Automatic valve cover ear milling machine

A technology of automatic valves and earphones, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems that the machining accuracy cannot be well guaranteed and the work efficiency is low, so as to achieve stable bidirectional flipping action and ensure machining accuracy , the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

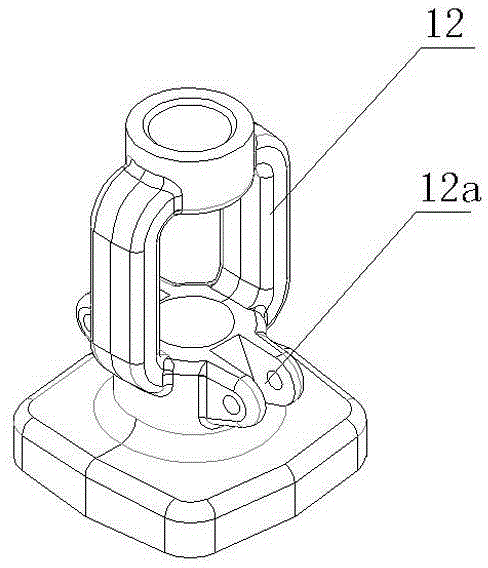

[0025] Such as image 3 As shown, the bonnet workpiece 12 has side ears 12a on both sides that need to be milled.

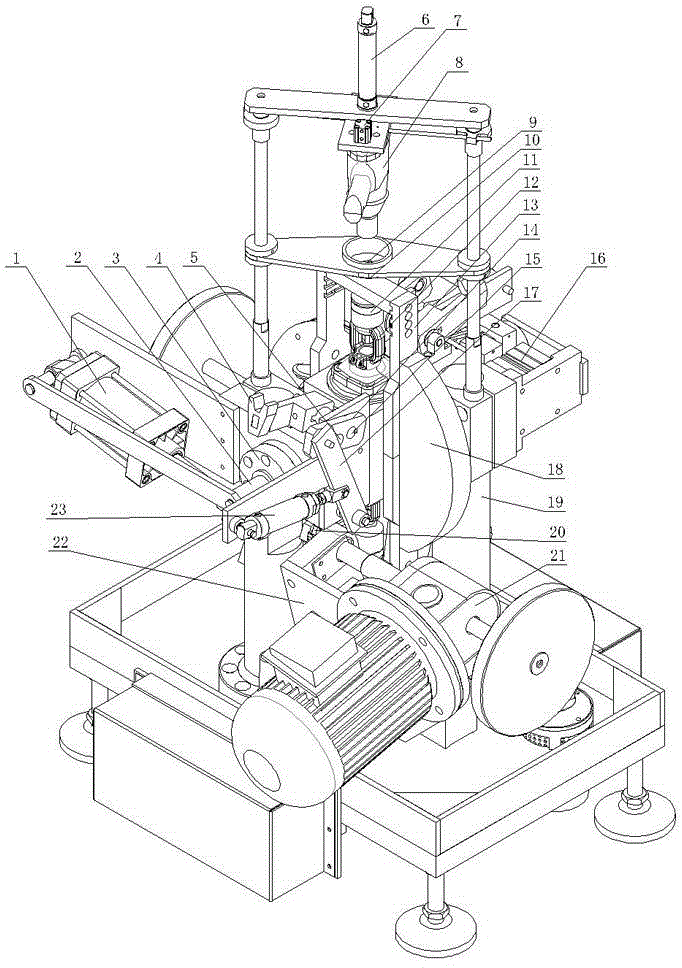

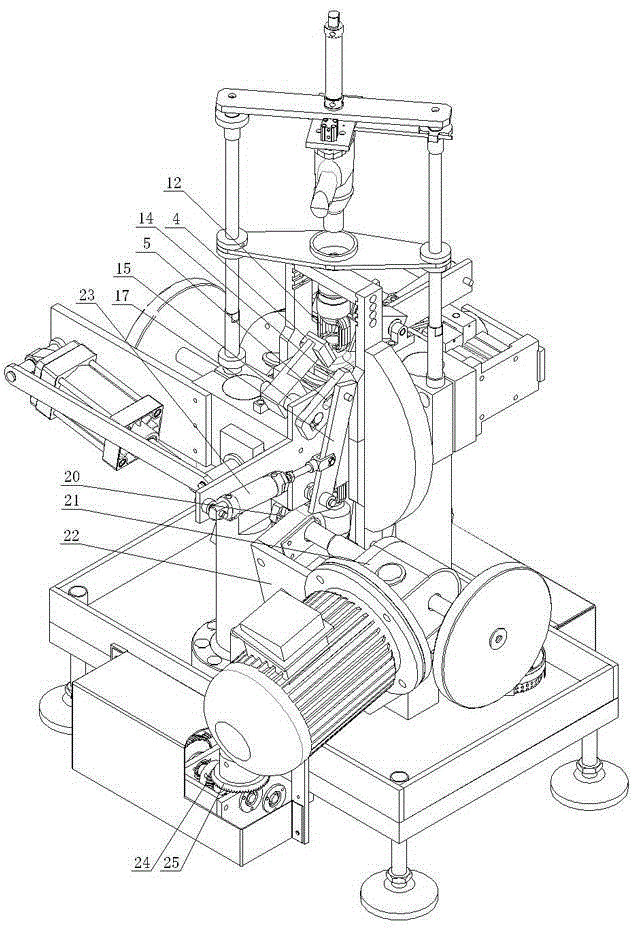

[0026] As shown in the figure, the automatic bonnet milling earphone of the present invention includes a fixing seat 19 and a turning frame 13, and the turning frame 13 performs a vertical 180-degree two-way turning action on the fixing seat 19 and is pushed by a turning mechanism, and the turning frame turns over Finally, it is locked by the flip locking mechanism. The flip frame 13 is provided with upper and lower workpiece positioning holes (for placing the workpiece 12) and upper and lower workpiece clamping blocks 11. The upper part of the fixing seat 19 is provided with a clamping operating mechanism and a pre-positioning Clamping mechanism, the bottom of fixed seat 19 is provided with milling power mechanism 21, when turning frame 13 is turned up or turned down position, pre-positioning pressing mechanism carries out pre-positioning and pressing to the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com