A gun head structure and method for adjusting the oxygen flow rate of converter top blowing by dual-channel oxygen flow

A top-blown oxygen and oxygen flow technology, which is applied in the manufacture of converters, etc., can solve the problems of increasing splashing, reducing oxygen utilization rate, and low dephosphorization efficiency, so as to prevent excessive foaming of slag, improve powder utilization rate, and improve The effect of the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

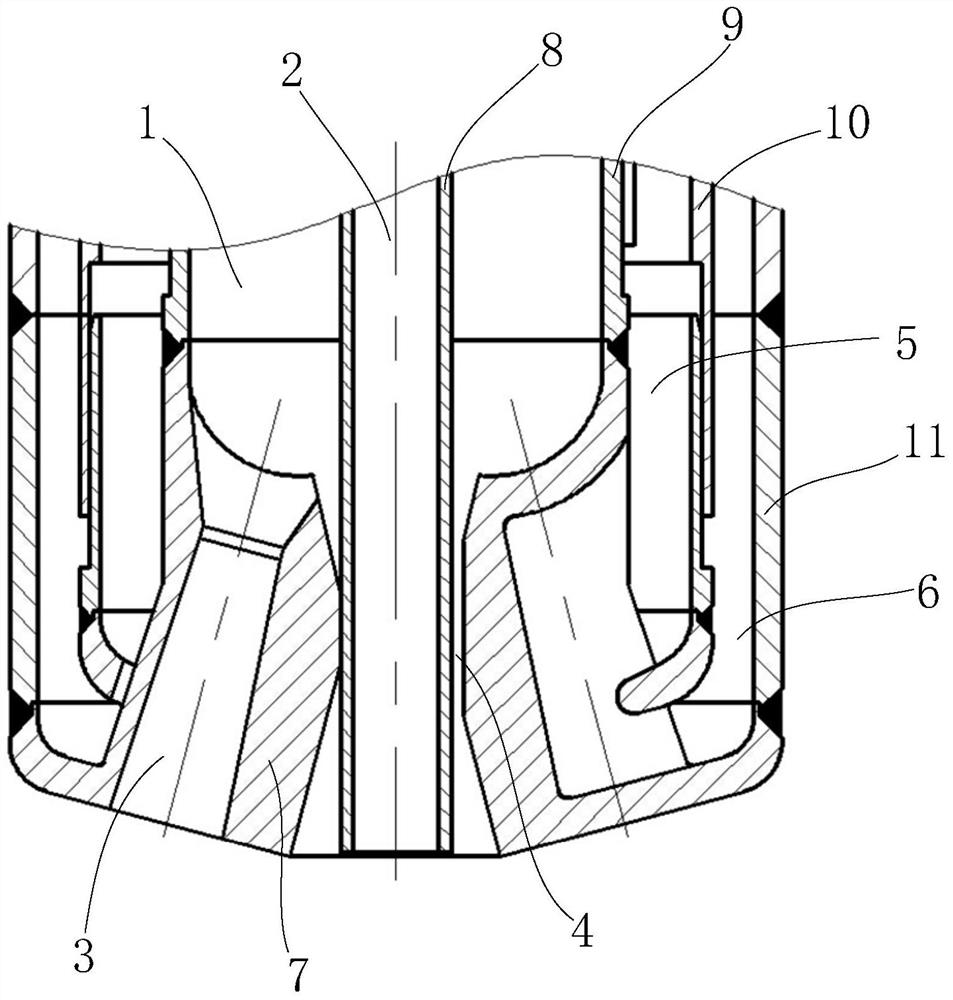

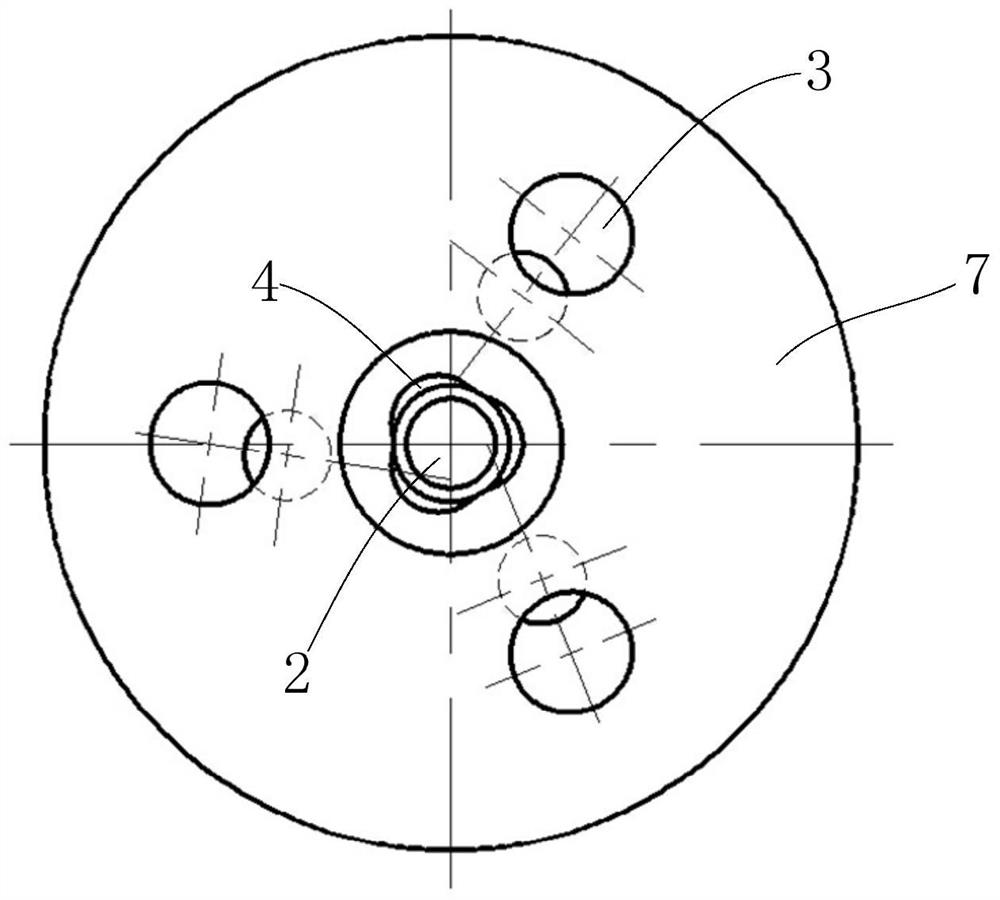

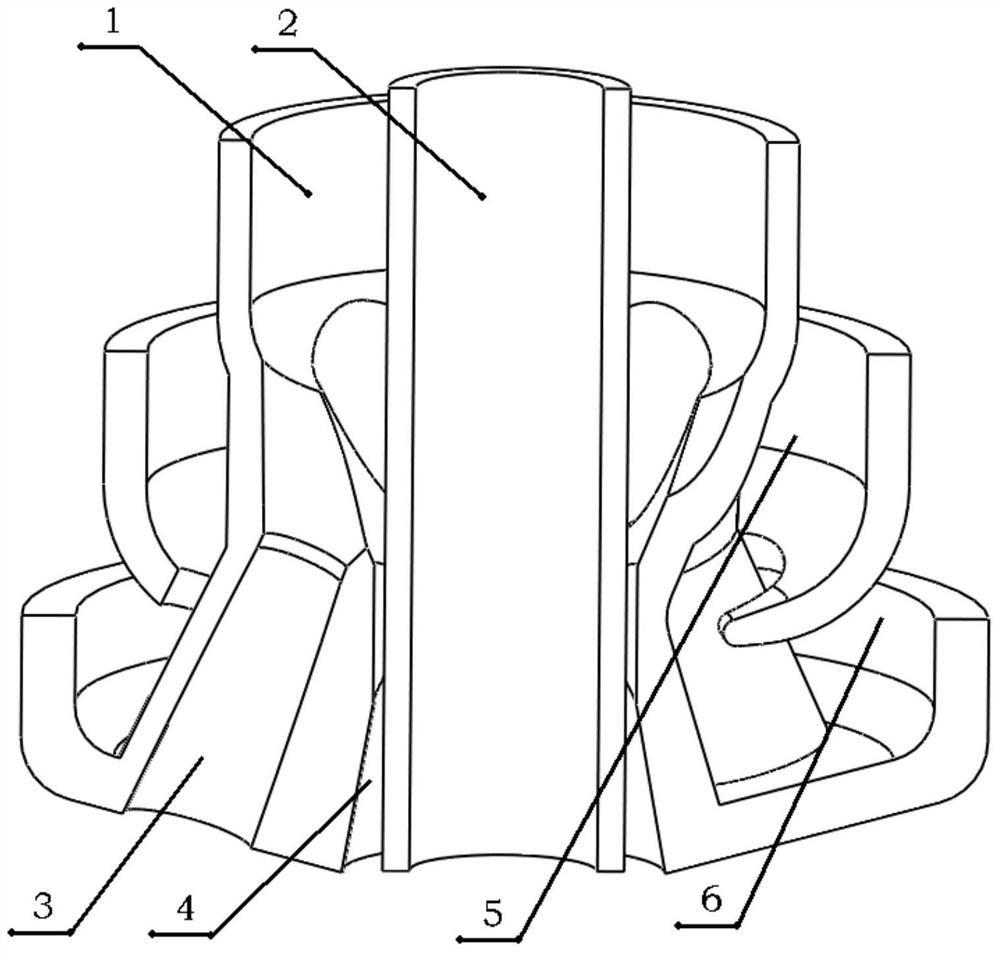

[0045] Such as Figure 1 to Figure 3As shown, a gun head structure for adjusting the flow rate of oxygen in the top of the converter by two-way oxygen flow, including a nozzle 7 and a central pipe 8, the nozzle 7 has a central hole, the central pipe 8 extends into the central hole of the nozzle 7, and the central pipe 8 Between the outer wall and the inner wall of the spray head 7, a spray channel that contracts first and then expands is formed along the spray direction, and an annular slot nozzle 4 is formed between the outer wall of the central tube 8 and the inner wall at the throat of the spray head 7, and the spray head 7 around the center hole A plurality of Laval type spouts 3 are arranged on the upper slope....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com