Quick slag-off device and slag-off method thereof

A slag removal and fast technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of long slag removal time, low slag removal efficiency, and iron slag retention, so as to reduce the slag removal time and improve work efficiency , the effect of reducing the waste of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described now in conjunction with accompanying drawing.

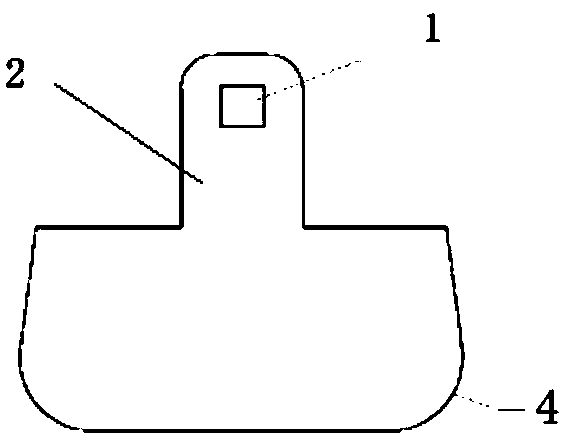

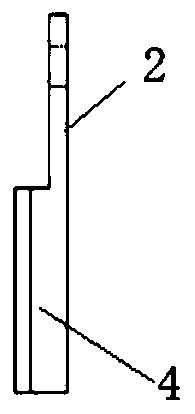

[0023] The present invention proposes a fast slag remover, such as figure 1 , 2 , 3, it comprises: slag removing connecting rod 6, O ring 3, slag removing head; The detachable O-rings 3 are connected together. This combination method has the characteristics of simple structure, convenient assembly, convenient manufacturing and processing, and can quickly replace the one-piece irregular steel part.

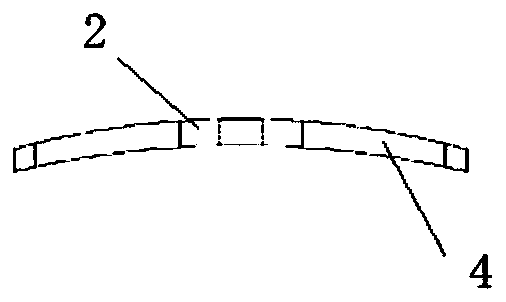

[0024] As one of the improvements to the above device, the slag removing head is an integrated convex structure, such as figure 1 with 2 As shown, it includes: connecting part 2 and slag head 4; connecting part 2 is provided with a square hole for connecting with slag removal connecting rod 6 through O-ring 3; slag head 4 is an arc protruding outward Shaped structure, and the four corners of the slag head 4 are set to be arc-shaped, forming a bottom edge with a large radian, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com