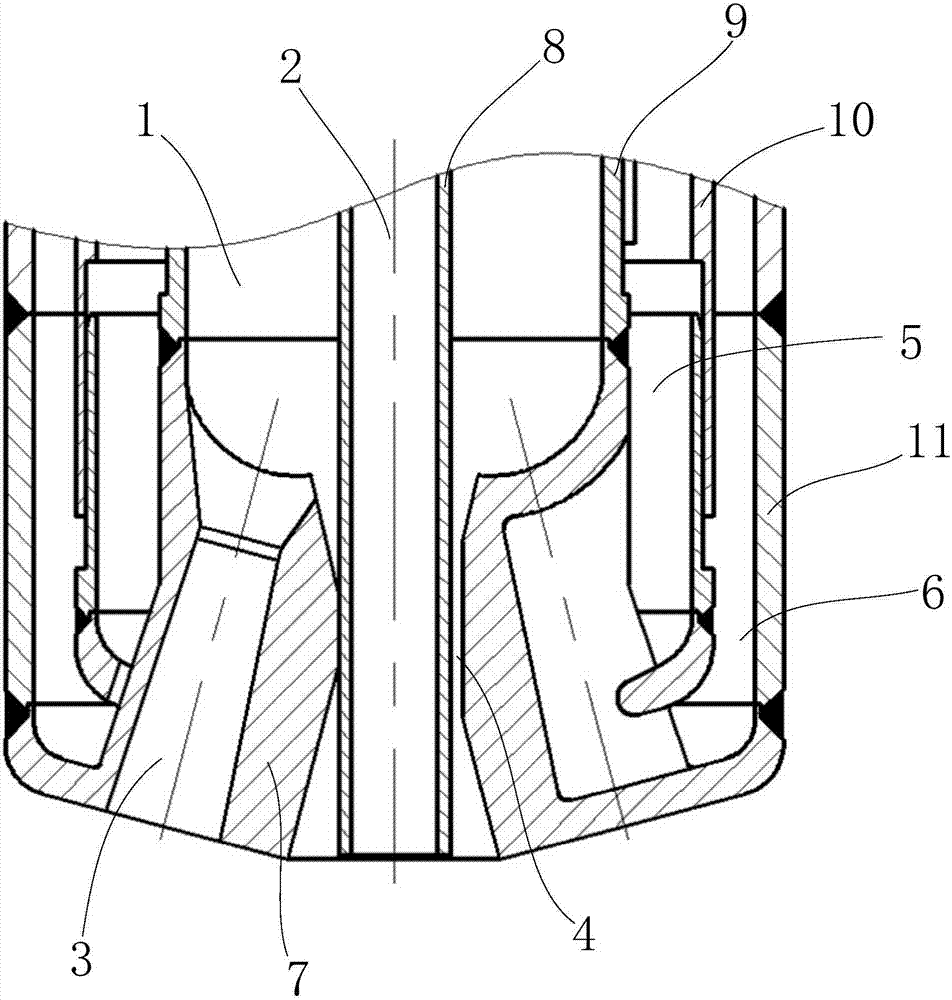

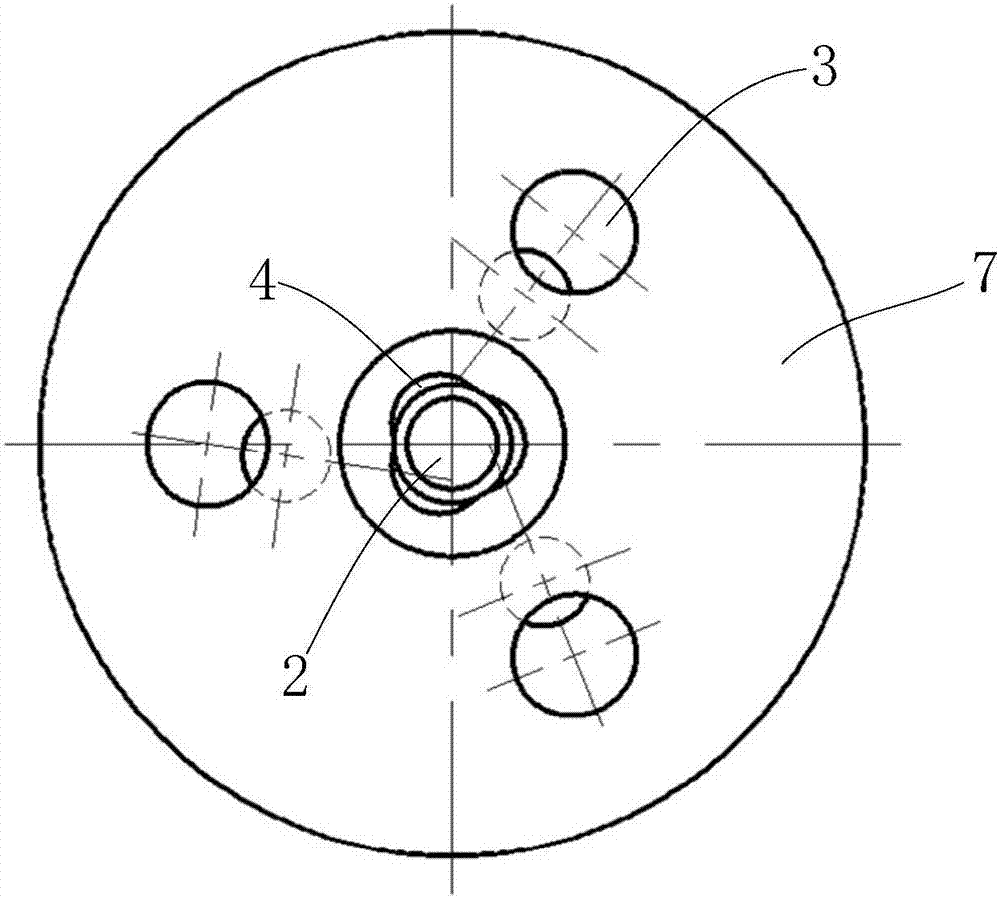

[0071] In this embodiment, medium-high phosphorus hot metal and light and thin steel scrap are used as raw materials, and the main components of the hot metal are: C 4.2%, Si 0.42%, Mn 0.38%, P 0.146%, S 0.008%. The temperature of molten iron is 1327°C. The scrap ratio is 7.1%. The steel scrap and molten iron are sequentially added to the top-bottom combined blowing converter. Add slag material according to the final slag alkalinity of 2.0. Afterwards, the dephosphorization powder spraying oxygen lance is used for smelting operation, and the oxygen supply intensity of the oxygen lance is 2.0Nm 3 / (min·t), the oxygen blowing time is 8min, and the lime powder is injected while supplying oxygen, and the powder injection speed is 300kg / min. Average bottom blow strength 0.1Nm 3 / (min t). Sampling analysis after smelting in the dephosphorization period shows that the semi-steel [P] content is 0.027%, the semi-steel [C] content is 3.08%, and the semi-steel temperature is 1380°C....

Embodiment 2

[0073] In this example, medium-high phosphorus molten iron and light and thin steel scrap are used as raw materials, and the main components of the molten iron are: C 4.2%, Si 0.30%, Mn 0.33%, P 0.131%, S 0.005%. The temperature of molten iron is 1329°C. The scrap ratio is 6.2%. The steel scrap and molten iron are sequentially added to the top-bottom combined blowing converter. Add slag material according to the final slag alkalinity of 2.2. Afterwards, the dephosphorization oxygen lance is used for smelting operation, and the oxygen supply intensity of the oxygen lance is 2.2Nm 3 / (min·t), the oxygen blowing time is 8.5min, and the lime powder is injected while supplying oxygen, and the powder injection speed is 600kg / min. Average bottom blow strength 0.1Nm 3 / (min t). Sampling analysis after smelting in the dephosphorization period shows that the content of semi-steel [P] is 0.023%, the content of semi-steel [C] is 2.98%, and the temperature of semi-steel is 1400°C. Aft...

Embodiment 3

[0075] In this example, medium-high phosphorus molten iron and light and thin steel scrap are used as raw materials, and the main components of the molten iron are: C 4.2%, Si 0.64%, Mn 0.20%, P 0.18%, S 0.006%. The temperature of molten iron is 1337°C. The scrap ratio is 10.7%. The steel scrap and molten iron are sequentially added to the top-bottom combined blowing converter. Add slag material according to the final slag alkalinity of 2.5. Afterwards, the dephosphorization oxygen lance is used for smelting operation, and the oxygen supply intensity of the oxygen lance is 2.2Nm 3 / (min·t), the oxygen blowing time is 9.2min, and the lime powder is injected while supplying oxygen, and the powder injection speed is 800kg / min. Average bottom blow strength 0.1Nm 3 / (min t). Sampling analysis after smelting in the dephosphorization period shows that the semi-steel [P] content is 0.028%, the semi-steel [C] content is 3.2%, and the semi-steel temperature is 1370°C. After the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com