Patents

Literature

44results about How to "Solve the deflection problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic assembly method and assembly system for strain gauge

InactiveCN102085611AGood assembly precisionImprove consistencyProgramme-controlled manipulatorGripping headsSimulationPersonal computer

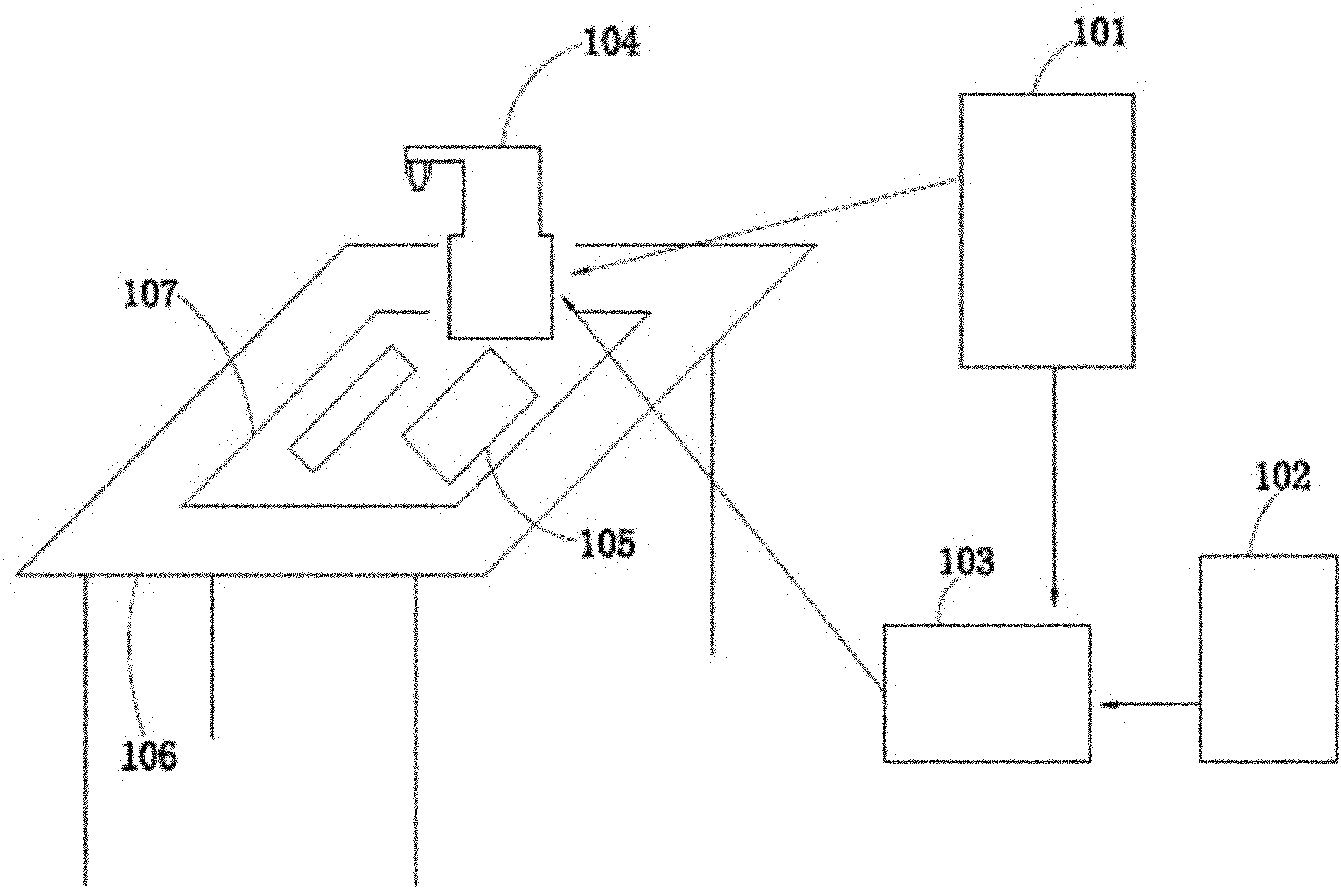

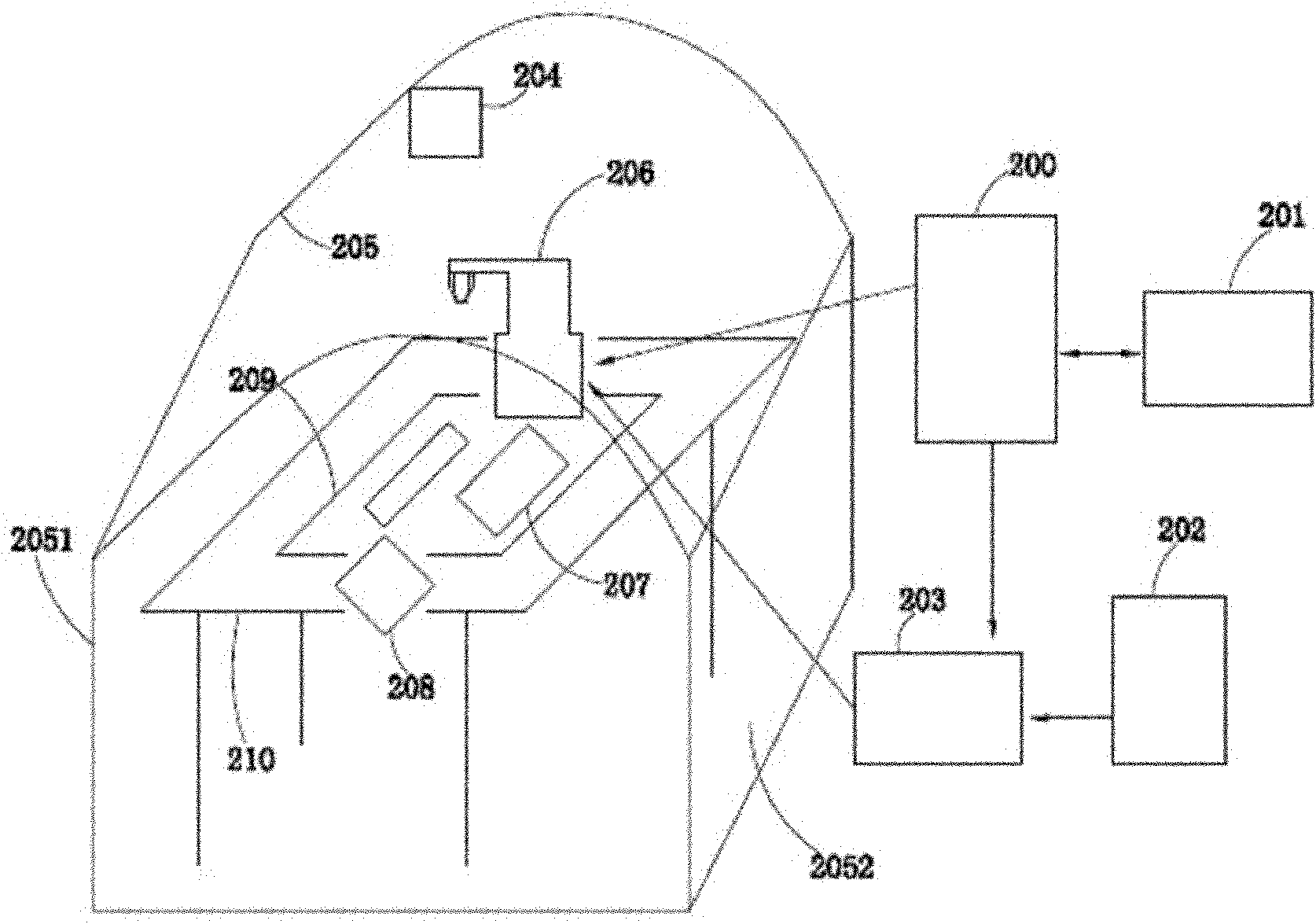

The invention discloses an automatic assembly method and assembly system for a strain gauge. The method comprises the following steps: automatically assembling a corresponding strain gauge with a control mechanical arm of an industrial personal computer; performing image acquisition on the suction position and placing position of the strain gauge by use of a centering camera and a bottom searching camera; calculating the central position, deflection angle and offset of the strain gauge according to the image information in the centering camera; meanwhile, calculating the type and direction of an elastic body and the central position of an assembly hole according to the image information of the elastic body for placing the strain gauge provided by the bottom searching camera; and after obtaining the information, transmitting the information to a mechanical arm control cabinet through a communication channel, wherein the mechanical arm control cabinet obtains a motion path of the mechanical arm according to the information, controls the motion track of the mechanical arm, and controls an air suction / placing controller to perform corresponding suction and placing operations. According to the invention, better assembly precision, uniformity and reliability of the strain gauge are obtained, and influence of the service life of a position sensor on the system reliability is solved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +1

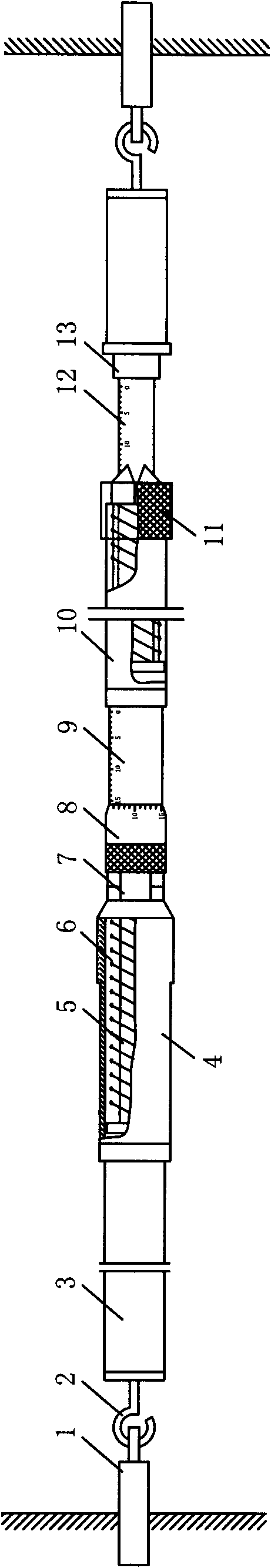

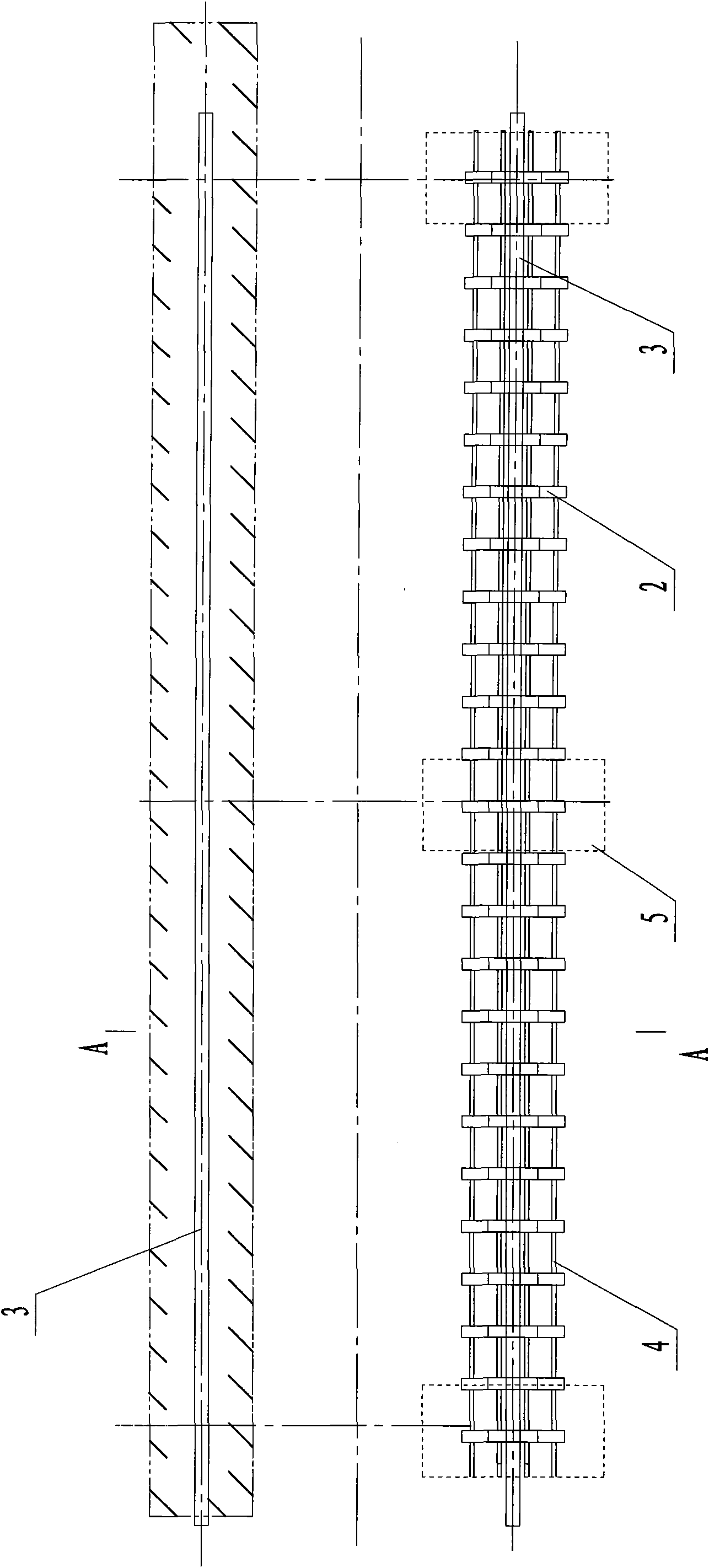

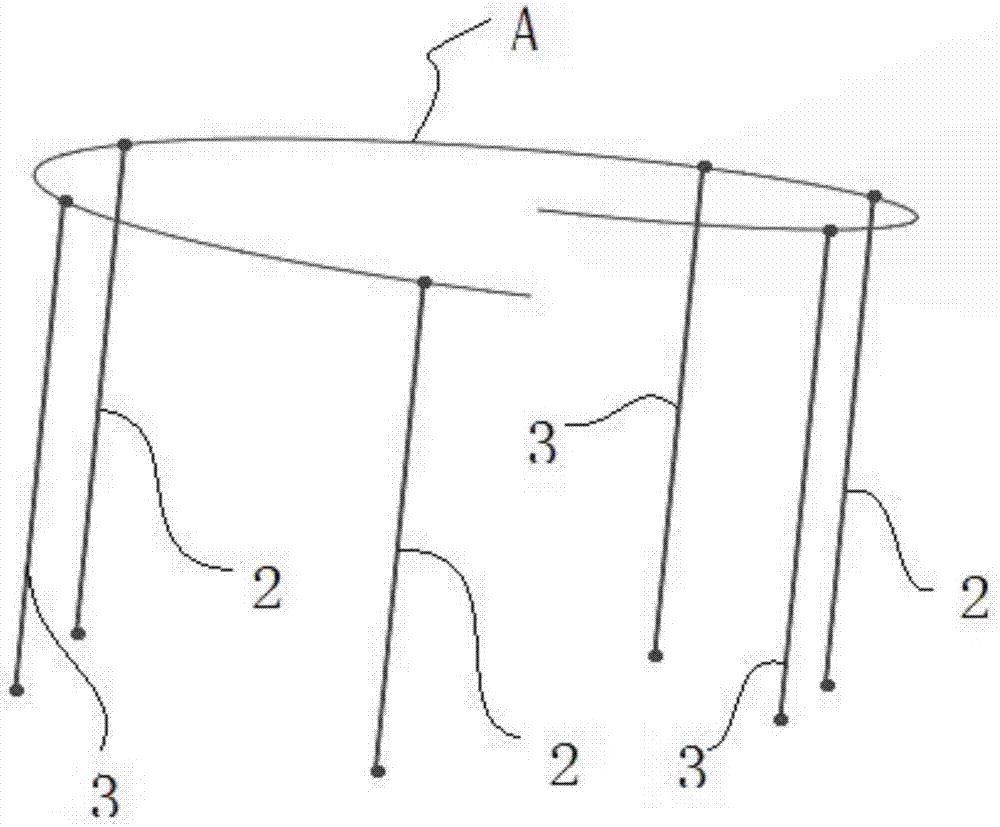

Precision rod type convergence gauge

InactiveCN101608897AEasy to testPrecise positioningMechanical solid deformation measurementsRailway tunnelMicrometer

A precision rod type convergence gauge comprises anchor heads which are respectively fixed at two ends of a measured distance, a universal hook and a tubular connecting rod; the precision rod type convergence gauge also comprises a micrometer caliper, wherein one end of the micrometer caliper is connected with an extracting-pulling type distance-measuring gauge and the other end is connected with a pull rod benchmark device which consists of a telescopic rod fixed with the micrometer caliper into a whole, a force-measuring spring guide sleeve matched with the telescopic rod and a limit spring. The connecting part of the force-measuring spring guide sleeve and the micrometer caliper is provided with a benchmark window marked with a benchmark line; the ends of the pull rod benchmark device and the extracting-pulling type distance-measuring gauge can be respectively connected with a plurality of sections of tubular connecting rods by threads; and an alignment line which can be aligned to the benchmark line of the benchmark window is arranged on the telescopic rod. The precision rod type convergence gauge is applicable to the stability monitoring of military caves, railway tunnels, bridges, underground hydraulic buildings and mine tunnel chambers, and the deformation observation of earth structures. The precision rod type convergence gauge has the advantages of the structure convenient for observation, high precision, combination of a plurality of sections of measurement rod and strong adaptability.

Owner:CHINA UNIV OF MINING & TECH

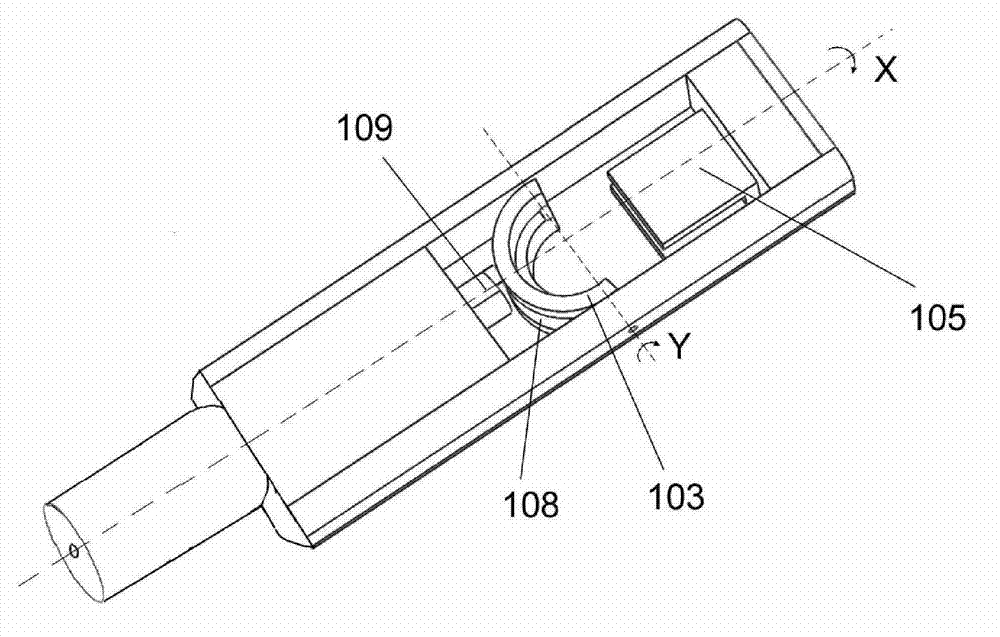

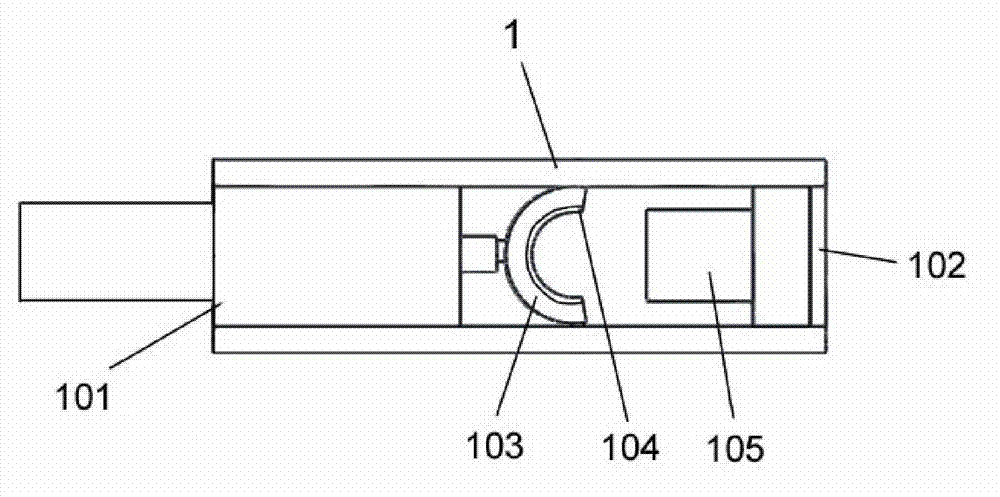

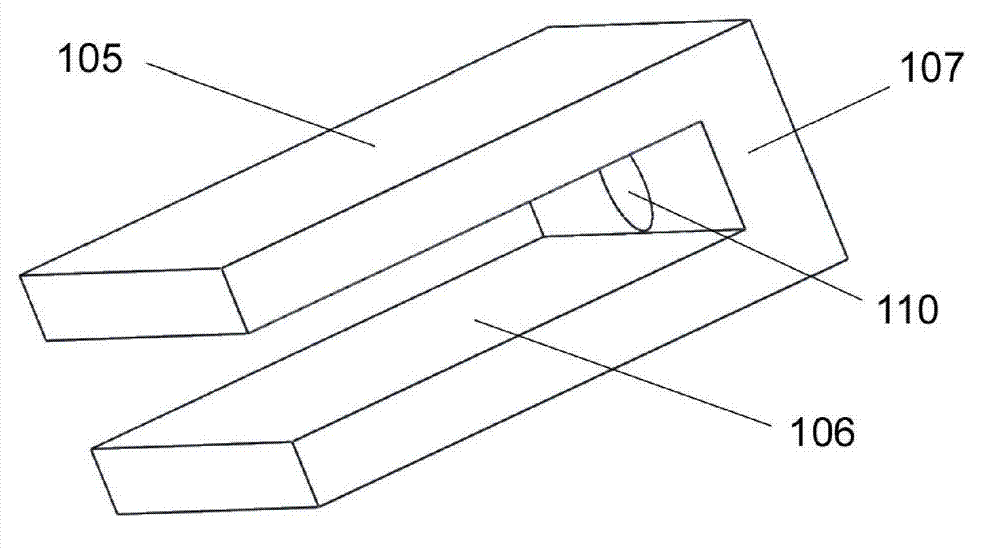

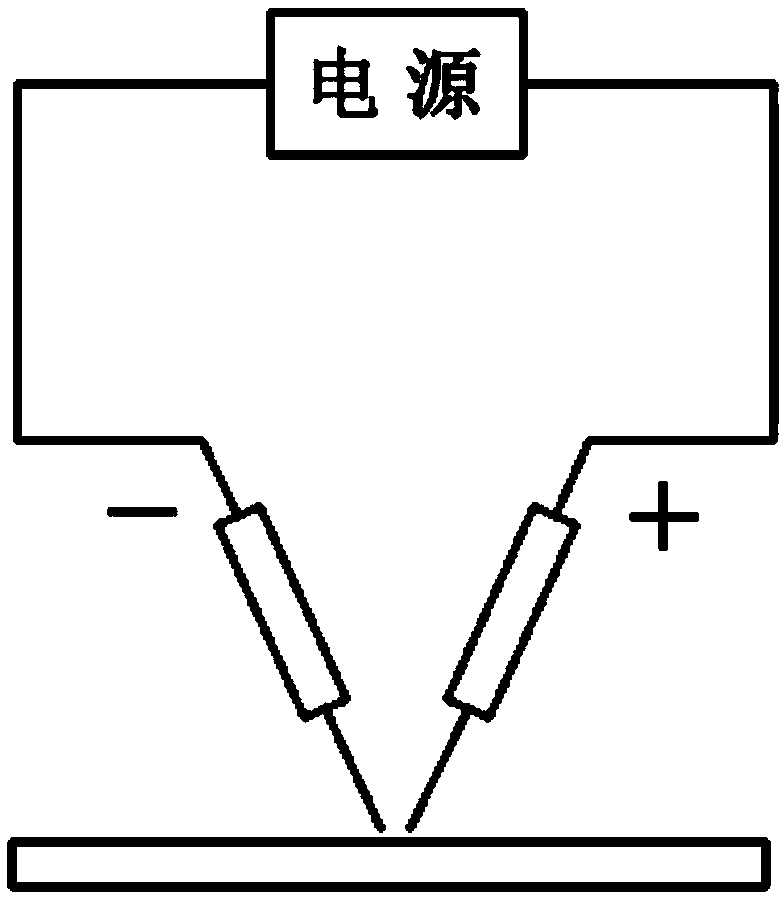

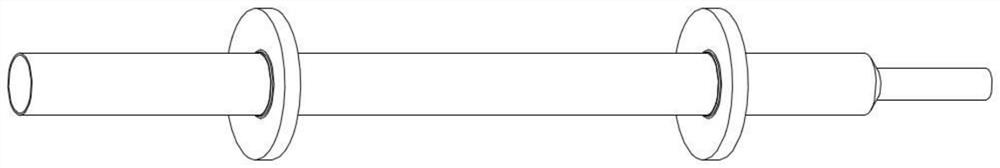

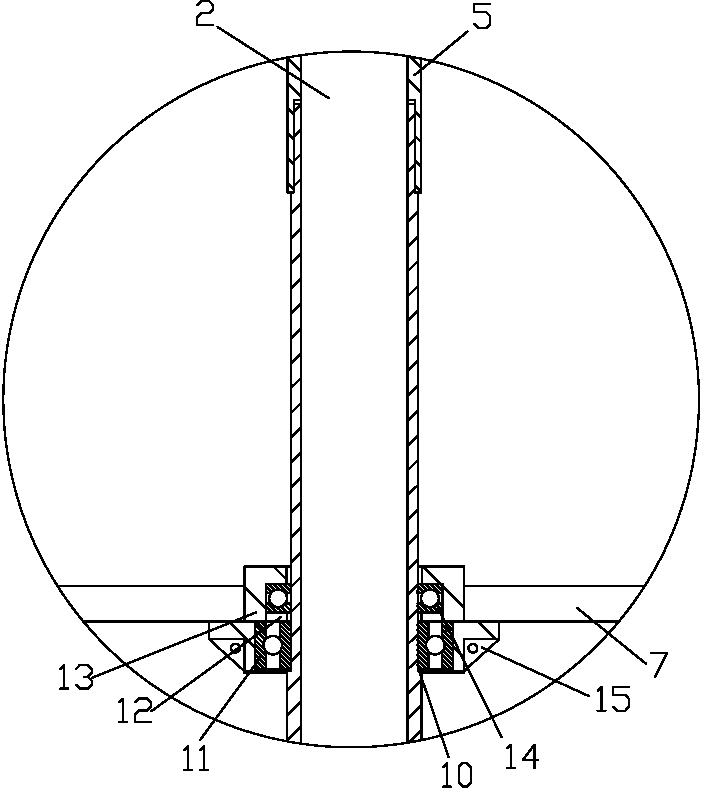

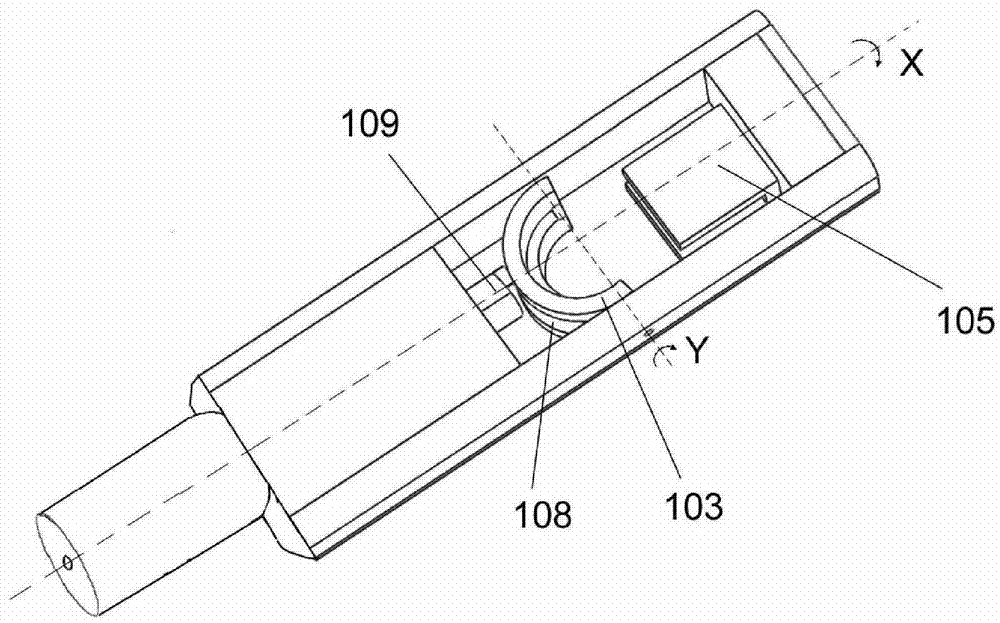

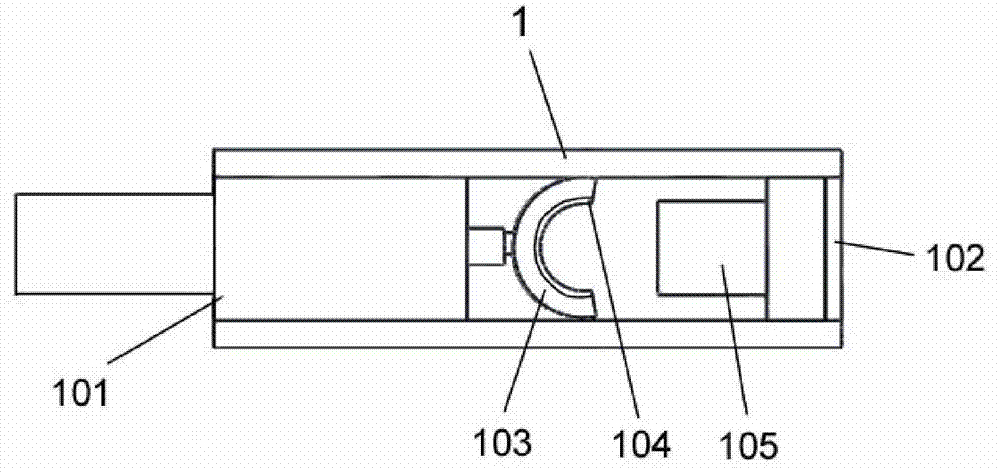

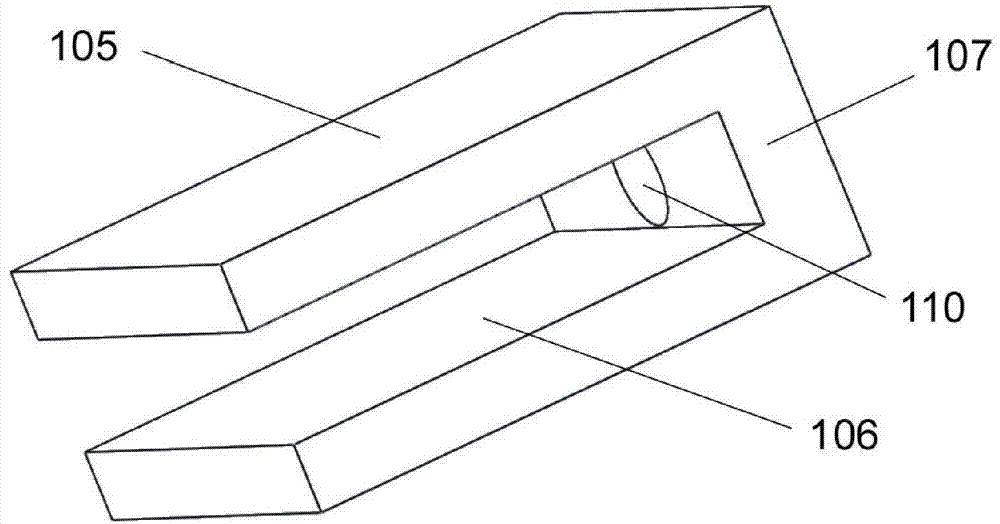

Sample rod for transmission electron microscope added with magnetic field

ActiveCN102820196AIncrease the magnetic field strengthSolve the deflection problemElectric discharge tubesTransmission electron microscopyMagnetic domain

The invention discloses a sample rod for a transmission electron microscope added with a magnetic field. The sample rod comprises a head frame, a carrier, a first magnetic coil and a second magnetic coil, wherein the head frame is provided with a first end part and a second end part along the length extending direction of the sample rod; the carrier is used for carrying a sample and is provided with a channel; an incident electron beam can pass through the channel; the carrier is arranged in the head frame and is close to the first end part of the head frame; the first magnetic coil is arranged in the head frame and is close to the second end part of the head frame; when the current is generated, a first magnetic field is generated by the first magnetic coil; the first magnetic field has a magnetizing effect on the sample; the second magnetic coil is arranged in the head frame and is close to the second end part of the head frame; the second magnetic coil is located under the first magnetic coil; when the current is generated, a second magnetic field is generated by the second magnetic coil; and under the action of the second magnetic field, the electron beam which deflects under the action of the first magnetic field deflects toward an incident direction. The sample rod provided by the invention can be used for researching the change in a magnetic domain of a magnetic material under the action of an externally added magnetic field.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

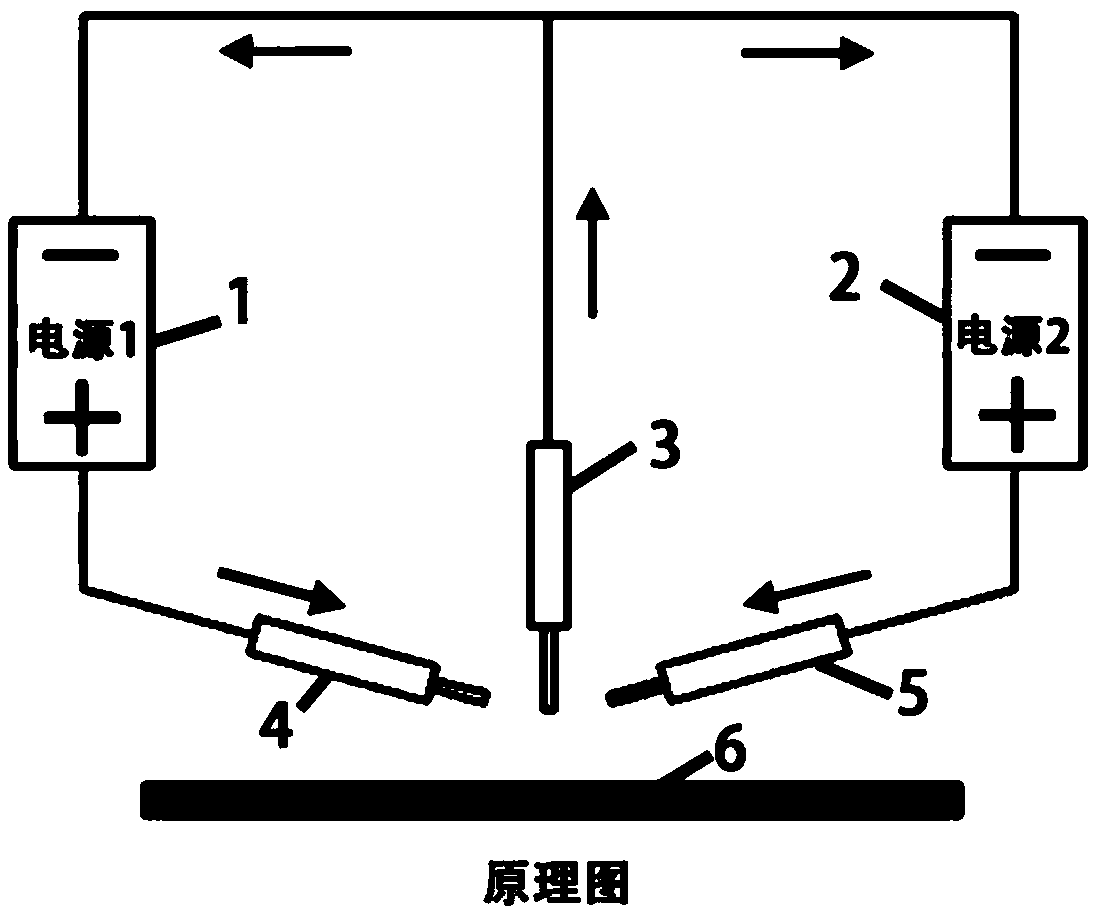

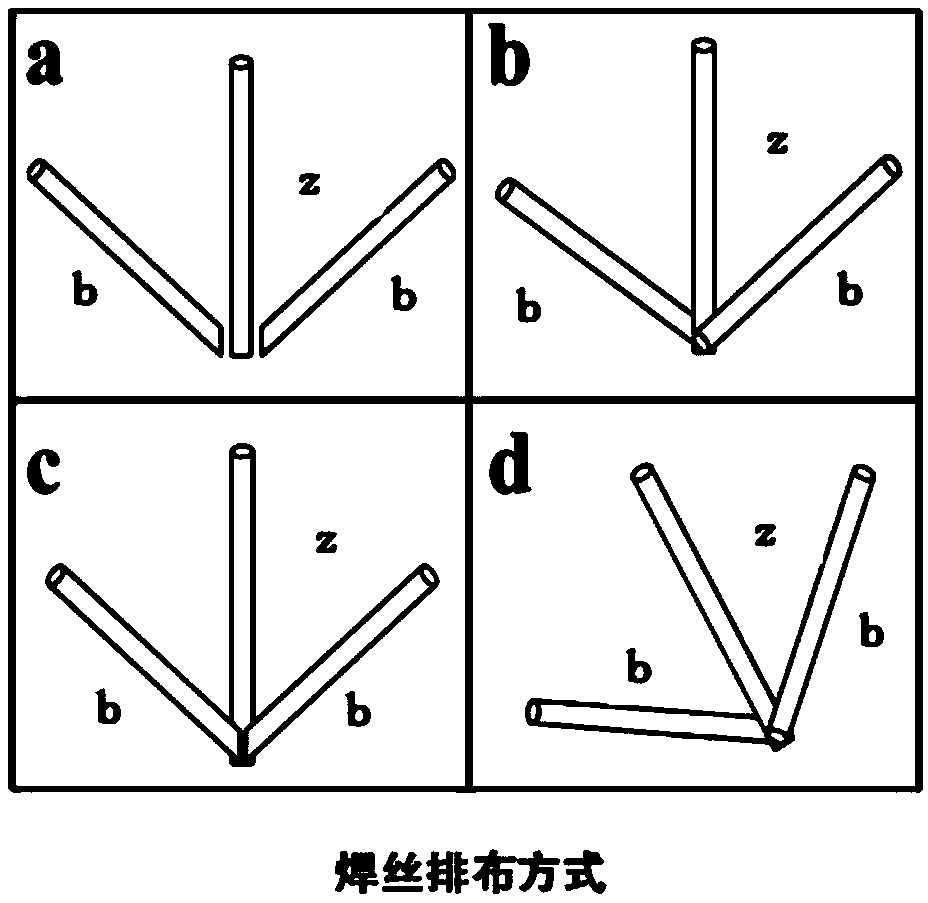

Three-wire gas shielded indirect arc welding method, device and application of method

ActiveCN109079287AIncrease heat inputHigh deposition coefficientArc welding apparatusWelding/soldering/cutting articlesEngineeringVolumetric Mass Density

Owner:DALIAN UNIV OF TECH

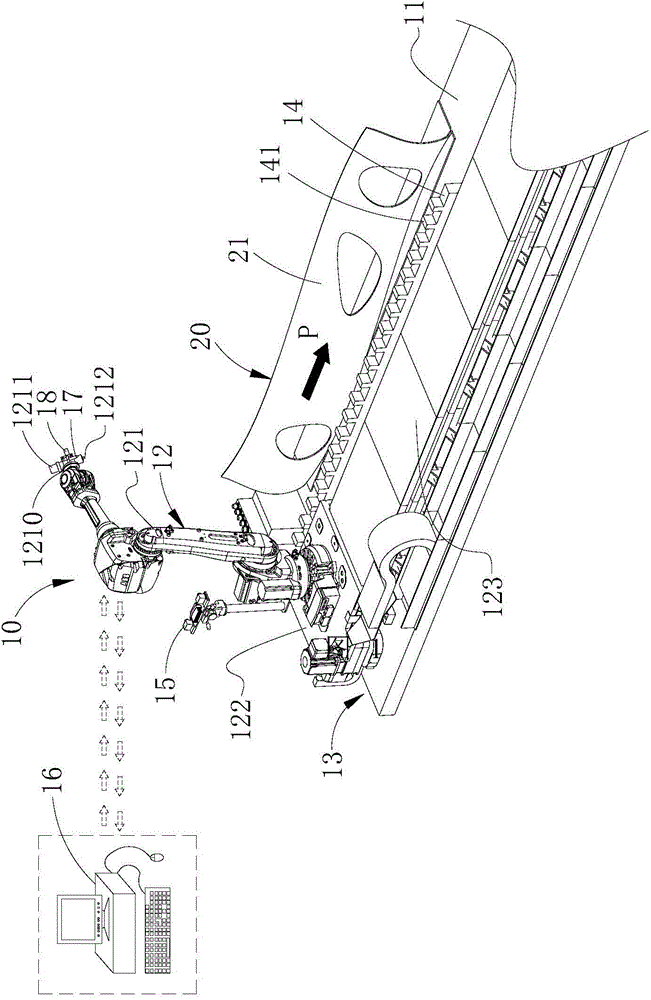

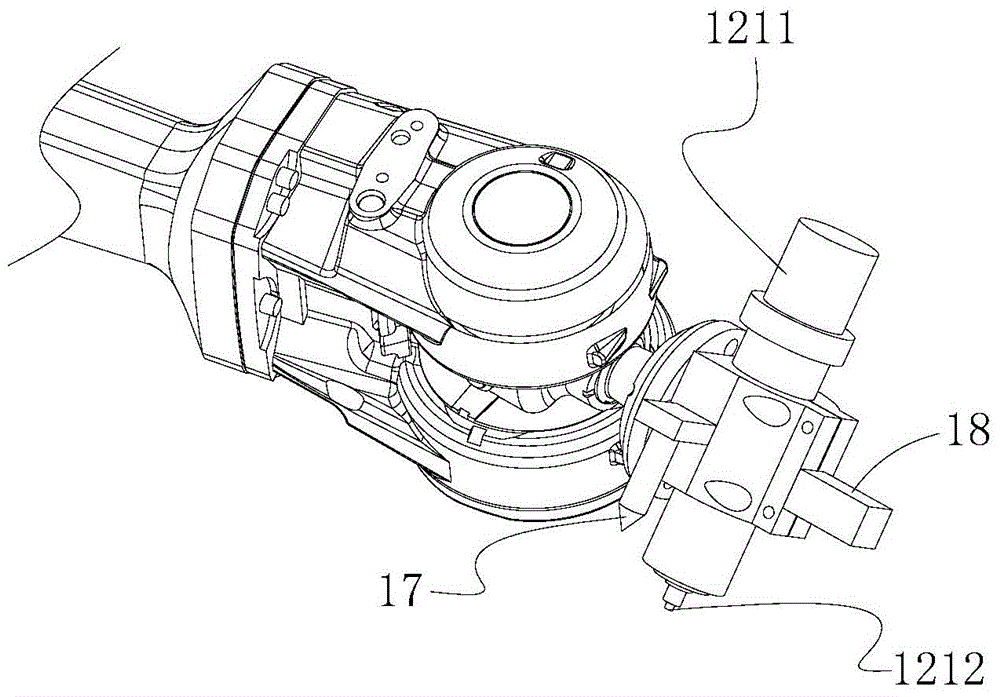

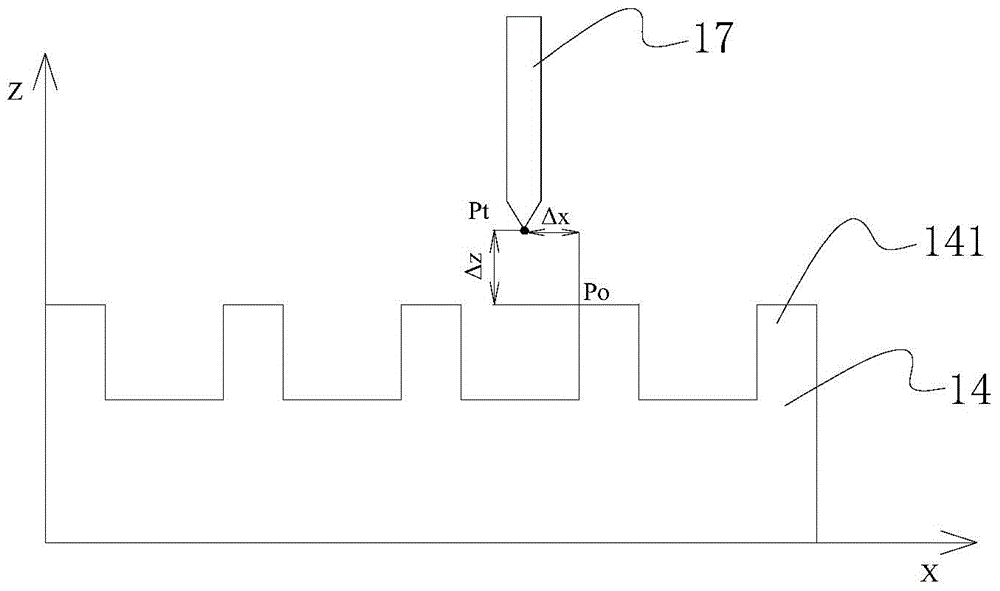

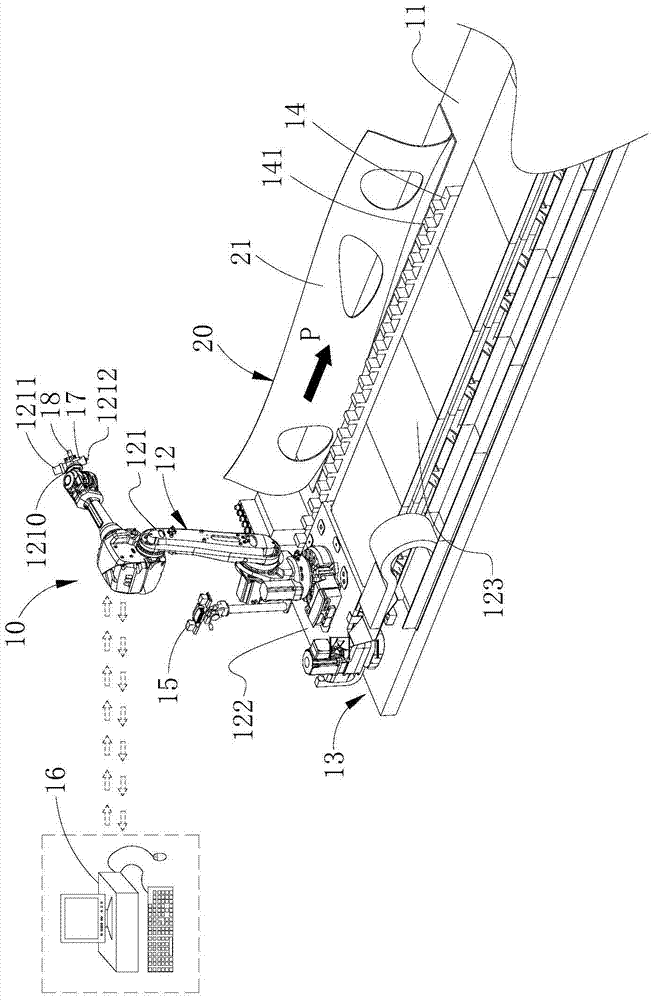

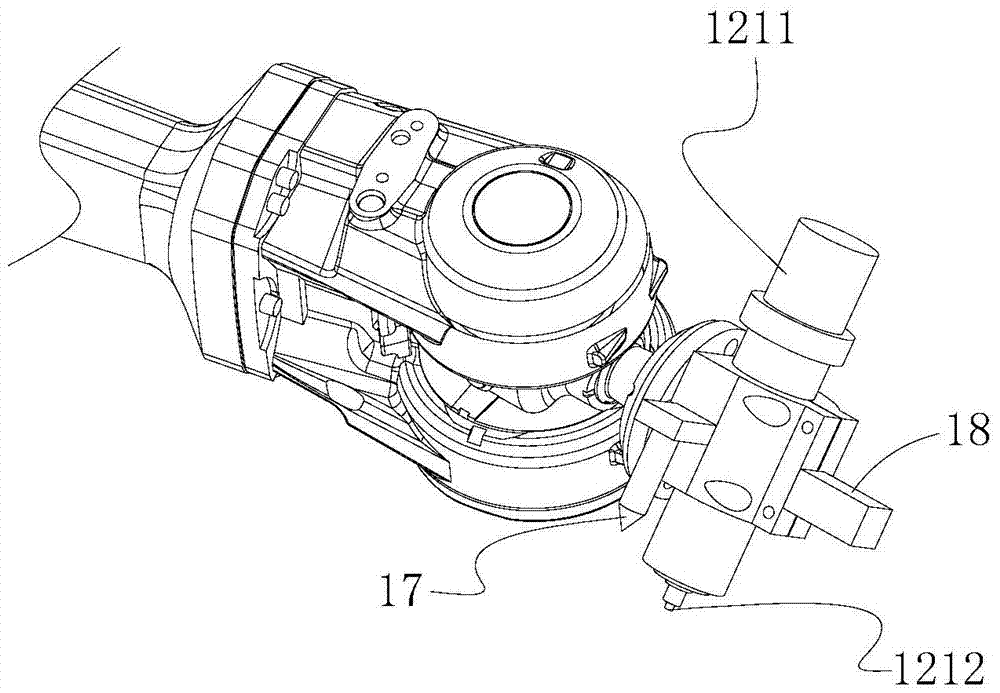

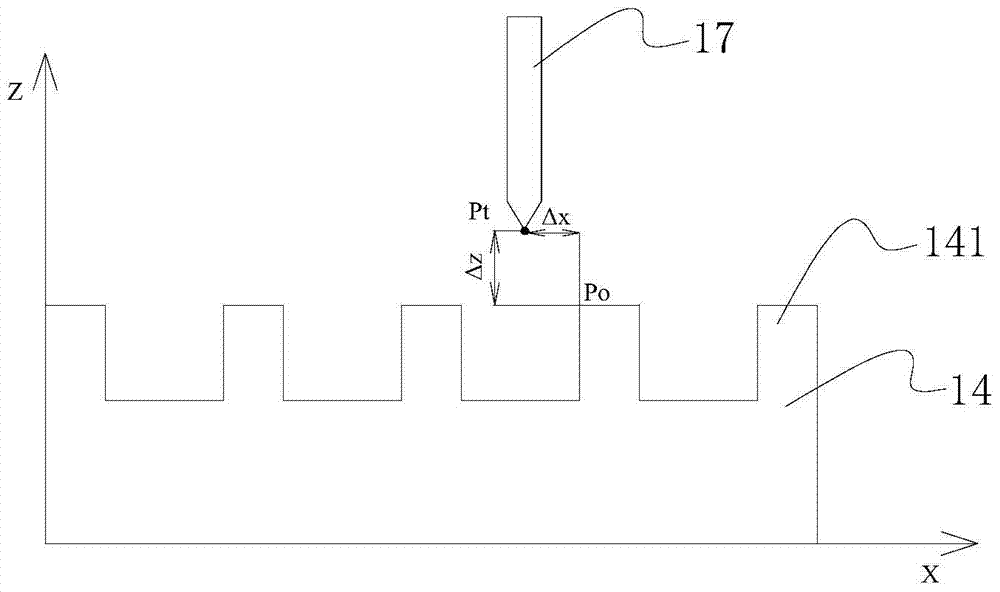

Machining method and machining equipment for parts with curved surfaces

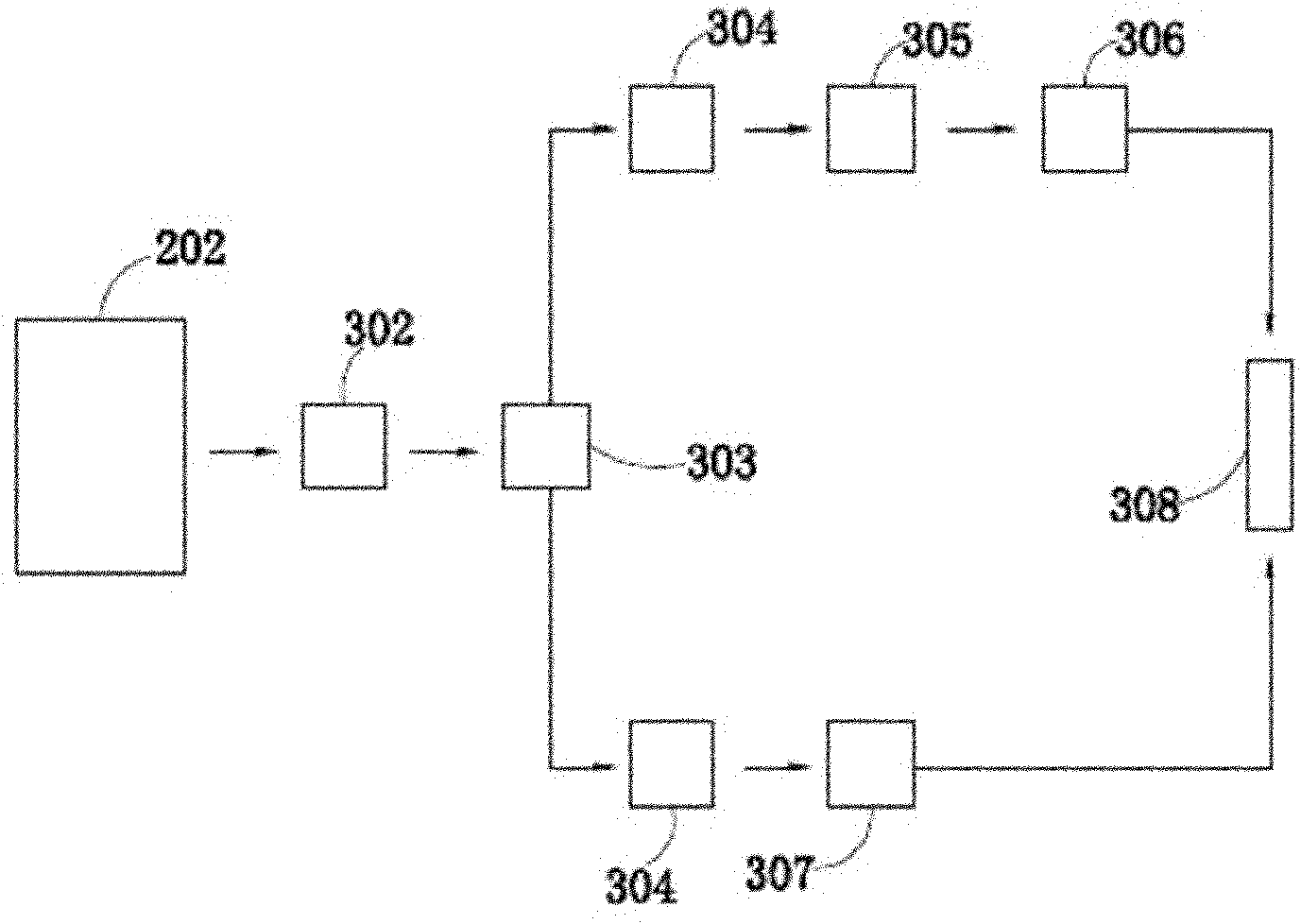

ActiveCN104858712AReduce machining errorsImprove machining accuracyProgramme-controlled manipulatorAutomatic control devicesData analysisImaging data

The invention provides a machining method for parts with curved surfaces. The machining equipment is provided with a robot, a posture calibration block, a three-dimensional scanning device and a host computer, and the machining method comprises the following steps: scanning a part I with a curved surface I and the posture calibration block with the three-dimensional scanning device; sending the obtain image data I to the host computer, so as to conduct reverse modeling and data analysis on the image data I, and further obtain a first relative deflection value; machining the part I; replacing the part I with another part II with a curved surface II after the part I is machined; scanning the part II and the posture calibration block with the three-dimensional scanning device; sending the obtain image data II to the host computer, so as to conduct reverse modeling and data analysis on the image data II, and further obtain a second relative deflection value; calculating the deflection error between the second relative deflection value and the first relative deflection value; carrying out compensation on the robot with the host computer according to the deflection error; machining the part II; repeating the above steps till all the parts are machined. The invention further provides machining equipment for the parts with the curved surfaces.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

Process for heating sleeve shaft through magnetic induction by large ring component

InactiveCN103170796AShorten the installation periodShorten round-trip shipping timesMetal working apparatusThermodynamicsThermal deformation

The invention relates to a process for heating a sleeve through magnetic induction by a large ring component. Finish machining is conducted on the ring component until certain size of the ring component is reached before shrinkage fit. In order to avoid thermal consumption after heating and prevent the surface of a ring from being burned due to the fact of partial overheat, asbestos cloth is coated and surrounds the outer surface of the ring, induction coils are wound on the outer surface of the ring, the ring is lifted above a rotating shaft through a crane, and after the ring is heated, when the minimum size of the ring is detected to meet requirements of a drawing through a measuring bar, the ring is smoothly dropped, and the shrinkage fit is conducted on the ring. After the ring is cooled to room temperature, size difference of an outer ring of the ring before the shrinkage fit and after the shrinkage fit is not larger than 0.02 millimeter. After the shrinkage fit is finished for the first time, the ring does not need machining a large equipment for the second time again after the shrinkage fit, the lowest heating temperature is controlled through intermediate-frequency electromagnetic induction heating, and deformation of the ring is small after the shrinkage fit after the ring is heated. The process for heating the sleeve shaft through magnetic induction by the large ring component has the advantages of being simple in operation, simple in required equipment, low in manufacturing cost, short in working period and the like, can save a large amount of cost from secondary machining to large-equipment machining, and is very high in application value.

Owner:HARBIN ELECTRIC MASCH CO LTD

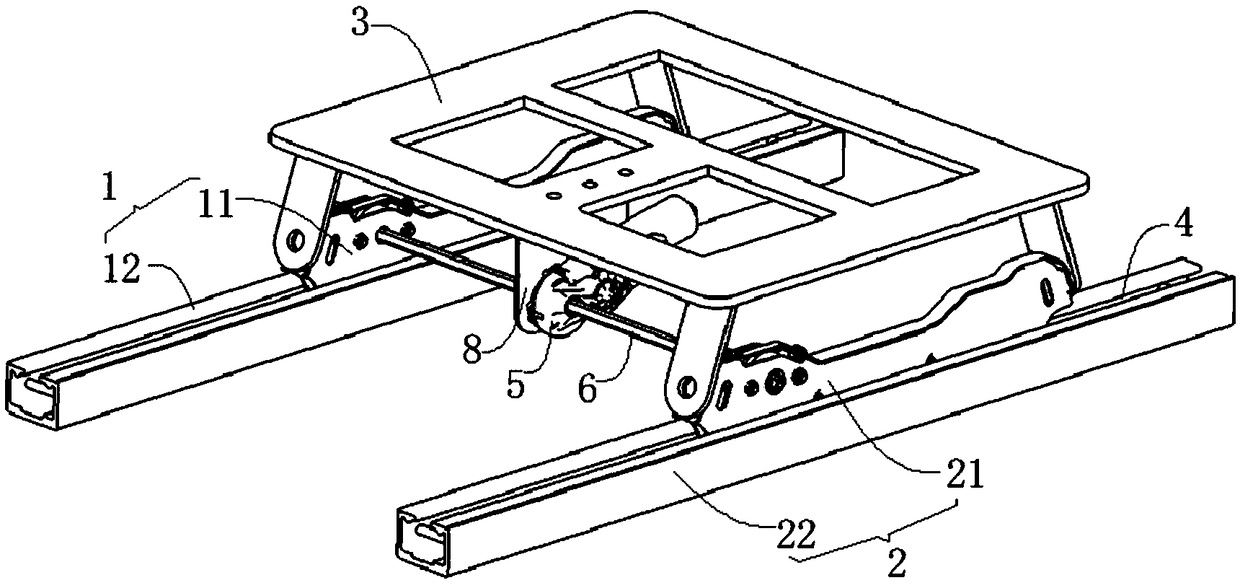

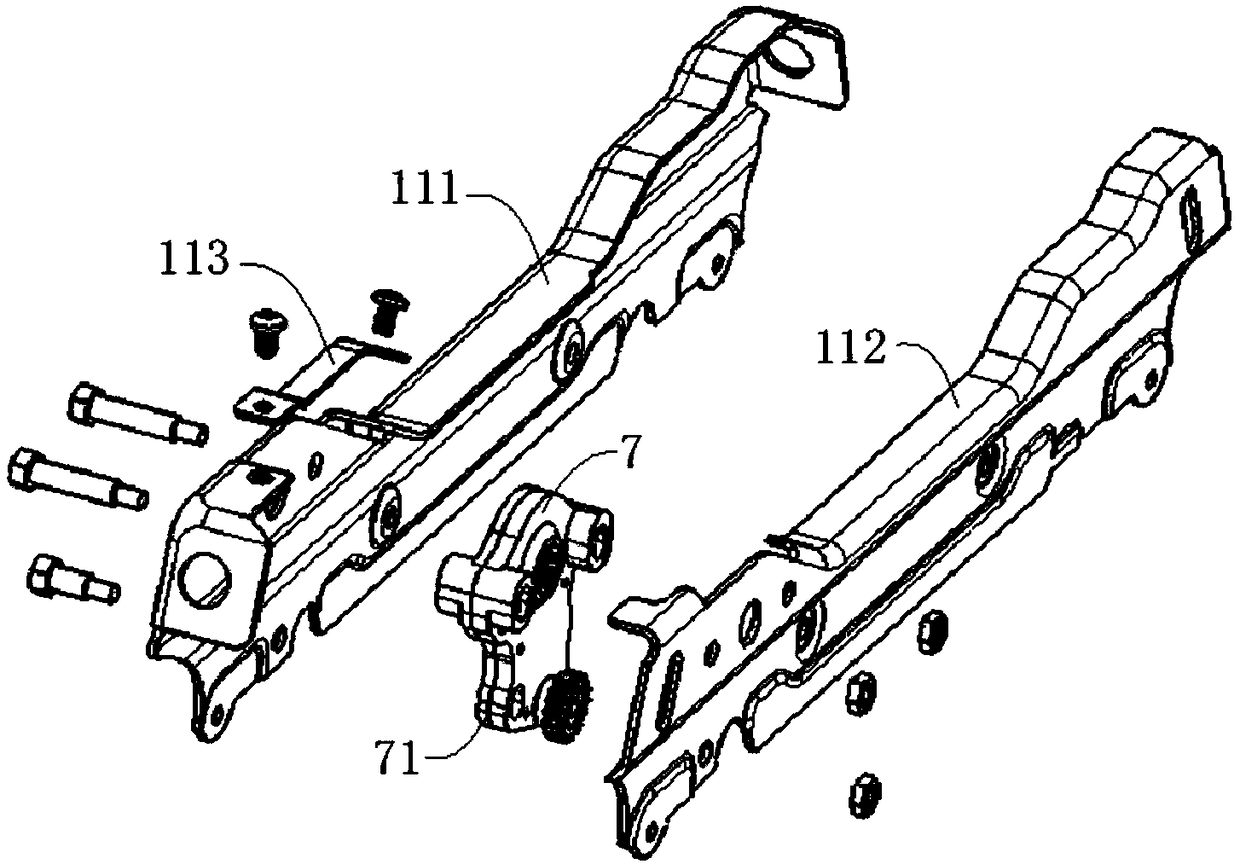

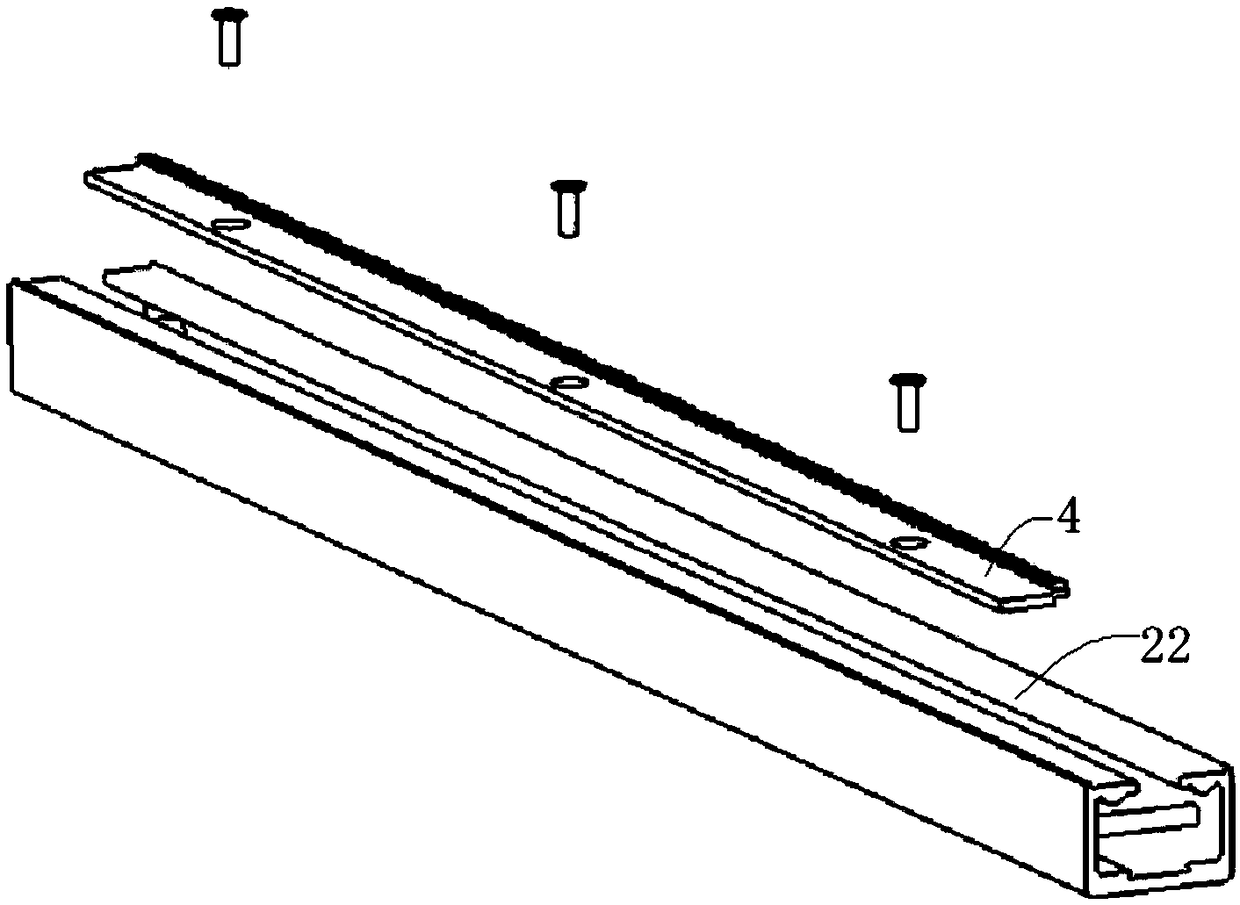

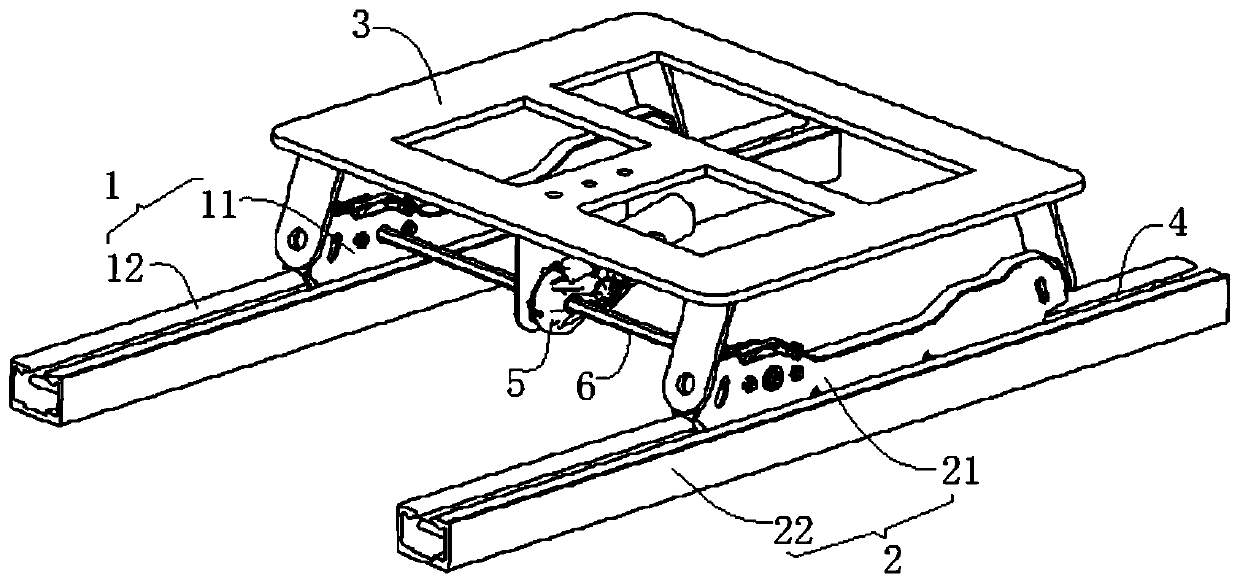

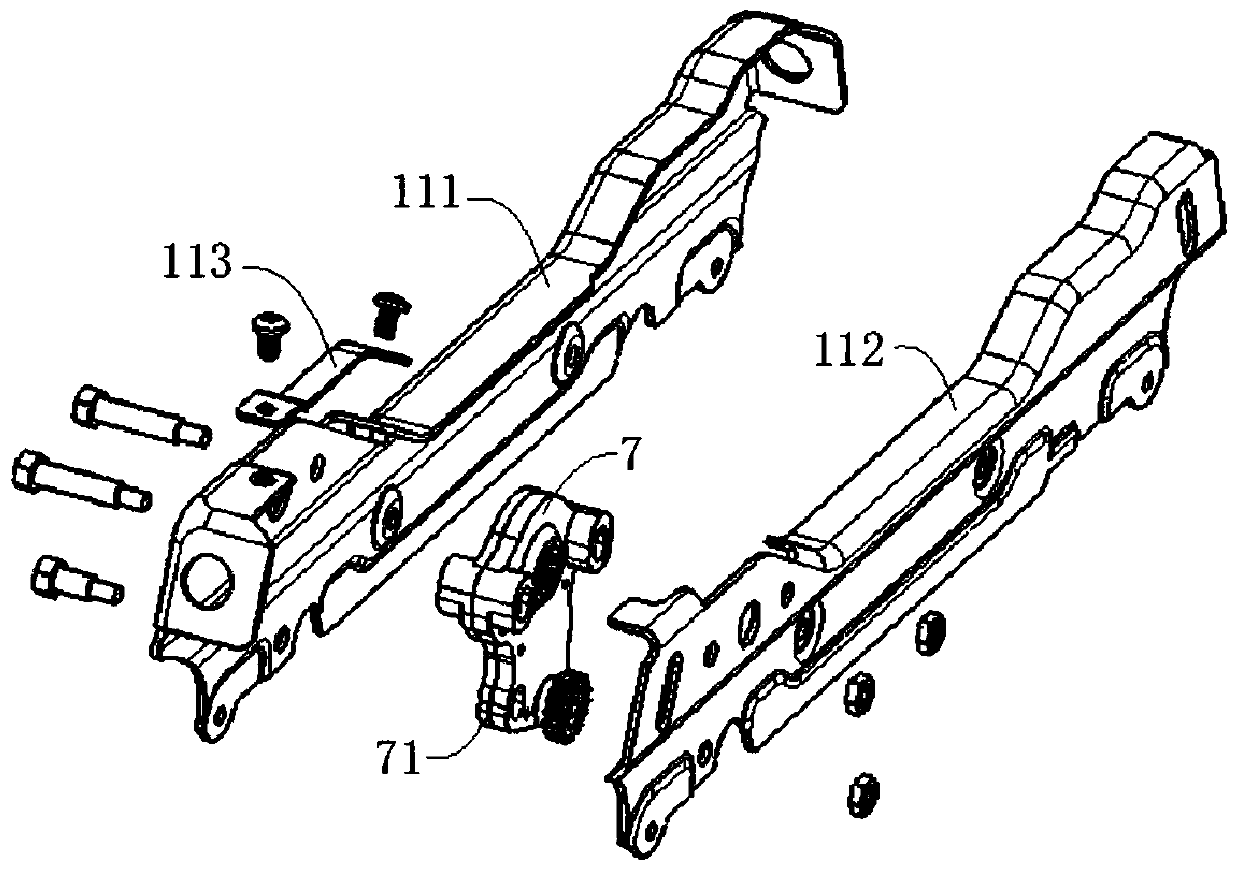

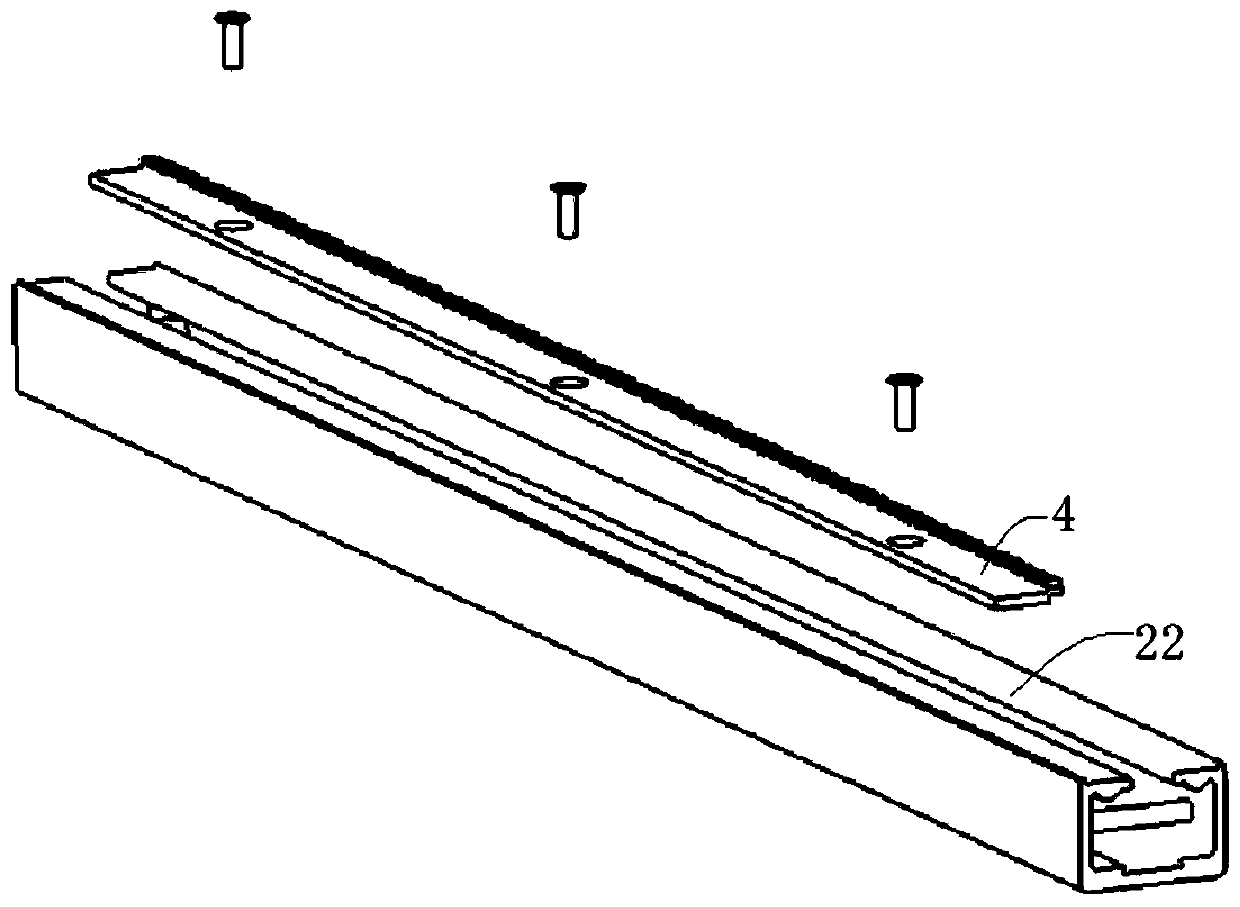

A new transmission system of electric long sliding rail

The invention discloses a novel transmission system of an electric long sliding rail, The sliding rail assembly comprises a left rail assembly and a right rail assembly, the left rail assembly comprises a slidably connected upper left rail and a lower left rail, the right rail assembly comprises a slidably connected upper right rail and a lower right rail, and the system comprises a slidably connected bridge with left and right sides fixed above the upper left rail and the upper right rail, respectively; A rack horizontally fixed in the inner grooves of the left lower rail and the right lowerrail; A driving motor connected to a middle lower surface of the slide rail connecting bridge; A transmission rod with a middle part connected with an output end of the drive motor; The transmission module comprises a housing, a driving gear and an output gear, wherein the output gear comprises an integrally formed meshing gear and a transmission gear. The transmission module is fixed inside the left upper rail and the right upper rail, respectively. The invention avoids the deflection problem of the filament rod in the long-stroke transmission, and effectively avoids the generation of abnormal sound.

Owner:KEIPER SEATING MECHANISMS CO LTD

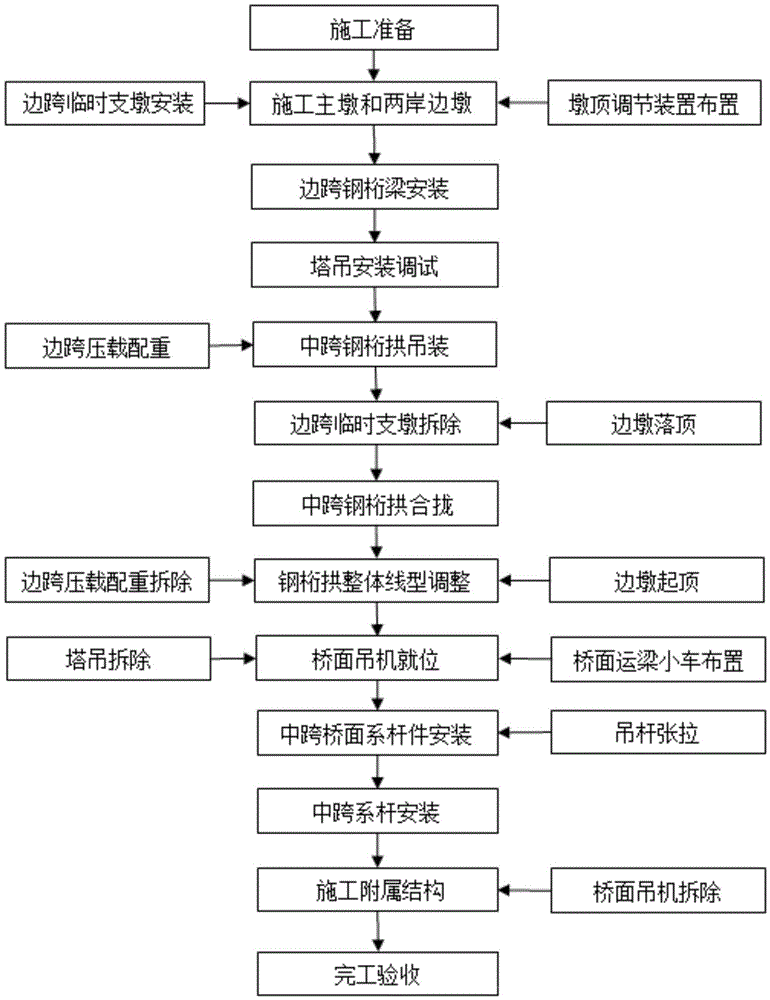

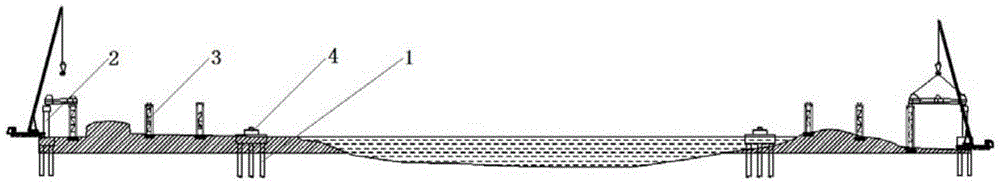

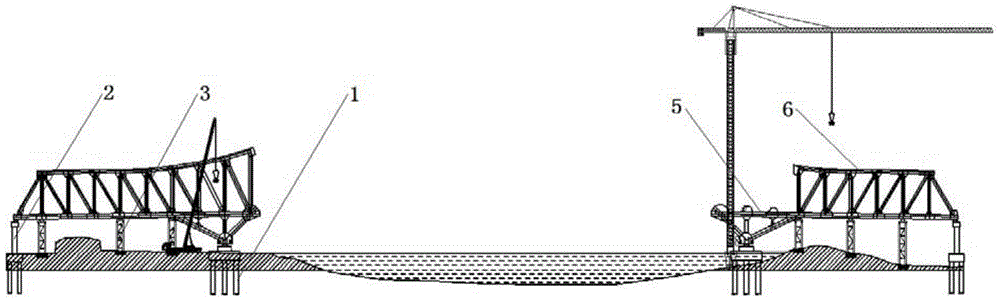

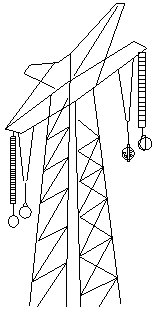

Construction method of middle-and-small-scale steel truss tied-arch bridge

ActiveCN105648914AReduce usageLifting speed is fastTruss-type bridgeBridge erection/assemblyBridge deckTower

The invention provides a construction method of a middle-and-small-scale steel truss tied-arch bridge. The construction method comprises the steps that steel beams on the upper portion of a main bridge are installed from supporting points on the two side edges to the midspan; all components of a main structure of side spans are installed firstly, then steel truss arches of a middle span are installed, lifting levers are installed after midspans of the steel truss arches are combined, and finally middle span tie bars and a bridge deck system of the middle span are installed through a crane; hoisting towers are symmetrically installed in the positions, corresponding to the two ends of the middle span, of the ground, and the steel truss arches of the middle span are hoisted through the cooperative construction of the two hoisting towers; hoisting arms of the two hoisting towers can cover the whole construction area specific to the middle-and-small-scale steel truss tied-arch bridge, and construction is conducted on the two sides at the same time, so that the hoisting speed is increased, and application of other hoisting equipment is reduced; during the installation of steel truss arch cantilevers of the middle span, the capsizing moment at the cantilever ends are balanced by adopting a ballast counterweight mode on the side spans, and the effect that the anti-capsizing stabilizing coefficient is larger than 1.3 is guaranteed; and when a combined section of the middle span is installed, jacks are arranged through pier tops of side piers, the combination error is adjusted in the mode that caving is conducted through the side piers and main piers are fixed, and the effect that the combined section can be installed smoothly is guaranteed.

Owner:HAIOD HEAVY ENG TECH

Double-pulley hanging method for synchronously unfolding ultrahigh-voltage multi-bundled conductor

InactiveCN103515860AReduce labor costsSave on wear and tearApparatus for overhead lines/cablesBolt connectionPulley

The invention discloses a double-pulley hanging method for synchronously unfolding an ultrahigh-voltage multi-bundled conductor. In the double-pulley hanging method, a connecting plate is used, wherein hanging holes with the same number of bundles of a conductor are formed on the outer periphery of the upper edge of the connecting plate; the hanging holes are used as hanging points; a hanging hole on the left side of the connecting plate and a hanging hole on the right side of the connecting plate are used as the hanging points for hanging two pulleys; the two hanging points have the same height; the hanging points are connected with the pulleys through parallel hanging plates; and the hanging points are connected and fixed with the parallel hanging plates through bolts. By the double-pulley hanging method, when a linear tower has an angle and the linear tower is adjacent to a tension tower, the pulleys deflect towards the inner corner sides and the two parallel hanging plates rightly clamp the connecting plate, so as not to affect flexible deflection of the pulleys, and perfectly solve the problems of circuit steering and pulley deflection.

Owner:STATE GRID CORP OF CHINA +1

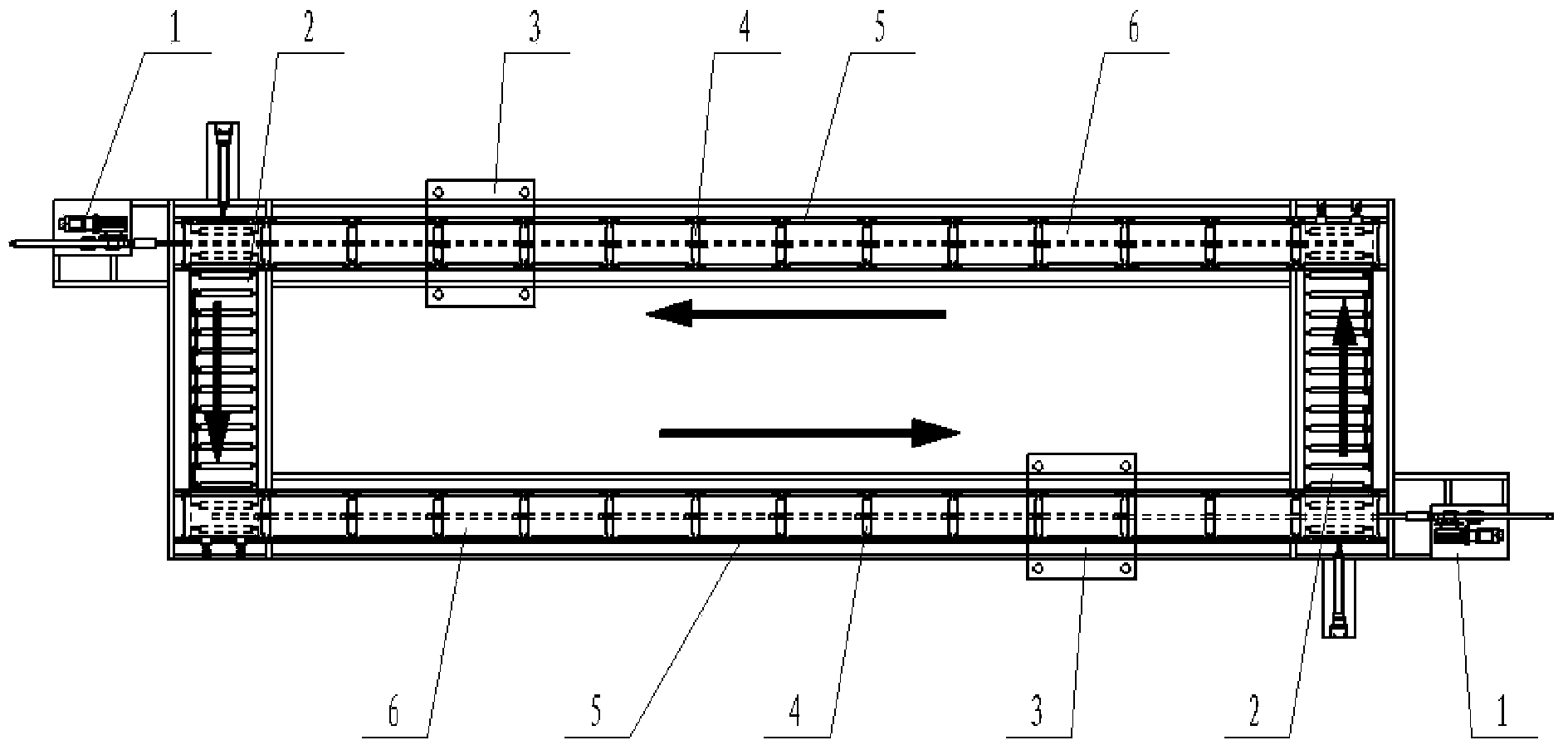

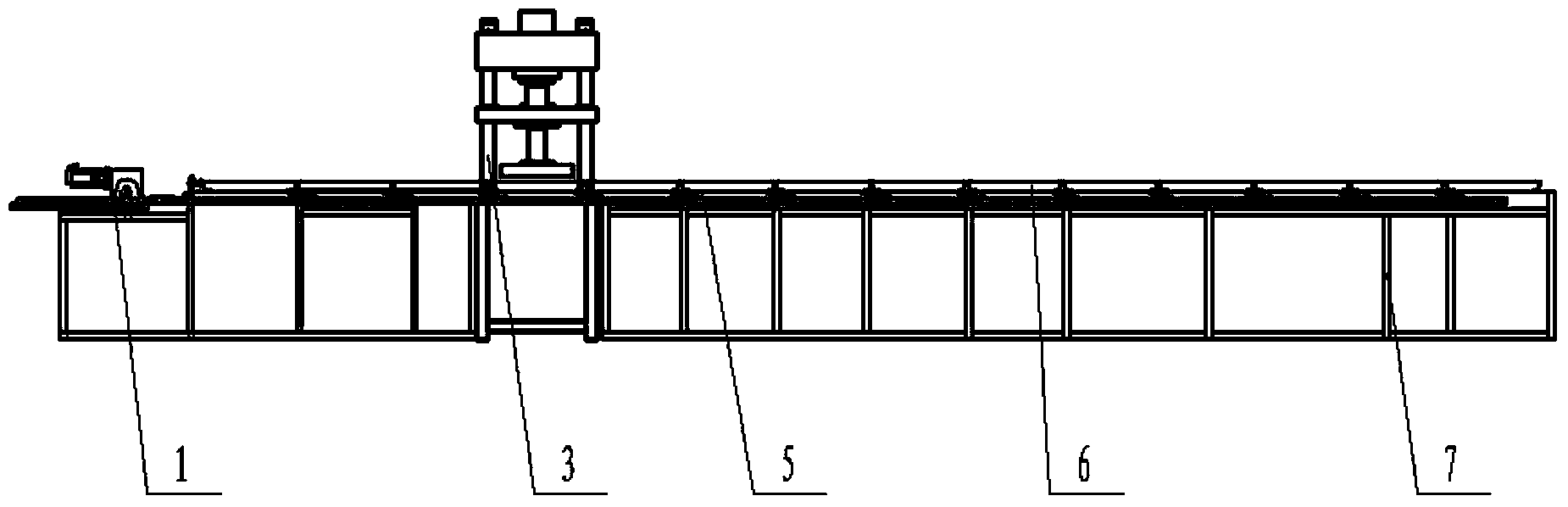

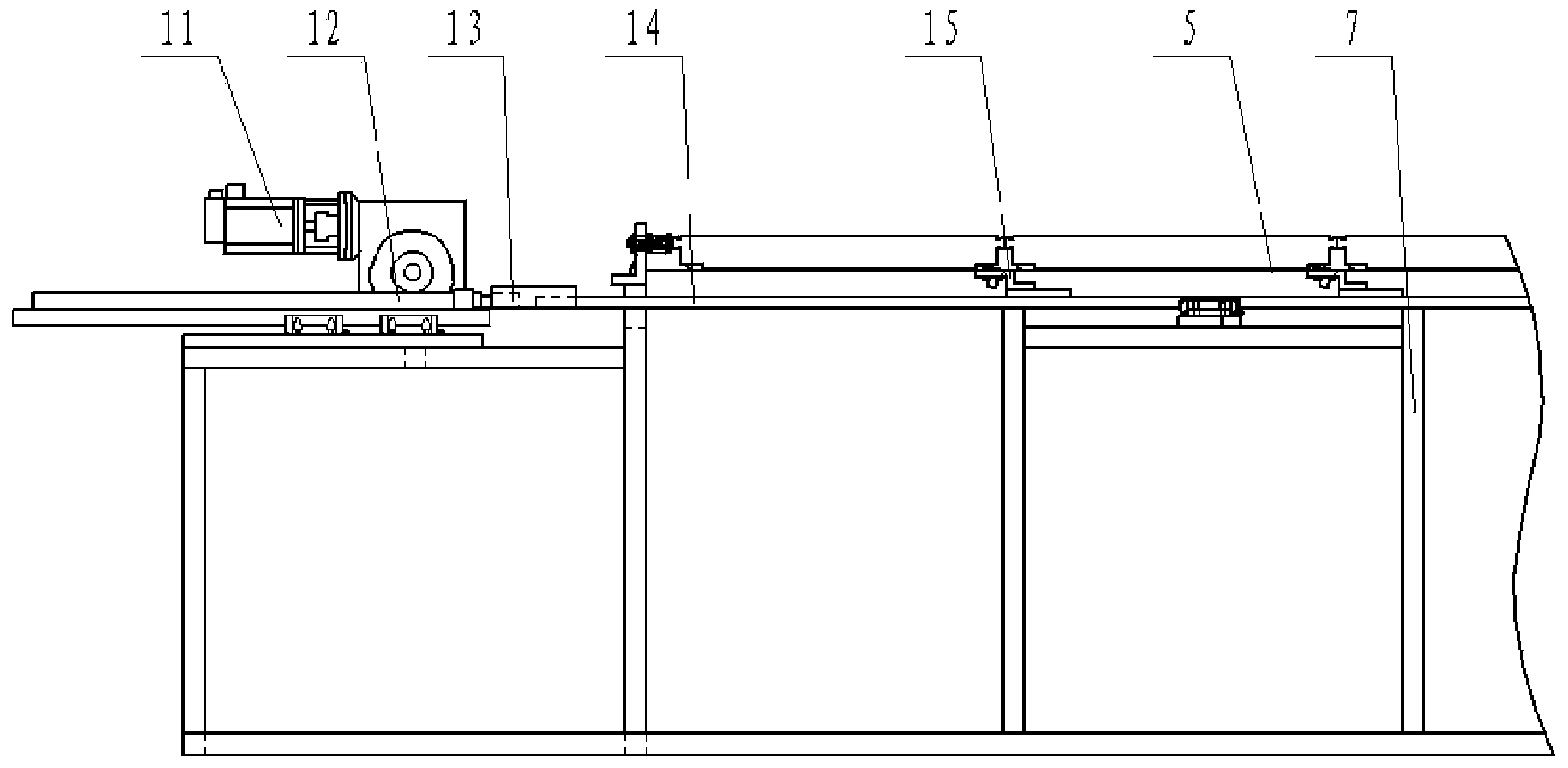

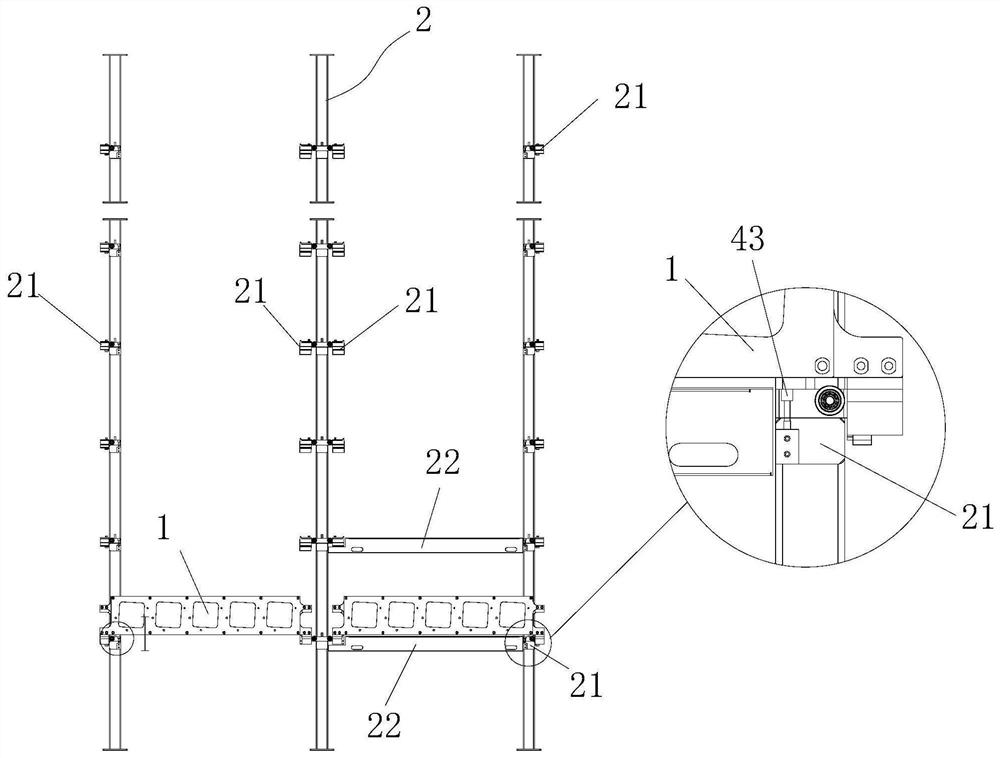

Horizontal die moving and circulating mechanism

ActiveCN103538142AOvercome the deflection problem that is easy to generate during the pushing processMove preciselyAuxillary shaping apparatusPunchingEngineering

The invention discloses a horizontal die moving and circulating mechanism which comprises a rack, two die flow lines and two punching machines. The die flow lines and the punching machines are mounted on the rack, the die flow lines are parallelly arranged, each die flow line is formed by linearly distributing dies in designed number, and the punching machines are mounted at the tail ends of the die flow lines respectively. The horizontal die moving and circulating mechanism is characterized by further comprising two die pulling devices and two sets of longitudinal die moving devices, the die pulling devices are arranged oppositely and mounted at the tail ends of the die flow lines respectively, the head end and the tail end of each die flow line are connected by one longitudinal die moving device, a circulating operation mechanism in process connection is formed in a same horizontal plane, dies circularly move along die flow line guide rails and the longitudinal die moving devices, the die flow line guide rails are mounted on the rack, and the die pulling devices and the punching machines are sequentially mounted at the tail ends of the die flow lines respectively.

Owner:HEBEI UNIV OF TECH

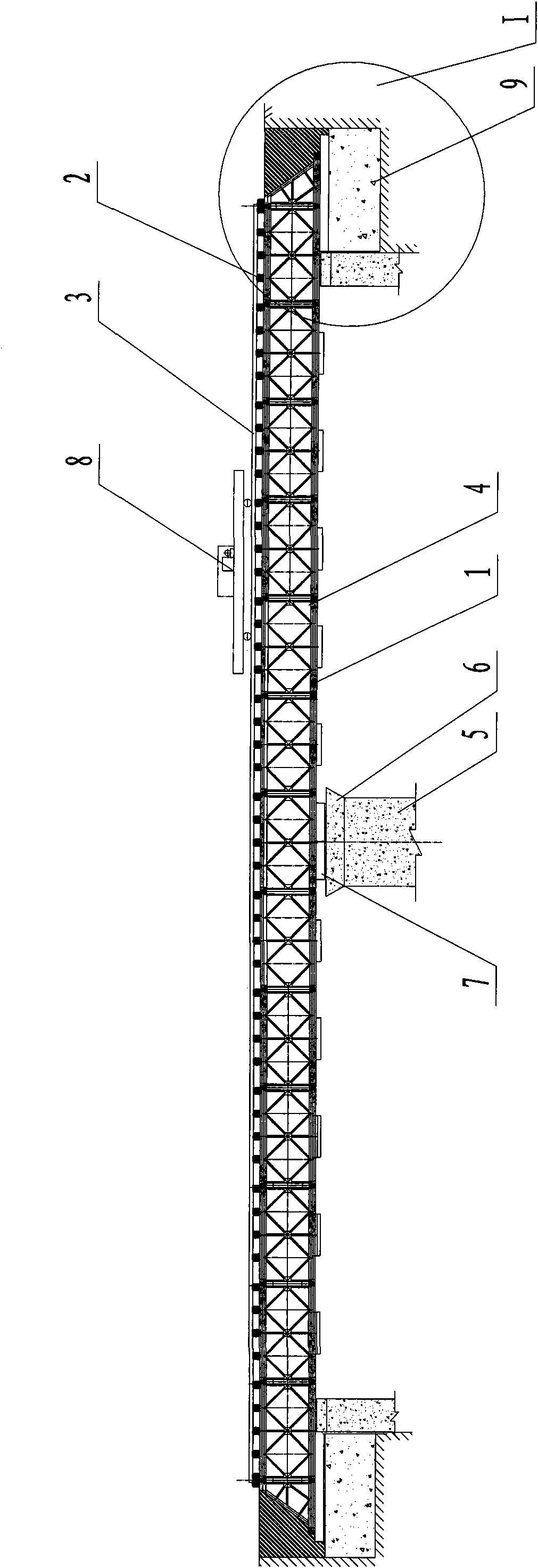

Break-of-gauge beam for large and long foundation pits and construction method thereof

InactiveCN101537968AEasy constructionSolve layout problemsTrolley cranesRunwaysSheet steelGantry crane

The invention provides a break-of-gauge beam for large and long foundation pits and a construction method thereof. The break-of-gauge beam comprises a matrix and steel sleepers for mounting gantry crane rails, wherein, the steel sleepers are fixed at the upper part of the matrix; and the matrix is formed by connecting a plurality of Bailey pieces via hinge pins. The construction method comprises the following steps: a. forming the matrix of the break-of-gauge beam by connecting a plurality of Bailey pieces via the hinge pins, and fixing two ends of the matrix into a concrete foundation provided with a U-shaped groove; b. mounting more than one supporting block below the middle part of the matrix, arranging a tray at the top of the supporting block and mounting steel plates between the tray and the matrix; and c. laying the steel sleeper for mounting the gantry crane rails at the upper part of the matrix to complete the construction of the break-of-gauge beam. The break-of-gauge beam for large and long foundation pits in the invention has the advantages of simple and compact structure, low cost, convenient construction, widely applicable range and high reliability.

Owner:CHINA RAILWAY TUNNEL

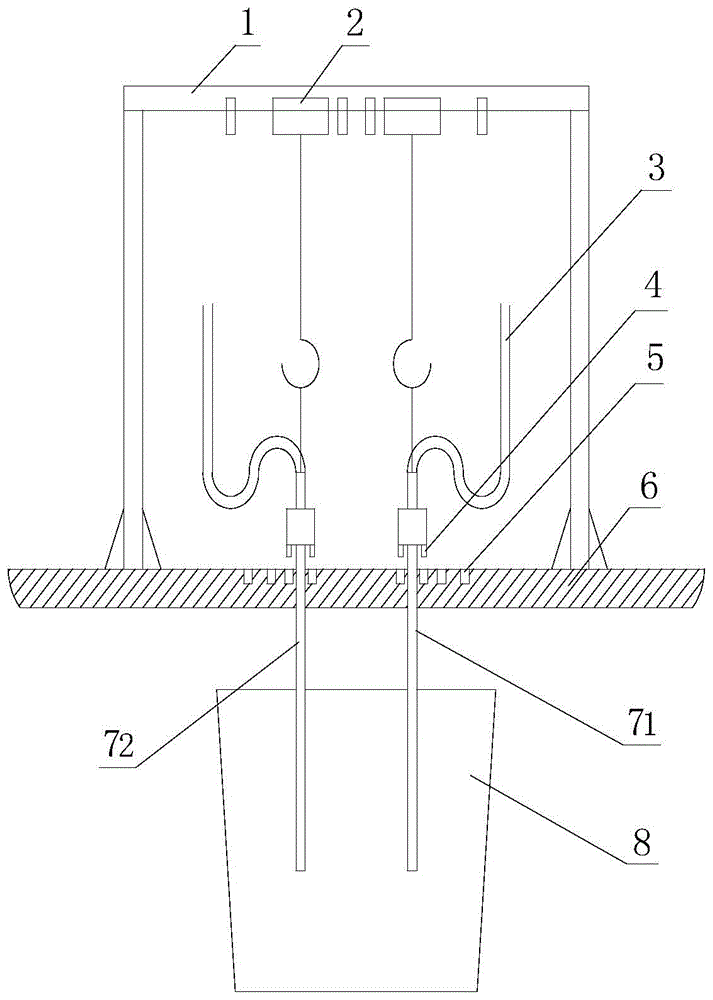

Surging molten iron slag-off method

ActiveCN105296709ASolve the deflection problemSimple mechanical structureCasting cleaning apparatusProcess efficiency improvementSlagInsertion depth

The invention provides a surging molten iron slag-off method. Two air injection guns are perpendicularly inserted into molten iron from the top of a molten iron tank. The interval between the two guns is 1 / 2 of the radius of a tank opening, the insertion positions are located at the points 1 / 2 of the radius of the tank opening, and the insertion depth ranges from 0.5 m to 2.5 m; the air supply intensity is controlled to be larger than or equal to 2 NL / (min t) and the pressure is larger than 0.7 MPa; the air supply intensity of the air injection gun A is controlled to be 2 NL / (min t), the air supply intensity of the air injection gun B is gradually increased till the molten iron boiling exposed face makes contact with the wall of the molten iron tank, the air supply intensity of the air injection gun A is adjusted to be the same as that of the air injection gun B till the area of the molten iron boiling exposed face is larger than 1 / 2 of the tank opening of the molten iron tank, and therefore slag-off operation is started; after slag-off operation is finished, the air injection guns are pulled out of the molten iron and inject air continuously for over 30 s; and hoist cranes are used for lifting the air injection guns, so that locating pins are away from locating holes from 190 mm to 210 mm, the hoist cranes are transversely moved till the interval between the two guns reaches the length of the radius of the tank opening and then the hoist cranes fall, and the locating pins fall into new locating holes. By the adoption of the surging molten iron slag-off method, slag-off time can be shortened and iron loss and the converter resulfurization amount generated in the desulfuration slag-off process can be effectively reduced.

Owner:ANGANG STEEL CO LTD

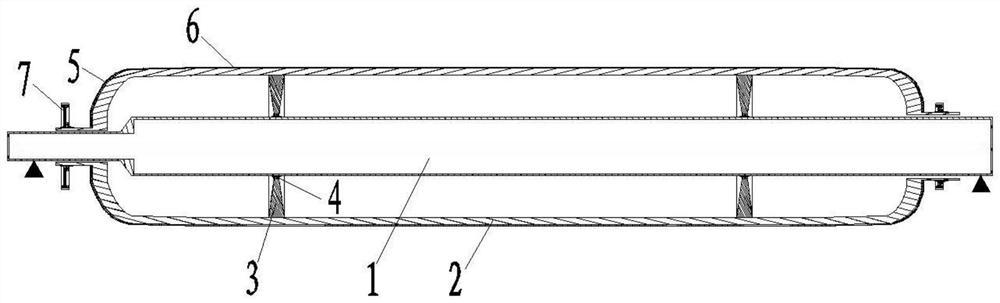

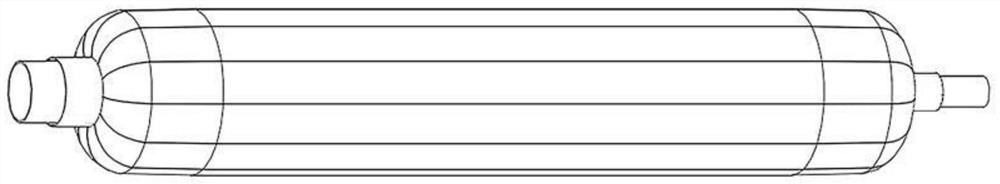

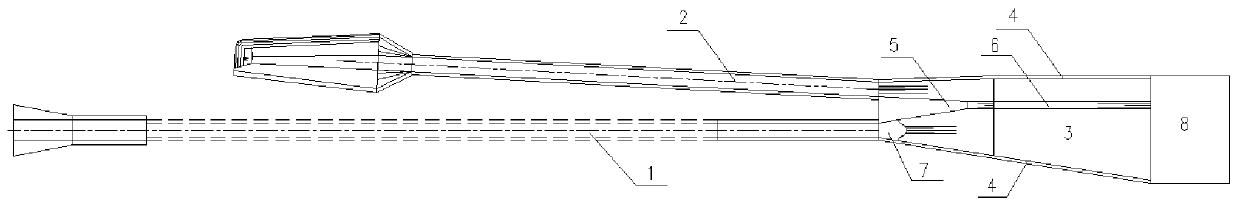

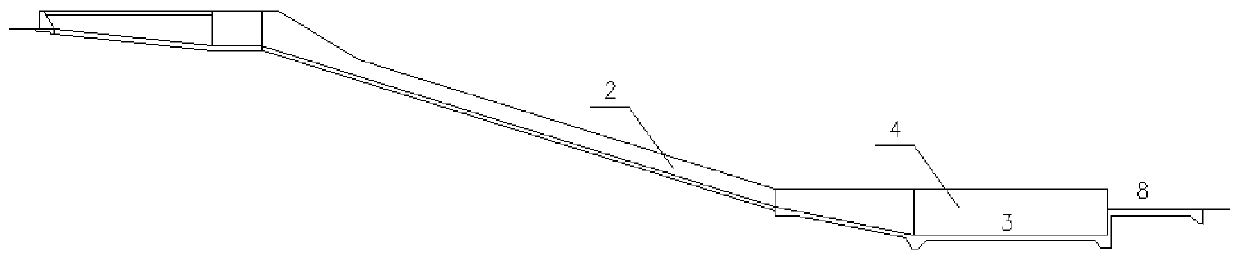

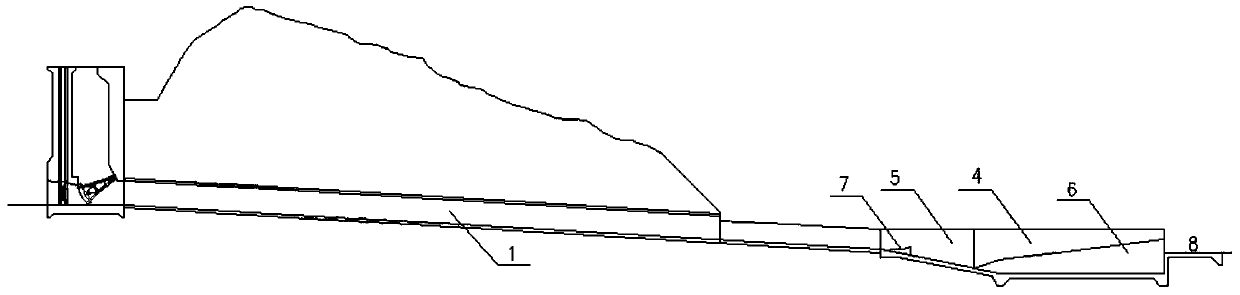

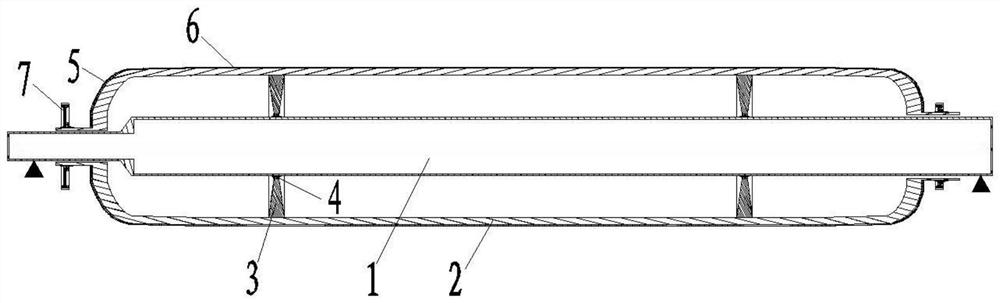

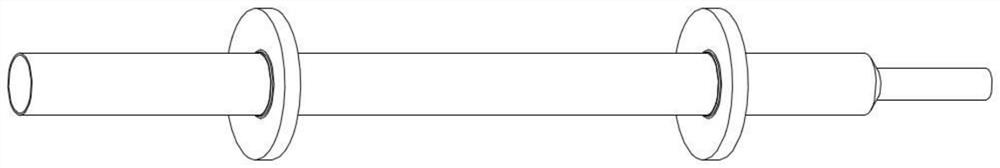

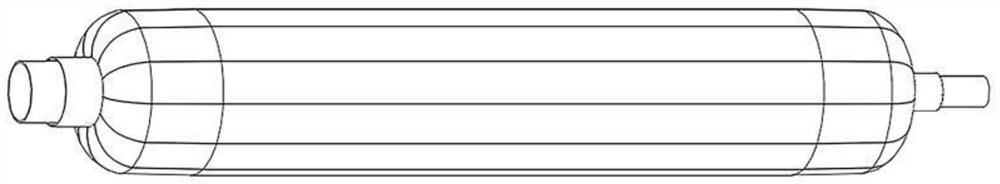

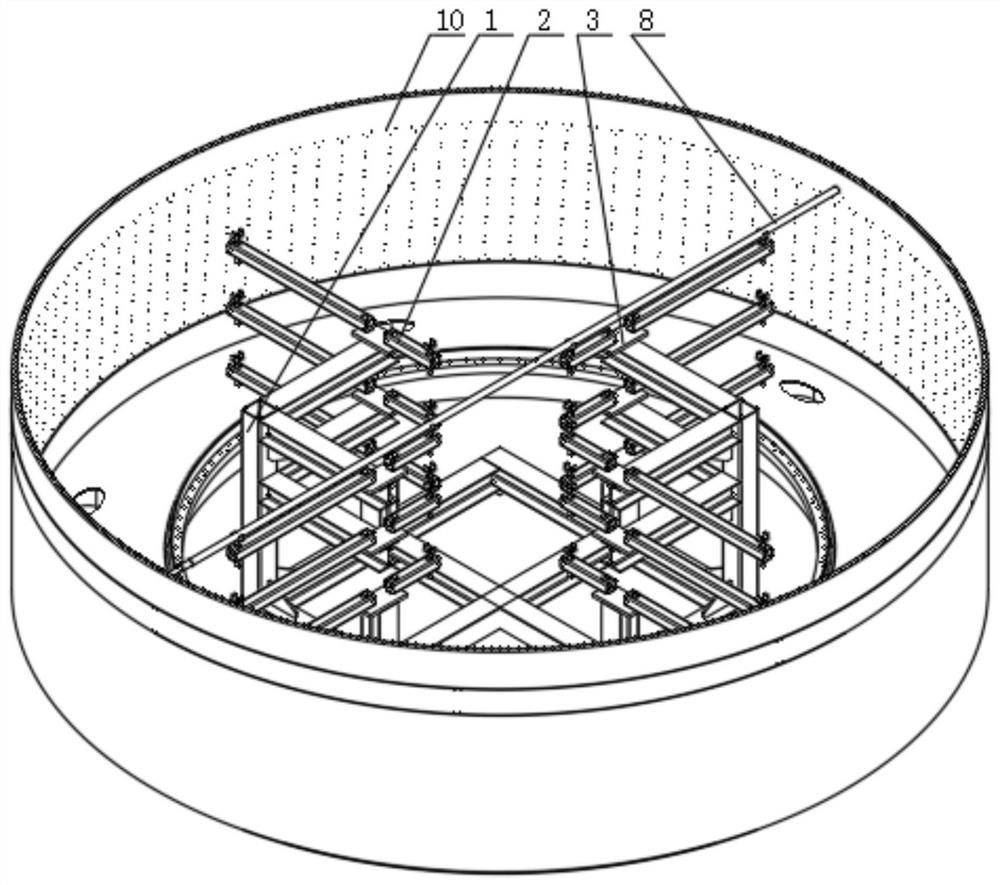

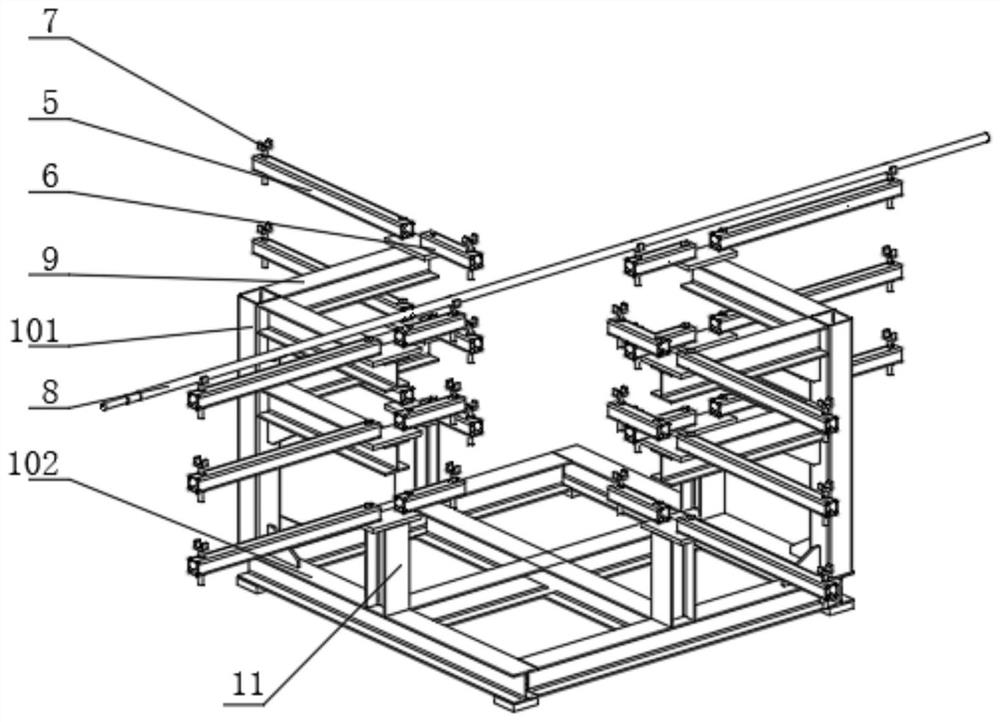

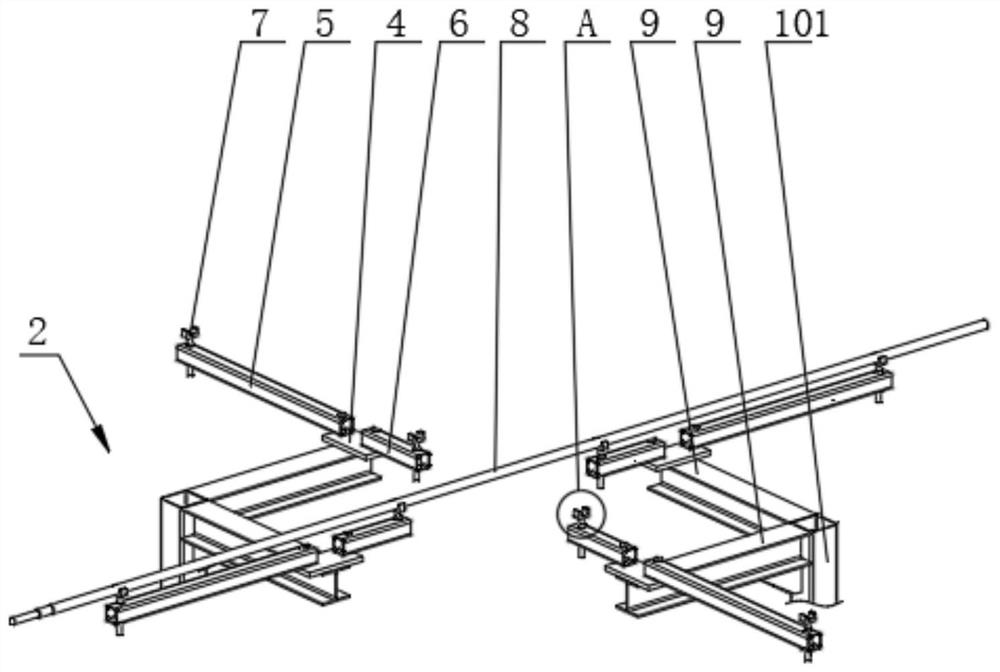

Large composite material winding body core mold device

The invention relates to the technical field of composite material winding shell core molds, and particularly discloses a large composite material winding body core mold device. The large composite material winding body core mold device comprises a core shaft, an outer mold, a first bearing seat, a second bearing seat, a first self-aligning bearing and a second self-aligning bearing; the first self-aligning bearing and the second self-aligning bearing are both arranged on the core shaft; the first bearing seat and the second bearing seat are correspondingly arranged on the first self-aligningbearing and the second self-aligning bearing; the outer mold is connected with the core shaft through the first bearing seat, the second bearing seat, the first self-aligning bearing and the second self-aligning bearing, and the outer mold is connected with a driving device. According to the composite material winding shell core mold, the movement modes of all existing core molds are overturned, the supporting span of the outer mold is greatly reduced, the deflection problem of the core mold is successfully solved from the design source, deformation between the outer mold and the core shaft iscompletely isolated through the two self-aligning bearings, and deflection deformation or thermal expansion deformation of the core shaft does not affect the outer mold.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Outlet energy dissipation arrangement structure for centralized arrangement of different water release structures on shore of hydroelectric project

PendingCN109750641ASolve the deflection problemSolve problems such as insufficient energy dissipationBarrages/weirsWater flowEngineering

The invention discloses an outlet energy dissipation arrangement structure for centralized arrangement of different water release structures on the shore of a hydroelectric project. The included anglebetween the axis of a flood discharge tunnel and the axis of a spillway is small, the outlet portions of the flood discharge tunnel and the spillway share one stilling pool for energy dissipation, the stilling pool is arranged in an asymmetric horn shape on a plane, the bottom of the stilling pool is composed of a slope transition section and a horizontal section, and the auxiliary energy dissipation facility comprises a diversion pier, a submerged middle partition wall, a waveform reverse arc small flip bucket and an apron. The diversion pier is positioned on the slope transition section ofthe stilling pool, and the initial end of the diversion pier is positioned in the middle of the flood discharge tunnel outlet and the spillway outlet and is a widened equal-top-elevation isolation wall, and the submerged middle partition wall is located at the downstream of the diversion pier and is a variable-top-elevation partition wall with equal width and gradually increased height, and the stilling pool is divided into a left part and a right part by the diversion pier and the submerged middle partition wall. The waveform reverse arc small flip bucket is located at the slope transition section of the stilling pool. According to the outlet energy dissipation arrangement structure, the problems that when a same asymmetric energy dissipation pool is adopted for centralized energy dissipation at different flood discharge building outlets, rotation and energy dissipation of high-speed asymmetric water flow are not sufficient are solved, and engineering investment is saved.

Owner:POWERCHINA BEIJING ENG

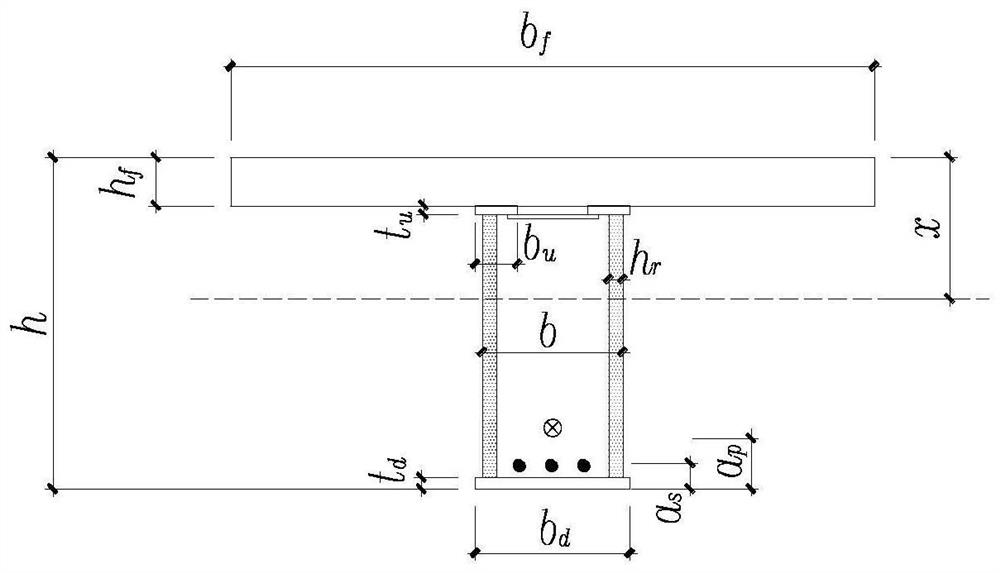

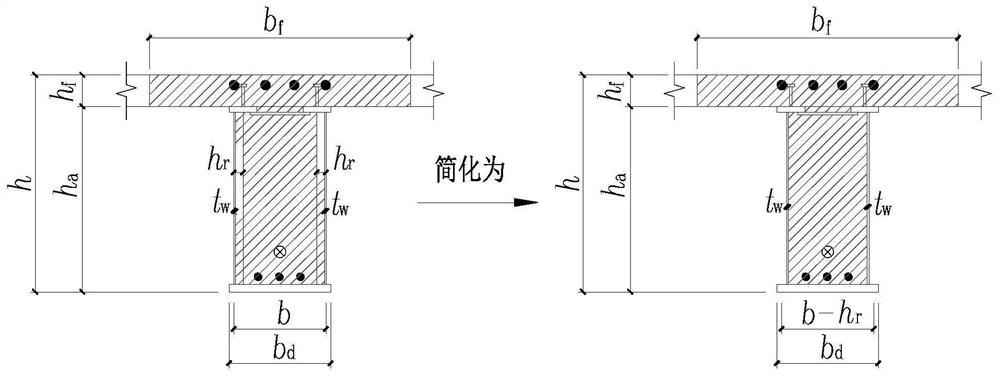

Method for calculating flexural rigidity of externally-wrapped corrugated side plate-concrete composite beam

PendingCN111611642AControl deflectionReduce crack widthGeometric CADDesign optimisation/simulationFloor slabElastic analysis

The invention discloses a method for calculating the flexural rigidity of an externally-wrapped corrugated side plate-concrete composite beam. By means of the method, the flexural rigidity of the externally-wrapped corrugated side plate-concrete composite beam can be rapidly calculated. The method comprises the steps that the thickness and width of a steel top plate and a steel bottom plate of anexternally-wrapped corrugated side plate-concrete composite beam, the wave height of a corrugated side plate, the height and width of a beam section, the height and width of a concrete floor and the elasticity modulus of concrete and steel are obtained; according to elastic analysis, the average value of the widths of the wave crests and the widths of the wave troughs of the corrugated steel plateis obtained according to the effective section width of concrete in the corrugated steel plate; the section of the composite beam is converted into the section of the steel beam by adopting a section conversion method to calculate the equivalent section neutralization axis of the composite beam; and the centroid of the section of the steel beam is obtained through conversion of the elastic neutralization axis of the composite beam, the distance x between the centroid of the section of the steel beam and the topmost end of the section is calculated, moment taking is conducted on the neutralization axis through concrete and a steel component, and the flexural rigidity is calculated through the moment taking result.

Owner:JIANGNAN UNIV

Processing method of curved surface parts and processing equipment of curved surface parts

ActiveCN104858712BSolve the deflection problemReduce machining errorsProgramme-controlled manipulatorAutomatic control devicesReverse modeling3d scanning

The invention provides a machining method for parts with curved surfaces. The machining equipment is provided with a robot, a posture calibration block, a three-dimensional scanning device and a host computer, and the machining method comprises the following steps: scanning a part I with a curved surface I and the posture calibration block with the three-dimensional scanning device; sending the obtain image data I to the host computer, so as to conduct reverse modeling and data analysis on the image data I, and further obtain a first relative deflection value; machining the part I; replacing the part I with another part II with a curved surface II after the part I is machined; scanning the part II and the posture calibration block with the three-dimensional scanning device; sending the obtain image data II to the host computer, so as to conduct reverse modeling and data analysis on the image data II, and further obtain a second relative deflection value; calculating the deflection error between the second relative deflection value and the first relative deflection value; carrying out compensation on the robot with the host computer according to the deflection error; machining the part II; repeating the above steps till all the parts are machined. The invention further provides machining equipment for the parts with the curved surfaces.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

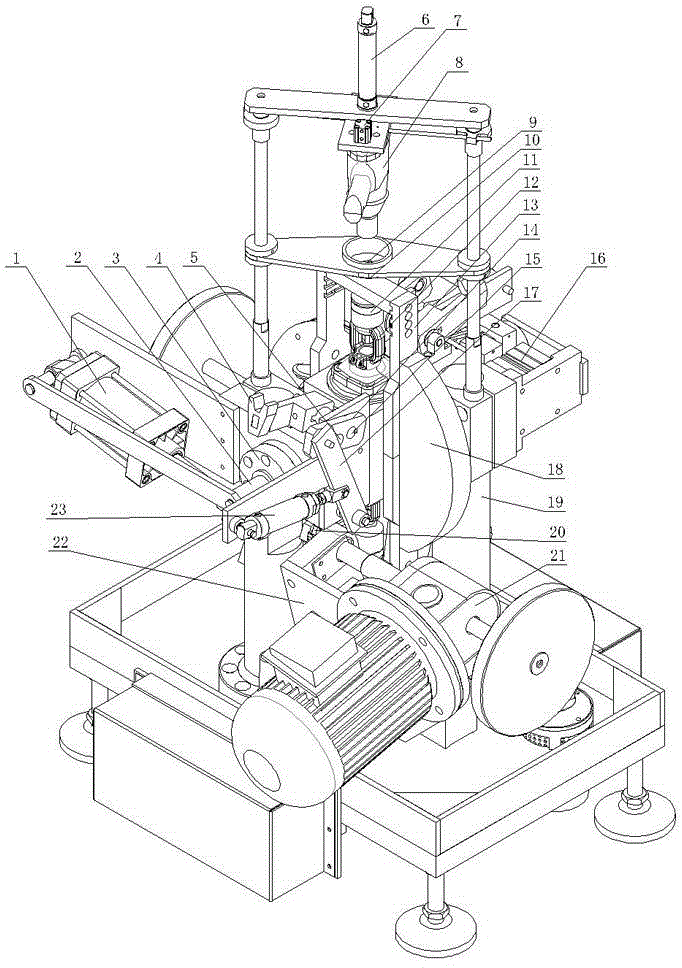

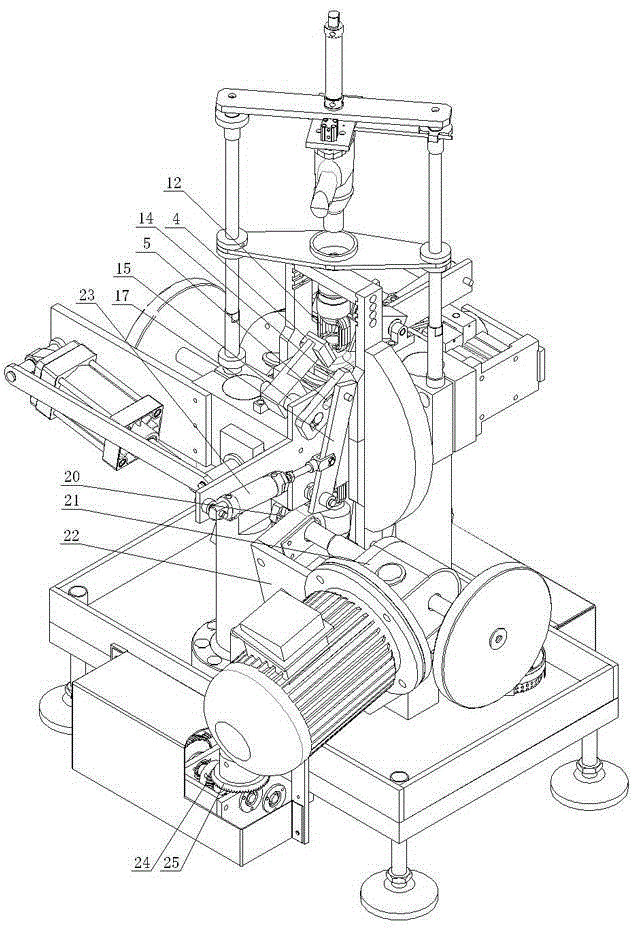

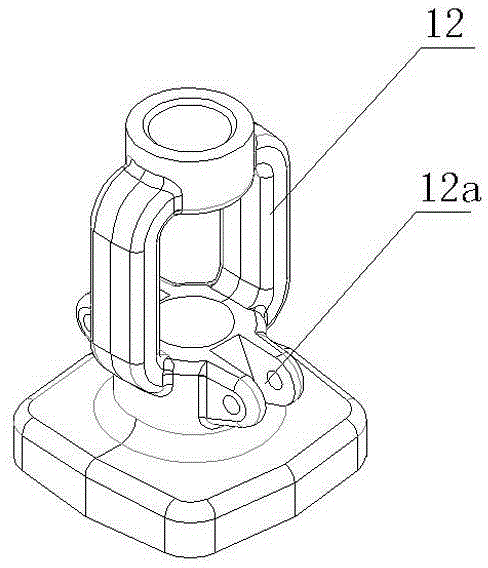

Automatic valve cover ear milling machine

ActiveCN104400088ATwo-way flip action is stableAccurate locationWork clamping meansMilling equipment detailsLocking mechanismEngineering

The invention discloses an automatic valve cover ear milling machine. The machine is characterized in that the machine comprises a fixed seat and an overturning rack, the overturning rack is bidirectionally overturns on the fixed seat at 180DEG in a vertical direction and is promoted by an overturning mechanism, the overturned overturning rack is locked by an overturning locking mechanism, the overturning rack is provided with an upper workpiece positioning hole, a lower workpiece positioning hole, an upper workpiece clamping block and a lower workpiece clamping block, the upper portion of the fixed seat is provided with a clamping operating mechanism and a pre-positioning compaction mechanism, the lower portion of the fixed seat is provided with a milling power mechanism, the pre-positioning compaction mechanism pre-positions and compacts the workpiece in the upper workpiece positioning hole when the overturning rack is in an upward turning or downward turning position, the clamping operating mechanism operates the upper workpiece clamping block to act in order to clamp the workpiece in the upper workpiece positioning hole, and after the milling power mechanism is promoted by an upper swinging mechanism, two side ear milling of the workpiece in the lower workpiece positioning hole is carried out by a disk miller. The automatic valve cover ear milling machine can realize the automatic milling processing of two side ears of the valve cover, substantially improves the work efficiency, and improves the processing precision.

Owner:浙江伯特利科技股份有限公司

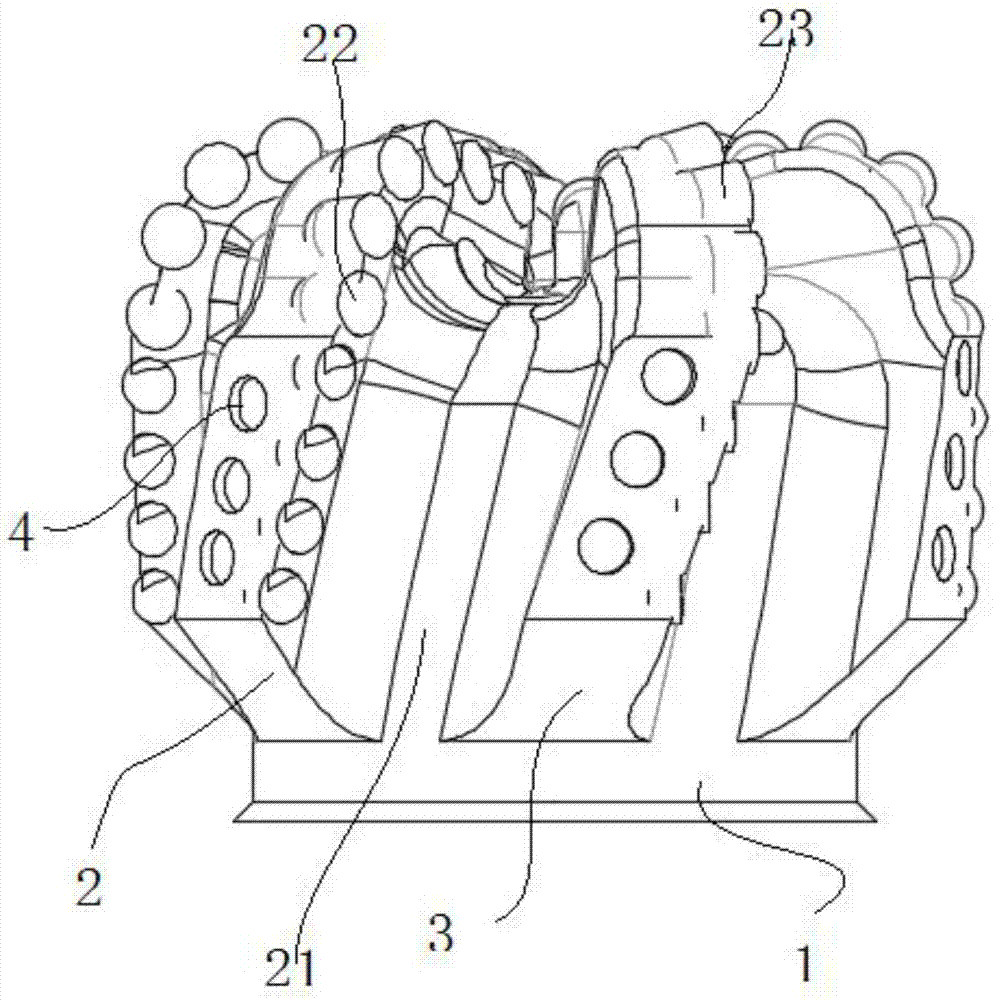

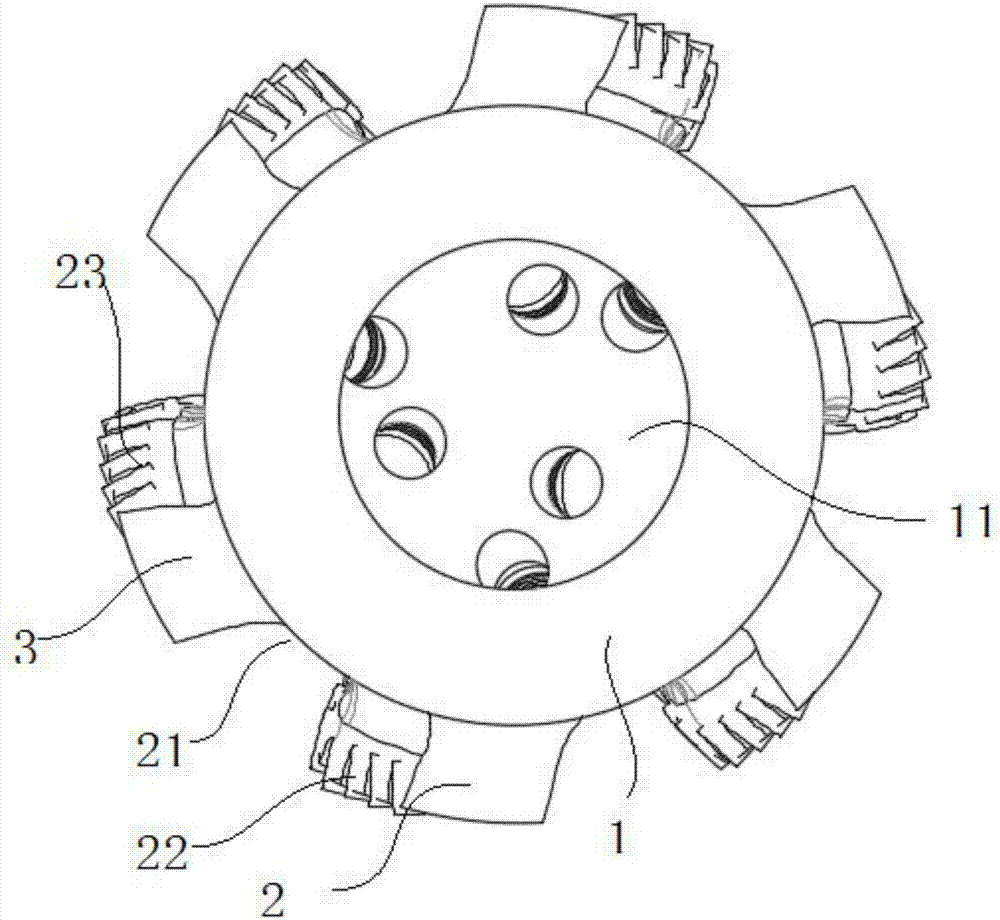

PDC drill bit for well drilling

ActiveCN106907112APrevent guide deflectionUnbalance reliefDrill bitsConstructionsMining engineeringWell drilling

The invention discloses a PDC drill bit for well drilling. The PDC drill bit comprises a drill bit body, a plurality of cutting edges and a plurality of flushing openings. A flushing cavity is formed in the drill bit body; the top ends of the cutting edges are reduced in sequence to form a spiral line structure, the cutting edges are arranged at a crown part of the drill bit body in a protruding mode, the angles formed between the adjacent cutting edges are different, a discharging groove is formed between any two adjacent cutting edges, a plurality of cutting tooth and a plurality of auxiliary cutting edges are arranged on the same sides of the cutting edges, the auxiliary cutting edges are arranged in the centers of the discharging grooves in a protruding mode and have the number equal to that of the discharging grooves, the tops of the auxiliary cutting edges are located at the midpoints of the connecting line of the top of the highest cutting edge and the top of the lowest cutting edge, and a plurality of auxiliary cutting teeth are arranged on the auxiliary cutting edges in the direction of the same sides of the cutting edges. The flushing openings are communicated with the flushing cavity. The problem that when a drill bit generates unbalanced force at the bottom of a well, the drill bit deflects is solved, and hole drilling stability is greatly improved.

Owner:YICHANG SHENDA PETROMACHINE

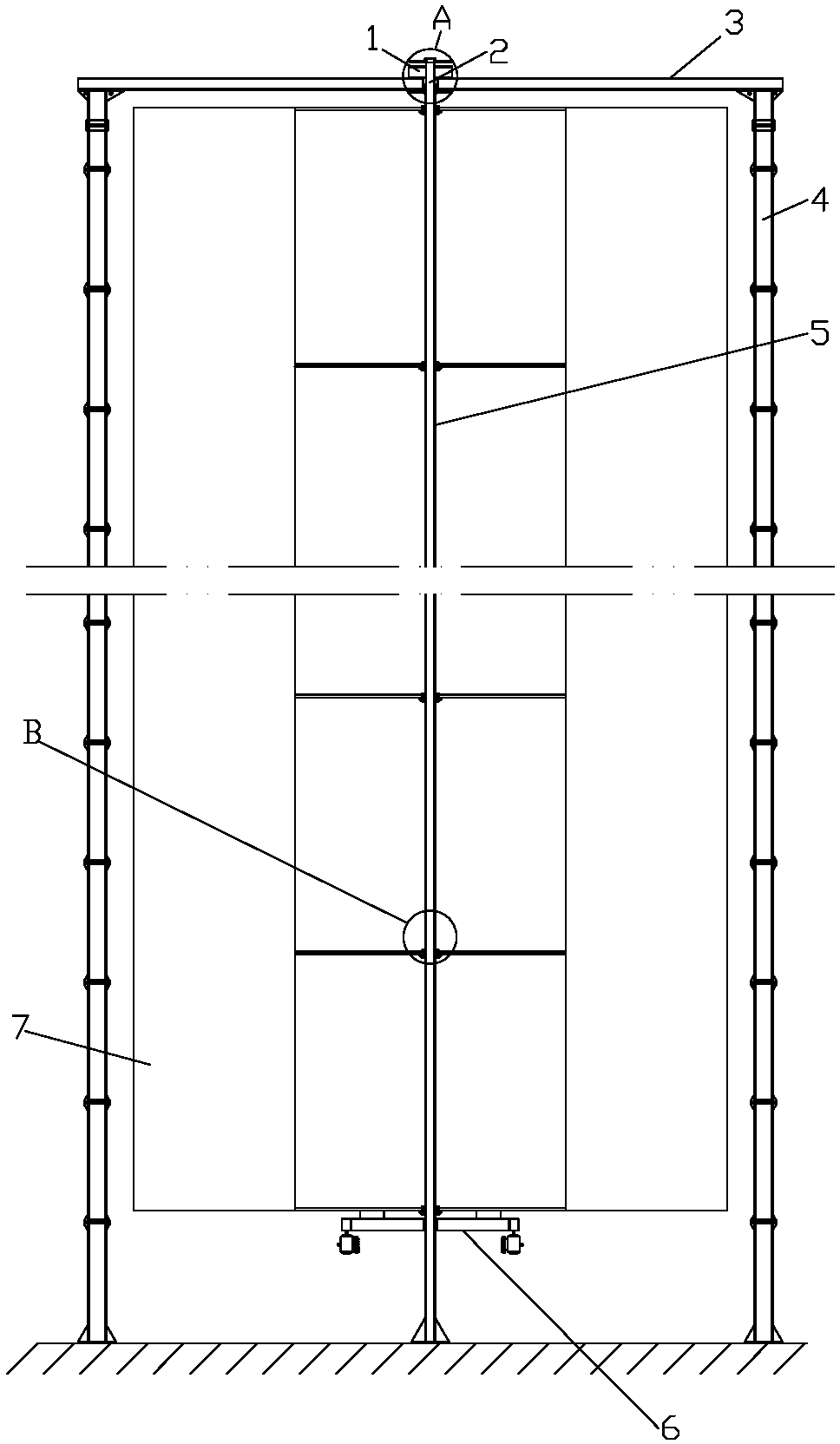

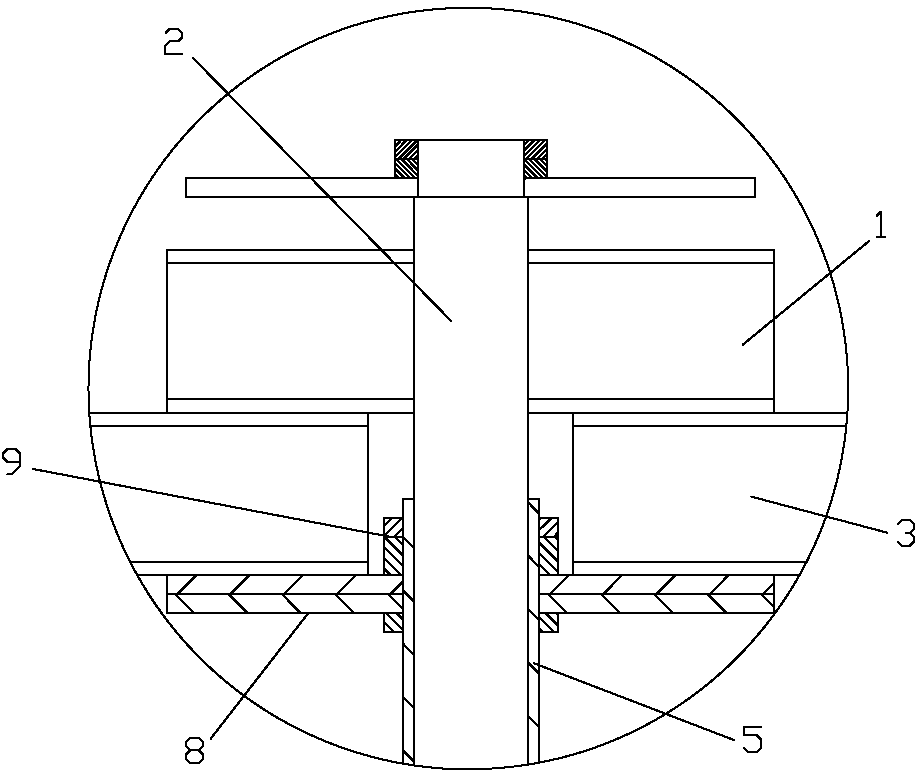

Vertical type suspension structure wind driven generator

InactiveCN103104414AImprove carrying capacityEasy to install and maintainFinal product manufactureMachines/enginesWind drivenTower

The invention relates to a vertical type suspension structure wind driven generator which comprises pneumatic devices, a power generation device, a suspension stand column, a suspension cross beam, bearing seats, a central stand column and a central stand column sleeve, wherein the top end of the suspension stand column is fixedly connected with the suspension cross beam, the central stand column is arranged on the outer side of the central stand column in a sleeved mode, the upper end of the central stand column sleeve is fixed on the suspension cross beam, a seam allowance is arranged on each section of the central stand column sleeve, multiple bearing seats are respectively arranged on the corresponding central stand column sleeve in a sleeved mode, and the lower end faces of bearings arranged in the bearing seats are pressed on the corresponding seam allowance. The pneumatic devices are arranged on the multiple bearing seats, and a power generator is connected with the pneumatic devices. By the technical scheme, tower type design is changed into hanging clock type design, so that bearing capacity of a whole wind driven generator is greatly improved, and the vertical type wind driven generator with the height of dozens of meters or even more can be manufactured. The vertical type suspension structure wind driven generator is simple in structure, and quite convenient to install and maintain, and greatly reduces manufacturing and maintenance cost.

Owner:丁万平

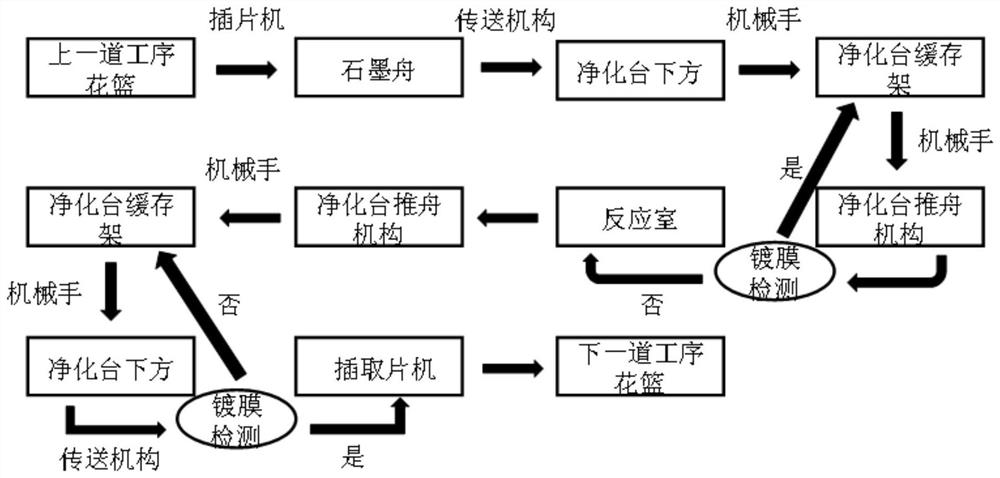

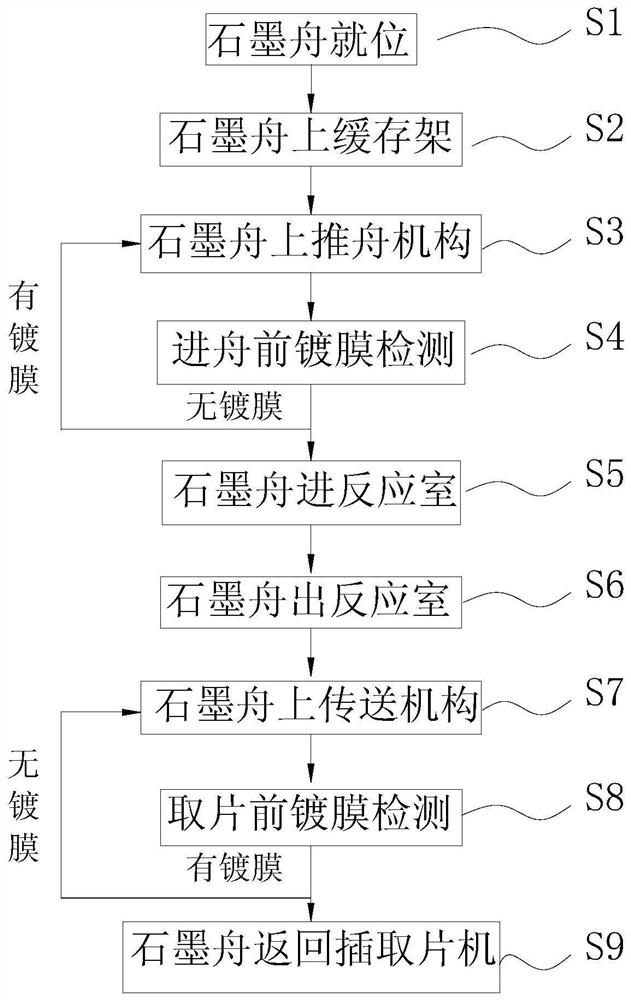

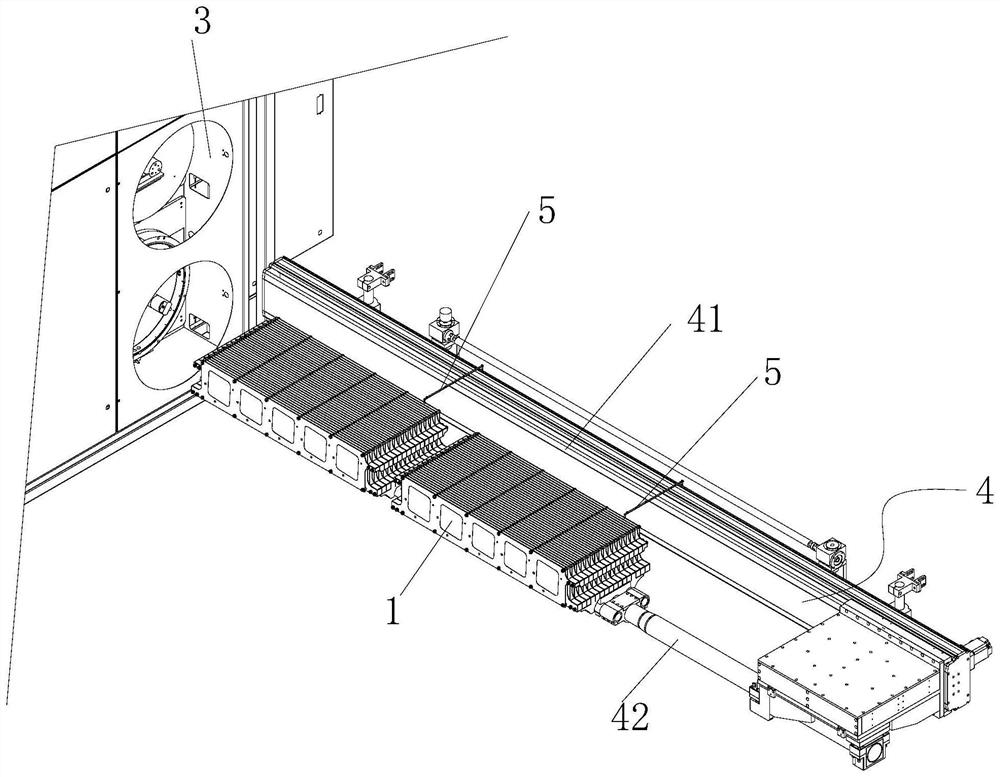

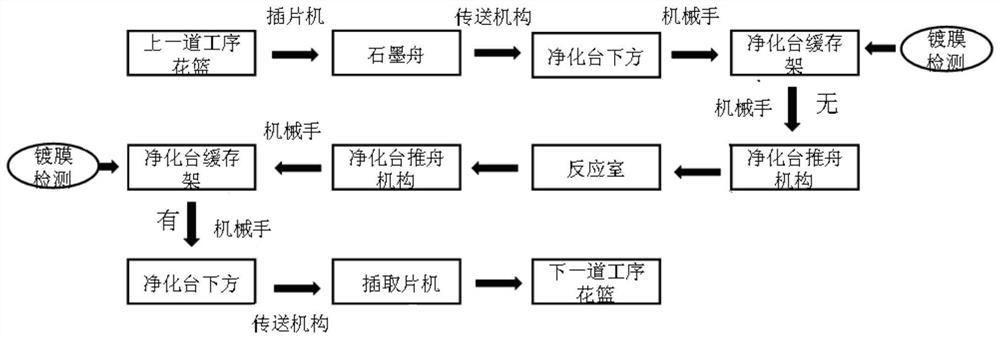

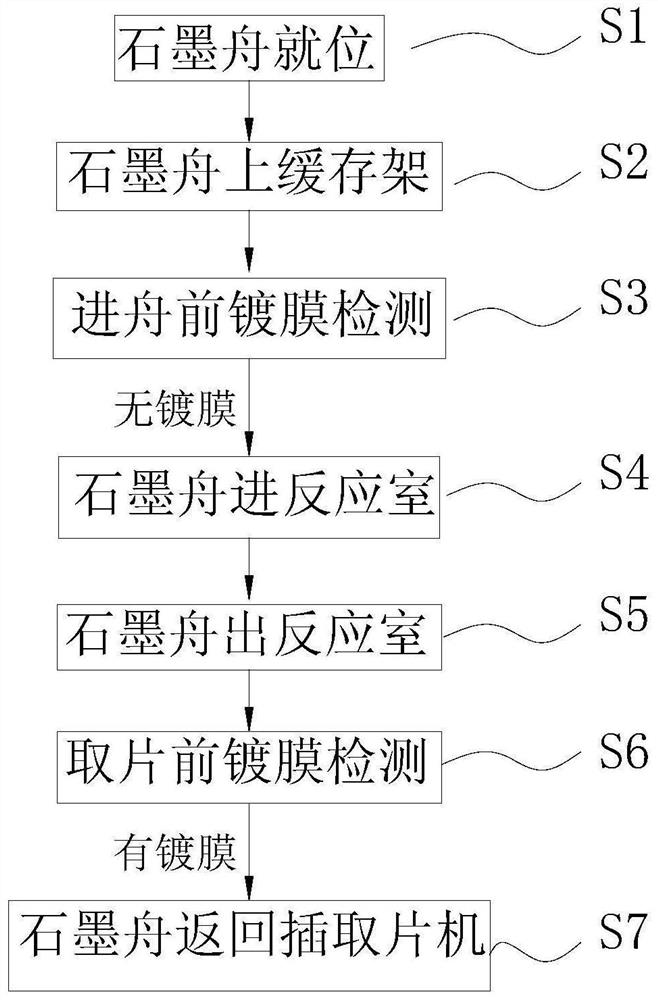

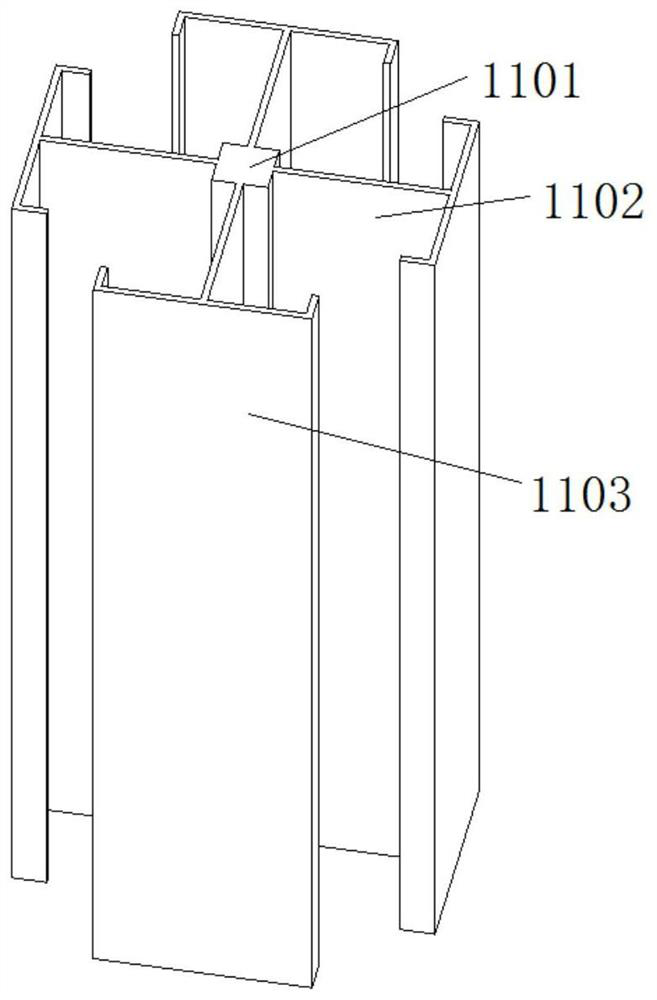

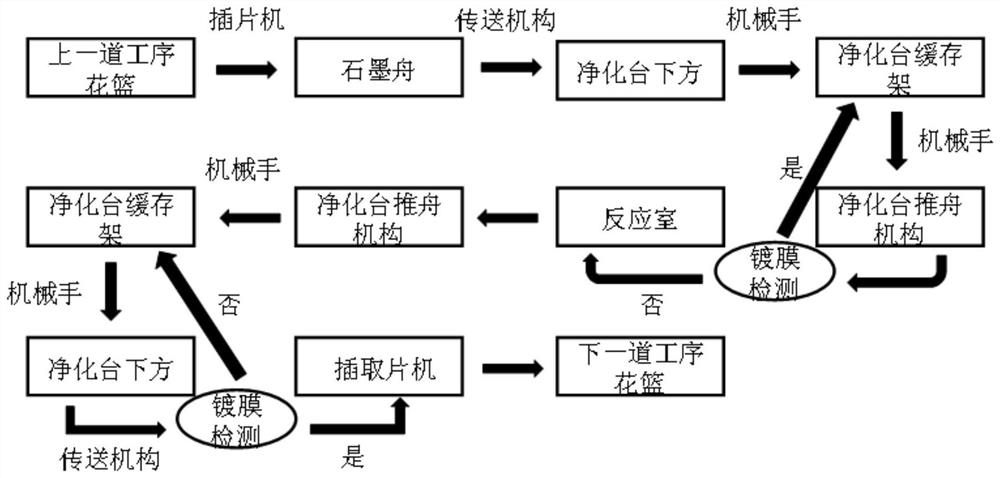

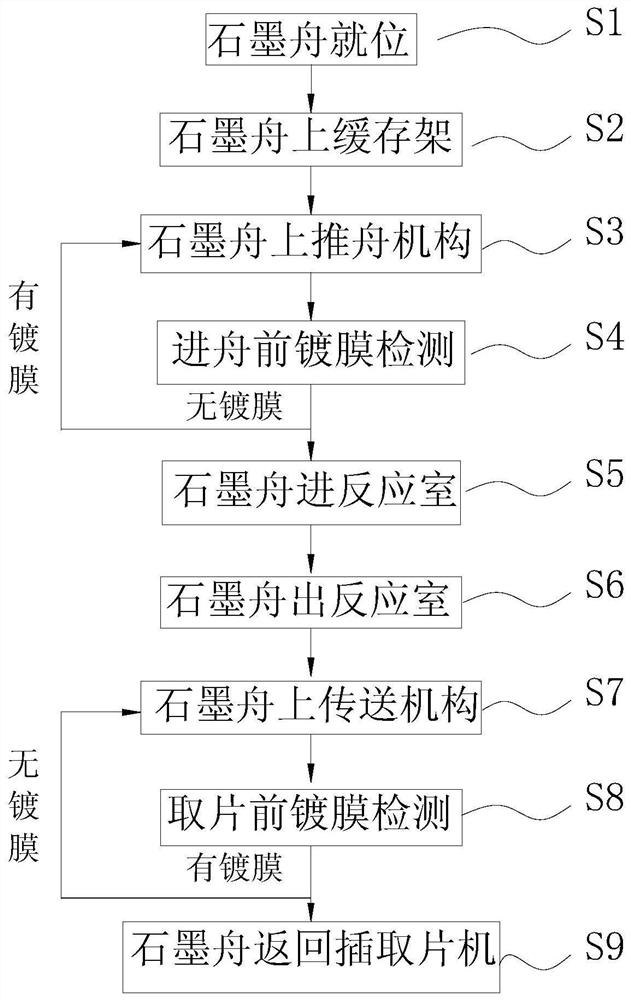

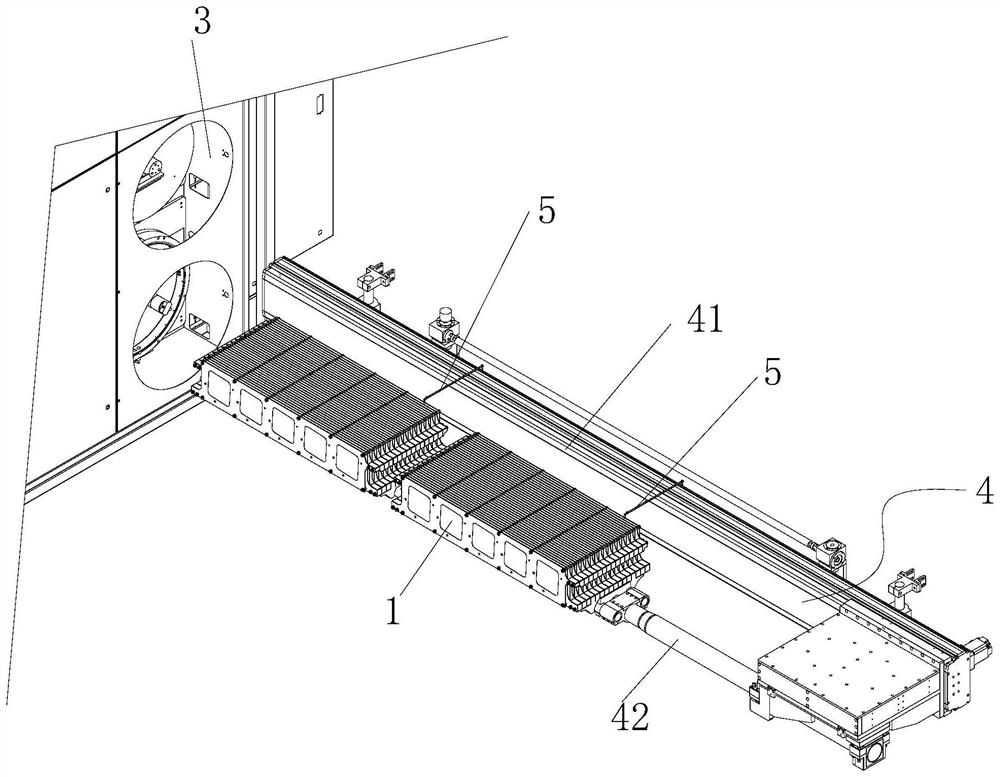

A method of loading and unloading PECVD surface coating

ActiveCN111628046BPrevent inflowImprove efficiencySemiconductor/solid-state device testing/measurementFinal product manufactureStructural engineeringGraphite

The invention discloses a material loading and unloading method for PECVD surface coating, which comprises a graphite boat in place, a graphite boat upper buffer frame, a graphite boat upper pushing mechanism, a coating detection before entering the boat, a graphite boat entering a reaction chamber, and a graphite boat exiting the reaction chamber , Transfer mechanism on the graphite boat, coating inspection before taking the film, graphite boat returning to the inserting and taking machine and other steps. The present invention adds two steps of coating detection step on the only way of the graphite boat, one of which is used to detect whether the silicon chip in the graphite boat that is about to enter the reaction chamber on the push boat mechanism has been coated, so as to avoid secondary coating in the reaction chamber , the second is used to detect whether the silicon wafers that will enter the inserting machine on the transfer mechanism are coated or not, so as to prevent the uncoated silicon wafers from flowing into the next process, so as to ensure that each boat of silicon wafers is coated and there is no repeated coating. The smooth production process is guaranteed, the efficiency of silicon wafers is more stable, and the quality of cells is improved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

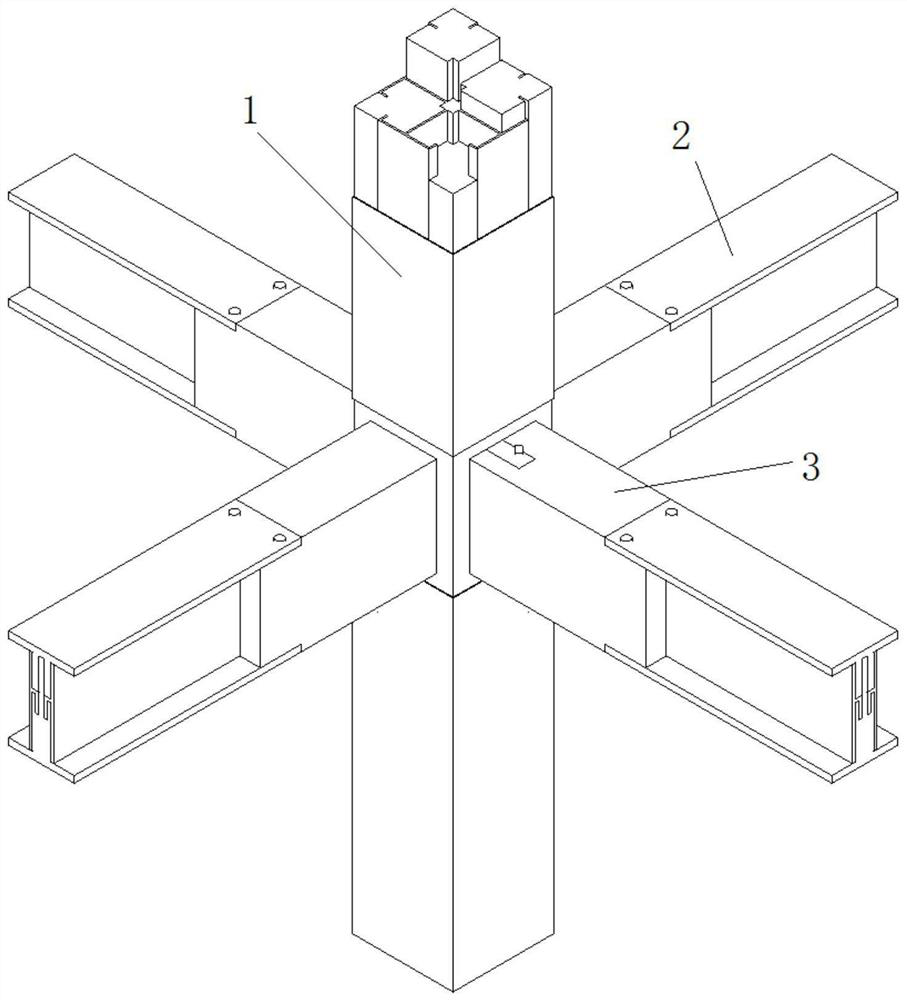

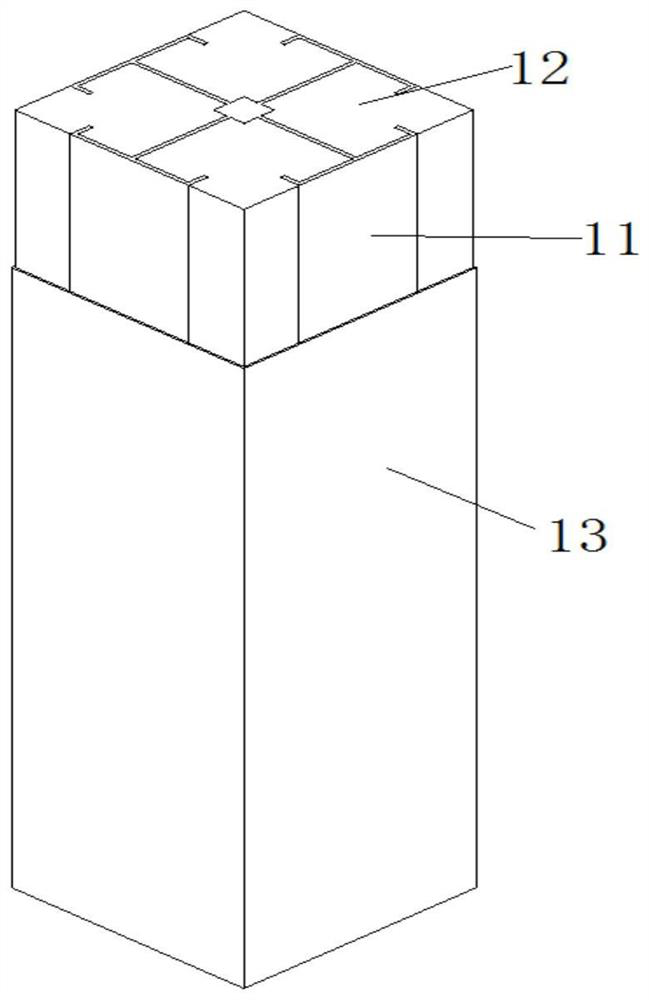

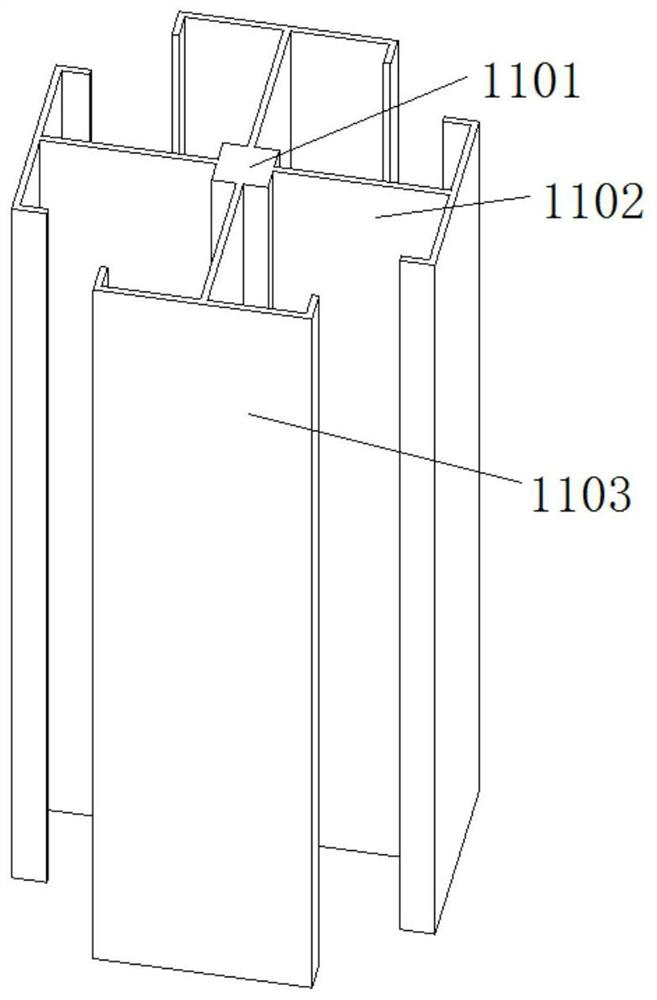

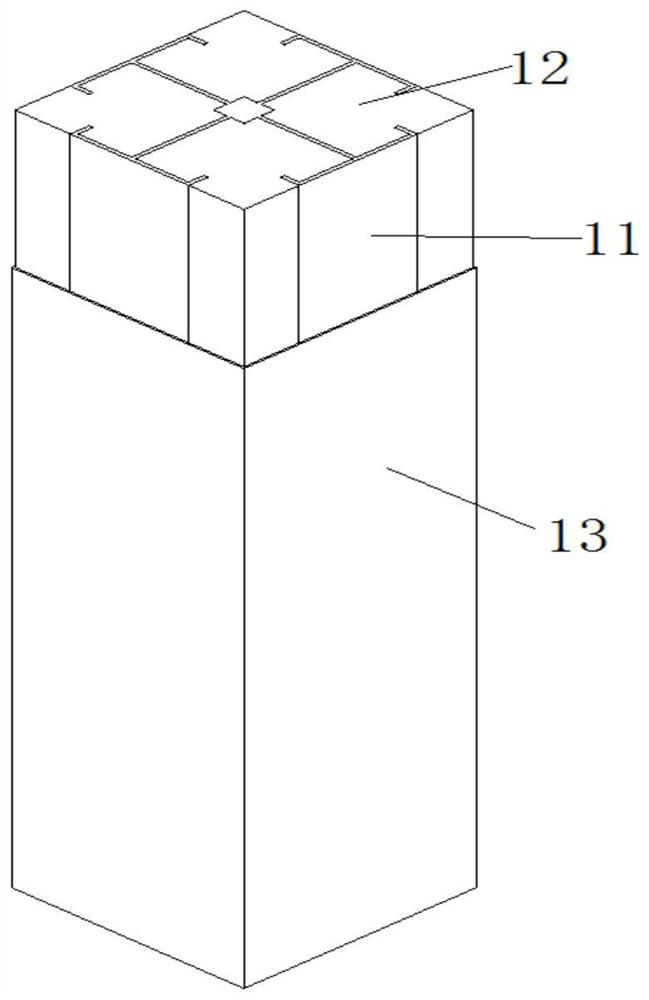

Mortise and tenon square steel-wood assembly joints and installation methods

ActiveCN112359982BMake sure the connection is fixedGuaranteed StrengthBuilding constructionsFiberEngineering

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

An electric long slide rail split transmission system

ActiveCN109094429BEasy to disassemble independentlyLarge travel rangeMovable seatsGear driveGear wheel

The invention discloses an electric long slide rail split transmission system. The slide rail includes a left rail assembly and a right rail assembly. The left rail assembly includes a left upper rail and a left lower rail that are slidably connected. Right upper rail and right lower rail, the system includes: slide rail connecting bridge, the left and right sides are respectively fixed above the left upper rail and right upper rail; The module is connected to the lower surface of the middle part of the slide rail connecting bridge; the transmission rod is connected to the output end of the drive module in the middle; the transmission module is respectively fixed inside the upper left rail and the upper right rail, wherein the transmission module includes a casing, a drive gear and The output gear, the output gear includes meshing gears, transmission gears and connecting bolts. The invention avoids the deflection problem of the long screw rod in long-stroke transmission, and effectively avoids the generation of abnormal sound. At the same time, it facilitates the independent disassembly and assembly operation of the transmission module in the slide rail.

Owner:KEIPER SEATING MECHANISMS CO LTD

The loading and unloading method of PECVD surface coating based on coating detection

ActiveCN111628045BPrevent inflowImprove efficiencySemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringGraphite

The invention discloses a PECVD surface coating loading and unloading method based on coating detection, including graphite boat in place, graphite boat upper buffer rack, coating detection before entering the boat, graphite boat entering the reaction chamber, graphite boat exiting the reaction chamber, and sheet taking Pre-coating inspection, graphite boat returning to the insertion and removal machine and other steps. In the present invention, a device for detecting whether the graphite boat is coated or not is installed on the buffer rack, and two steps of whether the coating is detected are added. One is that the manipulator directly grabs the graphite boat without coating on the buffer rack according to the detection result and puts it into the boat pushing mechanism. Then it is sent into the reaction chamber for coating by the push boat mechanism, which can avoid secondary coating in the reaction chamber. The second is that the manipulator grabs the coated graphite boat on the buffer rack according to the test results and puts it on the transmission mechanism, which is sent into the insertion mechanism by the transmission mechanism. The slicer takes slices to prevent uncoated silicon wafers from flowing into the next process, to ensure that each boat of silicon wafers is fully coated, and there is no repeated coating, ensuring a smooth production process.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

A large-scale composite winding body mandrel device

The invention relates to the technical field of composite material winding shell mandrels, and specifically discloses a large-scale composite material winding body mandrel device, including: a mandrel, an outer mold, a first bearing seat, a second bearing seat, and a first self-aligning bearing , the second self-aligning bearing; the first self-aligning bearing and the second self-aligning bearing are arranged on the mandrel; the first bearing seat and the second bearing seat are respectively arranged on the first self-aligning bearing and the second self-aligning bearing; The outer mold is connected with the core shaft through the first bearing seat and the second bearing seat, the first self-aligning bearing and the second self-aligning bearing, and the outer mold is connected with the driving device. The mandrel of the composite material winding shell provided by the present invention overturns the movement mode of all existing mandrels, greatly reduces the supporting span of the outer mold, and successfully solves the deflection problem of the mandrel from the design source. Two adjustments are adopted The core bearing completely isolates the deformation between the outer mold and the mandrel, and the deflection deformation or thermal expansion deformation of the mandrel will not have any influence on the outer mold.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Rotor support measuring tool and measuring method

PendingCN112284220AHeight adjustableImprove accuracyMechanical diameter measurementsMicrometerStructural engineering

The invention relates to a rotor support measuring tool and method. The tool comprises a vertical column and a plurality of layers of support assemblies stacked on the vertical column, and each support assembly comprises supporting rod assemblies located in four coordinate axis directions of a plane coordinate system; each supporting rod assembly comprises a supporting plate arranged on the vertical column, a first supporting leg and a second supporting leg, the first supporting leg and the second supporting leg are hinged to the two opposite edges of the supporting plate, the ends, deviatingfrom the supporting plate, of the first supporting leg and the second supporting leg are connected with a ruler bracket in a lifting mode, and the ruler bracket is used for bearing a micrometer. The tool is compact and reasonable in structure and convenient to operate, and multiple inner diameter data of different heights can be measured by arranging the multiple layers of support assemblies; theheight of the ruler brackets is adjustable, so that multiple sets of data can be measured again on the same support, and the accuracy of measurement results is improved.

Owner:WUXI BAOYE MACHINERY MFG

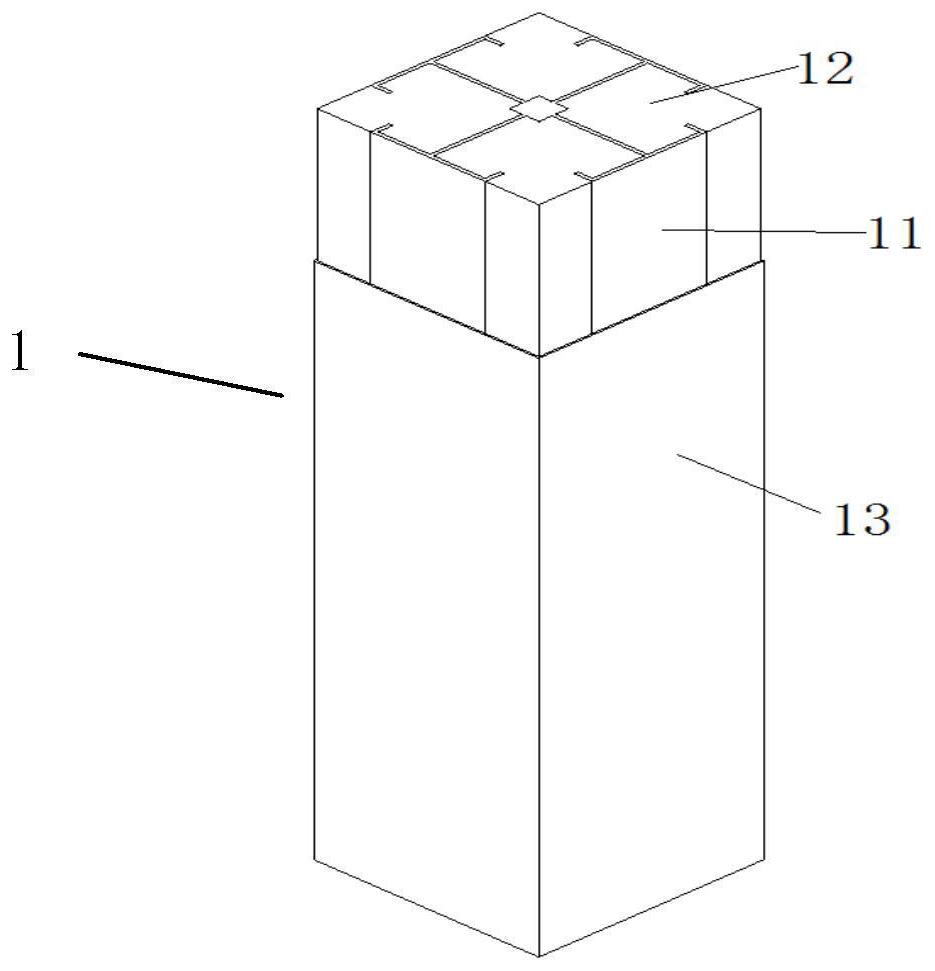

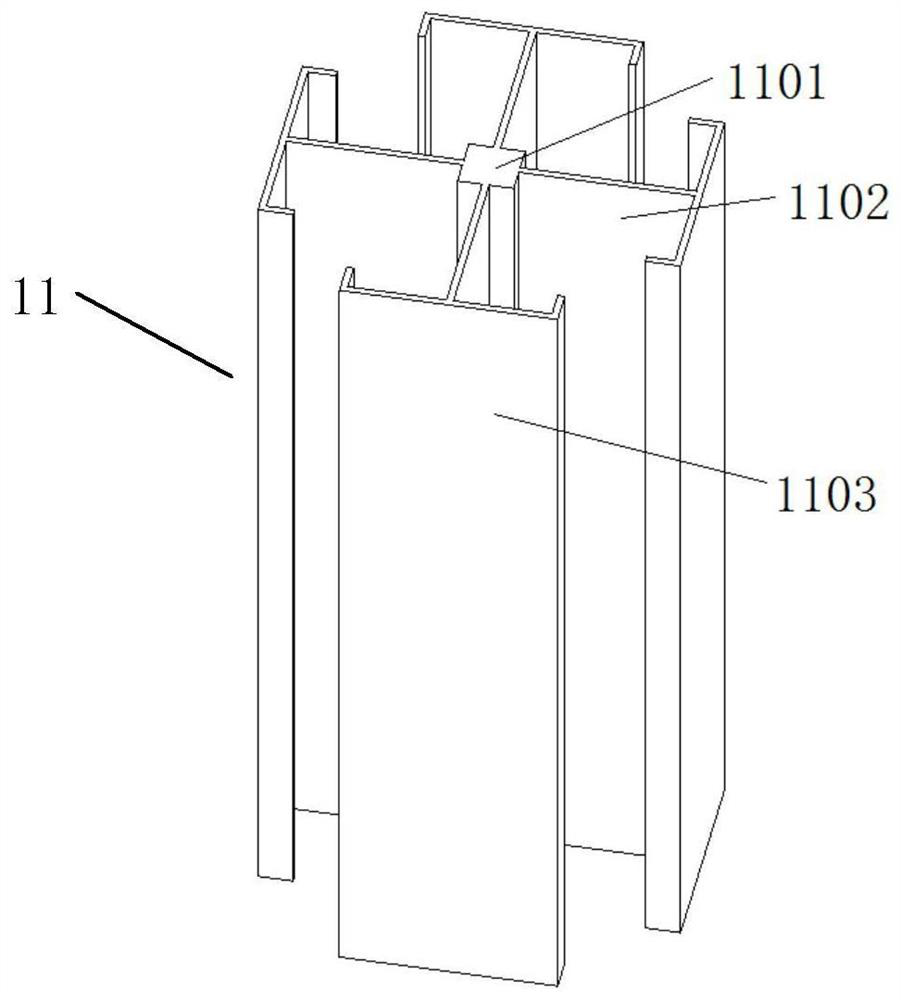

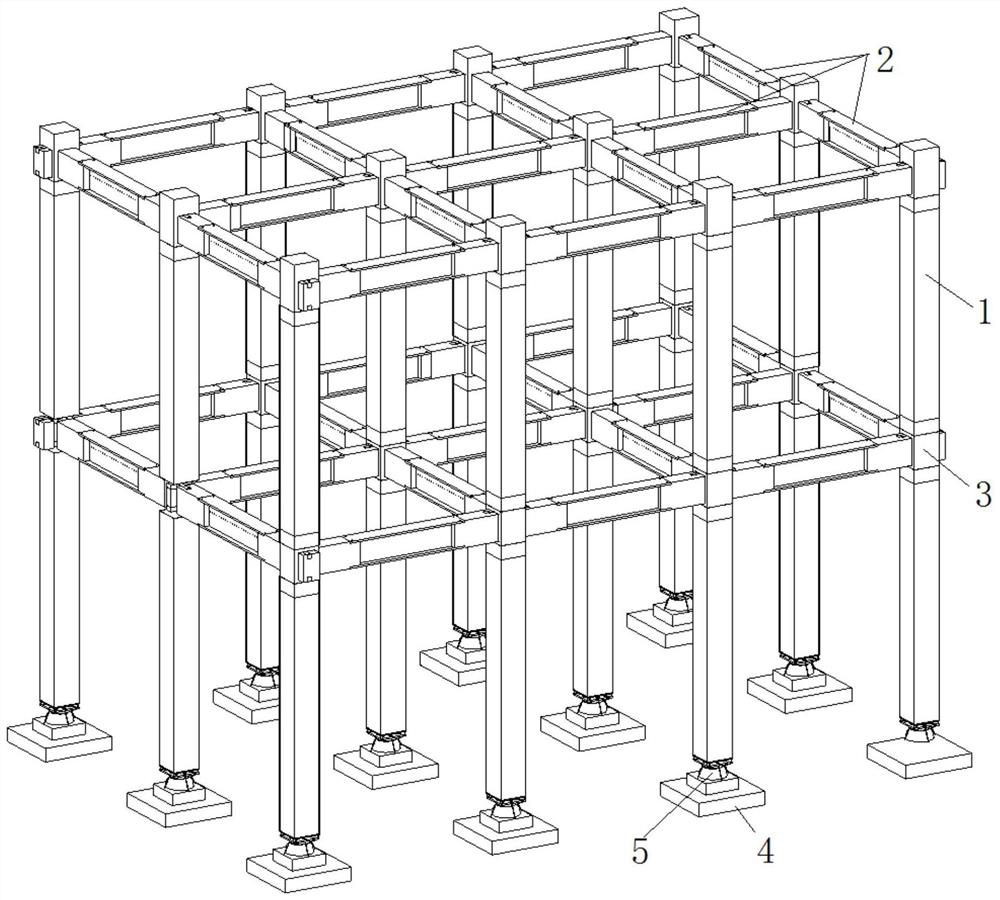

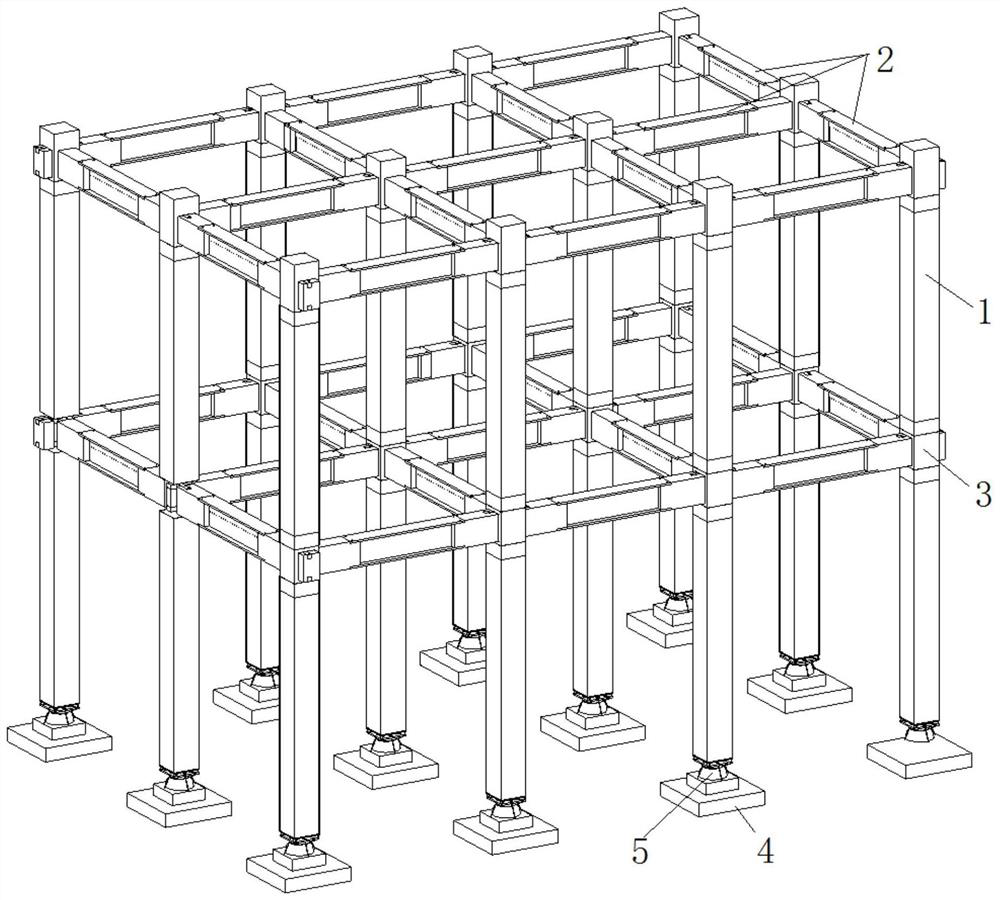

Energy-intensive timber frame structural system

ActiveCN112359971BReduce demandImprove bearing capacityProtective buildings/sheltersShock proofingHigh energyArchitectural engineering

The invention relates to the field of building structures, in particular to a high energy consumption wood frame structure system. A high-energy-consuming wood frame structure system of the present invention includes composite columns, composite beams, node connection components, foundations and foundation connectors, between adjacent composite columns up and down, and between composite columns and composite beams arranged horizontally They are all connected through node connection components, and the composite wooden columns at the bottom are installed on the foundation through foundation connectors. The composite wooden column of the present invention uses the intermediate steel member as the column skeleton, and the internal filling wood blocks are cooperatively supported, with high bearing capacity and strong bending resistance, and the use of filling wood blocks can reduce the demand for large-scale timber, and the gap between the filling wood blocks during earthquakes can be reduced. There can also be friction deformation energy consumption.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

High-energy-consumption wood frame structure system

ActiveCN112359971AReduce demandImprove bearing capacityProtective buildings/sheltersShock proofingAgricultural engineeringMechanical engineering

The invention relates to the field of building structures, in particular to a high-energy-consumption wood frame structure system. The high-energy-consumption wood frame structure system comprises combined columns, combined beams, joint connecting assemblies, foundations and foundation connecting pieces, wherein the vertically-adjacent combined columns are connected through the joint connecting assemblies, the combined columns and the transversely-arranged combined beams are connected through the joint connecting assemblies, and the combined wood columns at the lowermost end are installed on the foundations through the foundation connecting pieces. According to the high-energy-consumption wood frame structure system, middle steel components serve as a column framework for combined columns,wood blocks are filled in the column framework for cooperative supporting, the bearing capacity is high, the bending resistance is high, the requirement for large wood can be reduced by using the wood blocks, and friction deformation energy consumption can be achieved between the wood blocks during earthquakes.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Feeding and discharging method for PECVD surface coating

ActiveCN111628046ASmooth production processStable efficiencySemiconductor/solid-state device testing/measurementFinal product manufacturePhysicsSilicon chip

The invention discloses a feeding and discharging method for PECVD surface coating. The feeding and discharging method comprises the steps of graphite boat positioning, feeding a graphite boat to a buffer frame, pushing the graphite boat onto a boat pushing mechanism, coating detection before boat feeding, feeding the graphite boat into a reaction chamber, discharging the graphite boat out of thereaction chamber, feeding the graphite boat on a conveying mechanism, coating detection before sheet taking, returning the graphite boat to a sheet inserting and taking machine and the like. Accordingto the invention, two coating detection steps are added on an inevitable path of the graphite boat; namely, firstly, a boat pushing detection mechanism detects whether a silicon wafer in a graphite boat which is about to enter a reaction chamber is coated or not, secondary coating in the reaction chamber is avoided; and secondly, whether the silicon wafer to enter the wafer inserting and taking machine on the conveying mechanism is coated or not is detected, and the silicon wafers which are not coated are prevented from flowing into the next process, so that each boat of silicon wafers are coated, repeated coating is avoided, the smoothness of a production process is guaranteed, the efficiency of the silicon wafers is more stable, and the quality of battery pieces is improved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

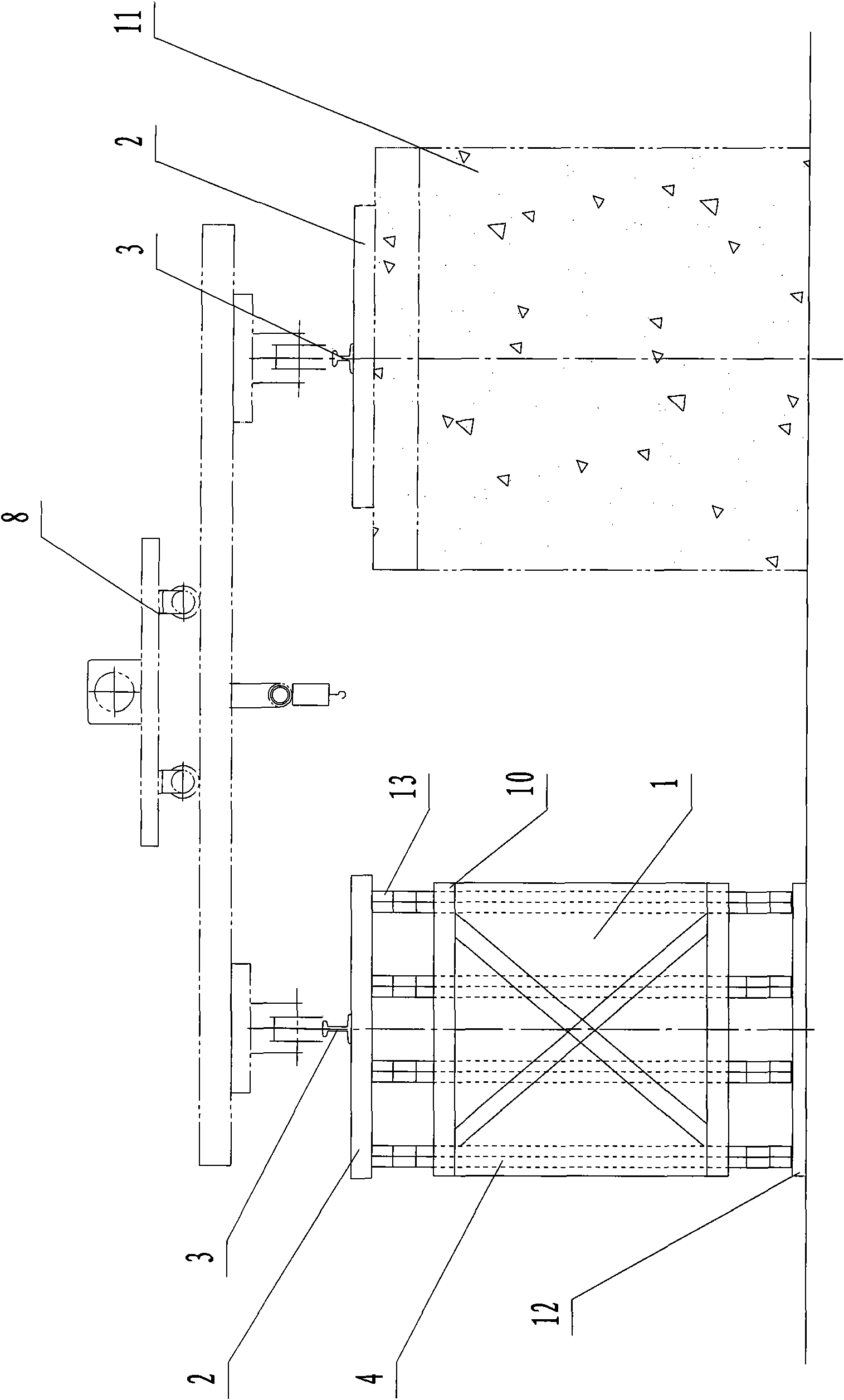

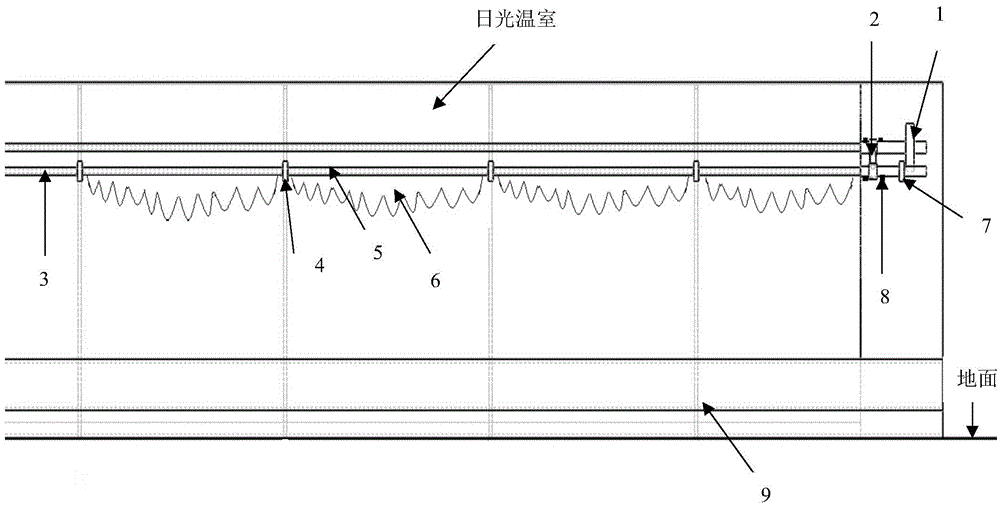

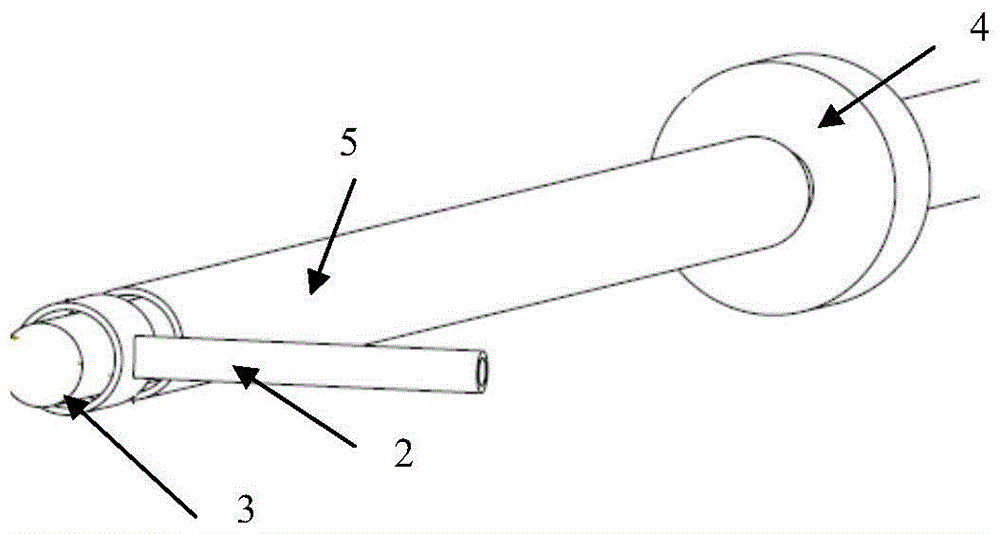

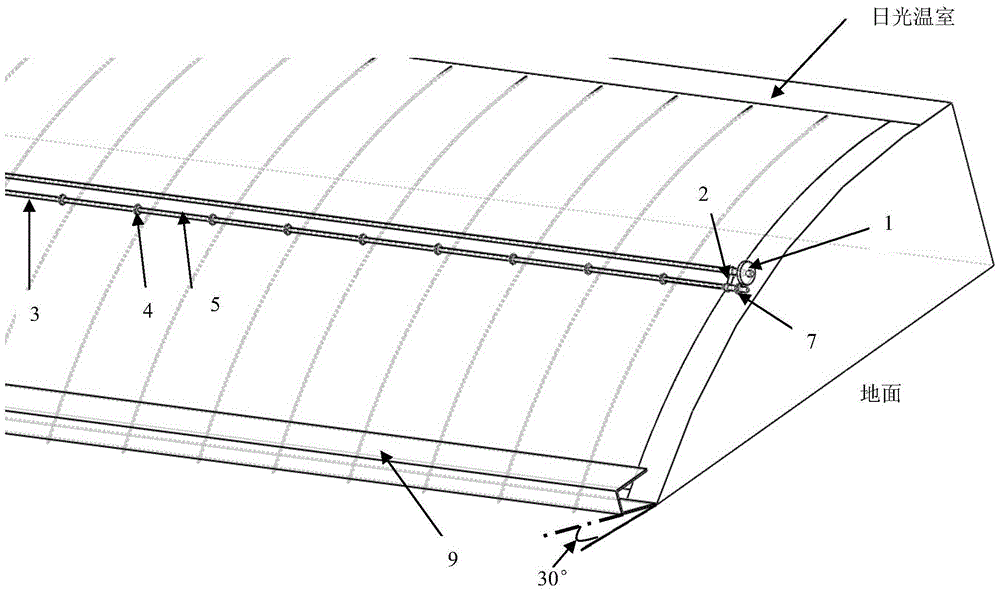

Method and device for removing dust from film in solar greenhouse

ActiveCN104815820BSolve the deflection problemControl lengthClimate change adaptationGreenhouse cultivationEngineeringMachining system

Owner:CHINA AGRI UNIV

Sample rod for transmission electron microscope added with magnetic field

ActiveCN102820196BIncrease the magnetic field strengthSolve the deflection problemElectric discharge tubesElectron microscopeScanning electron microscope

The invention discloses a sample rod for a transmission electron microscope added with a magnetic field. The sample rod comprises a head frame, a carrier, a first magnetic coil and a second magnetic coil, wherein the head frame is provided with a first end part and a second end part along the length extending direction of the sample rod; the carrier is used for carrying a sample and is provided with a channel; an incident electron beam can pass through the channel; the carrier is arranged in the head frame and is close to the first end part of the head frame; the first magnetic coil is arranged in the head frame and is close to the second end part of the head frame; when the current is generated, a first magnetic field is generated by the first magnetic coil; the first magnetic field has a magnetizing effect on the sample; the second magnetic coil is arranged in the head frame and is close to the second end part of the head frame; the second magnetic coil is located under the first magnetic coil; when the current is generated, a second magnetic field is generated by the second magnetic coil; and under the action of the second magnetic field, the electron beam which deflects under the action of the first magnetic field deflects toward an incident direction. The sample rod provided by the invention can be used for researching the change in a magnetic domain of a magnetic material under the action of an externally added magnetic field.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com