Surging molten iron slag-off method

A technology for slag removal and molten iron, which is applied in the field of slag removal technology in molten iron tanks, can solve the problems of increasing the gas supply strength, shortening the life of the jet gun, and accelerating the erosion of molten iron, etc. , Conducive to the effect of slag aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

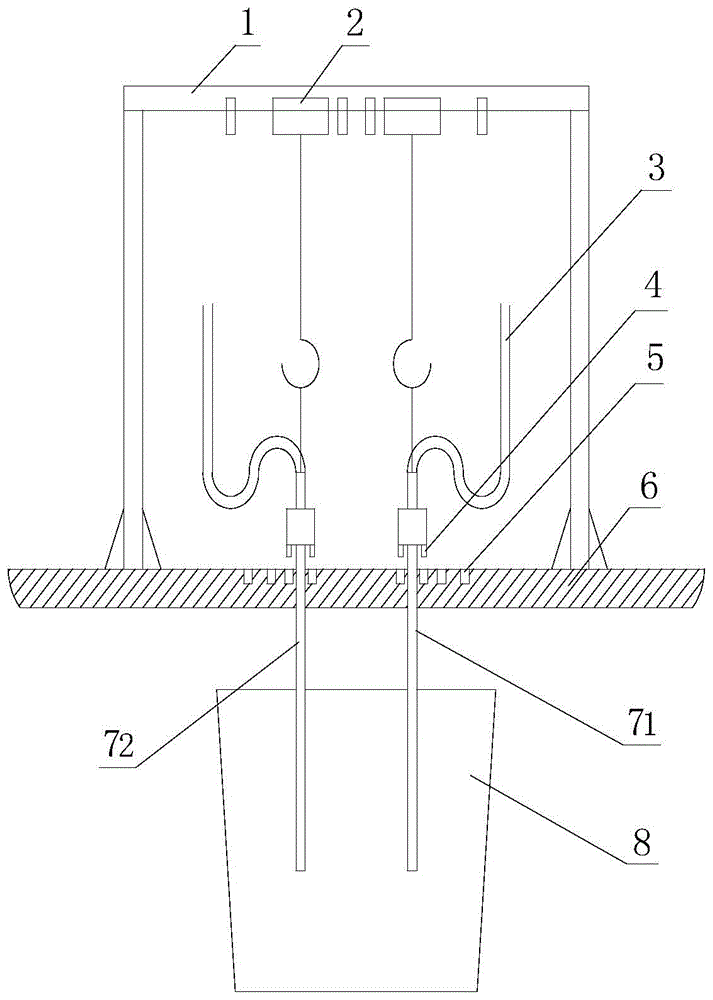

[0021] The amount of slag on the top of the molten iron is 3kg / t, the ratio of the clearance of the molten iron tank 8 to the diameter of the tank mouth is 0.13, and the temperature of the molten iron is 1400°C.

[0022] Iron ladle 8 is inclined 23 °. Start the hoist crane 2 and start to lower the A spray gun 71 and the B spray gun 72, so that the positioning pin 4 accurately falls into the positioning hole 5 on the operating platform 6, and the air supply valve of the air supply hose 3 is opened at the same time as the gun is lowered to control the intensity of the air supply 3NL / (min·t), pressure 0.75MPa.

[0023] Insert the A jet gun 71 and the B jet gun 72 vertically into the molten iron simultaneously from the top of the molten iron tank 8, the distance between the A jet gun 71 and the B jet gun 72 is 1 / 2 of the radius length of the tank mouth, and the insertion depth is 1 / 2 of the depth of the molten iron. The gas supply intensity of A jet gun 71 is constant, and the ga...

Embodiment 2

[0026] The amount of slag on the top of the molten iron is 5kg / t, the ratio of the clearance of the molten iron tank 8 to the diameter of the tank mouth is 0.16, and the temperature of the molten iron is 1350°C.

[0027] Iron ladle 8 is inclined 24 °. Start the hoist crane 2 and start to lower the A spray gun 71 and the B spray gun 72, so that the positioning pin 4 accurately falls into the positioning hole 5 on the operating platform 6, and the air supply valve of the air supply hose 3 is opened at the same time as the gun is lowered to control the intensity of the air supply 2NL / (min·t), pressure 0.70MPa.

[0028] Insert the A jet gun 71 and the B jet gun 72 vertically into the molten iron simultaneously from the top of the molten iron tank 8, the distance between the A jet gun 71 and the B jet gun 72 is 1 / 2 of the radius length of the tank mouth, and the insertion depth is 2 / 3 of the depth of the molten iron. The gas supply intensity of A jet gun 71 is constant, and the ga...

Embodiment 3

[0031] The amount of slag on the top of the molten iron is 10kg / t, the ratio of the clearance of the molten iron tank 8 to the diameter of the tank mouth is 0.2, and the temperature of the molten iron is 1300°C.

[0032] Iron ladle 8 is inclined 25 °. Start the hoist crane 2 and start to lower the A spray gun 71 and the B spray gun 72, so that the positioning pin 4 accurately falls into the positioning hole 5 on the operating platform 6, and the air supply valve of the air supply hose 3 is opened at the same time as the gun is lowered to control the intensity of the air supply 2NL / (min·t), pressure 0.70MPa.

[0033] Insert the A jet gun 71 and the B jet gun 72 vertically into the molten iron simultaneously from the top of the molten iron tank 8, the distance between the A jet gun 71 and the B jet gun 72 is 1 / 2 of the radius length of the tank mouth, and the insertion depth is 3 / 4 of the depth of the molten iron. The gas supply intensity of A jet gun 71 is constant, and the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com