Precision rod type convergence gauge

A convergent gauge and rod-type technology, applied in the field of measuring instruments, can solve problems such as poor measurement results, poor adaptability, and poor reliability, and achieve the effects of small deformation, strong adaptability, and convenient reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

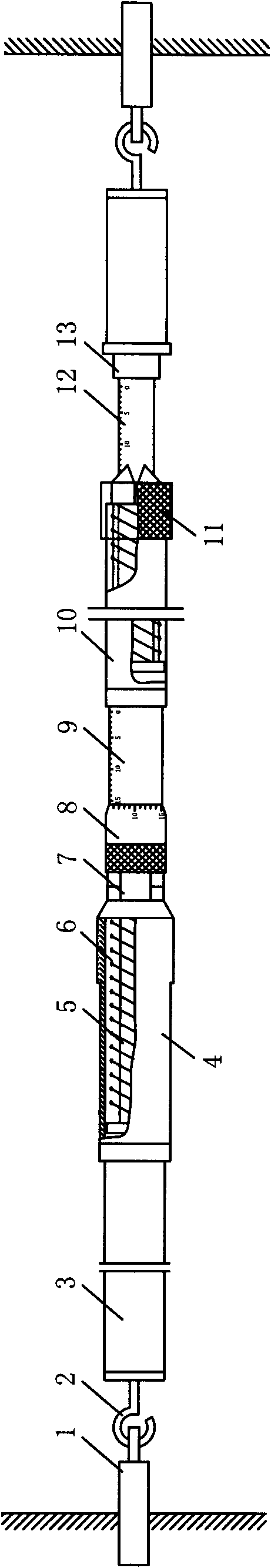

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0010] The precision rod-type convergent gauge of the present invention is mainly composed of an anchor head 1, a universal hook 2, a tubular connecting rod 3, a pull bar reference device, a spiral micrometer and a pull-out distance measuring ruler. The rod reference device and the pull-type distance measuring ruler are connected as one, and the end faces of the rod reference device and the pull-type distance measuring rod are both threaded with tubular connecting rods 3, and the tubular connecting rods 3 on both sides are respectively connected and anchored The universal hook 2 compatible with the head 1 and the anchor head 1 are respectively fixed at the two ends of the measured distance, and the tubular connecting rod 3 connected with the rod reference device can be connected with multiple connecting rods 3 according to the size of the distance measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com