Patents

Literature

51results about How to "Shorten the slag removal time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molten iron slagging-off method

The invention relates to the field of molten iron pretreatment technologies, in particular to a molten iron slagging off method which is characterized in that an inert gas is continuously blown into a liquid iron tank at the farthest end on the slagging-off side at the later period of slagging off. The method comprises the following steps of: (1) carrying out slagging off by using a slagging off machine after iron is molten until the thickness of a slag layer is smaller than 50 mm; (2) stretching a slag blowing pipe 300-400 mm below the level of the molten iron at the farthest end on the slagging off side, and controlling air pressure at 0.6-0.8 MPa and air flow at 15-30 Nm3 / h; and (3) stopping blowing the gas after slagging off is completed. The gas is nitrogen, and the purity is greater than 98%. The invention has the advantages that slag is discharged to the slagging off side and gathered through gas churning, the slagging off time can be obviously shortened and is controlled within 10 min, the sulfur moisture content of a deeply-desulfurized steel grade can be well satisfied, the resulfurization of the melting process is reduced, and simultaneously, the slagging off iron content is reduced.

Owner:ANGANG STEEL CO LTD

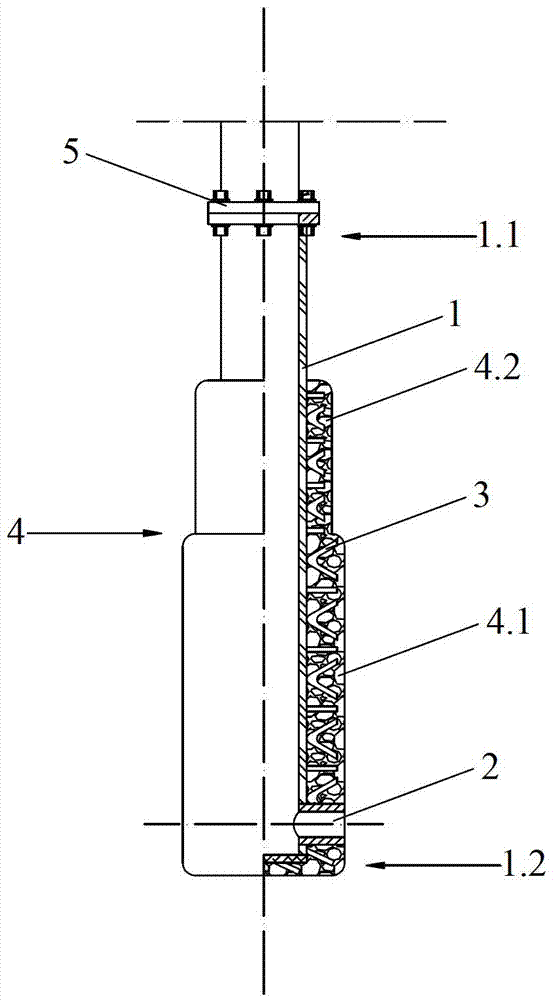

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

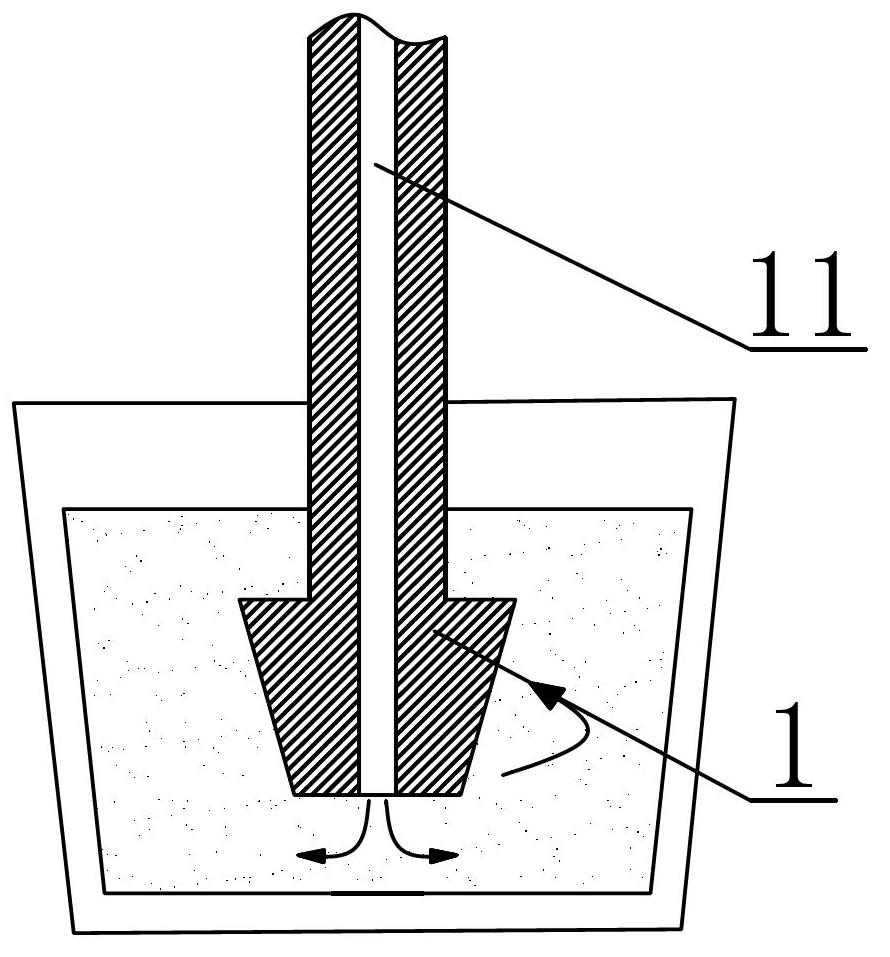

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

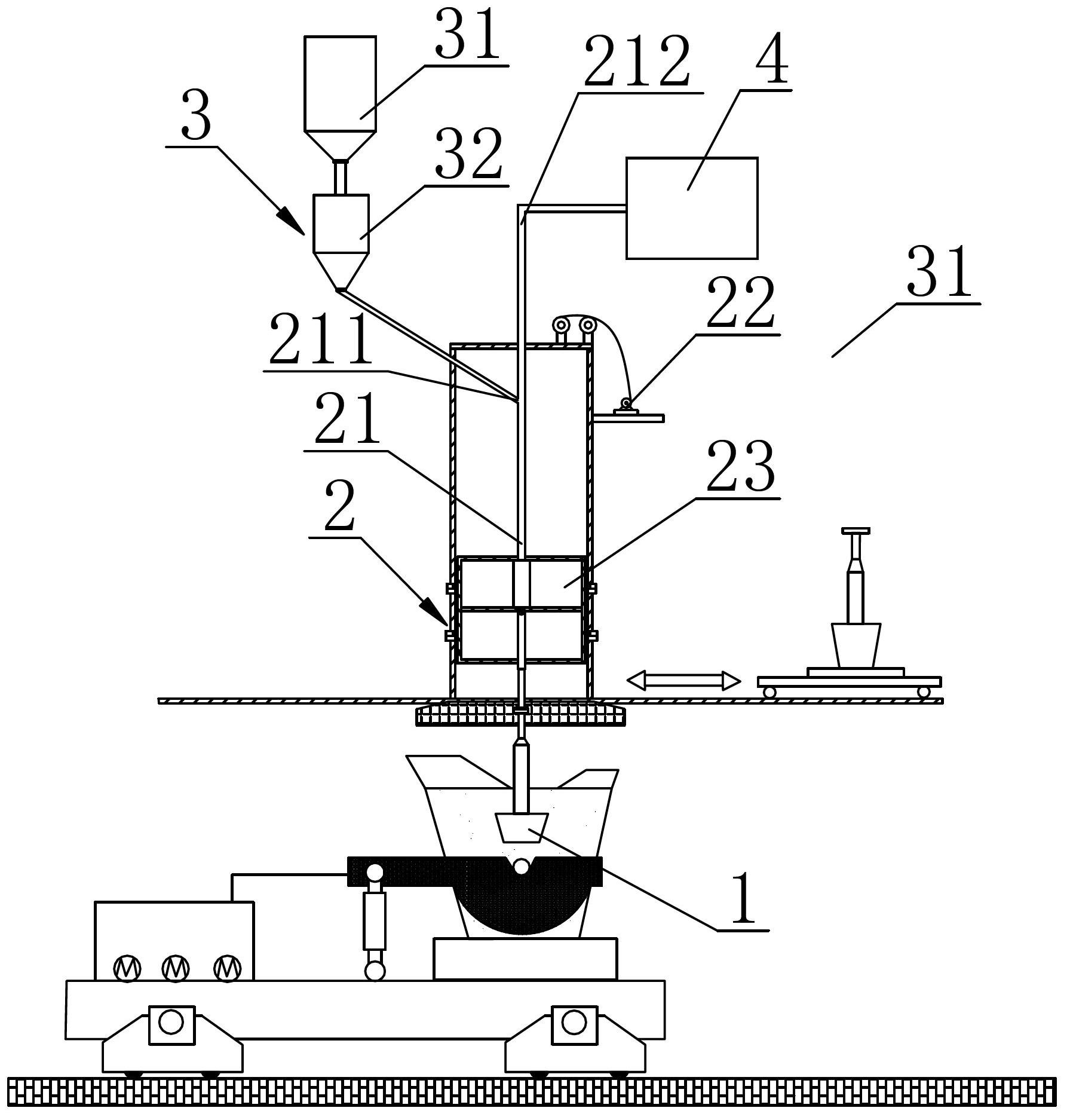

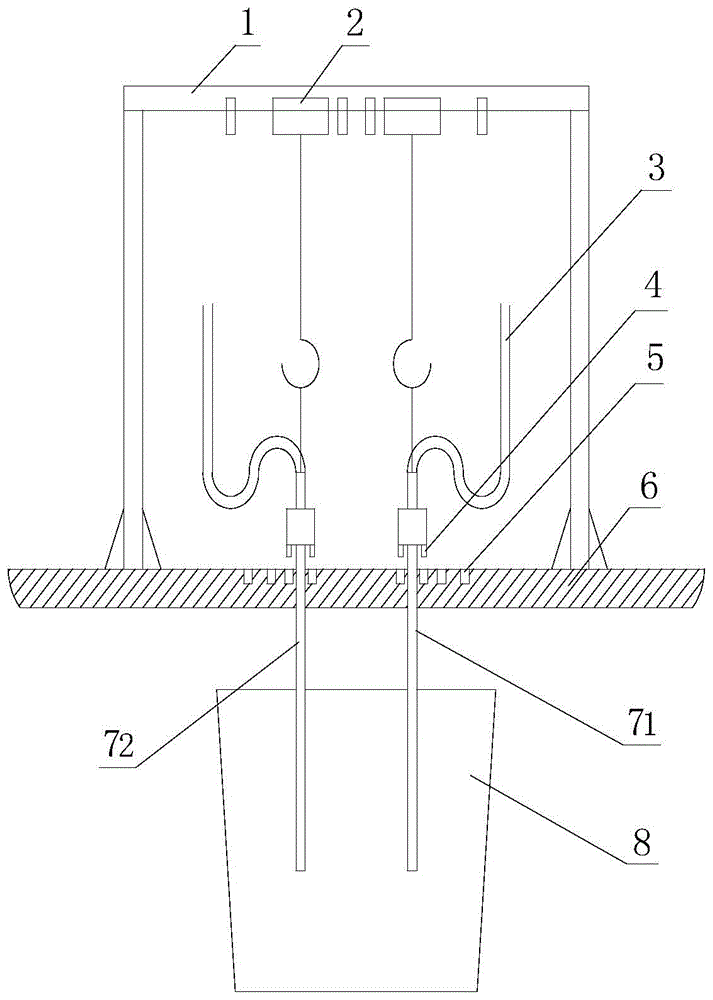

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

InactiveCN102676741AThe desulfurization cycle is shortenedReduced desulfurization working timeGranularityEngineering

The invention relates to a KR (knotted reactor) powder spraying, stirring and desulfurizing device. The KR powder spraying, stirring and desulfurizing device comprises a stirring head and a driving device for controlling the stirring head to act, wherein the driving device comprises a connecting rod linked with the stirring head, a lifting device for driving the connecting rod to move up and down and a stirring motor for driving the connecting rod to rotate. The KR powder spraying, stirring and desulfurizing device is characterized by further comprising a feeding system and a high-pressure gas source, wherein a through hole for introducing high-pressure inert gas and desulfurizing agents is formed on the stirring head, and an inlet of the through hole is communicated with a desulfurizing agent outlet and a high-pressure gas source outlet of the feeding system. The invention further relates to a method for desulfurizing molten iron by using the KR powder spraying, stirring and desulfurizing device. By using the device, efficient, fast and precise desulfurization can be realized, and the effects of reducing the requirements for granularity of desulfurizing agents, reducing the temperature drop and reducing the loss of the stirring head can be achieved.

Owner:ZENITH STEEL GROUP CORP

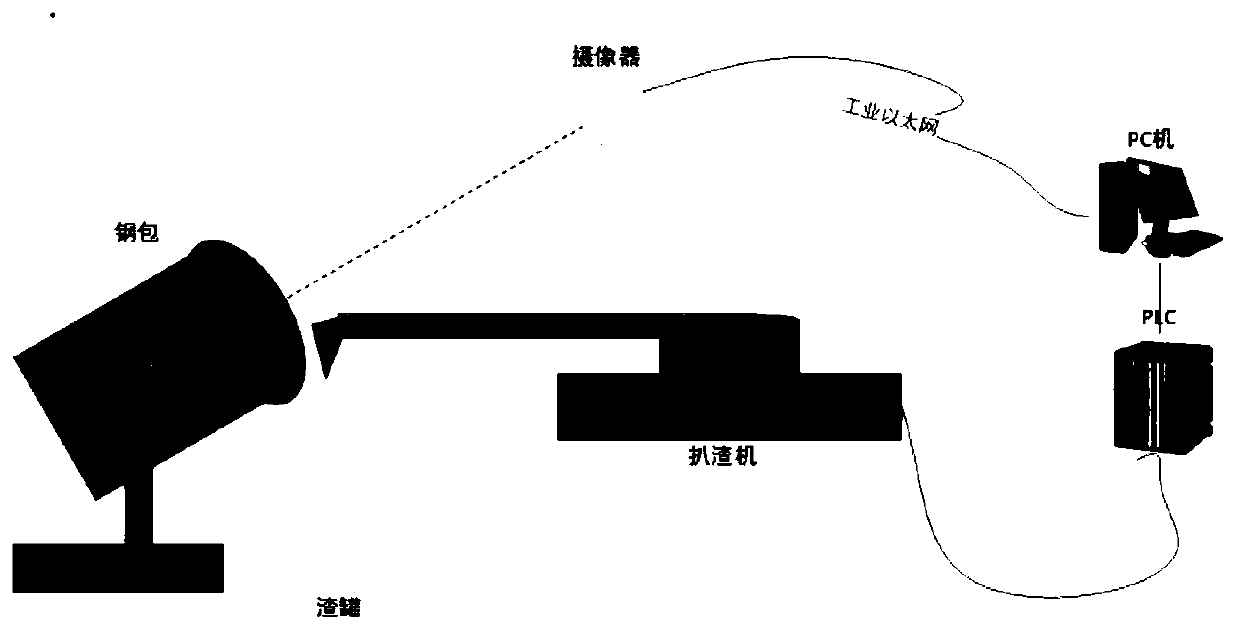

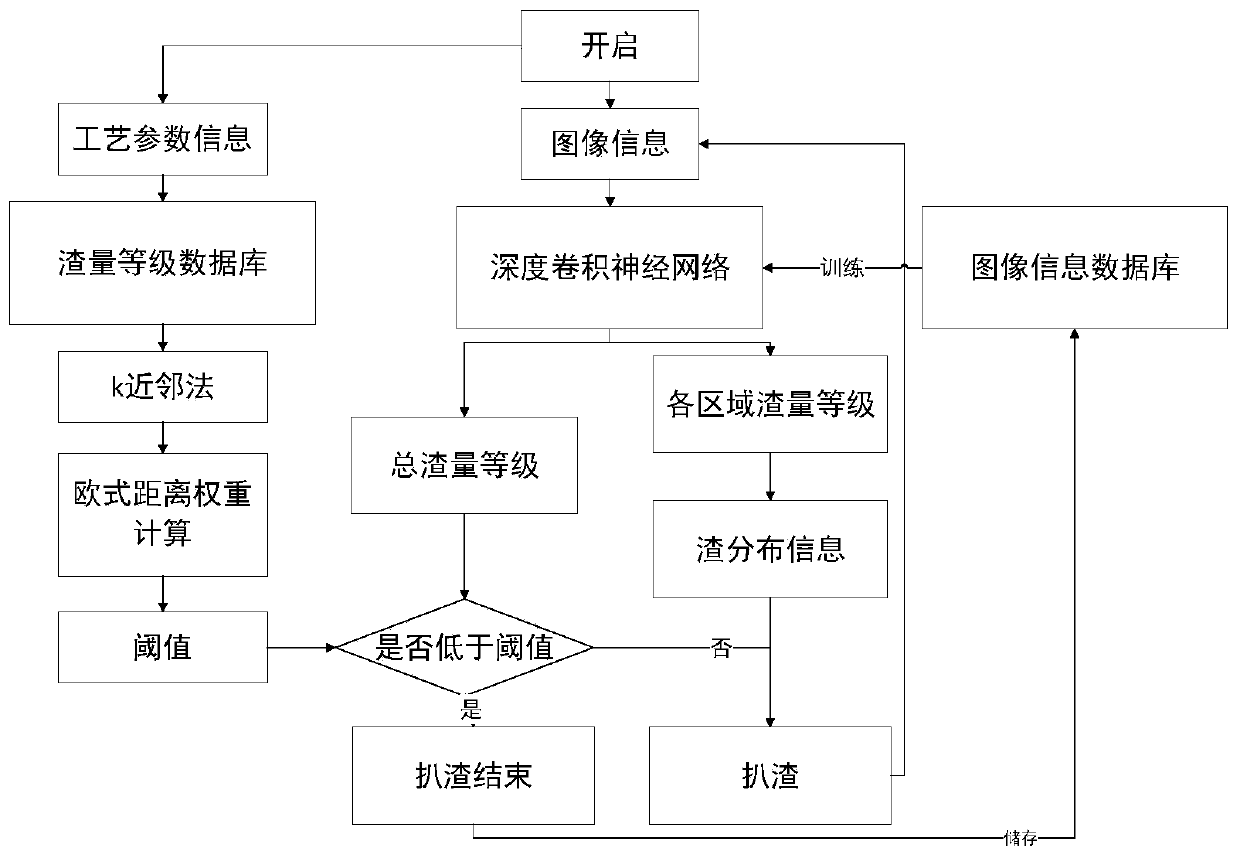

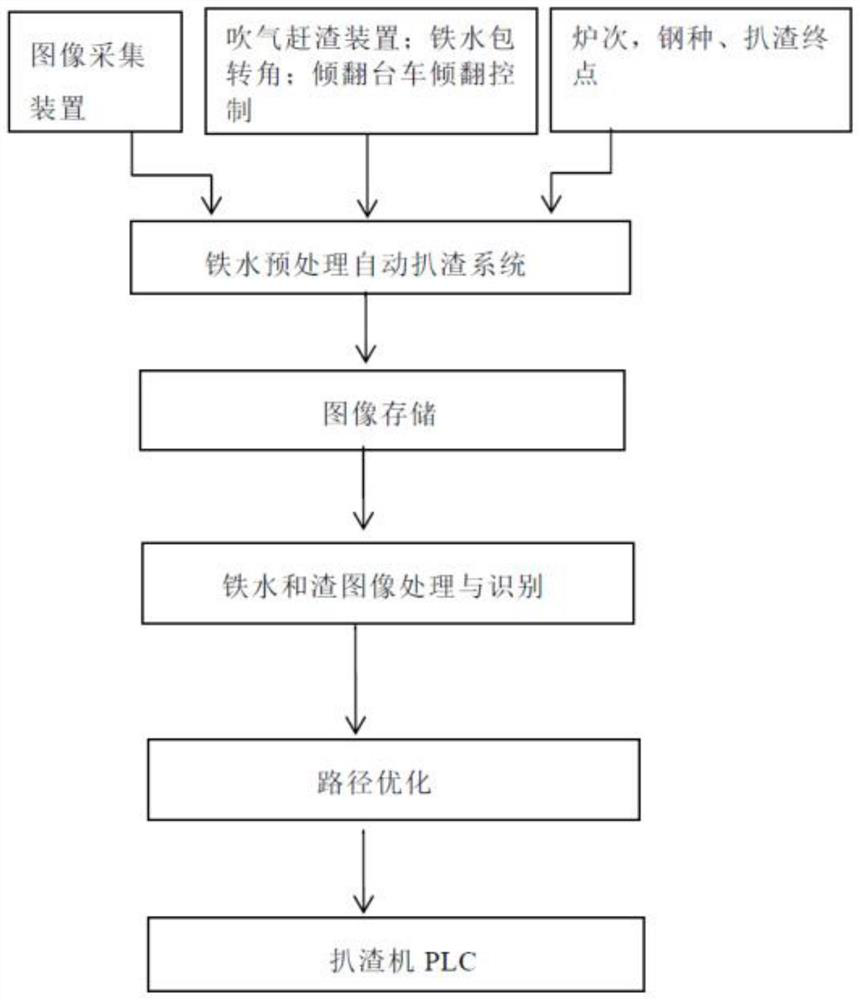

Molten iron automatic slagging-off control method based on deep learning

ActiveCN110781944AImprove robustnessReduce wasteCharacter and pattern recognitionNeural architecturesData setFeature extraction

The invention provides a molten iron automatic slagging-off control method based on deep learning. The method comprises the following steps: performing feature extraction on a collected ladle liquid level image, and manually labeling to obtain a slag quantity grade for constructing a data set of a deep convolutional neural network; establishing a deep convolutional neural network framework, and performing training optimization on the deep convolutional neural network model by using an Adam algorithm to obtain an optimized network model; constructing factor types through factors influencing molten iron desulphurization slag, selecting the factor types to which the slag quantity grade standard belongs through a k-nearest neighbor method, and obtaining deep convolutional neural network modelsof different factor types according to the steps 1 to 3; and determining the overall slag quantity grade according to the corresponding network model output layer data, and making a corresponding slagging-off action through system judgment according to the model output. According to the method, the on-site image information data can be fully mined, the optimal slagging-off process can be calculated, the model robustness is high, the slagging-off time can be effectively shortened, molten iron waste is reduced, and the production benefits of enterprises are improved.

Owner:WISDRI WUHAN AUTOMATION

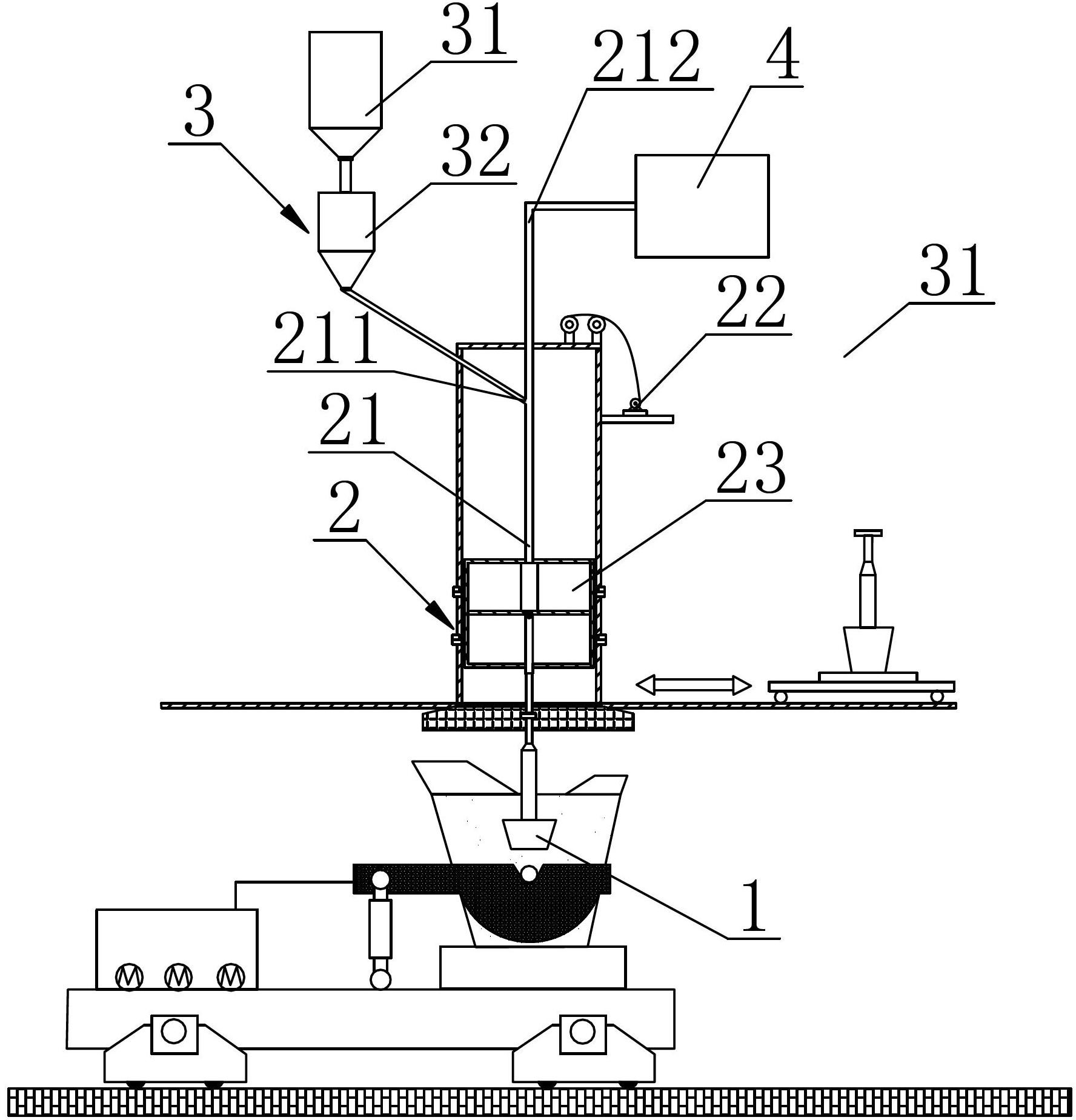

Efficient molten iron pretreatment automatic slagging-off method and system

ActiveCN112017145AReduce temperature dropImprove working environmentImage enhancementImage analysisSlag

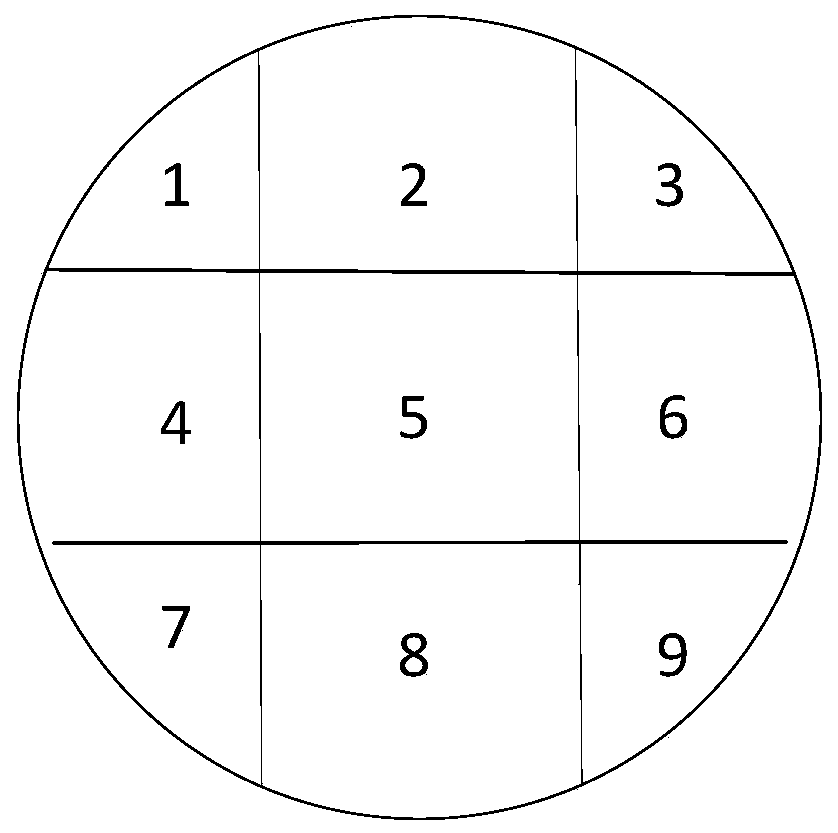

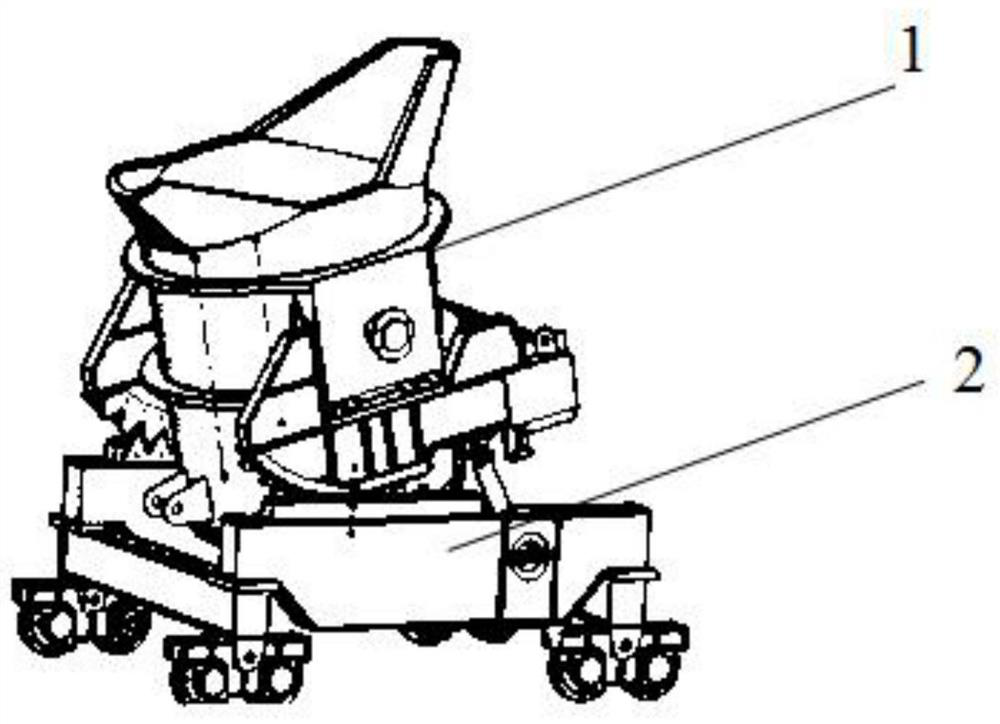

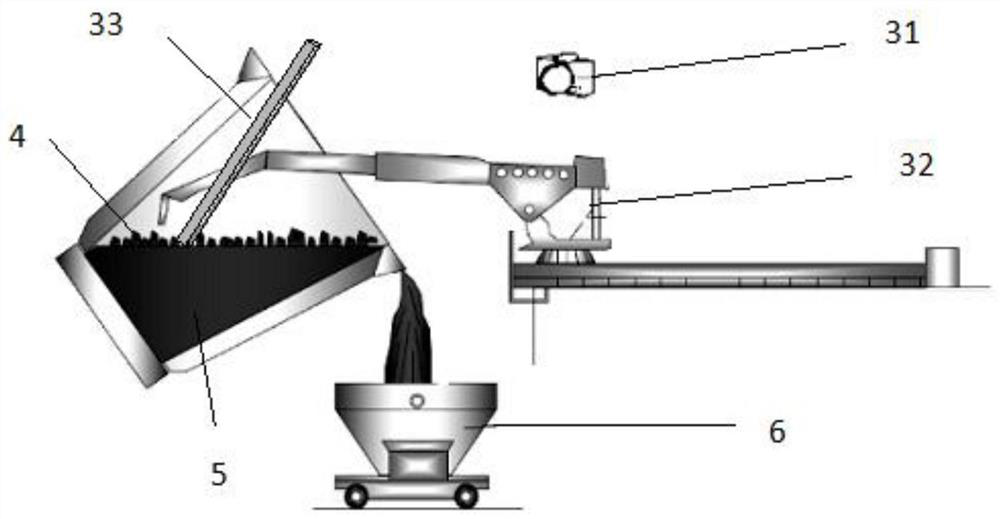

The invention discloses an efficient molten iron pretreatment automatic slagging-off method which comprises the following steps: acquiring an image of a ladle opening area, and preprocessing the image; recognizing the molten iron slag in the image to determine the position of the molten iron slag in the image and the total area proportion of the molten iron slag in the image; based on the positionof the molten iron slag in the image, the optimal slagging-off path is found, and the optimal slagging-off path is the path with the minimum ratio of the slagging-off time to the slagging-off amount;in the automatic slagging-off process, the slagging-off head is controlled to carry out slagging-off according to the optimal slagging-off path; and when the starting condition is met, the air blowing and slag removing device is started to gather the dispersed molten iron slag together so as to facilitate efficient slag removing, and the starting condition is that the total area proportion slag%of the molten iron slag in the image is smaller than a set air blowing and slag removing starting threshold value. In addition, the invention further discloses an efficient molten iron pretreatment automatic slagging-off system.

Owner:BAOSHAN IRON & STEEL CO LTD

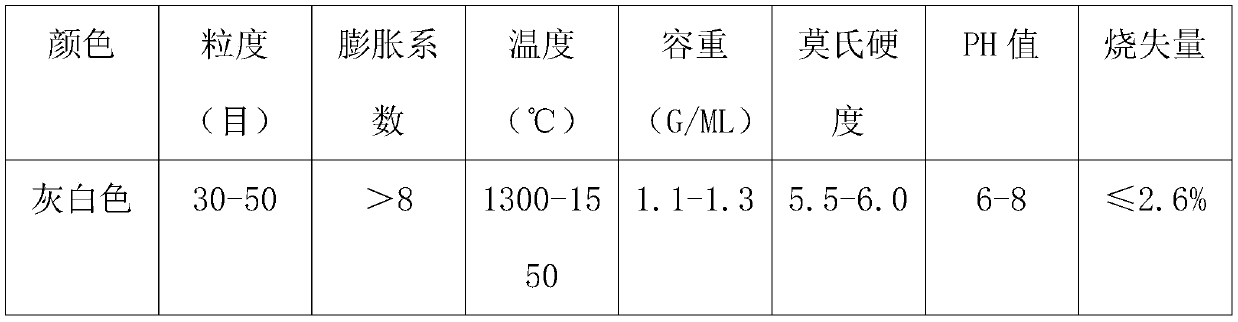

Sulfur-fixing agent for hot metal pretreatment of magnesium injection and deep desulphurization and desulphurization method thereof

InactiveCN101392310AGood ability to absorb sulfur and fix sulfurImproved sulfur absorption and fixation capacitySteelmakingSulfur

The invention relates to a sulfur-fixing agent for hot metal pretreatment magnesium injection deep desulphurization and a desulphurization method, which pertains to the technical field of hot metal pretreatment in the steelmaking process. The sulfur-fixing agent is added before hot metal charging or during hot metal charging in the hot metal pretreatment and the addition range is 2.0 kg / t to 4.0 kg / t iron which contains the following components by the weight percentages: CaO: 68 percent to 90 percent; MgO: 5 percent to 12 percent, SiO2: 1 percent to 5 percent, CaF2: 8 percent to 12 percent, Al2O3: 0 percent to 3 percent, MnO: 0 percent to 2 percent, S: less than 0.025 percent, and P2O5: less than 0.06 percent. The weight percentages of various slagging constituents in the sulfur-fixing agent are as follows: quick lime: 80 percent to 95 percent and fluorite: 5 percent to 20 percent. The sulfur-fixing agent has the advantages that: slag formed by adding the sulfur-fixing agent into the molten iron after magnesium injection has very high sulfur absorption capability, relatively small viscosity and relatively low melting point; after magnesium injection, a slag conglomeration agent is added to cause the slag to conglomerate into blocks which are easy to remove and resulfurization is prevented.

Owner:SHOUGANG CORPORATION

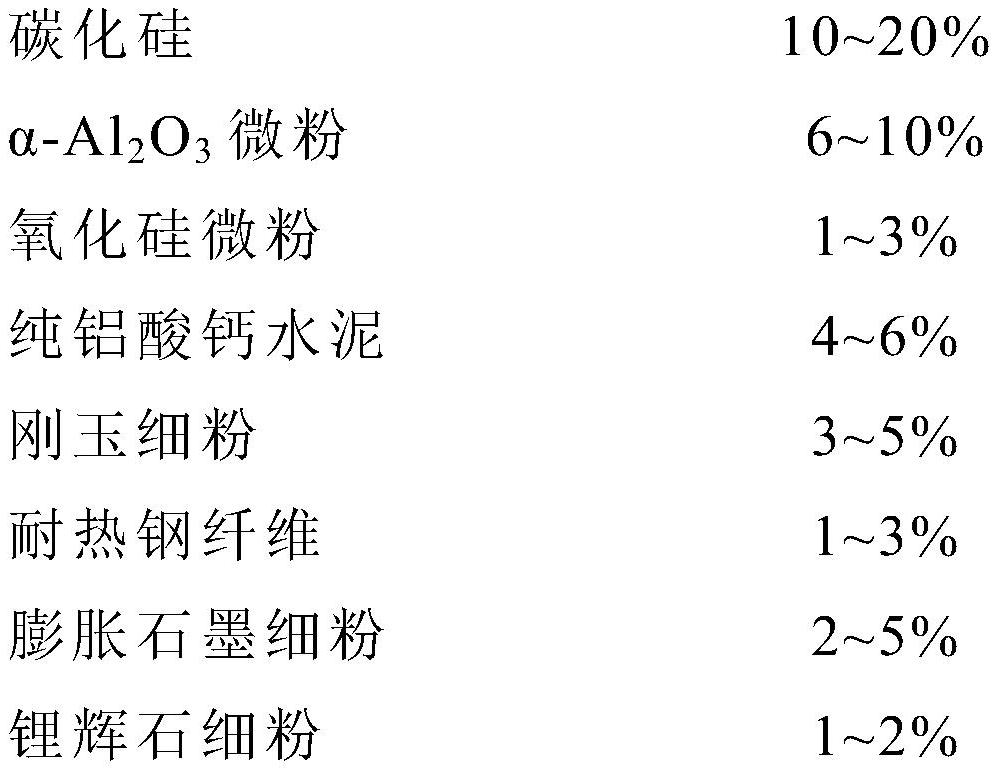

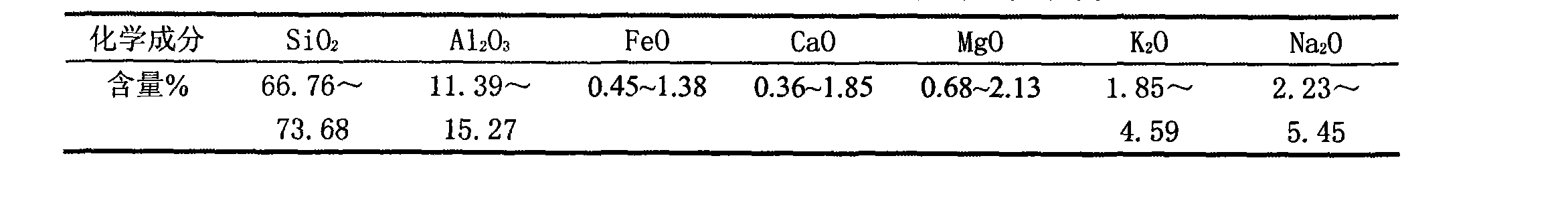

Deslagging agent used for smelting cast iron and preparation method thereof

The invention discloses a deslagging agent used for smelting cast iron and a preparation method thereof. The deslagging agent comprises, by weight, 70%-75.2% of silicon dioxide, 12.1%-15.9% of aluminum oxide, 0.5%-1.9% of ferric oxide, 1.2%-3.22% of sodium oxide, 1.9%-3.84% of potassium oxide, 0.9%-1.48% of calcium oxide, 0.47%-1.46% of magnesium oxide, and the balance iron and inevitable impurities. The deslagging agent used for smelting the cast iron mainly comprises SiO2 and Al2O3 and can instantly expand when sharply heated to the temperature of 1100DEG C or over so as to form a viscous active material of a porous structure, so that molten iron, slag in the molten iron, and impurities can adhere together to be gathered; the deslagging agent has a low heat conductivity coefficient so that heat conduction and thermal radiation on the surface of the molten iron can be effectively reduced, and a heat preservation effect is achieved; and the problems, such as corrosive pits, white spotsand wrinkles, which occur frequently during cast iron machining are solved while the defects are overcome.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

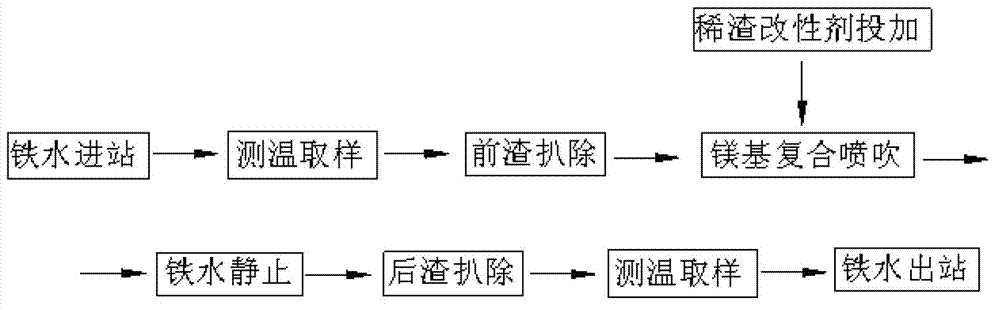

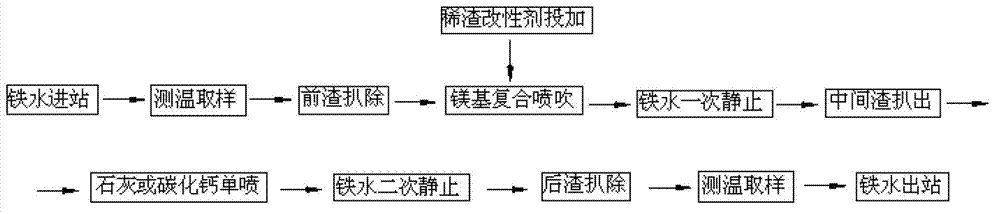

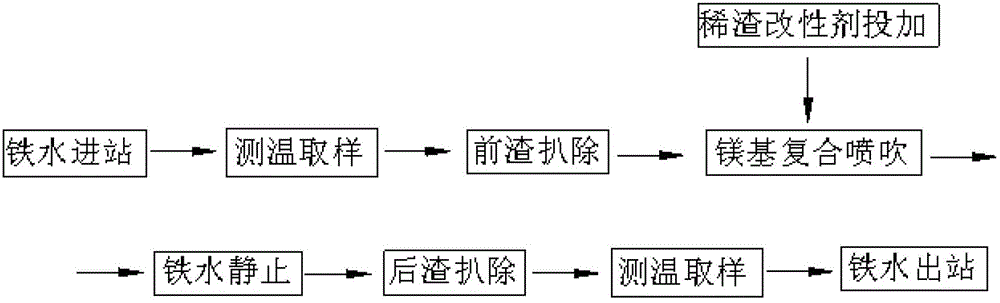

Deep desulfuration method for magnesium-based composite jetted molten iron

The invention discloses a deep desulfuration method for magnesium-based composite jetted molten iron. The deep desulphurization method comprises the following steps of: after the molten iron is fed and subjected to temperature measurement and sampling, scrabbling primary slag before a slag scrabbling station; subsequently desulfurating the molten iron in a magnesium-based composite jetting mode at a jetting and desulfuration station, adding a lean slag modifier in the jetting process and modifying the lean slag of the solid or semi-molten desulfurated slag; subsequently transferring to the slag scrabbling station to carry out primary standing on the molten iron and accomplish middle slag scrabbling; separately jetting lime or calcium carbide at the jetting and desulfuration station so as to carry out deep desulfuration on the molten iron and coagulate and modify residual liquid slag; after the separate jetting, transferring the molten iron tank to the slag scrabbling station to carry out secondary standing on the molten iron and accomplish later slag scrabbling; and after the later slag scrabbling, measuring the temperature, sampling and discharging the molten iron so as to meet the requirements on a molten iron material of a low-sulfur steel. The deep desulfuration method adopts a mode that desulfurated slag of different properties is respectively modified and scrabbled, and has the advantages of simplicity in operation, convenience in application and sufficiency in desulfurated slag modification.

Owner:武汉钢铁有限公司

Molten iron slag removing method

InactiveCN102825248AShorten the slag removal timeImprove the intrinsic and surface quality of steelCasting cleaning apparatusSlagSmelting

The invention provides a molten iron slag removing method. The method comprises the following steps of: controlling the distance between the slag surface of molten iron and the jar edge of a molten iron jar to be greater than 300 mm; inclining the molten iron jar in an angle of 5 DEG to 9.5 DEG by utilizing an iron hook, and enabling the distance between the upper end of the slag surface and the jar edge of the molten iron jar to be 50 to 100 mm; removing slags from the surface of the molten iron in the molten iron jar by utilizing a slag remover after the molten iron is desulfured; adding slag accumulating agents to the molten iron according to the proportion of adding 0.3 to 0.5 kg of the slag accumulating agent to every ton of the molten iron; and after slag removing, adding heat preserving agents according to the proportion of adding 0.3 to 1.2 kg of the heat preserving agent to every ton of the molten iron. According to the invention, the slag removing time is shortened greatly, i.e. the slag removing time is shortened from 10 minutes to 8 minutes; and the slags in the molten iron jar are removed to a maximum extent, i.e. the slag removing rate is improved from 71% to 83%, so that the slag removing loss of the molten iron is lowered by 13.2%. Therefore, the internal quality and the surface quality of steel material are improved, and the smelting cost is lowered.

Owner:ANGANG STEEL CO LTD

Molten iron non-pollution electromagnetic slag conglomeration method

The invention provides a molten iron non-pollution electromagnetic slag conglomeration method. Travelling wave magnetic field slag conglomeration devices, each of which is formed by a coil, an iron core and a shell, is prepared; each shell is internally provided with the corresponding coil; each coil is internally provided with a cooling water pipe and is provided with the corresponding iron corewhich is connected with a two-phase or three-phase alternating current at the middle part; a molten iron tank is inclined to a slag skimming position to prepare slag skimming; the travelling wave magnetic field slag conglomeration devices are put on the two sides of a slag outlet of the molten iron tank respectively to push molten iron to generate a specific circumfluence, and slags, difficultly mechanically eliminated, at corner portions of the molten iron tank are brought to the nearby of the slag outlet of the molten iron tank; and a downward electromagnetic force applied to the molten ironis much larger than an electromagnetic force applied to the slags, so that iron in the slags is separated out to enter the molten iron, and separation of the iron in the slags is realized. The molteniron non-pollution electromagnetic slag conglomeration method provided by the invention can eliminate a slag skimming dead angle, reduces the slag skimming action, shortens the slag skimming time, improves the operation efficiency, promotes separation of the iron and the slags, reduces loss of the molten iron, lowers the production cost and can effectively reduce secondary pollution brought by air blowing, slag skimming and the like.

Owner:ANGANG STEEL CO LTD

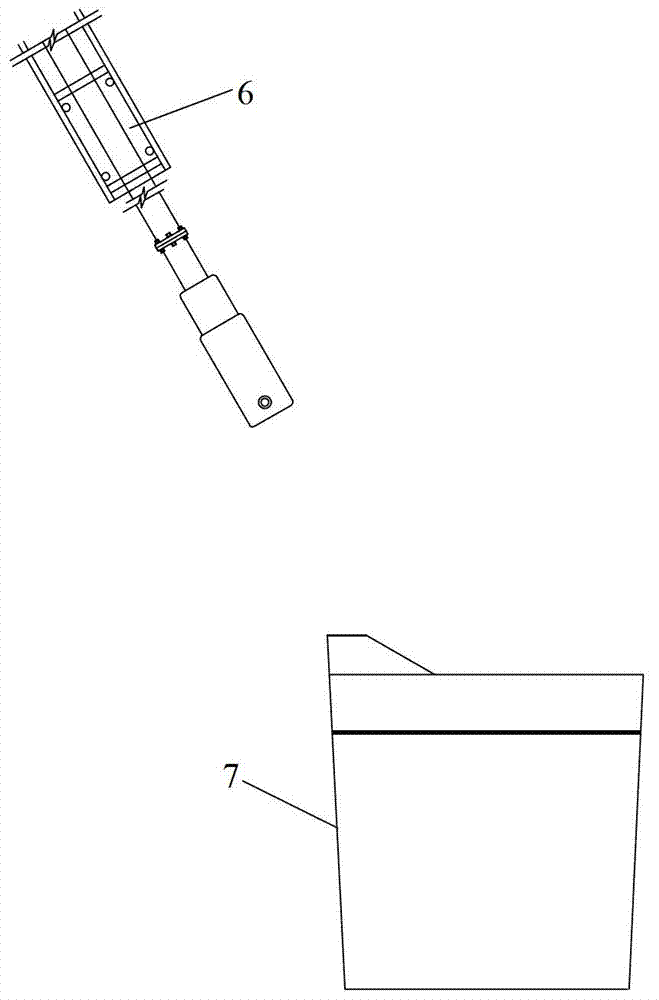

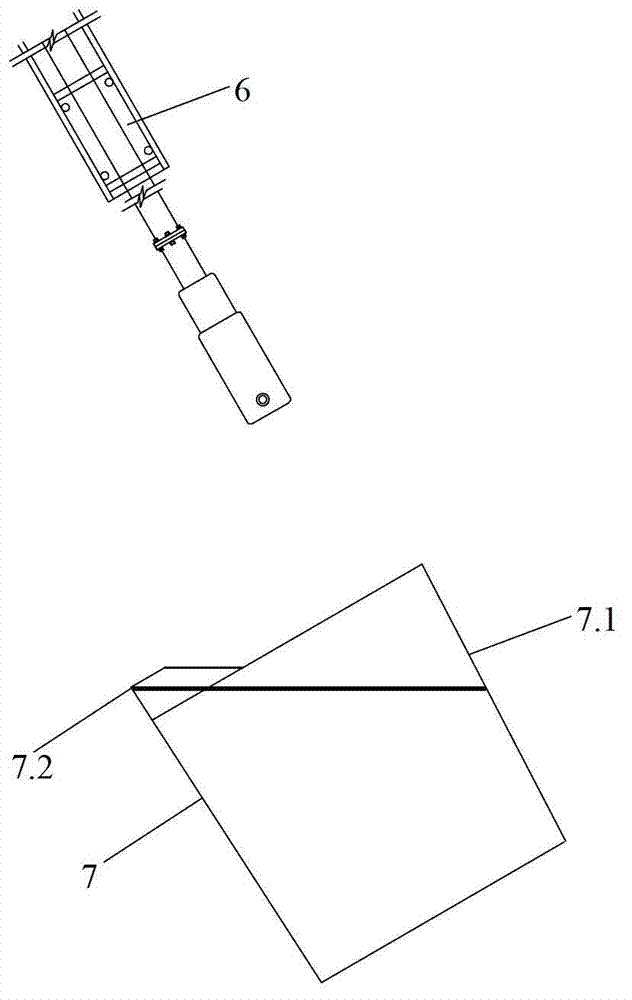

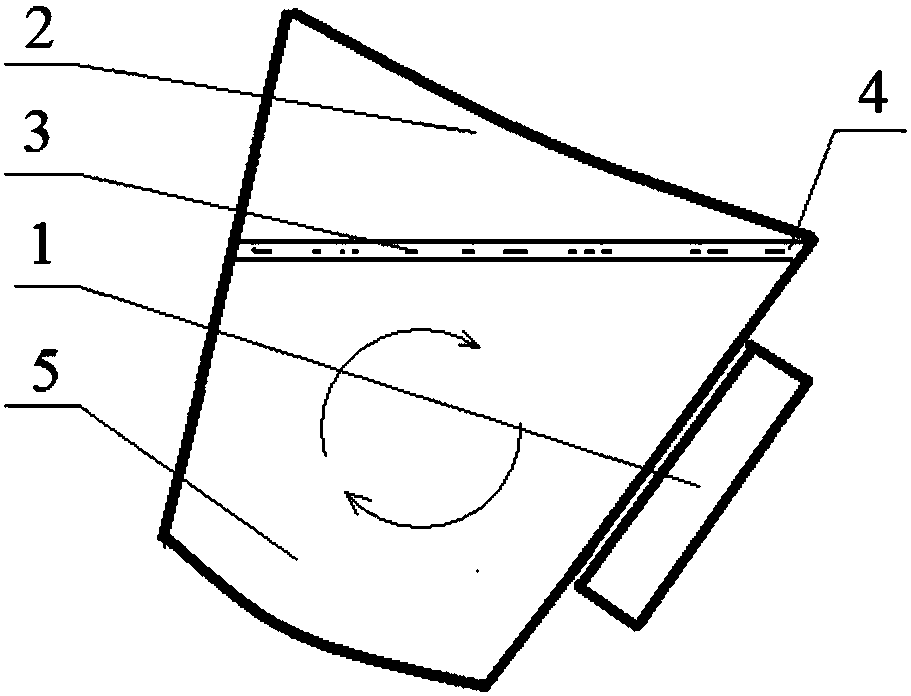

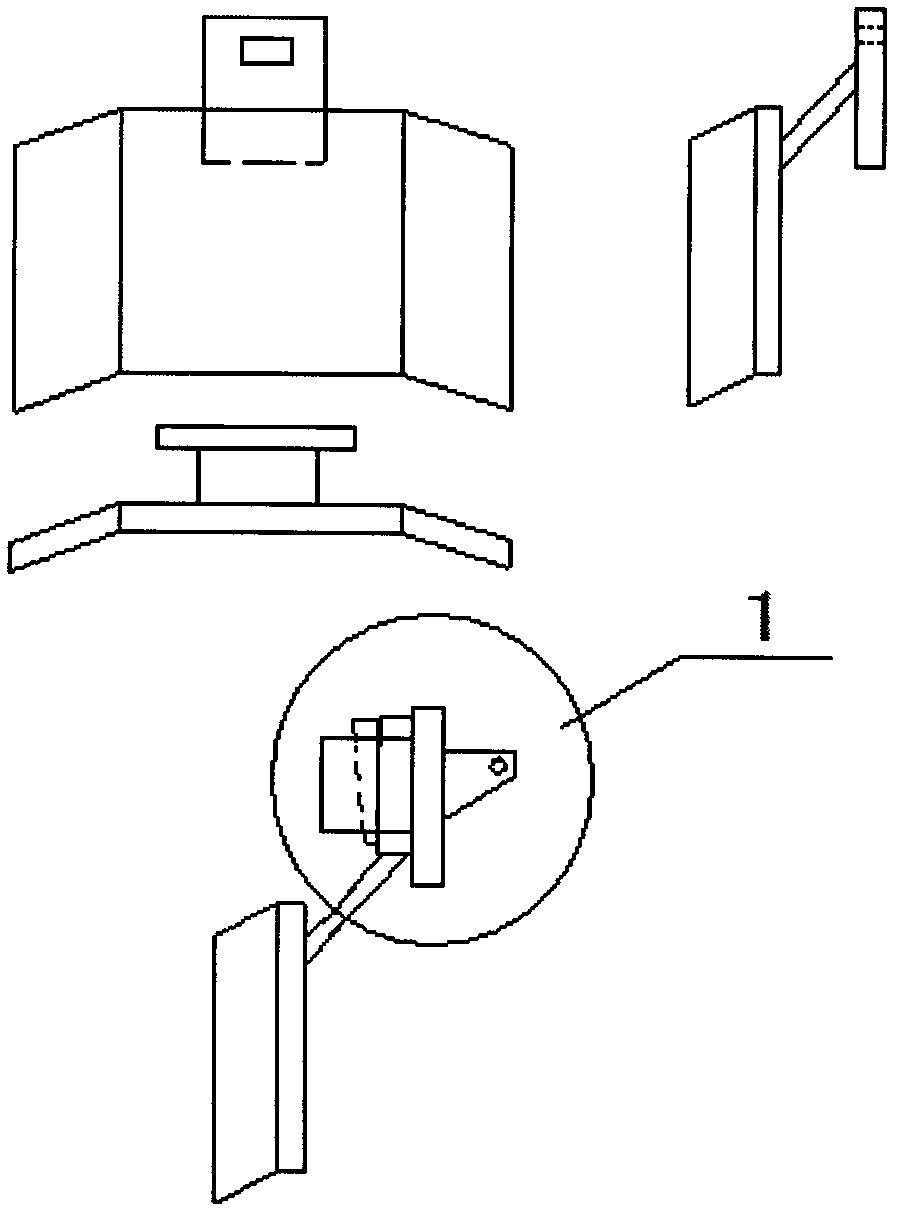

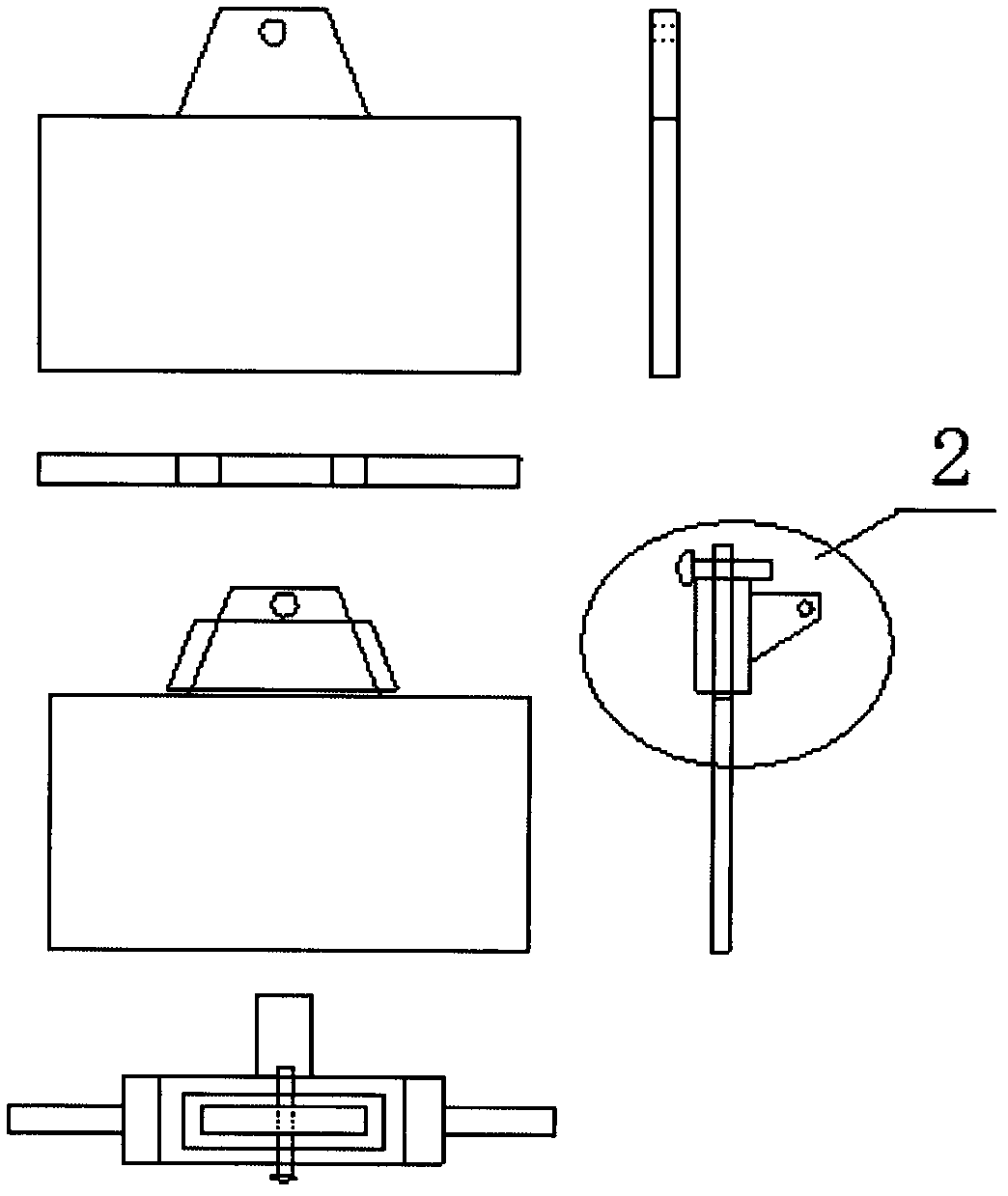

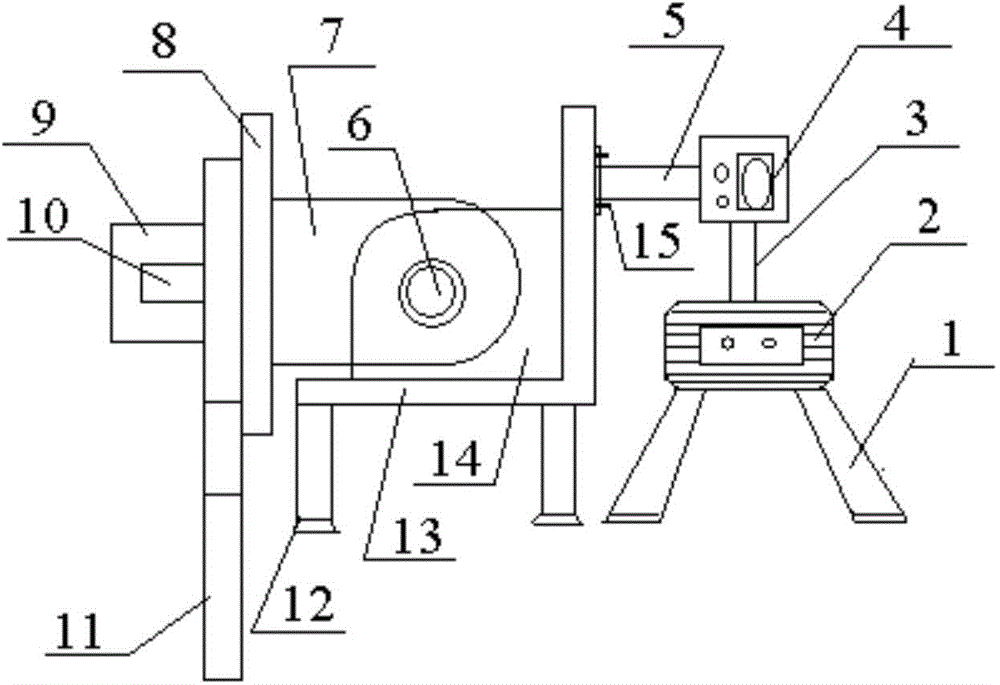

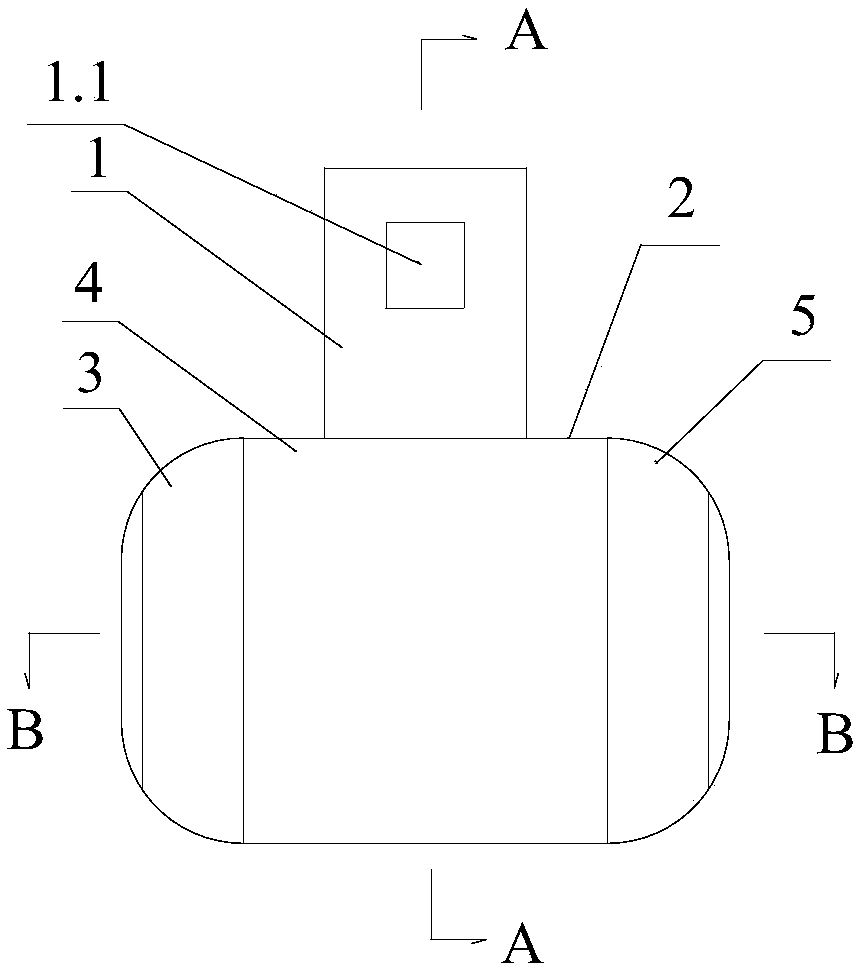

Blow-boiling-type slag gathering device

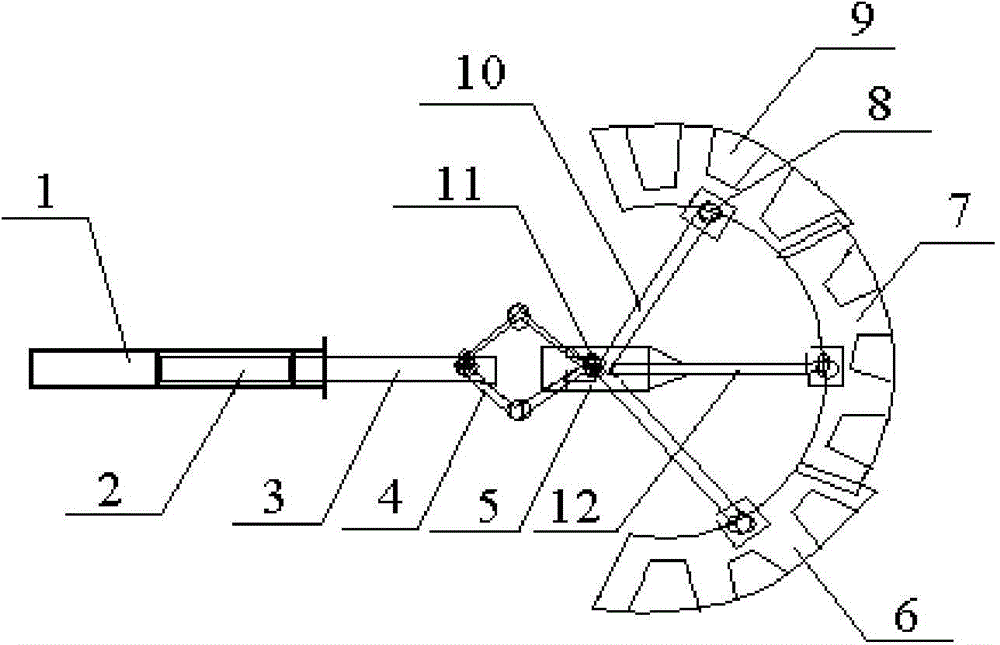

The invention relates to a blow-boiling-type slag gathering device which is characterized by comprising a frame (5), a first driving device (6), a swing arm (3), a connecting rod (4), a control arm (2) and an air injection gun (1), wherein the connecting rod (4) is hinged on the frame (5); the first driving device (6) is fixed on the frame (5); the first driving device (6) is used for driving the swing arm (3) to rotate; two ends of the control arm (2) are respectively hinged with the connecting rod (4) and the swing arm (3); the frame (5), the swing arm (3), the connecting rod (4) and the control arm (2) form a four-rod mechanism; and the air injection gun (1) is fixedly connected with the control arm (2).

Owner:武汉榕盛科发冶金机械设备制造有限公司

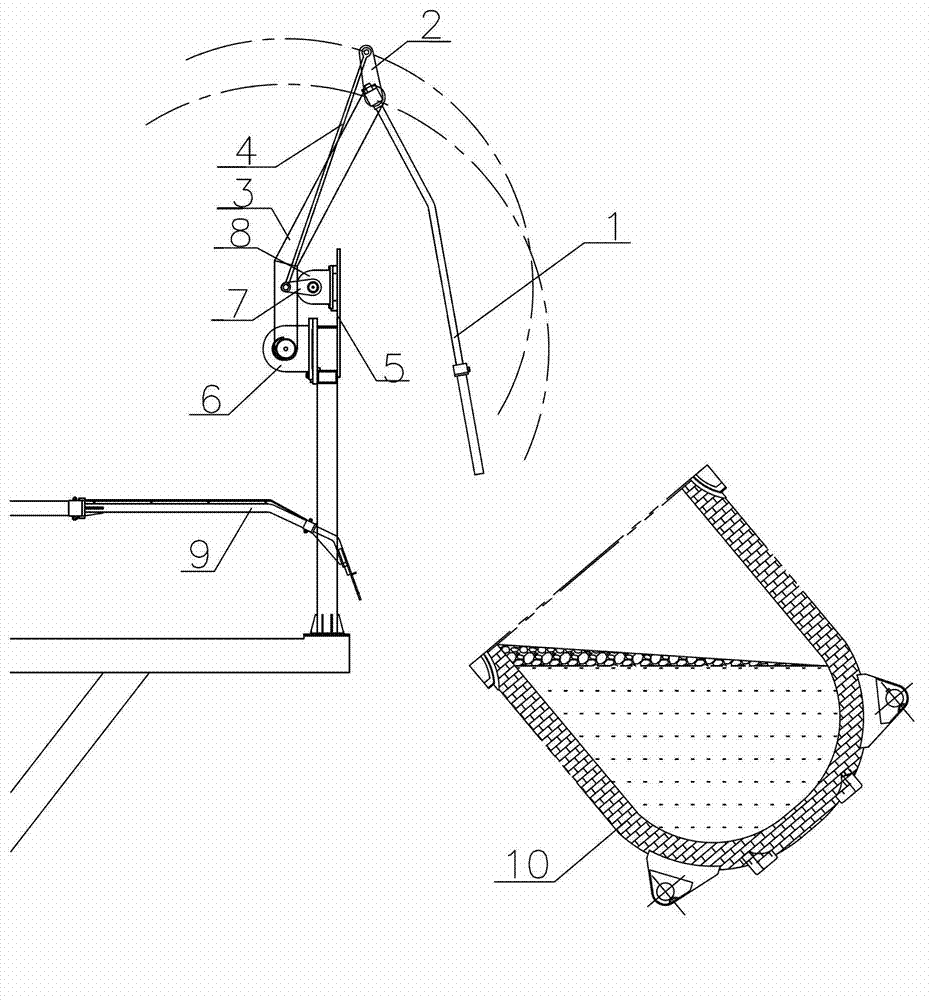

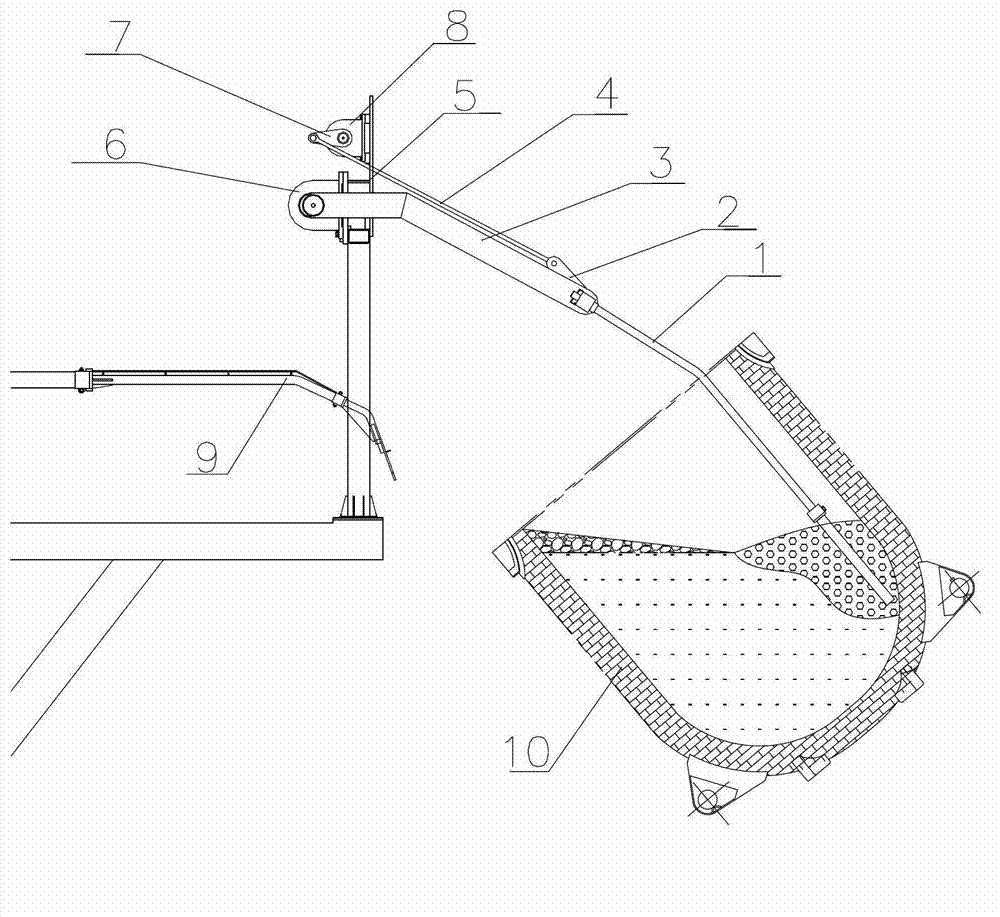

Surging molten iron slag-off method

ActiveCN105296709ASolve the deflection problemSimple mechanical structureCasting cleaning apparatusProcess efficiency improvementSlagInsertion depth

The invention provides a surging molten iron slag-off method. Two air injection guns are perpendicularly inserted into molten iron from the top of a molten iron tank. The interval between the two guns is 1 / 2 of the radius of a tank opening, the insertion positions are located at the points 1 / 2 of the radius of the tank opening, and the insertion depth ranges from 0.5 m to 2.5 m; the air supply intensity is controlled to be larger than or equal to 2 NL / (min t) and the pressure is larger than 0.7 MPa; the air supply intensity of the air injection gun A is controlled to be 2 NL / (min t), the air supply intensity of the air injection gun B is gradually increased till the molten iron boiling exposed face makes contact with the wall of the molten iron tank, the air supply intensity of the air injection gun A is adjusted to be the same as that of the air injection gun B till the area of the molten iron boiling exposed face is larger than 1 / 2 of the tank opening of the molten iron tank, and therefore slag-off operation is started; after slag-off operation is finished, the air injection guns are pulled out of the molten iron and inject air continuously for over 30 s; and hoist cranes are used for lifting the air injection guns, so that locating pins are away from locating holes from 190 mm to 210 mm, the hoist cranes are transversely moved till the interval between the two guns reaches the length of the radius of the tank opening and then the hoist cranes fall, and the locating pins fall into new locating holes. By the adoption of the surging molten iron slag-off method, slag-off time can be shortened and iron loss and the converter resulfurization amount generated in the desulfuration slag-off process can be effectively reduced.

Owner:ANGANG STEEL CO LTD

Novel dross removal head

The invention provides a novel dross removal head. The novel dross removal head comprises a base, movable dross removal plates, a fixed dross removal plate and a hydraulic cylinder. The hydraulic cylinder is located in a stretchable arm and connected with a push-pull rod, the base is connected with the push-pull rod through hinged rods, the movable dross removal plates and the fixed dross removal plate are arranged on the base, the movable dross removal plates are connected with the base through movable supporting arms, the fixed dross removal plate is connected with the base through a fixed supporting arm, the movable dross removal plates and the fixed dross removal plate are connected with the movable supporting arms and the fixed supporting arm through wedge pieces, the hinged rods, the movable supporting arms, the fixed supporting arm and the base are connected together through a main shaft, and the movable dross removal plates and fixed dross removal plate are provided with grooves. The novel dross removal head is reasonable in structure, simple in design and convenient to operate; the working efficiency is improved, time is shortened, heat losses of solutions in the process and the solutions taken out during dross removing are reduced, the frequency is increased, yield is increased, cost is reduced, energy resources are saved, and the service life is prolonged.

Owner:天津吉泰空调通风设备有限公司

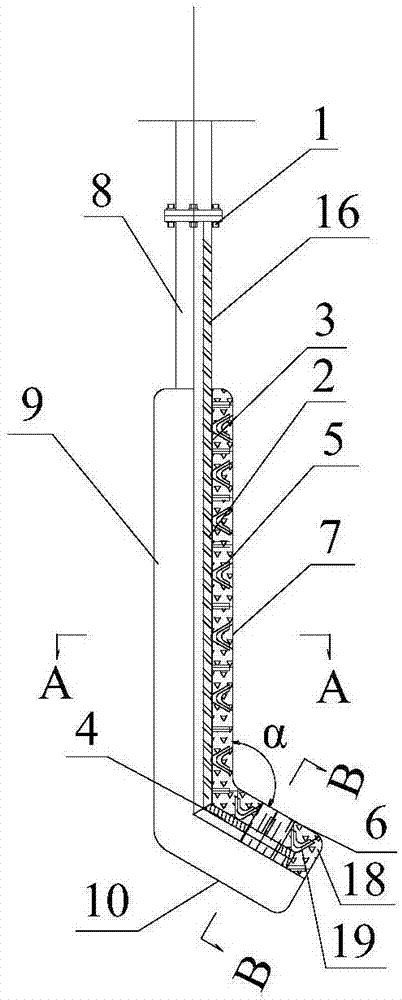

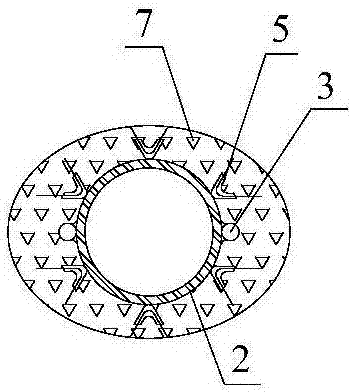

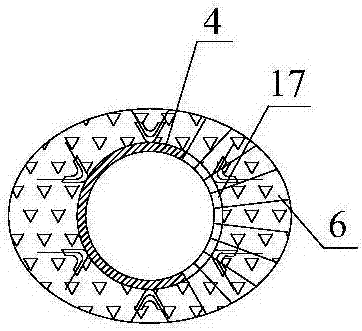

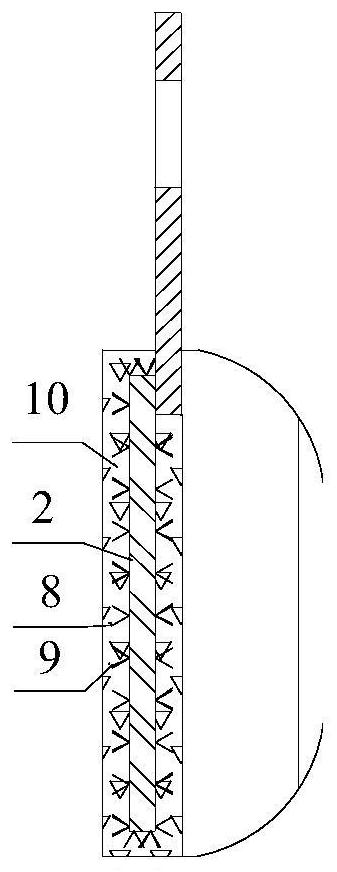

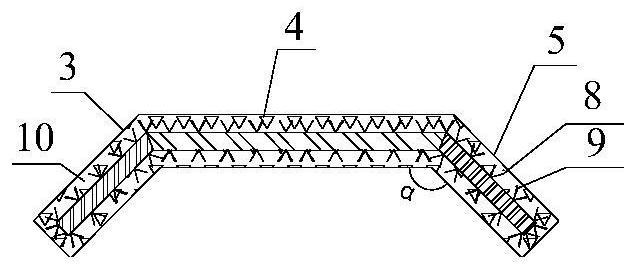

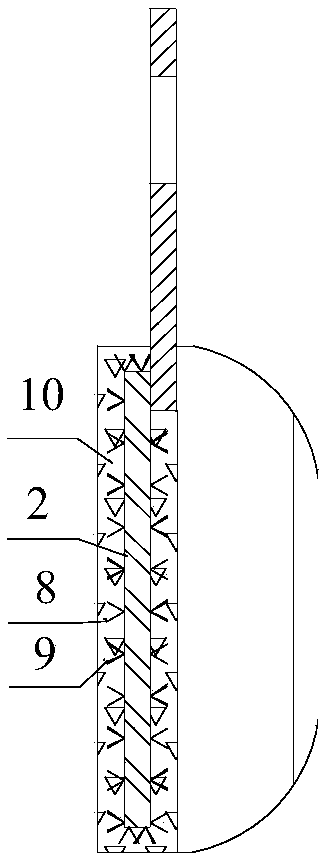

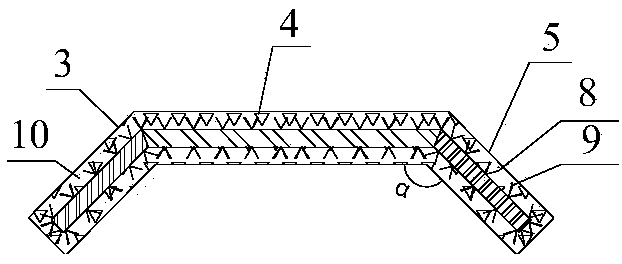

Top oblique insert type spray gun, preparation method and using method for air blowing slag accretion

The invention discloses a top oblique insert type spray gun for air blowing slag accretion. A connecting section comprises a metal connecting pipe and a connecting part, a gun body section comprises a metal main pipe, a gun body section refractory castable lining and a gun body section V-shaped anchoring part, and a nozzle section comprises a metal spray pipe, a nozzle section refractory castable lining and a nozzle section V-shaped anchoring part. The metal spray pipe and the metal main pipe are in welded communication, and an included angle alpha formed by the metal spray pipe and the metal main pipe is greater than 0 degree and less than 180 degrees. A diffuse type nozzle facing to the molten iron surface during air blowing is arranged in the nozzle section refractory castable lining, and a through hole which corresponds to the diffuse type nozzle and communicates with the diffuse type nozzle in the radial direction is formed in the side wall of the upper half portion of the metal spray pipe in the radial direction. Advantages of the top gun air blowing auxiliary deslagging technology and advantages of the molten iron jar air brick ventilation auxiliary deslagging technology are highly gathered, all kinds of disadvantages existing in conventional top gun air blowing or air brick ventilation are fully overcome, and the comprehensive purposes of reducing deslagging iron losses, shortening deslagging time, prolonging the service life of a molten iron jar and the air blowing slag accretion spray gun and lowering deslagging process cost are realized.

Owner:武汉钢铁有限公司

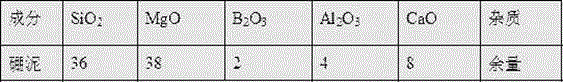

Ladle slag conglomeration agent prepared by boric sludge

The invention relates to the technical field of ferrous metallurgy, in particular to a ladle slag conglomeration agent prepared by boric sludge. The slag conglomeration agent is made of raw materials including, in weight percent, 50%-65% of boric sludge, 30%-40% of silica and 5%-10% of emery powder. A preparation method of the slag conglomeration agent mainly includes the steps of grinding, distributing, blending and pelleting. The ladle slag conglomeration agent is added into a ladle slag layer before slag removal and after powder injection desulfurization pretreatment is performed in a ladle, the agglomeration performance of desulfurization slag can be effectively improved, slag collection and slag removal efficiency is increased, slag removal frequency is decreased, slag removal time is shortened, slag removal iron loss can be reduced, molten iron backflow is decreased, desulfurization effects are ensured, and the ladle slag conglomeration agent has remarkable economic and social benefits and is worthy of popularization.

Owner:江阴智产汇知识产权运营有限公司

Molten iron pretreatment slag skimming process

The invention relates to a slag-raking technology of pre-treatment for molten iron, belonging to the refining field of pig iron. The invention is characterized in that: the slag-raking technology of pre-treatment for molten iron comprises the following steps: compressed air with the pressure 0.6MPa is blown by a blowing device, when the compressed air reaches 2 meters under the liquid level of the molten iron in the ladle, the air rises up to turn over the molten iron, thus generating boiling surface on the liquid level of the molten iron, due to the generation of the boiling surface of the molten iron, the initial state of the molten iron slag remained on the surface of the ladle is changed, for instance, the boiling surface of the molten iron extrudes the molten iron slag, resulting in polymerization of the molten iron slag. The invention can remove dead space of slag-raking, reduce actions of slag-raking, shorten time of slag-raking, improve work efficiency, reduce loss of the molten iron, and lower the production cost. A ladle with air brick internally mounted or externally mounted is the ideal facility for the pre-treatment of the molten iron.

Owner:吴兴伟

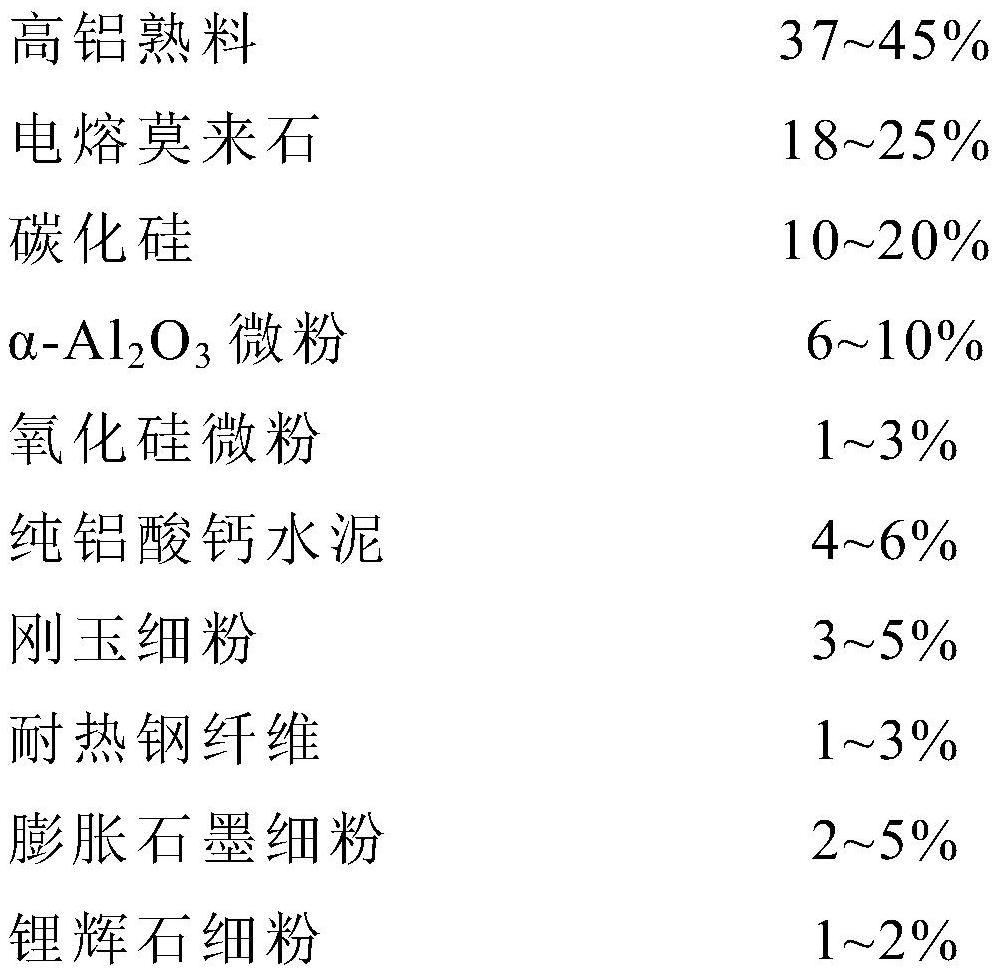

Slag-adhesion-preventing refractory castable for molten iron composite slagging-off plate, and preparation method and use method of slag-adhesion-preventing refractory castable

ActiveCN113105256AImprove high temperature resistanceImproved thermal shock stabilityCasting cleaning apparatusProcess efficiency improvementCarbon filmPolyvinyl alcohol

The invention discloses a slag-adhesion-preventing refractory castable for a molten iron composite slagging-off plate, and a preparation method and a use method of the slag-adhesion-preventing refractory castable, wherein the anti-sticking slag refractory castable comprises 37-45% of high alumina clinker, 18-25% of electro-fused mullite, 10-20% of silicon carbide, 6-10% of alpha-Al2O3 micro powder, 1-3% of silicon oxide micro powder, 4-6% of pure calcium aluminate cement, 3-5% of corundum fine powder, 1-3% of heat-resistant steel fibers, 2-5% of expanded graphite fine powder, and 1-2% of spodumene fine powder. Auxiliary raw materials comprise an antioxidant, polyvinyl alcohol explosion-proof fibers and a water reducing agent, and the surface of the corundum fine powder is coated with a nano carbon film; the comprehensive purposes of prolonging the service life of the composite slagging-off plate, preventing slag from adhering to a refractory material lining of the slagging-off plate, improving the slagging-off efficiency, shortening the slagging-off time, reducing the slagging-off iron loss, avoiding the labor intensity of manual cleaning of adhered slag of the conventional composite slagging-off plate, simplifying the slagging-off operation and the like are achieved.

Owner:武汉钢铁有限公司

Molten iron pretreatment slag collecting agent

InactiveCN101372722AThe desulfurization rate has no effect onNo pollutionCasting cleaning apparatusSlagPre treatment

The invention discloses a slag-collecting agent of pre-treatment for molten iron, containing the following raw materials by weight percentage: 60-80 parts of perlite, 5-15 parts of potassium-sodium feldspar and 10-20 parts of white sand. Compared with the traditional technique, the invention has the advantages as follows: 1 the time of slag-raking is short, after the slag-collecting agent is added, the process furnace is slagged totally with good effect of slagging, slag appears big block to rake easily and completely; the time of slag-raking is 1 / 3 times that of slag-raking without the slag-collecting agent, the slag is completely raked, the quantity of slag in the molten iron is decreased, thus efficiently improving the condition of the molten iron entering furnace; 2 iron loss is little, after the slag-collecting agent is added, the iron loss of the iron slag is reduced from average 6.25kg iron per ton to below 1kg iron per ton; 3 the desulfurization degree of the molten iron is not influenced; 4 As the agent causes no pollution to environment in used, and is of no toxicity, no dust, no smell, convenient operation, wide source of materials and low cost, the requirements of steel plants can be fully met.

Owner:凯蒂(信阳)新型材料有限公司

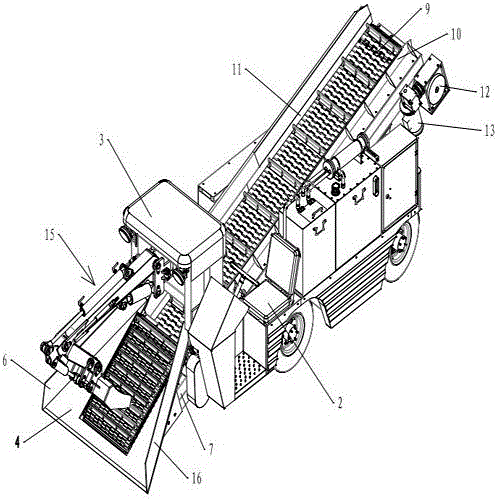

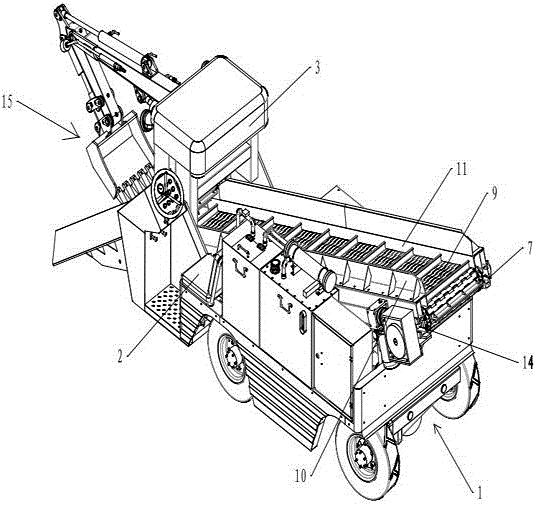

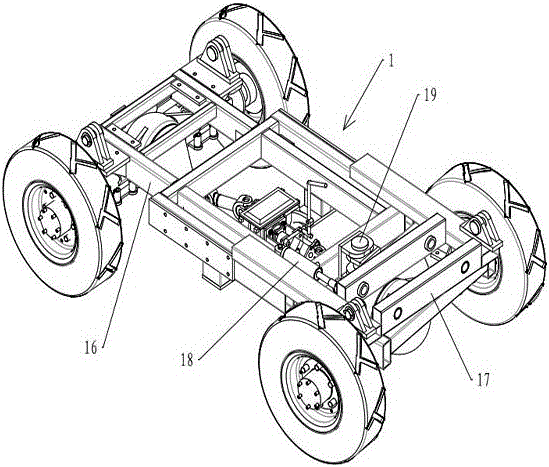

Mining gravel hoeing and conveying integrated machine

ActiveCN106006064AReduce labor intensityReduce the difficulty of operationLoading/unloadingMechanical conveyorsMining engineeringMachine

A mining gravel hoeing and conveying integrated machine comprises a plurality of wheels, a hoeing machine chassis, a wheel driving system and a cab. A portal frame is mounted above the front portion of the hoeing machine chassis, a gravel conveying system is mounted on the hoeing machine chassis in the front-back direction and comprises a rack arranged front and back, the middle of the bottom end of the rack is hinged to the top end of the front portion of the hoeing machine chassis, and the rear portion of the bottom end of the rack is hinged to a piston rod of a lifting oil cylinder. The bottom of a cylinder body of the lifting oil cylinder is hinged to the top end of the rear portion of the hoeing machine chassis, a main conveyor is mounted on the rear middle portion of the upper portion of the rack and comprises an annular main conveying belt arranged in the front-back direction, a left separation plate is arranged on the left side of the main conveying belt, and a right separation plate is arranged on the right side of the main conveying belt. According to the mining gravel hoeing and conveying integrated machine, the aims of lowering the labor intensity of workers, relieving the operation difficulty for the workers and improving the production efficiency are achieved.

Owner:烟台智联科创矿山设备有限公司

High-efficiency slag removal plate for hot metal slag removal

ActiveCN109676121BExtended service lifeEasy and economical to makeCasting cleaning apparatusRecycling and recovery technologiesBoard structureMetal

Owner:武汉钢铁有限公司

Slag conglomeration agent for hot metal pretreatment of magnesium injection and deep desulphurization and use method thereof

The invention relates to a slag conglomeration agent applied to hot metal pretreatment magnesium injection deep desulphurization and an application method thereof, which pertain to the technical field of hot metal pretreatment in the steelmaking process. The slag conglomeration agent is sealed and packaged at 3kg to 7kg after magnesium injection or scattered on the slag surface evenly in the formof particulate. The addition amount is 0.5 kg / t to 1.0kg / t iron which contains the following components by the weight percentages: MgO: 32 percent to 40 percent, SiO2: 0.4 percent to 1.1 percent, S: 0.010 percent to 0.025 percent, water: 0 percent to 0.5 percent, and the rest is CaO and inevitable impurities. The weight percentages of various slagging constituents in the slag conglomeration agentare as follows: light-burned dolomite: 85 percent to 100 percent, and quick lime: 0 percent to 15 percent. The slag conglomeration agent has the advantages that: the slag conglomeration agent can be added immediately after magnesium injection to cause slag to form into blocks which are easy to remove, and resulfurization is prevented by adding acid slag conglomeration agent that is generally adopted.

Owner:SHOUGANG CORPORATION

Novel desulfuration slag rake

InactiveCN103157786AQuality improvementReduce manufacturing costCharge manipulationCasting cleaning apparatusSlagUltimate tensile strength

The invention provides an integrated desulfuration slag rake, wherein manufacturing of an original slag rake is simplified, and the novel desulfuration slag rake does not have a welding portion. Strength of the novel desulfuration slag rake is enhanced, service life of the novel desulfuration slag rake is prolonged, and the novel desulfuration slag rake is flexible and convenient to use. Original wedge pin connection is changed into the connection method of surface-to-surface contact, a protruded rectangular body which can be used for hanging of the slag rake is omitted, a connection trapezoid hole is welded on a connection portion, the slag rake can be placed into the connection trapezoid hole, and the width of the connection trapezoid hole is consistent with the thickness of the slag rake. During installation, a connection port of the slag rake is directly and wholly inserted into the trapezoid hole to form the surface-to-surface contact, and an inserting bolt is placed on the trapezoid hole to prevent falling-off. No stress exists, so that no deformation occurs. Replacement is convenient and rapid, manufacturing cost is lowered, and drossing efficiency is improved.

Owner:TIANJIN TIANTIE METALLURGICAL GRP

Novel dross removal device

InactiveCN104439230AReduce labor intensityReduce operational failuresCharge manipulationCasting cleaning apparatusNumerical controlEngineering

The invention provides a novel dross removal device. The novel dross removal device comprises a motor, a numerical control instrument, an L-shaped support and a dross removal plate. The motor is connected with the numerical control instrument through a connecting rod, the numerical control instrument is connected with the L-shaped support through a stretchable arm, the stretchable arm is fixed to the L-shaped support through nuts, a single-lug plate is welded to the interior of the L-shaped support and movably connected with a double-lug plate through a hinged shaft, the double-lug plate is welded to the inner side of a stop plate, a hanging rod is arranged on the outer side of the stop plate, the dross removal plate with a hanging rod hole is fixed to the hanging rod through a locking pin, and a plate head of the dross removal plate is in an circular arc shape. The novel dross removal device is simple in design and convenient to use; as the numerical control instrument is installed, automation of the dross removal process is achieved, the dross removal efficiency is improved, and the labor intensity of an operator is reduced. The novel dross removal device is suitable for dross removal of steel ladles and hot metal ladles and also suitable for dross removal of various other furnaces.

Owner:天津吉泰空调通风设备有限公司

Desulfurization slag modifier and molten iron desulfurization method

ActiveCN114250334AStrong desulfurization abilityLow melting pointProcess efficiency improvementSlagRaw material

The invention provides a desulfurized slag modifier and a molten iron desulfurization method, and the desulfurized slag modifier comprises the following raw material components in 100 parts by weight: 60-75 parts by weight of soda ash with the Na2CO3 weight percentage of not less than 90 wt%; the weight percentage of CaO in the lime powder is not less than 80wt%; the content of CaF2 in the fluorite powder is not less than 80 wt%, and the content of CaF2 in the fluorite powder is 10-15 parts. When the desulfurization slag modifier provided by the invention is used for desulfurization, a part of pre-slag can be reserved in a ladle, and the desulfurization slag modifier can modify the pre-slag, so that the desulfurization capacity of the pre-slag is improved, the slagging-off time of the pre-slag is shortened, the temperature of molten iron is prevented from being too high, the desulfurization efficiency is effectively improved, and remarkable economic benefits are brought to enterprises.

Owner:湖南华菱涟源钢铁有限公司 +1

Slag conglomeration agent for treating magnesium and magnesium alloy

Owner:SOUTHWEST UNIV

Efficient slagging-off plate for molten iron slagging off

ActiveCN109676121AExtended service lifeEasy and economical to makeCasting cleaning apparatusRecycling and recovery technologiesMetallurgyOff time

The invention discloses an efficient slagging-off plate for molten iron slagging off. The efficient slagging-off plate for molten iron slagging off comprises a connecting part and a working part, wherein the working part comprises a left side plate, an intermediate plate and a right side plate; the left side plate and the right side plate are symmetrically distributed along a center line of the intermediate plate; an included angle between the left side plate and the intermediate plate and the included angle between the right side plate and the intermediate plate are 120-160 degrees; the totalthickness H of the working platform is 75-100mm; the ratio of the total width A of the working part to the diameter D of an opening of a molten iron cylinder is 0.2-0.3; the ratio of the total heightB of the working part to the total width A is 0.55-0.75; and the ratio of the width A of the intermediate plate to the total width A of the working part is 0.5-0.8. According to the efficient slagging-off plate for molten iron slagging off, the structure design of the slagging-off plate and the structure size of the molten iron cylinder are designed in a fitting manner, the slagging-off plate isof a saddle structure, and the size is optimized, etc., so that the purposes of improving the slagging-off efficiency, reducing the iron loss in slagging off, reducing the slagging-off time, reducingthe times of slagging off, prolonging the service life of the slagging-off plate and other purposes for improving comprehensive economic technical preparation of molten iron slagging off can be achieved.

Owner:武汉钢铁有限公司

A kind of foaming agent used in the molten iron pretreatment process, its preparation method and application

ActiveCN107586910BReduce slag scraping iron lossNo increase in preprocessing investmentFoaming agentEconomic benefits

The invention discloses a foaming agent used in a liquid iron pretreatment process as well as a preparation method and an application of the foaming agent. The foaming agent comprises raw materials inpercentage by weight as follows: 5%-20% of a foaming material, 5%-12% of a carbon substance and 75%-90% of a silicon dioxide material. The preparation method of the foaming agent comprises the following steps: the raw materials are mixed in the formula ratio and broken into granules with grain size smaller than or equal to 10 mm. With adoption of the foaming agent used in the liquid iron pretreatment process, slagging-off iron loss in the liquid iron pretreatment process can be reduced remarkably, the slagging-off time can be shortened remarkably, on the premise that the investment of liquidiron pretreatment is not increased, the slagging-off time can be shortened by 1-2 min, the slagging-off iron loss can be reduced by 3-6 kg of iron per ton, and substantial economic benefits are realized.

Owner:MAANSHAN IRON & STEEL CO LTD

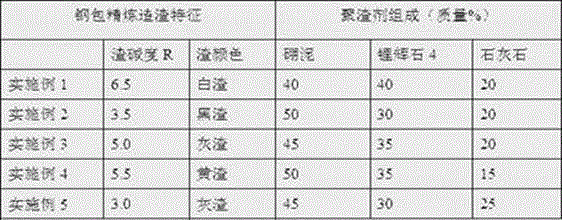

A kind of slagging agent for ladle furnace slagging refining and its preparation and use method

The invention relates to the technical field of ferrous metallurgy, in particular to a slag accretion agent for ladle furnace slagging and refining, and a preparation method and an application method thereof. The slag accretion agent is used for slag accretion during slagging-off after secondary liquid steel slagging and refining in a ladle furnace and comprises, by weight, 40-50% of boron mud, 30-40% of spodumene and 15-25% of limestone. The preparation method mainly includes drying, crushing, grinding, dosing, blending and pelleting. The slag accretion agent for ladle furnace slagging and refining is added to a ladle top slag layer after slagging and refining and before slagging-off in the ladle furnace. The slag accretion agent has the main advantages that steel slags are emulsified to reduce their density, agglomeration performance of the steel slags is improved effectively, slag-metal separation is promoted, slag accretion efficiency and slagging-off efficiency are improved, slagging-off time is shortened, slagging-off iron loss is reduced, and liquid steel rephosphorization and resulfurization are reduced to guarantee refining effect and the like, so that the slag accretion agent has remarkable economic and social benefits and is worth popularization.

Owner:江阴智产汇知识产权运营有限公司

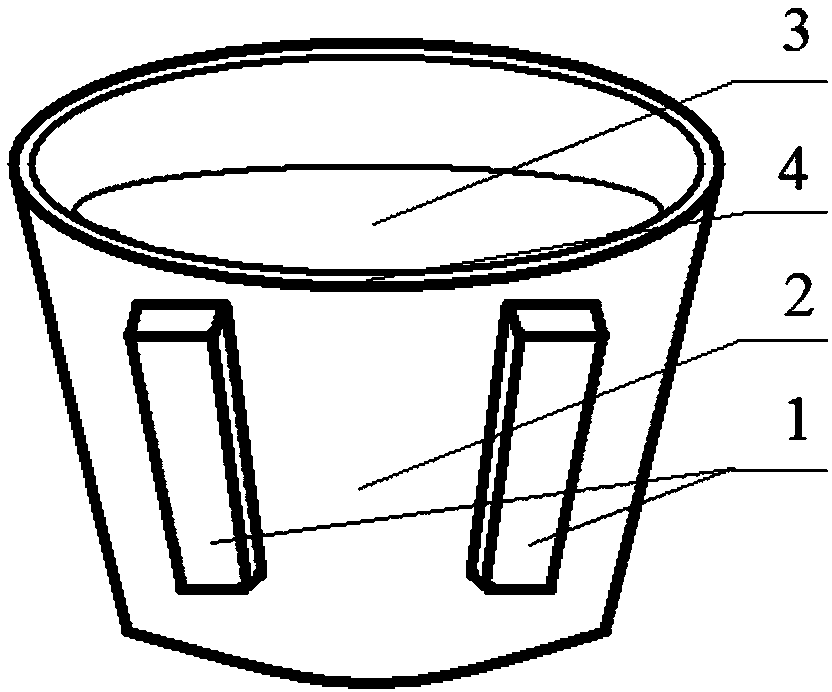

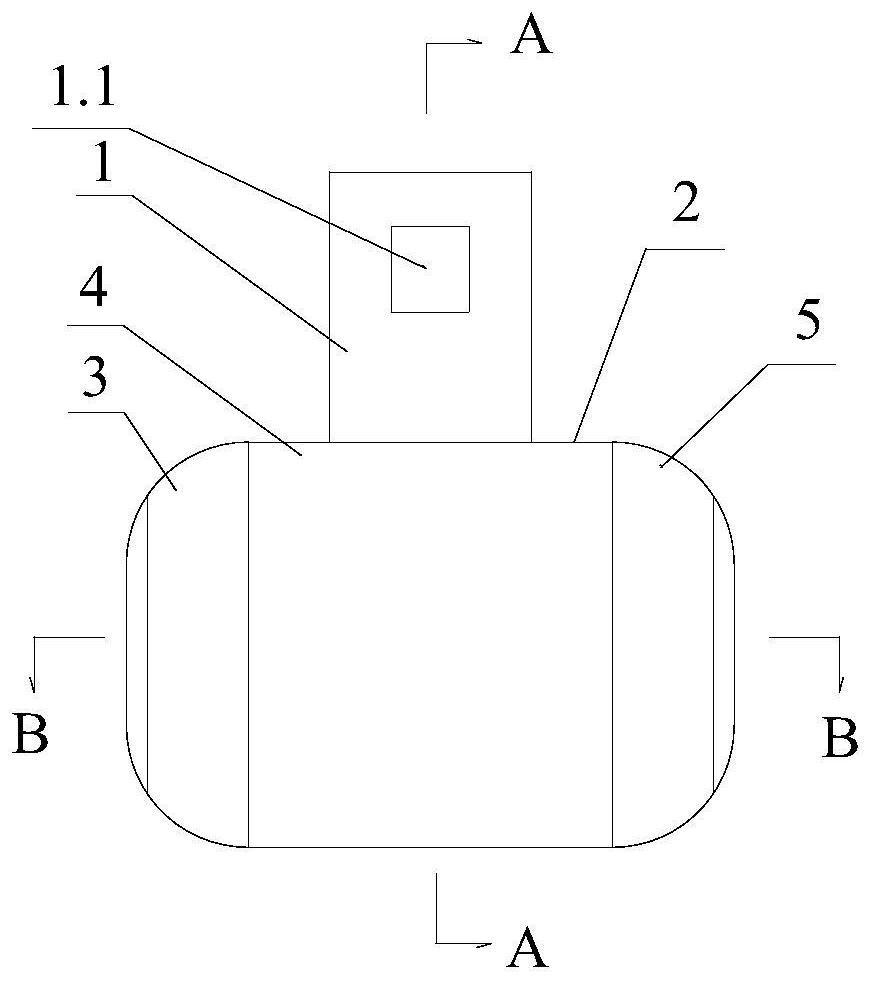

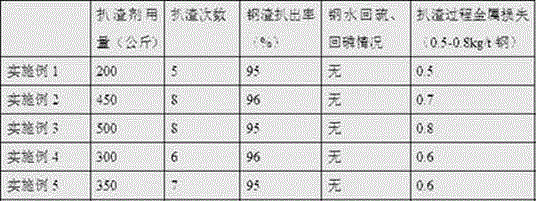

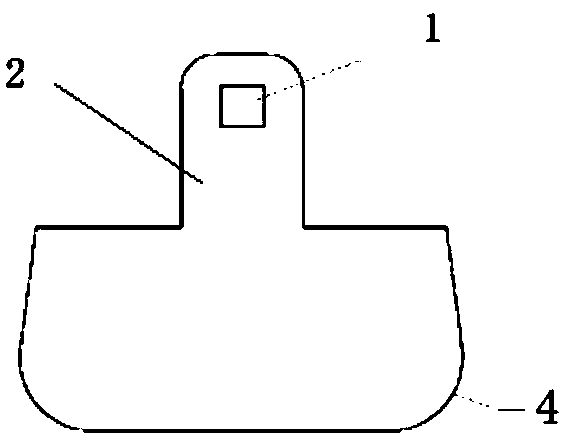

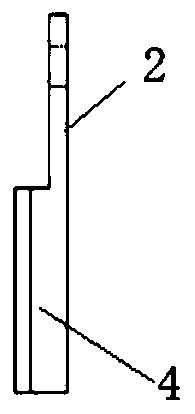

Quick slag-off device and slag-off method thereof

PendingCN109807316AAvoid wastingEasy to handleCasting cleaning apparatusProcess efficiency improvementSlagBiomedical engineering

The invention relates to a quick slag-off device. The quick slag-off device comprises a slag-off connecting rod (6), an O-shaped ring (3) and a slag-off head. A round hole is formed in the end portionof the slag-off connecting rod (6). A square hole is formed in the end portion of the slag-off head. The slag-off connecting rod and the slag-off head are connected together through the detachable O-shaped ring (3). The quick slag-off device has the characteristics of being simple in structure, convenient to assemble and convenient to make and machine, and with the quick slag-off device, an integrated irregular steel part can be quickly replaced.

Owner:SHANDONG IRON & STEEL CO LTD

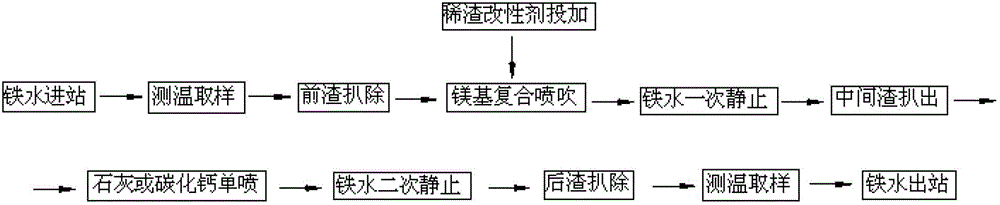

Deep desulfuration method for magnesium-based composite jetted molten iron

The invention discloses a deep desulfuration method for magnesium-based composite jetted molten iron. The deep desulphurization method comprises the following steps of: after the molten iron is fed and subjected to temperature measurement and sampling, scrabbling primary slag before a slag scrabbling station; subsequently desulfurating the molten iron in a magnesium-based composite jetting mode at a jetting and desulfuration station, adding a lean slag modifier in the jetting process and modifying the lean slag of the solid or semi-molten desulfurated slag; subsequently transferring to the slag scrabbling station to carry out primary standing on the molten iron and accomplish middle slag scrabbling; separately jetting lime or calcium carbide at the jetting and desulfuration station so as to carry out deep desulfuration on the molten iron and coagulate and modify residual liquid slag; after the separate jetting, transferring the molten iron tank to the slag scrabbling station to carry out secondary standing on the molten iron and accomplish later slag scrabbling; and after the later slag scrabbling, measuring the temperature, sampling and discharging the molten iron so as to meet the requirements on a molten iron material of a low-sulfur steel. The deep desulfuration method adopts a mode that desulfurated slag of different properties is respectively modified and scrabbled, and has the advantages of simplicity in operation, convenience in application and sufficiency in desulfurated slag modification.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com