Mortise and tenon square steel-wood assembly joints and installation methods

A square steel, mortise and tenon technology, applied in the direction of construction, building structure, etc., to achieve the effect of ensuring construction quality, solving deflection problems, and high-level construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing.

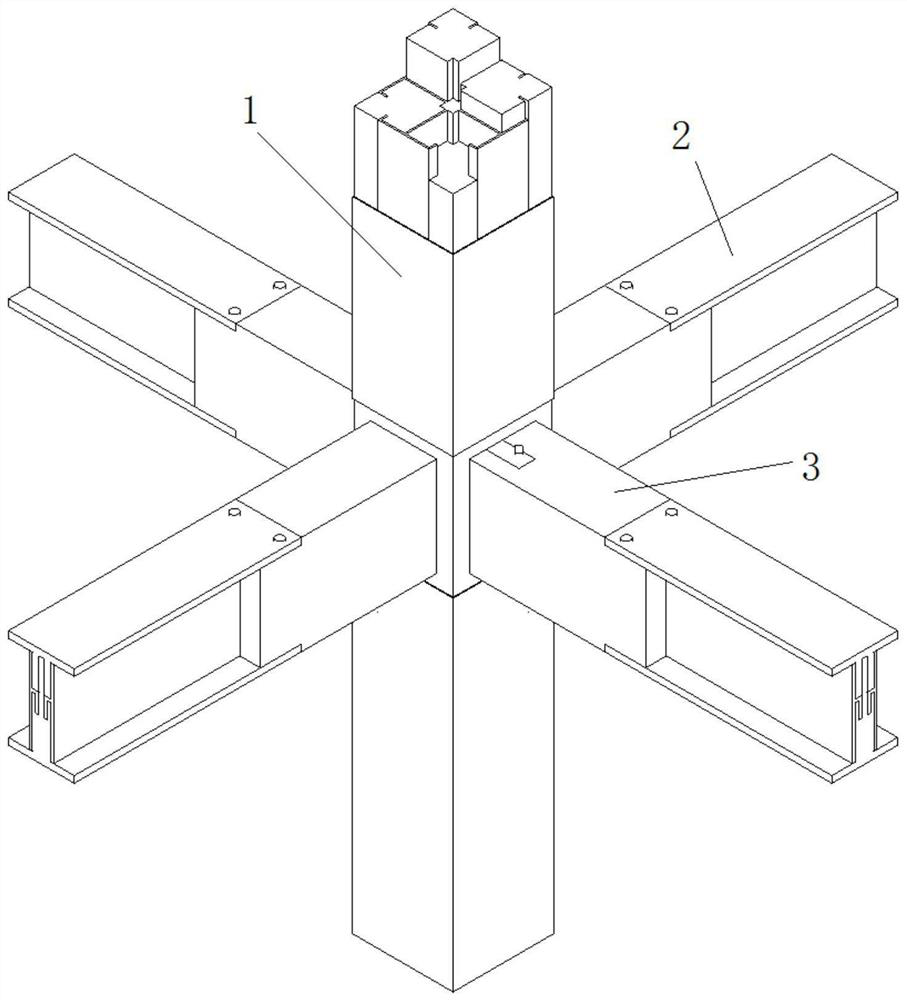

[0055] Such as figure 1 As shown, the mortise-and-tenon square steel-wood assembly node of the present invention includes a composite column 1, a composite beam 2 and a node tenon-tenon assembly 3, and the composite column 1 and the composite beam 2 are connected by a node tenon-tenon assembly 3;

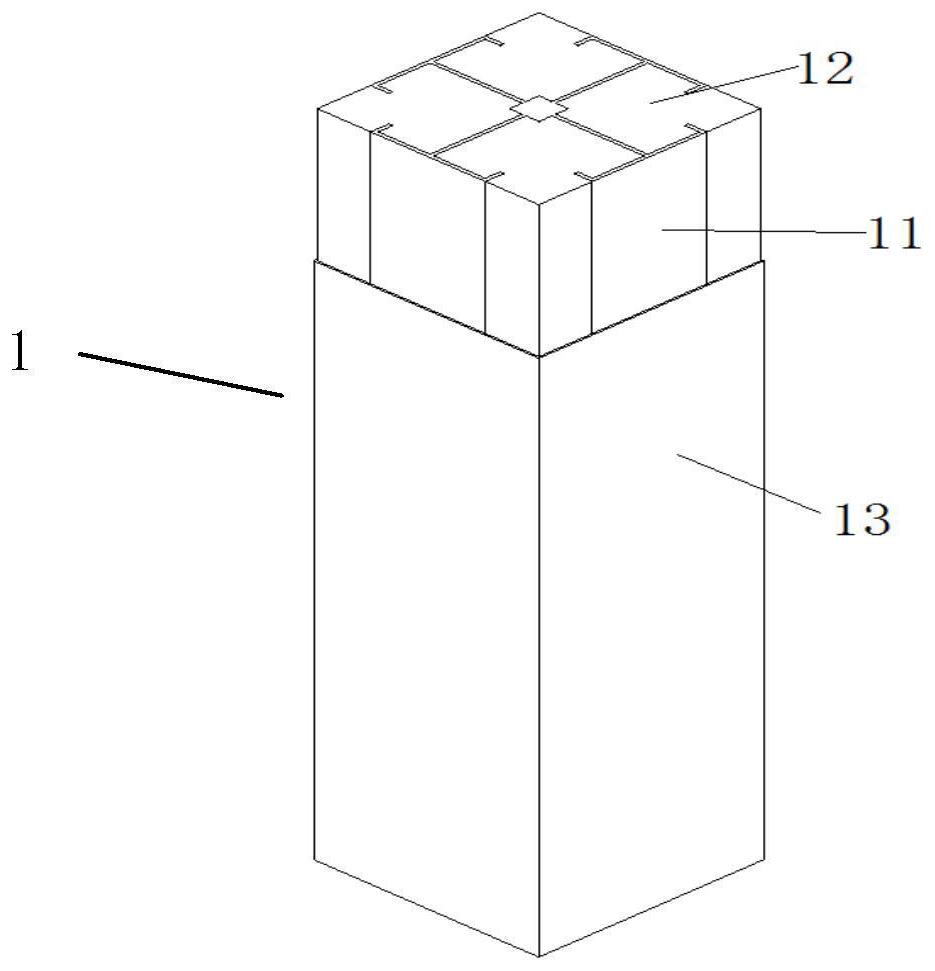

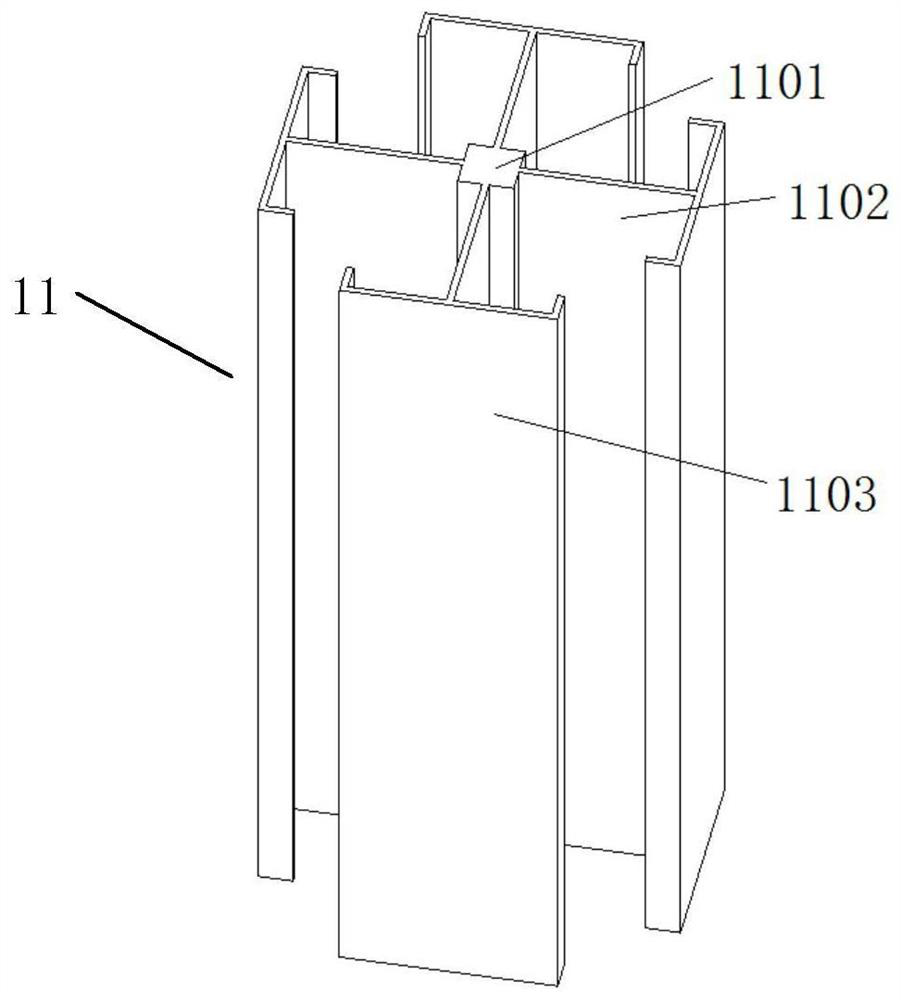

[0056] Such as Figure 2-4 As shown, the combined column 1 includes a steel insert 11 and a filler block 12. The steel insert 11 includes a central connecting column 1101, a connecting plate 1102 and a coaming 1103. The central connecting column 1101 is a square column, and the four central connecting columns 1101 A connecting plate 1102 protrudes vertically from the side, the end of the connecting plate 1102 is vertically fixed with a surrounding plate 1103, the left and right ends of the surrounding plate 1103 are folded inward, and the adjacent two surrounding plates 1103 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com