Feeder for pre-dephosphorization of molten iron in iron-storage tap trough and its pre-dephosphorization method

A technology of tapping trough and feeding machine, applied in the field of molten iron pretreatment, can solve the problems of increasing temperature drop and process time, limited space of blast furnace casting house, and inability to arrange powder spraying system, etc. control, stable dephosphorization effect, and good dephosphorization kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

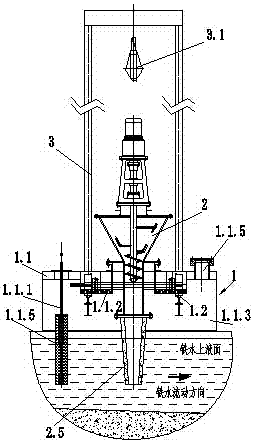

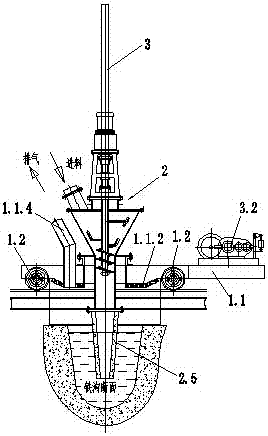

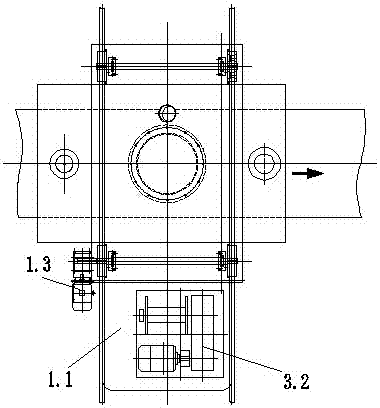

[0026]Embodiment 1: The iron-storage type tap ditch carries out the molten iron pre-dephosphorization feeder, including the electric traveling device 1 that can be placed on the top of the tap ditch and can travel back and forth along the tap ditch, and the feeding device installed on the electric traveling device 1 2. The electric traveling device 1 includes a chassis 1.1, a traveling wheel 1.2, and a deceleration motor 1.3 that drives the traveling wheel 1.2 to move; the feeding device 2 sequentially includes a deceleration motor 2.1, a frame 2.2, and a deceleration motor 2.1 from top to bottom. The rotating shaft 2.3, the conical silo 2.4 and the detachable feeding cone 2.5 at the end of the conical silo 2.4, the rotating shaft 2.3 extends into the conical silo 2.4, and the feeding device 2 is installed vertically with the chassis 1.1 , the conical silo 2.4 passes through the chassis 1.1, and the detachable feeding cone 2.5 extends into the tap ditch iron storage tank to a d...

Embodiment 2

[0027] Embodiment 2: The iron-storage type tap ditch is used for the pre-dephosphorization feeder of molten iron, and the material composition of the detachable feeding cone pipe is as follows: 8~5mm super bauxite 20wt%, 5~3mm mullite 7wt% , 3~1mm mullite 9 wt%, 1~0mm mullite 15wt%, 3~1mm andalusite 5wt%, 1~0mm andalusite 9 wt%, 1~0mm white corundum 10wt%, 100 mesh kyanite 5 wt%, mullite micropowder 10wt%, silica fume micropowder 5 wt%, 70 cement 5 wt%, per 100 parts plus heat-resistant steel fiber 5 wt%, azoformamide 0.005wt%, sodium hexametaphosphate 0.2 wt%, boron glass 0.5 wt%.

Embodiment 3~8

[0028] Embodiment 3~8: with reference to embodiment 1, as shown in the table:

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com