High-entropy alloy additive manufacturing device and additive manufacturing method

A high-entropy alloy and additive manufacturing technology, which is applied in the direction of manufacturing tools, electrode support devices, metal processing equipment, etc., can solve problems such as energy waste, material performance changes, high material removal rate, and complex manufacturing methods, and achieve structural and Easy to use, flexible installation location, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

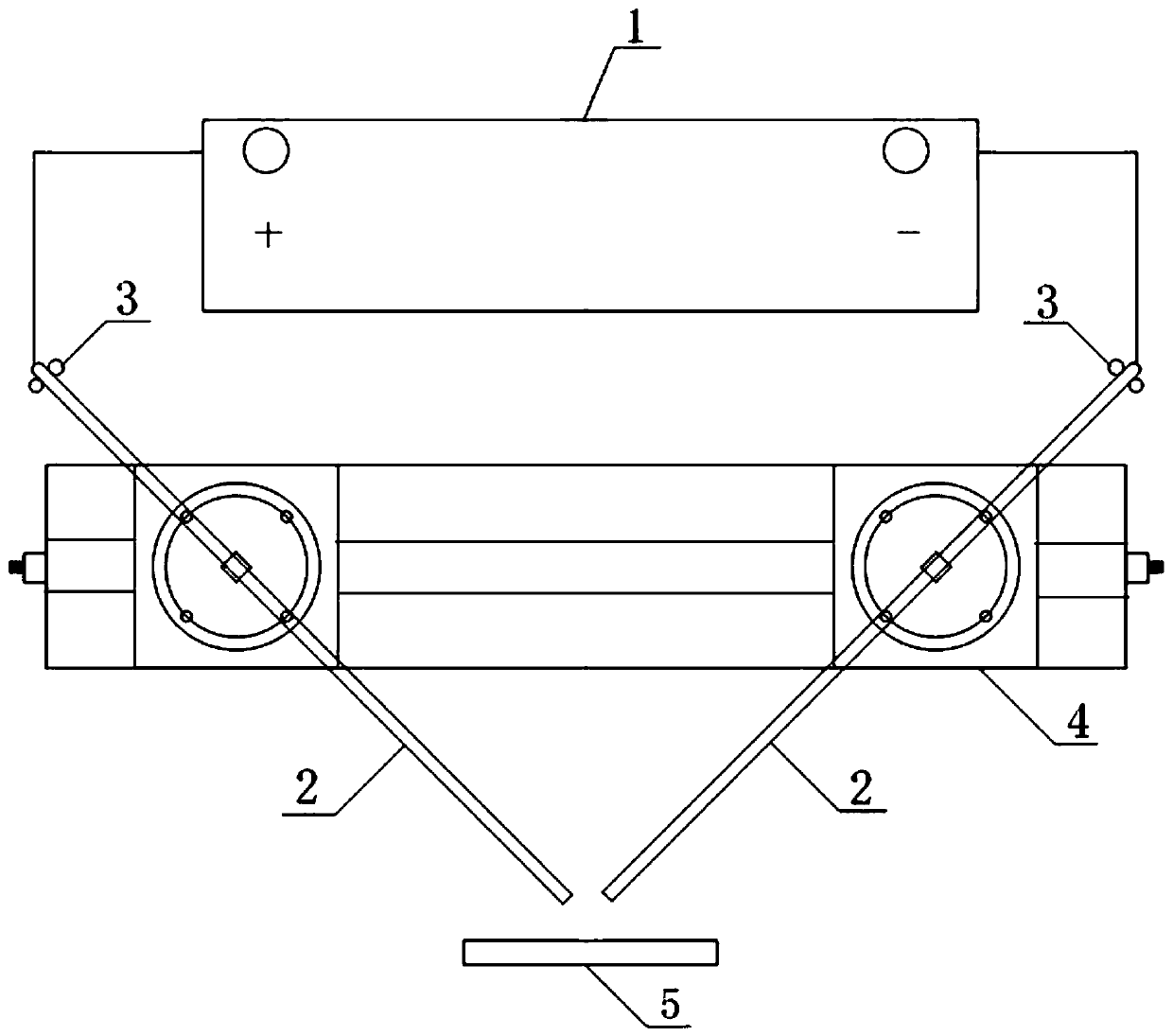

[0040] Such as figure 1 As shown, a high-entropy alloy additive manufacturing device includes:

[0041] The welding wire clamp 4 is used to fix two welding wires 2, the two welding wires 2 are on the same plane, and the axes of the two welding wires 2 intersect;

[0042] The AC power supply 1 is provided with two output terminals, and the two output terminals are respectively connected to the conductive tip of one welding wire 2;

[0043] Two wire feeders 3 are respectively connected to one of the welding wires 2 and located at one end of the welding wire 2 close to the contact tip for feeding the welding wire 2 in the axial direction.

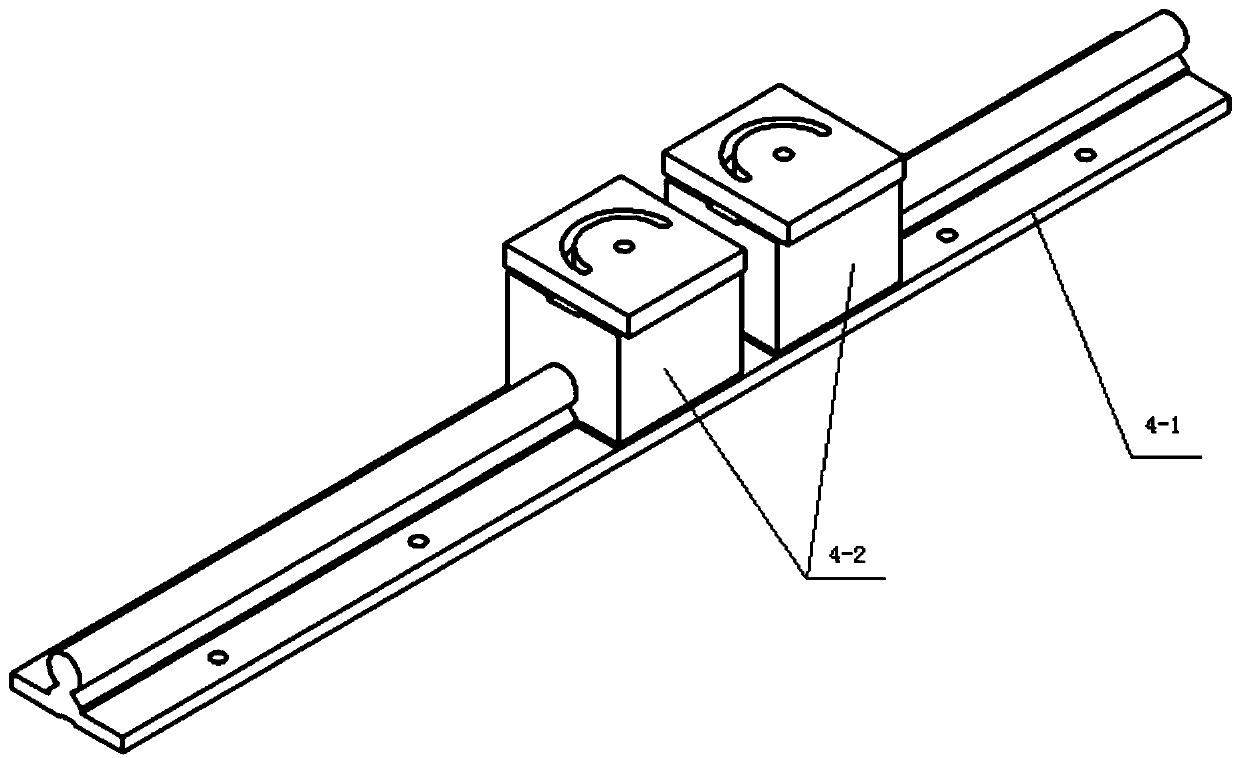

[0044] Such as figure 2 As shown, as a specific embodiment of the present invention, the welding wire clamp 4 includes a linear slide rail 4-1 and two sliders 4-2 that can move along the linear slide rail 4-1, and the slider 4 -2 Fix the welding wire 2 through the welding torch fixedly connected with the slider 4-2.

[0045] The linear sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com