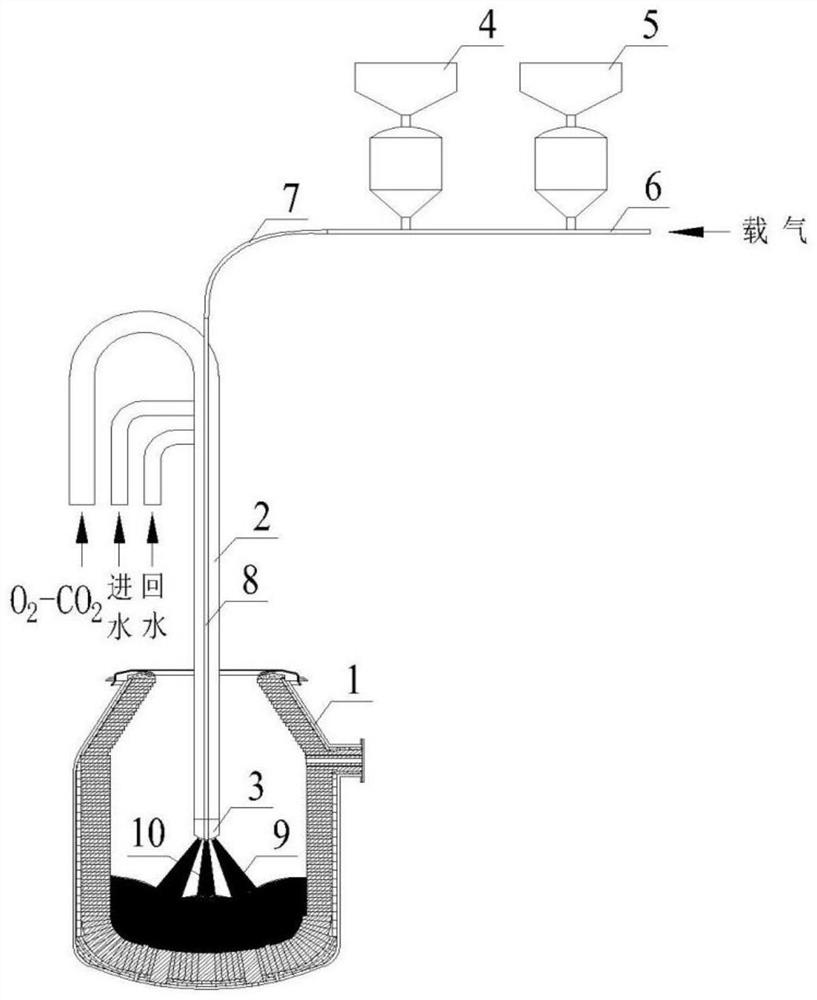

Multifunctional oxygen lance system for converter steelmaking and steelmaking method

A converter steelmaking and multi-functional technology, applied in the field of iron and steel smelting, can solve the problems of low heat recovery efficiency of adding warming agent to the silo, reducing the calorific value of converter gas, and high price of silicon temperature raising agent, so as to achieve comprehensive economic benefits, Improve the dephosphorization and desulfurization efficiency of the converter and reduce the effect of carbon and oxygen accumulation at the end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

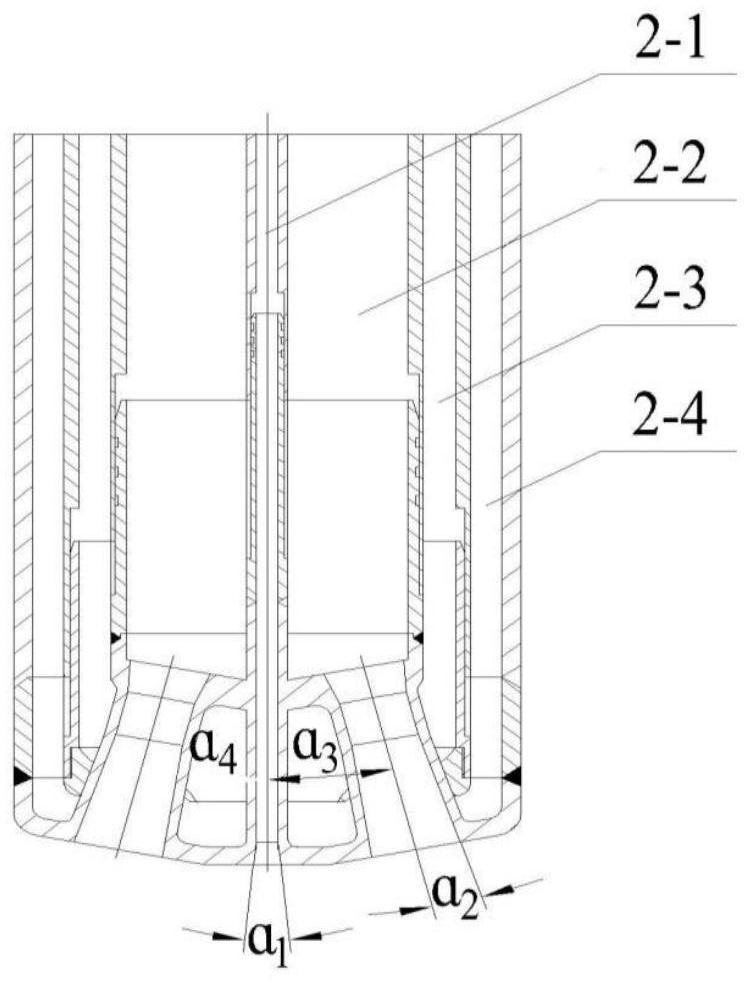

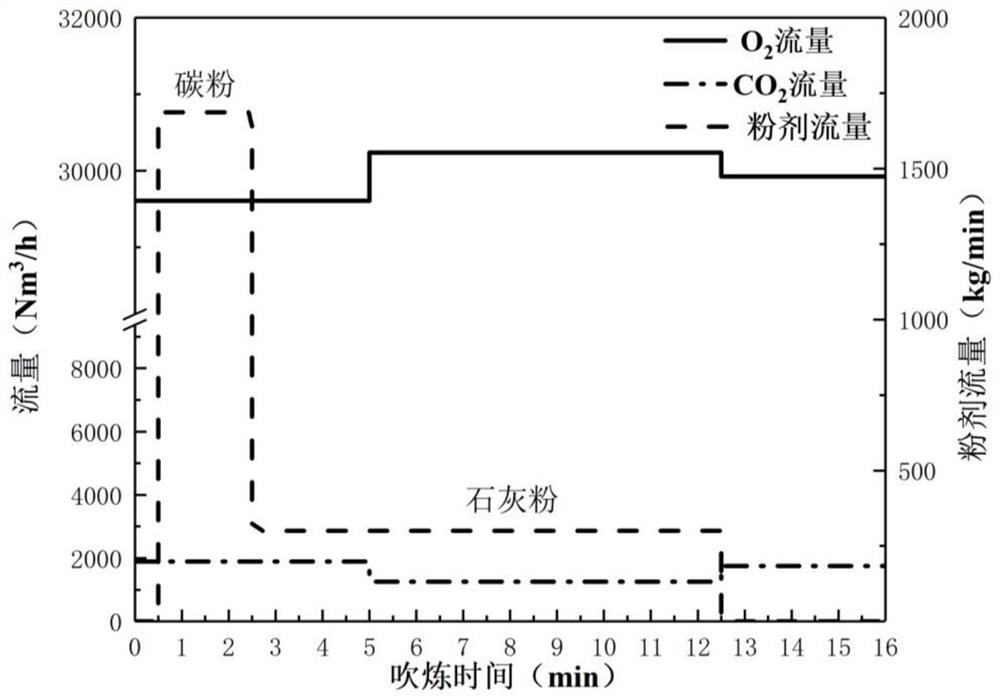

[0031] The present invention is applied to the smelting process of 150-ton converter adopting OG method for dust removal, the oxygen supply time is 16 minutes, and the main blowing air flow rate is 31500Nm 3 / h, the medium is O 2 and CO 2 , powder spray carrier gas flow rate is 3150Nm 3 / h, the carrier gas medium is N 2 and CO 2 , the spraying powder flow rate is 1687kg / min, the number of main spray holes is 5, the Mach number is 2.04, the central hole Mach number is 1.8, the carbon content of the carbon powder is 84%, the particle size is 150 mesh, and the lime powder particle size is 200 mesh. According to the smelting conditions, the powder injection system and air injection system can be flexibly adjusted.

[0032] 1) After filling the toner spray tank and lime powder spray tank with powder, pressurize to 1.5MPa;

[0033] 2) Collect the molten iron composition, determine the tapping conditions, and set the amount of carbon powder injected to 3374kg;

[0034] Table 1 ...

Embodiment 2

[0045] The invention is applied to the smelting process of 300-ton converter adopting LT method for dust removal, the oxygen supply time is 15 minutes, and the main blowing air flow rate is 60000Nm 3 / h, the medium is O 2 and CO 2 , powder spray carrier gas flow rate is 5400Nm 3 / h, the carrier gas medium is N 2 and CO 2 , the powder injection flow rate is 2090kg / min, the number of main injection holes is 6, the Mach number is 2.12, the central hole Mach number is 1.92, the fixed carbon content of anthracite coal powder is 82%, the particle size is 200 mesh, and the lime powder particle size is 200 mesh. According to the smelting conditions, the powder injection system and air injection system can be flexibly adjusted.

[0046] 1) After filling the anthracite powder spray tank and lime powder spray tank with powder, pressurize to 1.5MPa;

[0047] 2) Collect the molten iron composition, determine the tapping conditions, and set the amount of carbon powder injected to 4180k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mach number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com