Method for reinforcing welding joint of aluminum/magnesium alloy thick plate by carbon nano pipe

A carbon nanotube and welded joint technology, which is applied in the field of carbon nanotube reinforced aluminum/magnesium alloy thick plate welded joints, can solve the problems of poor welding seam forming quality, coarse welding seam microstructure, and reduced mechanical properties of welded joints. The effect of improving welding structure, improving mechanical properties, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

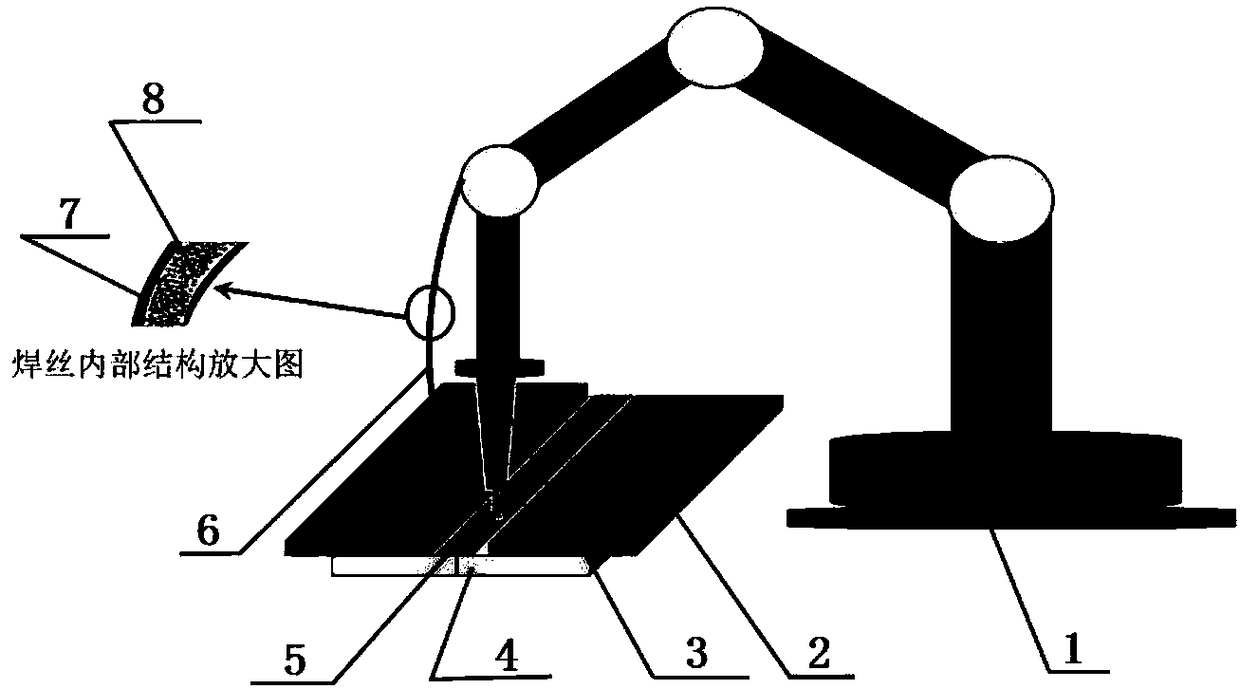

[0061] Argon-arc butt welding of 6061 aluminum alloy rolled plates (welding diagram as shown in figure 1 shown):

[0062] (1) The thickness of the 6061 aluminum alloy rolled plate is 7mm, and the size is 70×130mm;

[0063] (2) Before welding, use sandpaper and steel brush to remove the oxide layer on the surface of the plate to be welded, and then clean the surface of the plate with acetone to remove various impurities;

[0064] (3) The active welding wire reinforced by carbon nanotubes has a diameter of 2.0mm, and the shell material is made of pure aluminum, and the inner core is not implanted. The mass percentage of the mixed powder composed of carbon nanotubes and composite active flux is: CNT: 1.1%, CaF 2 : 10.3%, ZnCl 2 : 14.5%, CaCl 2 : 13.6%, SiO 2 : 22.3%, TiO 2 : 24.7%, Te: 13.5%;

[0065] (4) The carbon nanotubes and the composite active flux are ball milled together by a ball milling method, so that the carbon nanotubes are uniformly dispersed in the composit...

Embodiment 2

[0069] Argon-arc butt welding of AZ31 magnesium alloy rolled plates (welding schematic diagram as shown in figure 1 shown):

[0070] (1) The thickness of AZ31 magnesium alloy rolled plate is 6mm, and the size is 60×120mm;

[0071] (2) Before welding, use sandpaper and steel brush to remove the oxide layer on the surface of the plate to be welded, and then clean the surface of the plate with acetone to remove various impurities;

[0072] (3) The active welding wire reinforced by carbon nanotubes has a diameter of 1.6mm, and an AZ31 inner core with a diameter of 0.8mm is implanted inside, and the shell material is made of pure aluminum. The mass percentage of the mixed powder composed of carbon nanotubes and composite active flux is: CNT: 0.9%, CaF 2 : 11.3%, ZnCl 2 : 13.5%, CaCl 2 : 14.7%, SiO 2 : 23.4%, TiO 2 : 23.8%, Te: 12.4%;

[0073] (4) The carbon nanotubes and the composite active flux are ball milled together by a ball milling method, so that the carbon nanotubes a...

Embodiment 3

[0077] Argon-arc butt welding of 5050 aluminum alloy rolled plates (welding schematic diagram as shown in figure 1 shown):

[0078] (1) The thickness of the 5052 aluminum alloy rolled plate is 7mm, and the size is 70×130mm;

[0079] (2) Before welding, use sandpaper and steel brush to remove the oxide layer on the surface of the plate to be welded, and then clean the surface of the plate with acetone to remove various impurities;

[0080] (3) The active welding wire reinforced by carbon nanotubes has a diameter of 2.0mm, and the shell material is made of pure aluminum, and the inner core is not implanted. The mass percentage of the mixed powder composed of carbon nanotubes and composite active flux is: CNT: 2.3%, CaF 2 : 13%, ZnCl 2 : 15%, CaCl 2 : 10.7%, SiO 2 : 24%, TiO 2 : 20%, Te: 15%;

[0081] (4) The carbon nanotubes and the composite active flux are ball milled together by a ball milling method, so that the carbon nanotubes are uniformly dispersed in the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com