Feeding and discharging method for PECVD surface coating

A surface coating and coating technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of affecting the production efficiency of the whole line. Cell quality, no coating, no silicon wafer coating detection in graphite boats To achieve stable efficiency, smooth production process, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

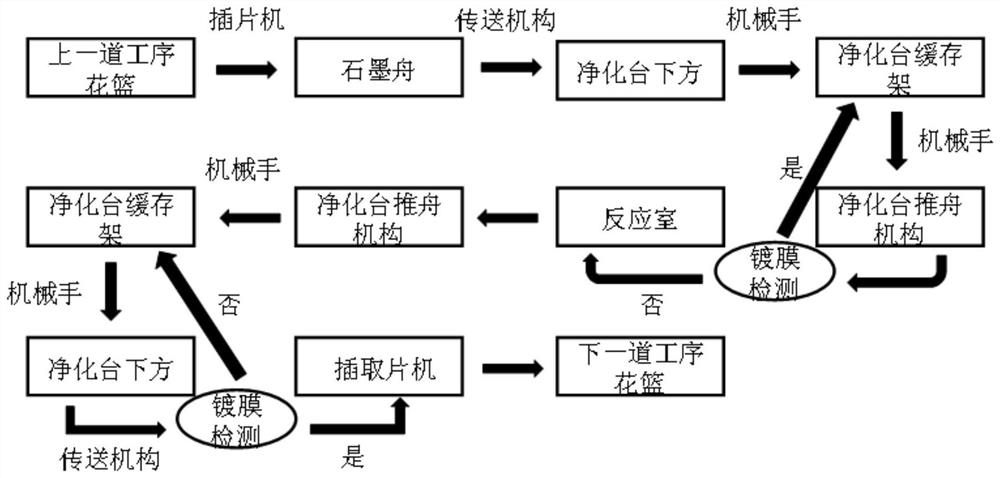

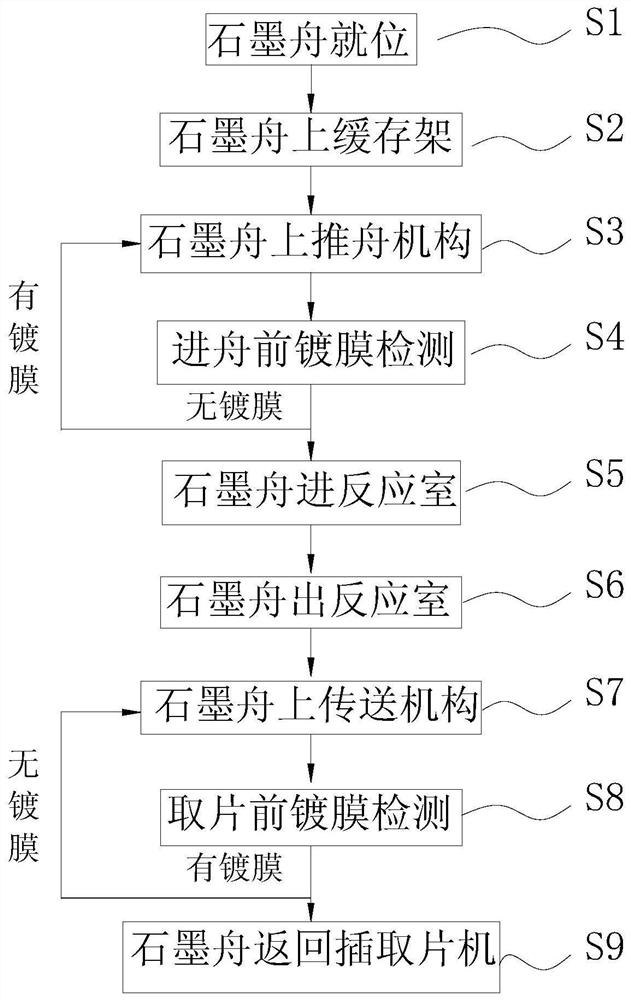

[0052] Such as figure 1 with figure 2 As shown, the loading and unloading method of the PECVD surface coating of the present embodiment comprises the following steps:

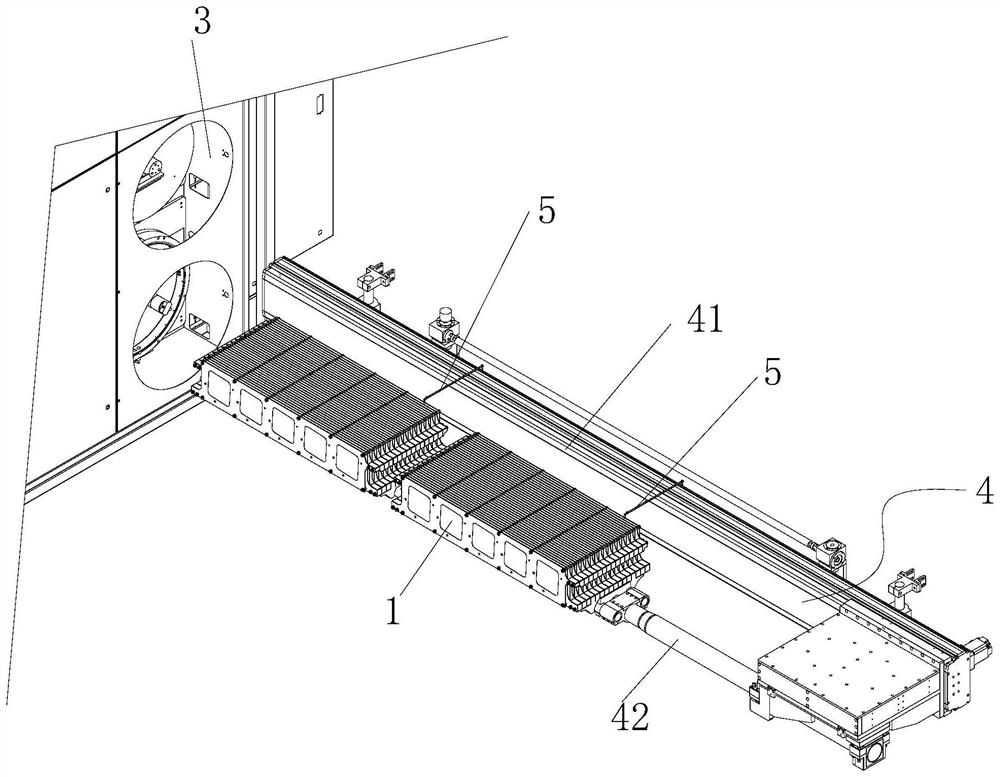

[0053] S1. The graphite boat is in place: the graphite boat 1 inserted by the inserting and unloading machine moves to the bottom of the PECVD purification table through the conveying mechanism 2. The chip taker inserts the silicon chip into the graphite boat 1;

[0054] S2. Cache shelf on the graphite boat: the manipulator grabs the graphite boat 1 and puts it on the cache shelf of the clean bench to wait;

[0055] S3. The pushing mechanism on the graphite boat: there is space in the reaction chamber 3, and the manipulator grabs the graphite boat 1 on the buffer rack and puts it on the pushing mechanism 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com