An electric long slide rail split transmission system

A technology of transmission system and long slide rail, which is applied to movable seats, special positions of vehicles, vehicle parts, etc., can solve problems such as large deflection of screw rods, increase production, and difficulty in analysis of slide rail problems, and achieve extended stroke range, The effect of avoiding abnormal noise and facilitating independent disassembly and assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

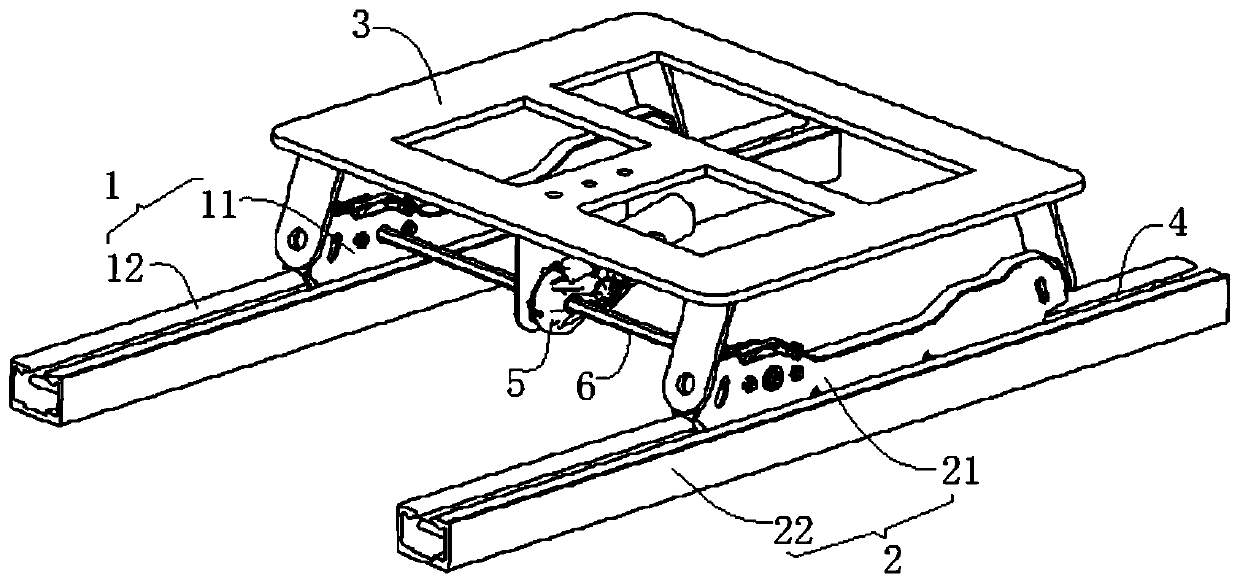

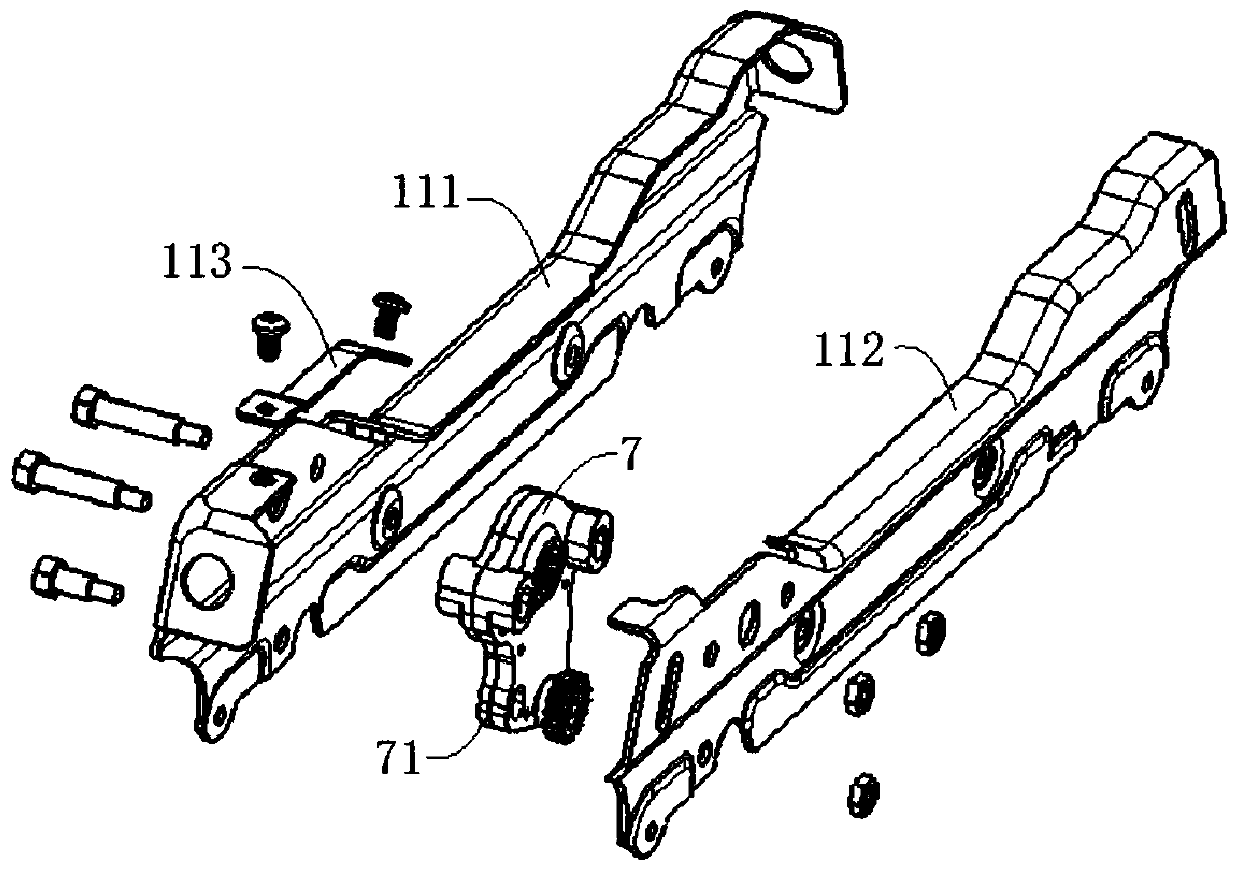

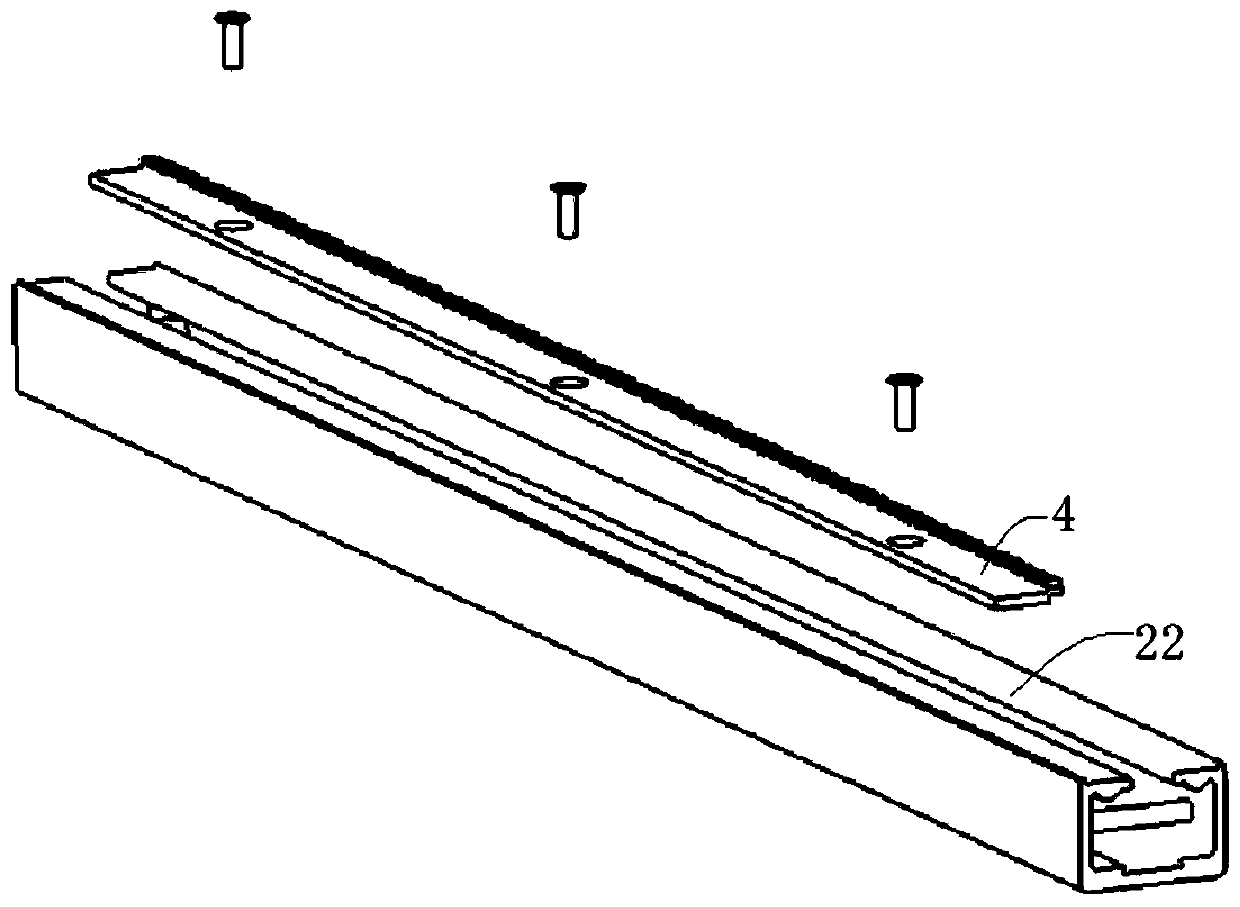

[0028] refer to Figure 1-6 As shown, the electric long slide rail split transmission system of the present invention, the slide rail includes a left rail assembly 1 and a right rail assembly 2, the left rail assembly 1 includes a left upper rail 11 and a left lower rail 12 that are slidably connected, and the right rail assembly Into 2 comprises the upper right rail 21 and the lower right rail 22 of sliding connection, and this system comprises:

[0029] Slide rail connecting bridge 3, left and right sides are respectively fixed on the top of left upper rail 11 and right upper rail 21; Slide rail connecting bridge 3 can guarantee the synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com