Molten iron non-pollution electromagnetic slag conglomeration method

A non-polluting, molten iron technology, applied in the field of smelting technology, to eliminate dead ends of slag scavenging, shorten slag scavenging time, and reduce slag scavenging actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

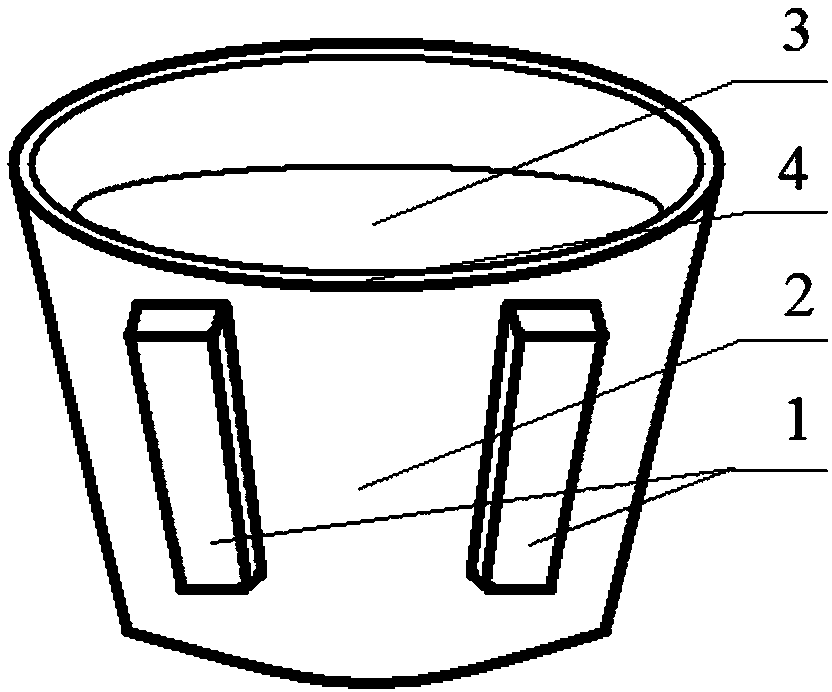

[0021] 1. Tilt the 100-ton molten iron tank 2 to the slag removal position to prepare for slag removal.

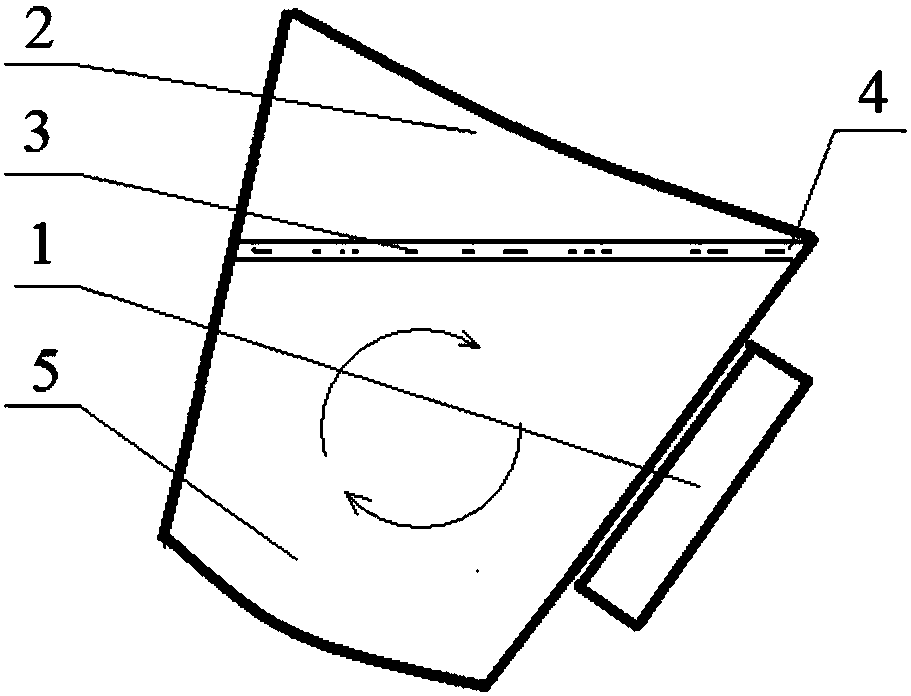

[0022] 2. Place a traveling wave magnetic field slag accumulator 1 with a power of 200kW and a frequency of 10Hz on both sides of the slag outlet 4 of the molten iron tank 2, and use the specific circulation generated by the molten iron 5 to separate the corners of the molten iron tank 2. The removed slag 3 is brought to the vicinity of the slag outlet 4 of the molten iron tank 2.

[0023] 3. Separation of iron in slag. Continue to apply the traveling wave magnetic field for 1 minute after electromagnetic slag gathering, so that the mixture of slag and iron can stay in the traveling wave magnetic field for a longer period of time, so as to improve the separation efficiency of slag and iron and reduce the iron loss.

[0024] After that, the slag can be removed with a slag remover. After cleaning, the molten iron tank is ready to enter the next process.

[0025] The avera...

Embodiment 2

[0027] 1. Tilt the 100-ton molten iron tank 2 to the slag removal position to prepare for slag removal.

[0028] 2. Place a 300kW traveling wave magnetic field slag accumulator 1 with a frequency of 10Hz on both sides of the slag outlet 4 of the molten iron tank 2, and collect the slag 3 at the corners of the tank that is not easy to be mechanically removed through the flow of the molten iron 5 to the slag outlet 4 nearby.

[0029] After the desulfurization slag is gathered, use a slag remover to remove the slag. After cleaning, the molten iron tank is ready to enter the next process.

[0030] The average time for removing slag in Example 2 was reduced from 11 minutes / time to 8 minutes / time. The iron loss of slag removal per ton of steel is reduced from 15kg / t to 13kg / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com