Three-wire gas shielded indirect arc welding method, device and application of method

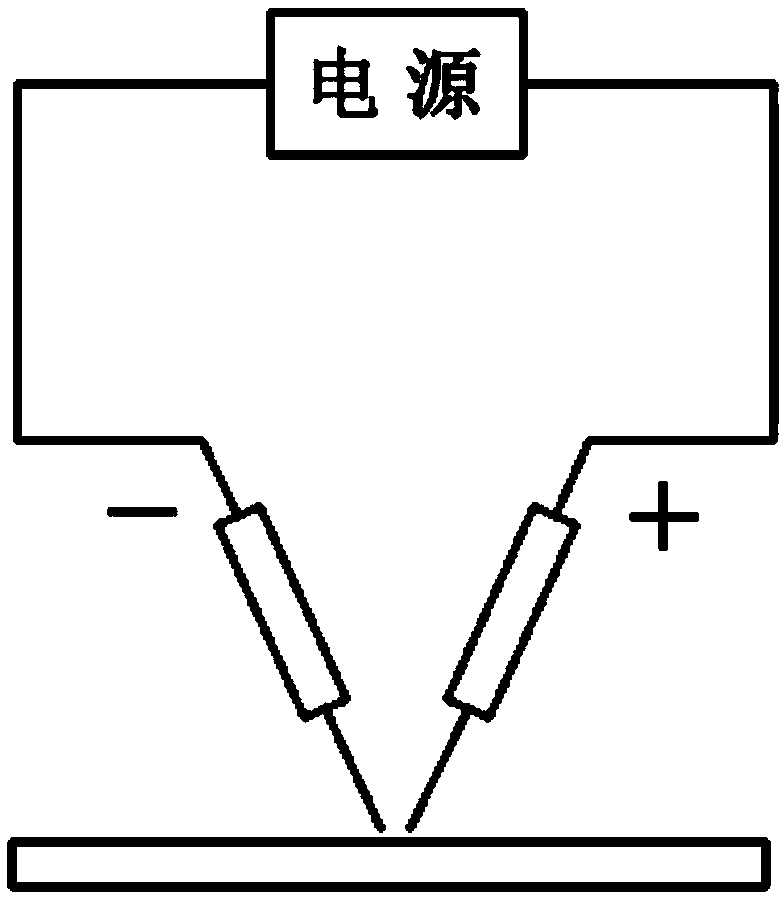

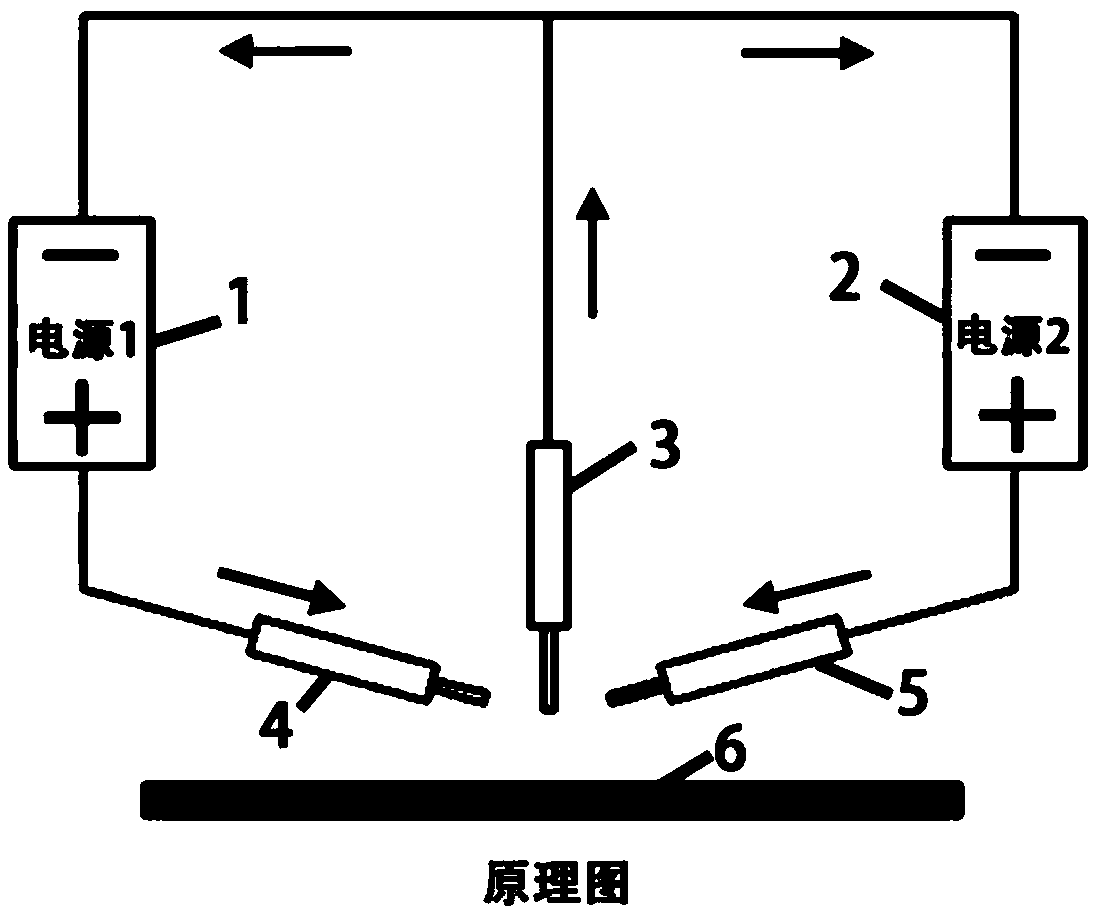

A gas shielded, arc welding technology, applied in arc welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problem of two indirect arc tail deflection, etc., to improve arc stiffness, optimize the spatial distribution of magnetic field, workpiece The effect of increased heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: three-wire gas-shielded indirect arc parallel surfacing.

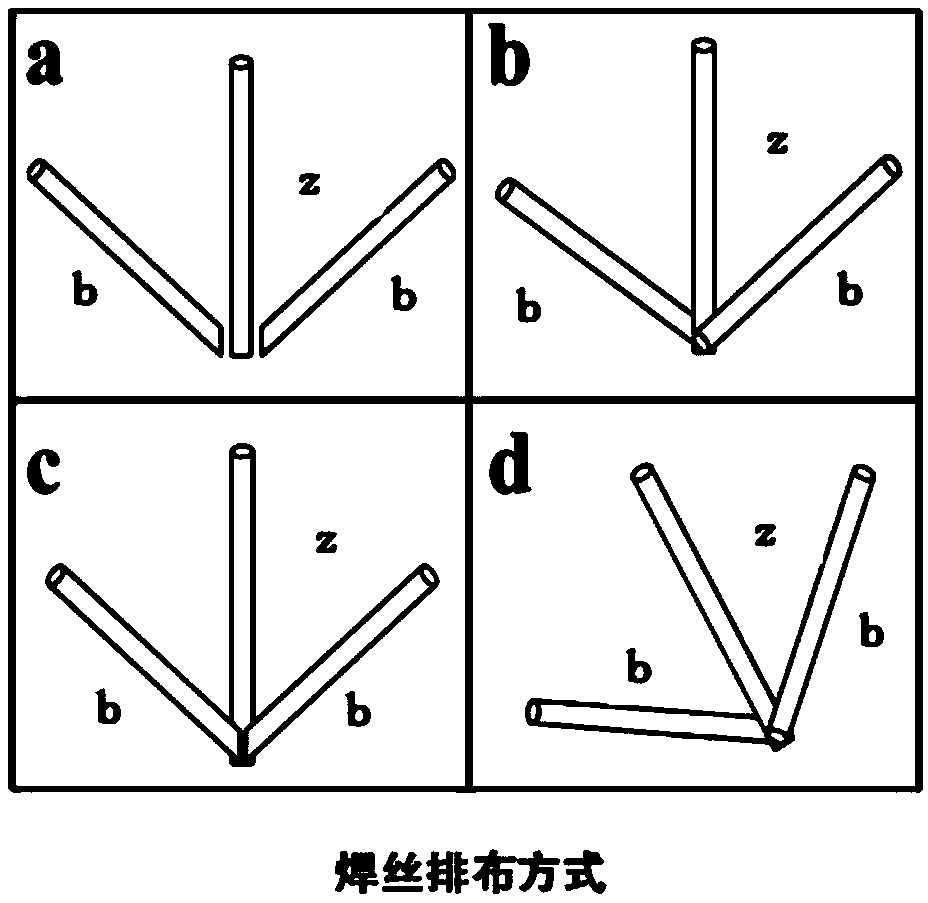

[0069] use Figure 5 The welding wire distribution shown in , the angle between the main wire 3 and the horizontal direction is 45°, the angle between the first side wire 4 and the second side wire 5 and the main wire 3 is 30° respectively, and the two side wires are distributed in the corner of the main wire 3 Both sides are mirror-symmetrical with respect to the main wire, and the two side wires are in contact with the main wire 3 respectively, and the two contact points are on the same horizontal line. Among them, the three steel welding wires are ER50-6, the diameter of the main wire 3 is 1.6mm, and the diameter of both wires is 1.2mm. The power supply uses a DC power supply as the first arc power supply 1 and a pulsed DC power supply as the second arc power supply 2. The corresponding protective gas is 80% CO 2 and 20% Ar mixed gas; plane surfacing welding was carried out on the Q235 steel plat...

Embodiment 2

[0071] Example 2: three-wire gas-shielded indirect arc vertical surfacing.

[0072] use Figure 5 The welding wire distribution shown in , the angle between the main wire 3 and the horizontal direction is 45°, the angle between the two side wires and the main wire 3 is 30°, and the two side wires are distributed on both sides of the main wire 3 and are mirror-symmetrical about the main wire , and the wires on both sides are in contact with the main wire 3 respectively, and the two contact points are on the same horizontal line. Among them, the three steel welding wires are ER50-6, the diameter of the main wire 3 is 1.6mm, and the diameter of both wires is 1.2mm. The power supply adopts a DC power supply and a pulsed DC power supply, and the corresponding shielding gas is 80% CO 2 and 20% Ar mixed gas; plane surfacing welding was carried out on the Q235 steel plate as the base material, the surfacing direction was perpendicular to the vertical surface where the welding wire wa...

Embodiment 3

[0073] Embodiment 3: Single-pass forming gas-shielded three-wire indirect arc welding.

[0074] like Figure 7 , the distribution of the welding wire used is shown in Figure 5 As shown, the angle between the main wire 3 and the side wire is 30 degrees, the main wire diameter is 1.6mm, the diameter of the two side wires is 1.2mm, the welding wire type is ER50-6, the welding base material is Q235 low carbon steel, and the plate size is 300mm ×150mm×10mm, the bevel angle is 20°, no blunt edge, ceramic liner 7 is used on the back, the butt gap is 2mm, the total welding current used is 320A, the welding speed is 735mm / min, and the single pass forming is very good of welded joints. Due to its small groove angle, high welding wire deposition rate and fast welding speed, it has the characteristics of high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com