Fluoride-free slag-making fluxing agent for converter steel making

A technology of converter steelmaking and flux, which is applied in the field of iron and steel metallurgy, can solve the problems of low slagging efficiency, fluorine pollution, unfavorable early rapid slagging and dephosphorization, etc., to improve dephosphorization and desulfurization capabilities, improve alkalinity and oxidation performance and achieve the effect of waste slag reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The present invention will be further elaborated below in conjunction with embodiment; Embodiment is only used to illustrate the present invention, is not to limit the present invention in any way

[0023] (1) Raw materials

[0024] The raw materials that embodiment adopts are as follows, and when referring to percentage below, all are percentage by weight:

[0025] The chemical composition of spodumene is: Li 2 O 5.0%, Al 2 o 3 19.56%, SiO 2 73.25%, Na 2 O 0.28%, K 2 O 0.22%, MnO 0.04%, TiO 2 0.03%, P 2 o 5 0.11%, CaO 0.06%, and the balance is trace impurities;

[0026] The chemical composition of active lime is: 100%>CaO≥90.0%, 5%≥MgO>0, 2.5%≥SiO 2 >0, the rest include Al 2 o 3 trace impurities;

[0027] Iron oxide is a mixture of rolled steel sheet and sintered ore powder, of which Fe 2 o 3 The quality score is 86%;

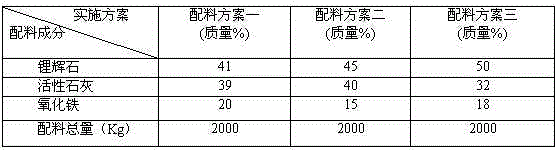

[0028] Take the above-mentioned raw materials and weigh them after baking at 100-150°C, and mix according to the three batching m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com