Construction method of middle-and-small-scale steel truss tied-arch bridge

A technology of tied arch bridges and construction methods, applied in truss bridges, bridges, bridge forms, etc., can solve problems such as increasing the installation difficulty and stability of hoisting equipment, affecting the structural strength of bridge deck rods, and the bending deformation of bridge deck rods. Achieve the effect of ensuring construction quality, ensuring hoisting quality and efficiency, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

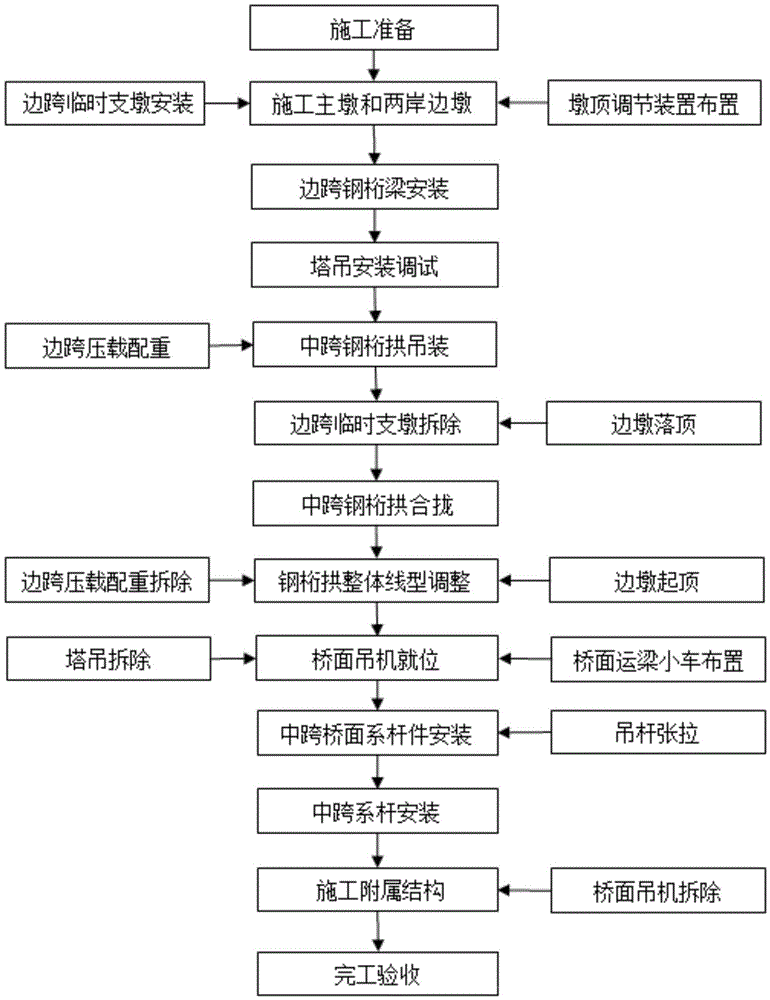

[0039] In this embodiment, taking the three-span continuous steel truss arch bridge as an example, the construction method of the small and medium-sized steel truss tied arch bridge provided by the present invention is elaborated. The span distribution of the main bridge is 61.65m side span + 152m middle span + 61.65m side span, considering the structural rigidity Four piers (including two main piers in the middle and side piers on both sides) are selected for the pier form. For the specific construction plan, see figure 1 , including the following steps:

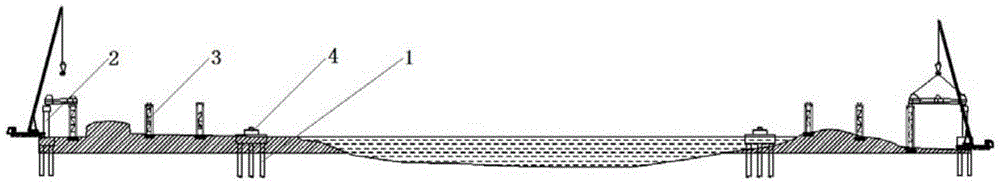

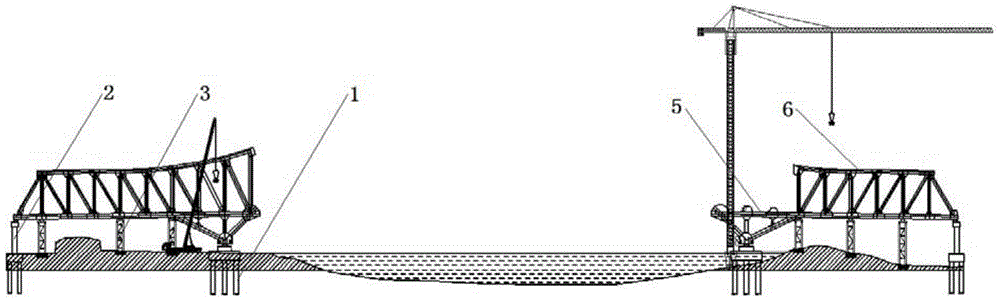

[0040] (1) see figure 2 , carry out preliminary construction preparations, select a location to store the members of the steel truss tie-bar arch bridge and pre-assemble the hoisting units, construct the main pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com