Continuous production system of high-strength vertical corrugated paperboard

A corrugated cardboard and production system technology, applied in the direction of mechanical processing/deformation, can solve the problems of low production efficiency and achieve the effects of improving production efficiency, coherent production process, and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

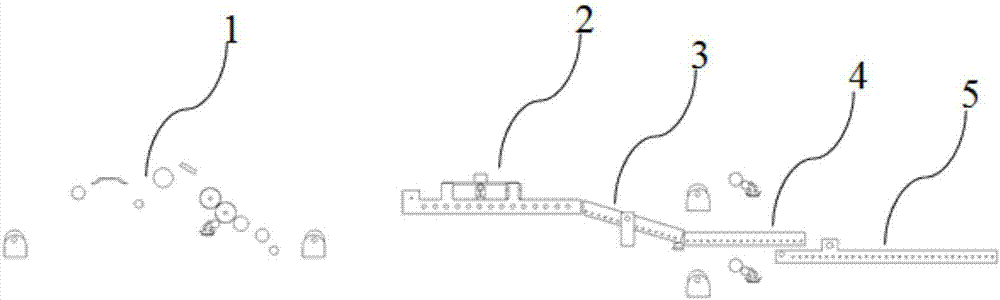

[0035] refer to Figure 1 to Figure 6 , a continuous production system for high-strength vertical corrugated cardboard, including an overall frame and an intermediate corrugation forming unit 1, an indentation forming unit 2, and a vertical stacking unit that are sequentially arranged between the side walls of the overall frame along the production line Unit 3, transition transport unit 4 and outer paper pasting unit 5,

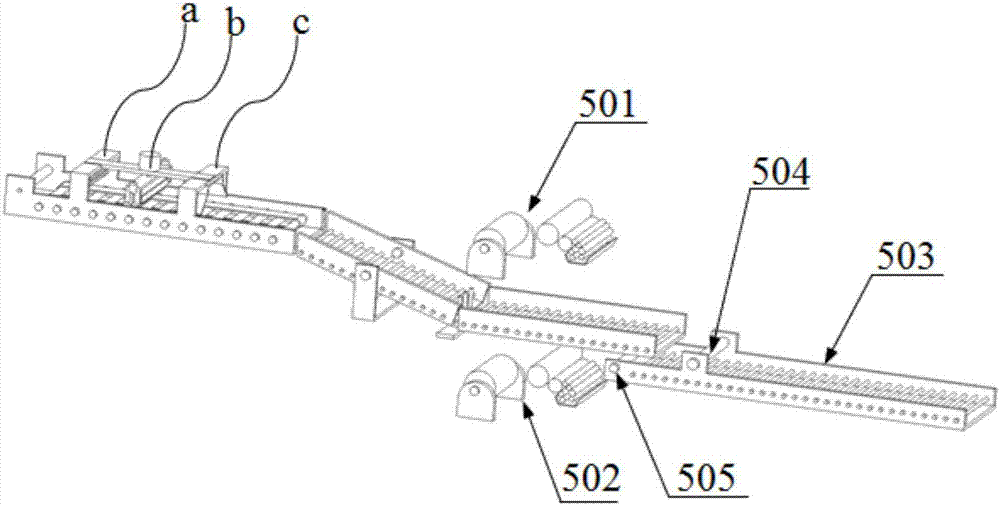

[0036] The indentation forming unit 2 includes an indentation section conveying mechanism, and an indentation mechanism b is arranged in the middle of the indentation section conveying mechanism;

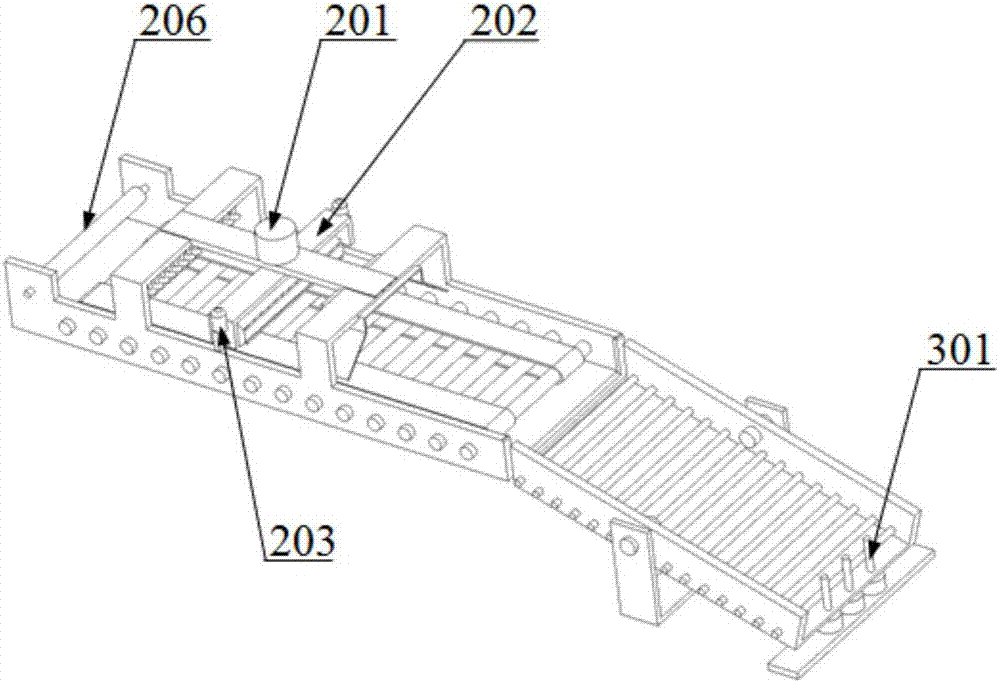

[0037] The vertical stacking unit 3 is rotatably installed between the side walls of the overall frame. When the vertical stacking unit 3 is in an inclined state, the top of the vertical stacking unit 3 is connected to the end of the creasing movement bracket. When the stacking unit 3 is in a horizontal state, the other end of the vertical stacking unit 3 is conne...

Embodiment 2

[0040] This embodiment is modified on the basis of the first embodiment.

[0041] refer to Figure 1 to Figure 6 , a continuous production system for high-strength vertical corrugated cardboard, including an overall frame and an intermediate corrugation forming unit 1, an indentation forming unit 2, and a vertical stacking unit that are sequentially arranged between the side walls of the overall frame along the production line Unit 3, transition transport unit 4 and outer paper pasting unit 5,

[0042] The indentation forming unit 2 includes an indentation section conveying mechanism, and an indentation mechanism b is arranged in the middle of the indentation section conveying mechanism;

[0043] The vertical stacking unit 3 is rotatably installed between the side walls of the overall frame. When the vertical stacking unit 3 is in an inclined state, the top of the vertical stacking unit 3 is connected to the end of the creasing movement bracket. When the stacking unit 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com