Method and device for removing dust from film in solar greenhouse

A solar greenhouse and dust removal device technology, applied in greenhouse cultivation, chemical instruments and methods, cleaning methods and utensils, etc., to achieve the effect of simple structure, easy promotion and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

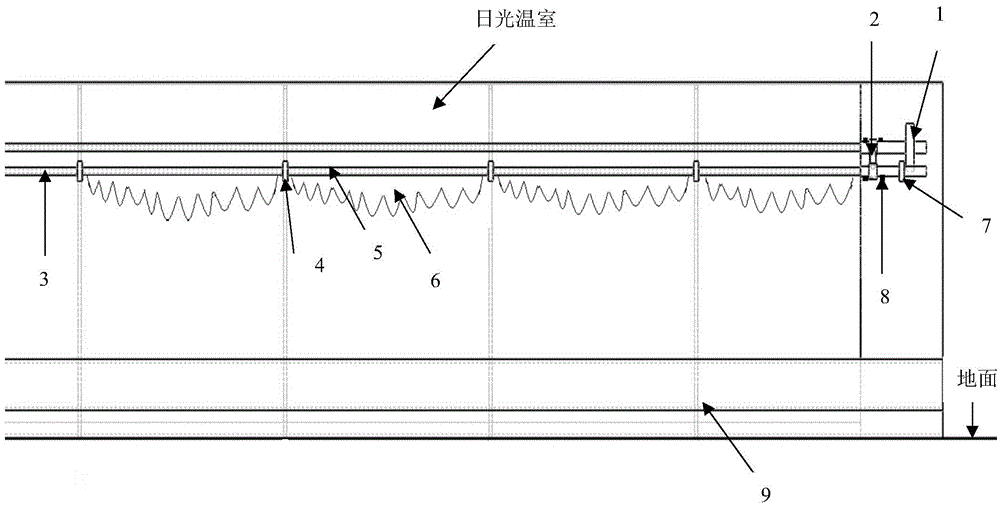

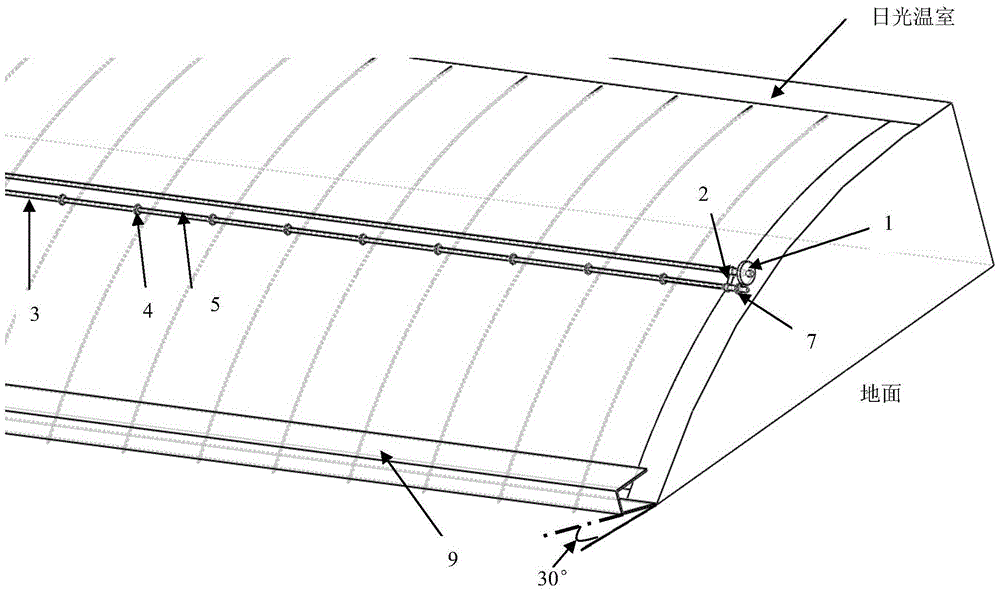

[0038] In the solar greenhouse of the Shangzhuang Experimental Base of China Agricultural University, install the solar greenhouse film dust removal device, such as figure 1 Shown.

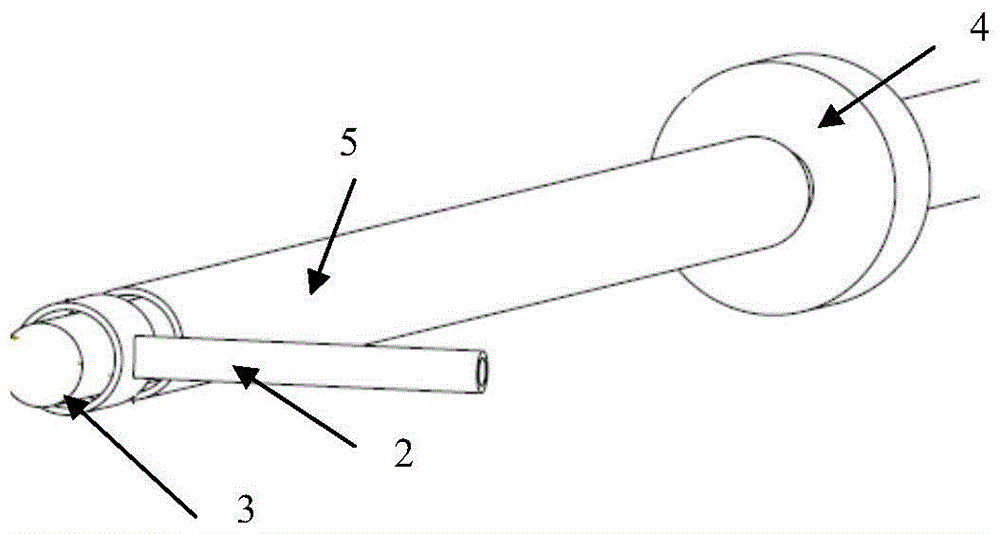

[0039] In this embodiment, the roller shutter machine adopts a side-rolling heat-preserving drape machine; the connecting piece 2 selects a connecting sleeve for the sleeve connection; the cylinder 4 selects sponge material; the sleeve 5 selects plastic material; Made of electrostatic adsorption materials, the effect of adsorbing and erasing dust is obvious.

[0040] Put the connecting sleeves on the shaft 1 and the dust removal rod 3 of the heat-preserving roller blind respectively, so that the dust removal rod 3 can be pulled up and down by the roller shutter shaft 1; because the supporting roller 7 and the dust removal rod 3 are fixedly connected , Supported on the east and west gables of the greenhouse, to ensure that the dust removal rod 3 rolls under the traction of the roller shutter shaft 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com