Horizontal die moving and circulating mechanism

A circulation mechanism and horizontal movement technology, applied in the field of machinery, can solve the problems of large deflection and strong vibration of the driving guide rail, inaccurate mold placement, and reduced production efficiency, so as to improve product qualification rate and production efficiency, reduce maintenance costs, and extend service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

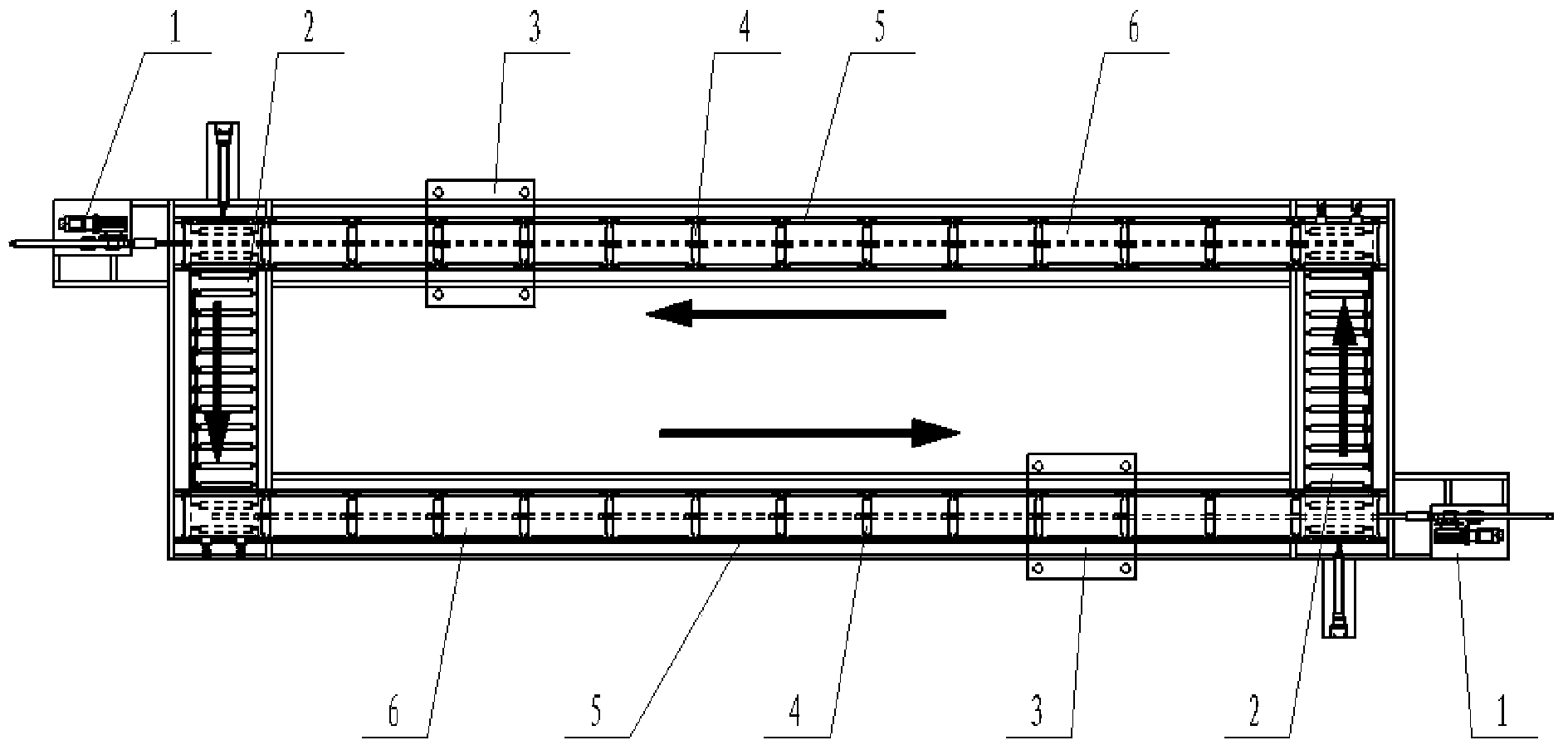

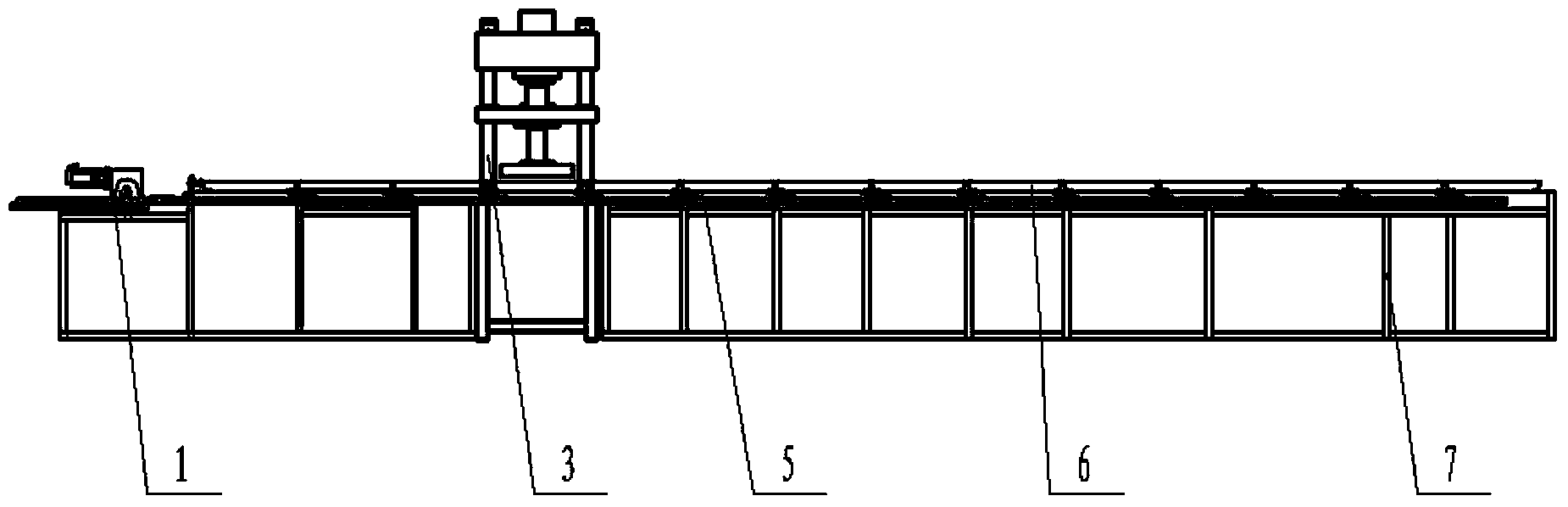

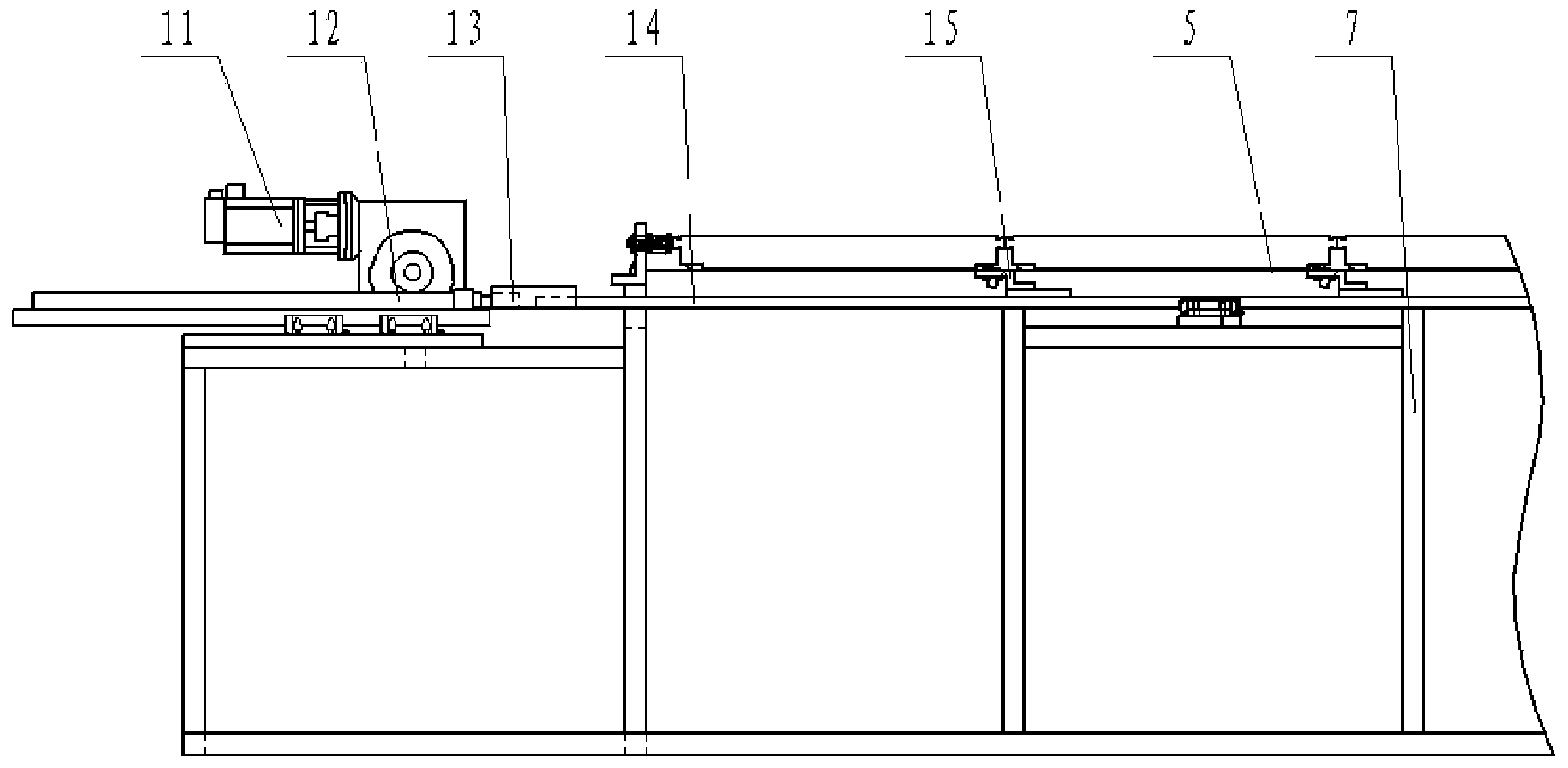

[0014] The mold horizontal movement cycle mechanism (referred to as cycle mechanism, see Figure 1-5 ), the circulation mechanism includes a frame 7 and two mold lines 4 and two stamping machines 3 installed on the frame 7; the two mold lines 4 are arranged in parallel, and are composed of a designed number of molds 6 distributed in a straight line. 3 is installed at the end of each mold assembly line 4; it is characterized in that the mechanism also includes two mold pulling devices 1 and two sets of mold longitudinal moving devices 2, and the two mold pulling devices 1 are arranged in front and back, installed on each mold The tail end of the assembly line 4; the head and tail ends of the two mold assembly lines 4 are respectively connected by a set of mold longitudinal moving devices 2, and form a process-connected cycle operation mechanism in the same hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com